Automatic de-molding agent spraying system

A technology of automatic mold release and mold release agent, which is applied in the field of forging mold release, which can solve the problems of the sticking shape and design shape of forging parts and molds, the amount of coating on the mold surface is difficult to grasp, inconsistent, etc., and achieve the effect of avoiding damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

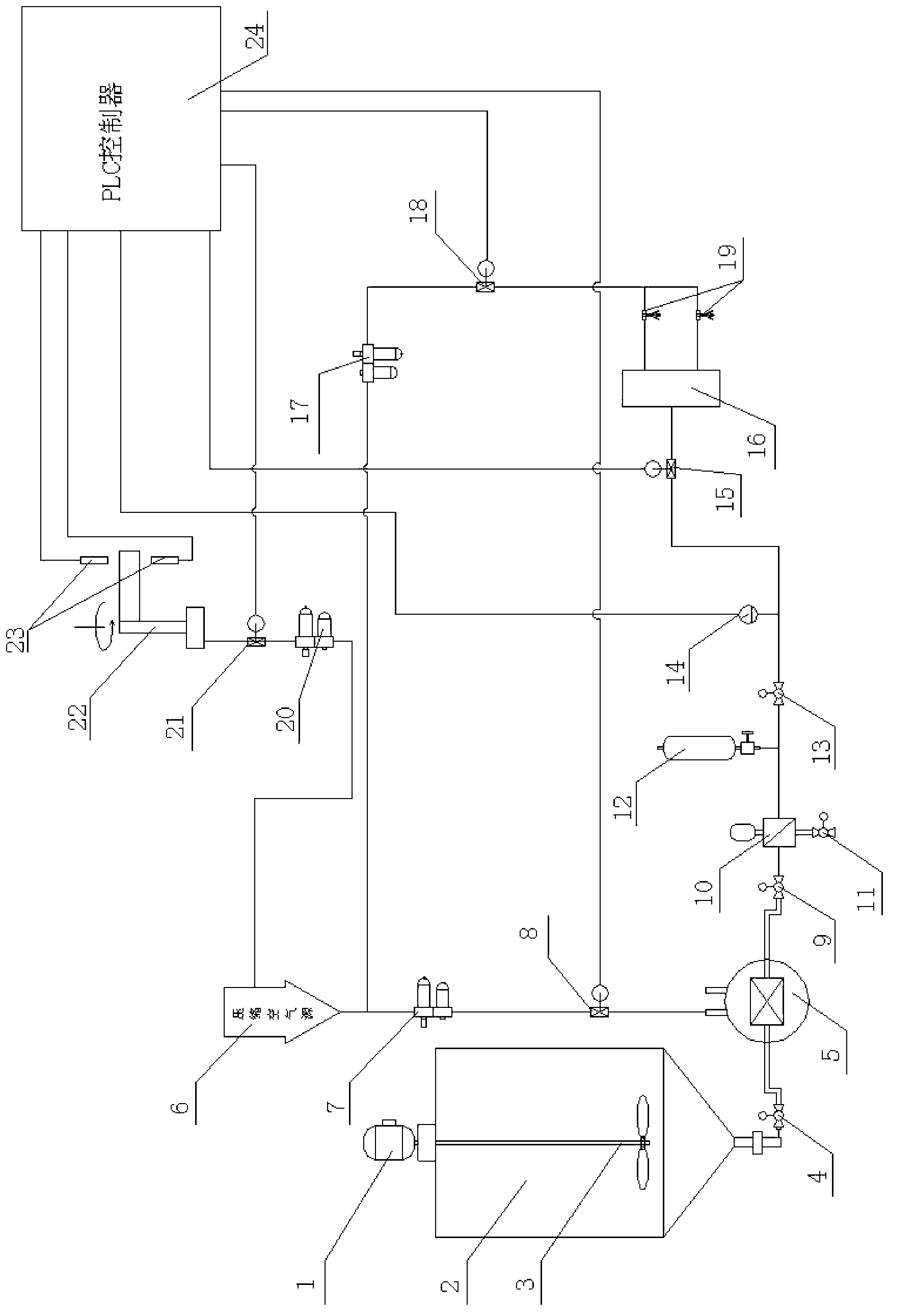

[0027] The present invention will be further described in detail below in conjunction with the accompanying drawings and through specific embodiments. The following embodiments are only descriptive, not restrictive, and cannot limit the protection scope of the present invention.

[0028] An automatic release agent spraying system, comprising a mixing tank 2, a compressed air source 6, a high-pressure pneumatic plunger pump 5 and a spray gun 19, the mixing tank is connected to the spray gun through a release agent delivery pipeline, and the compressed air source is compressed The air delivery pipeline is connected with the spray gun. The spray gun mixes the compressed air with a certain amount of high-pressure graphite release agent, and then sprays it out at high pressure from the spray gun. The graphite release agent is dispersed into mist droplets by the air flow, and the graphite release agent Atomization is achieved, thereby achieving a uniform coating of the release agent ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com