Gasoline direct injection fuel injection pump

A gasoline direct injection and fuel injection pump technology, which is applied to fuel injection pumps, fuel injection devices, engine components, etc., can solve problems such as insufficient time for air and gasoline to mix, affecting engine economy, power, and fuel consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but the present invention is not limited to the scope of the described embodiments.

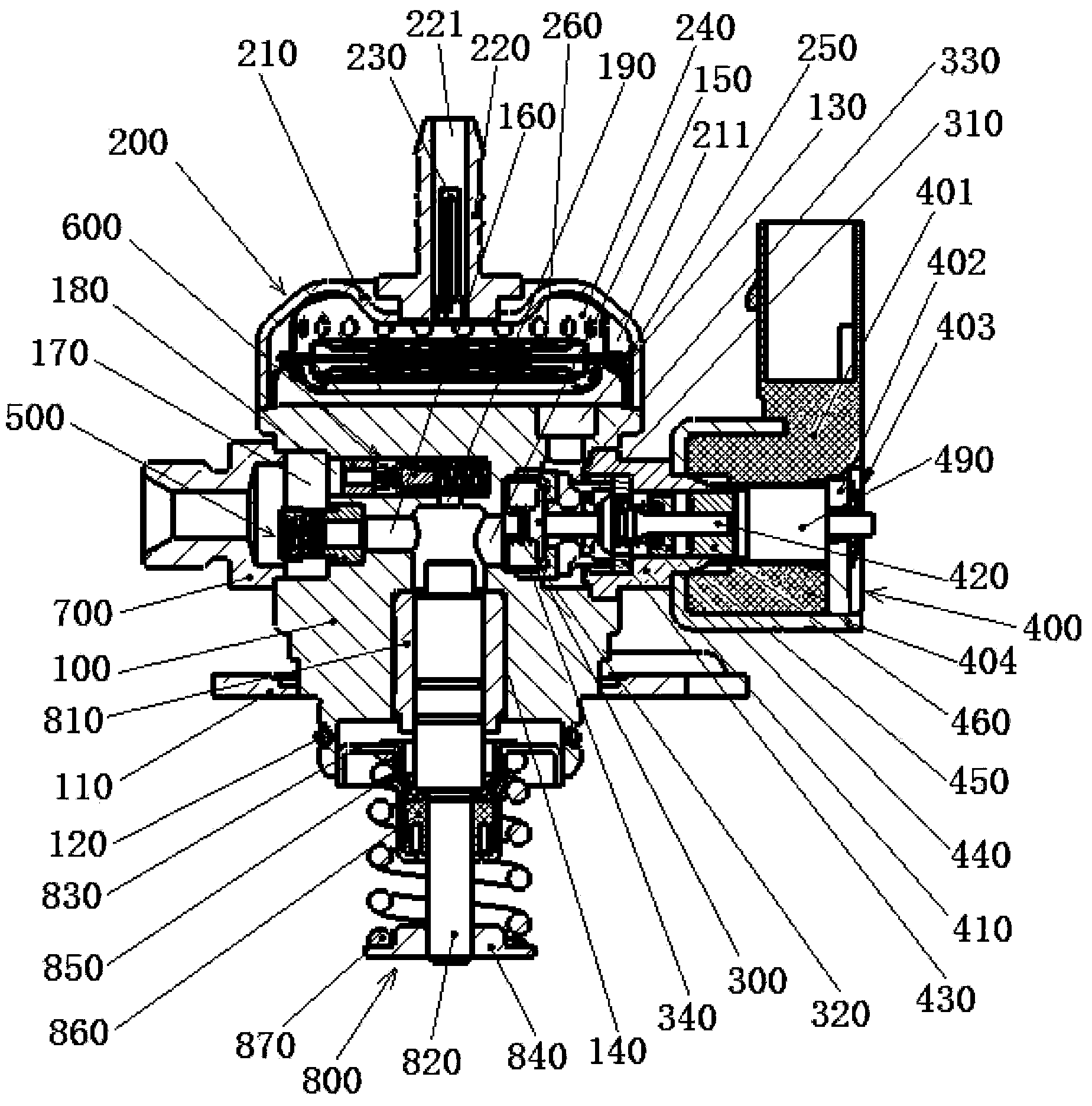

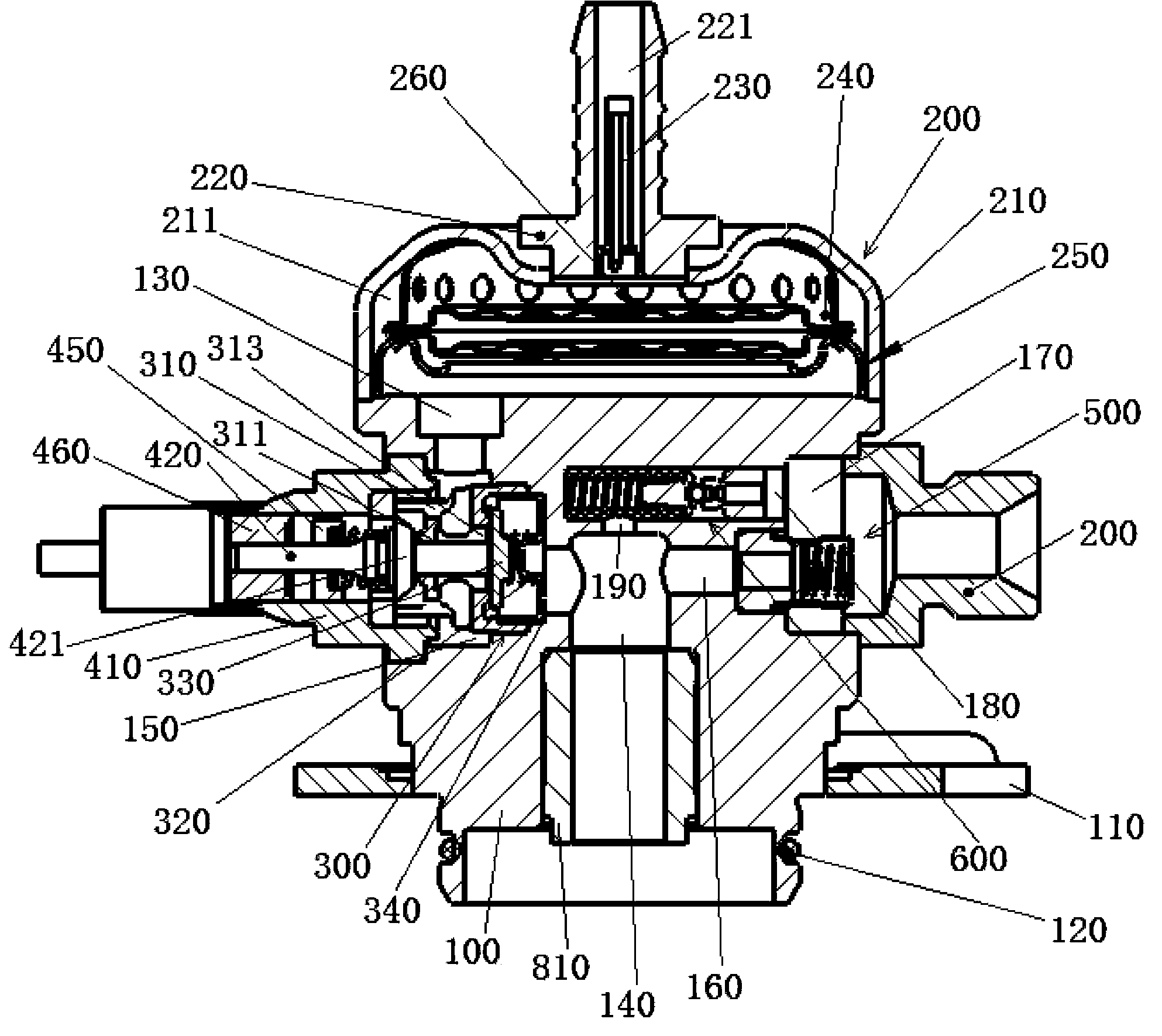

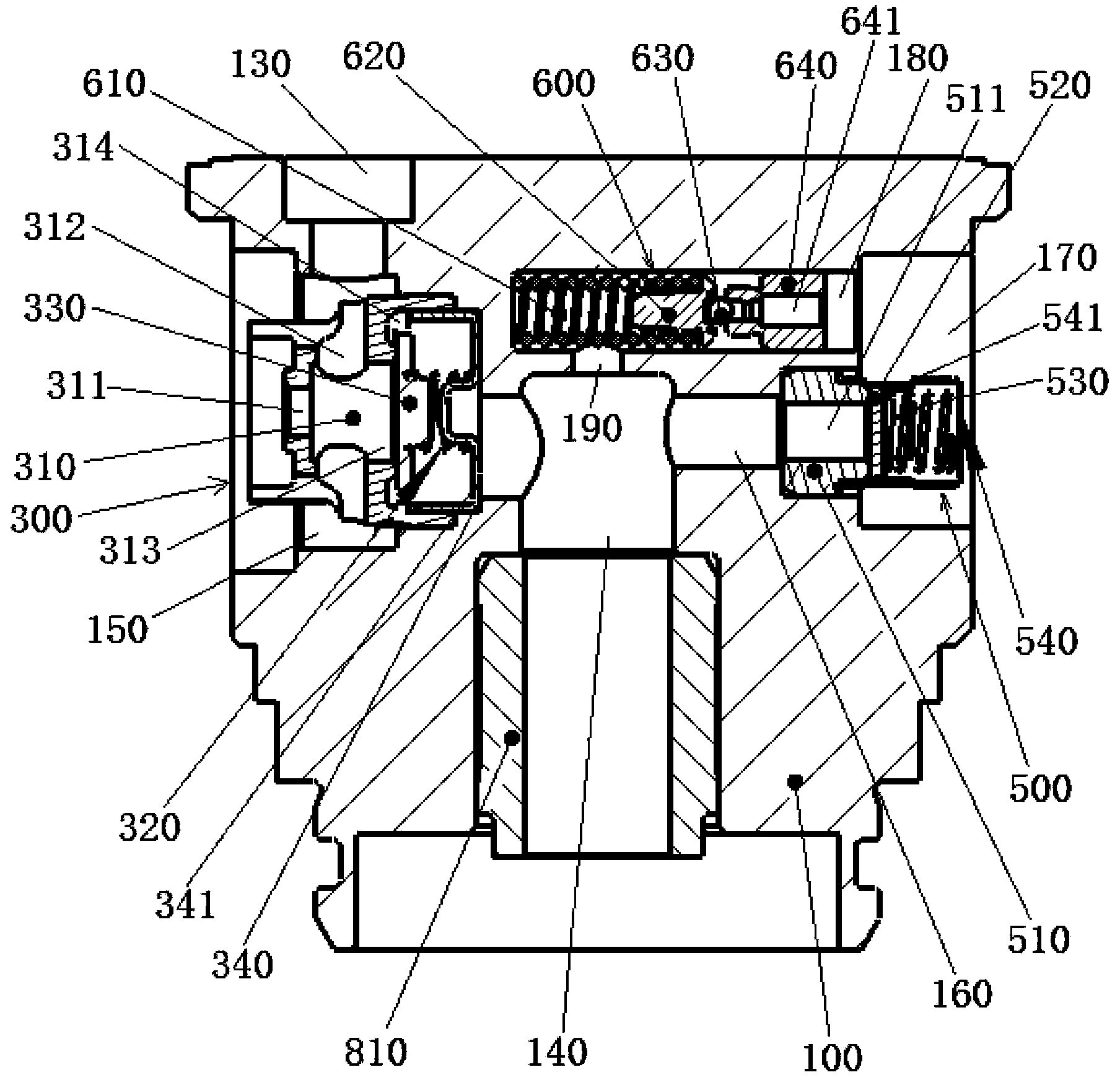

[0035] see figure 1 , the gasoline direct injection fuel injection pump shown in the figure includes a pump body 100, and the lower part of the pump body 100 is directly installed on the engine cylinder head (not shown in the figure) through a flange 110 and an O-ring 120 .

[0036] The upper part of the pump body 100 is provided with an axial oil inlet hole 130, the center of the lower part is provided with an axial plunger valve hole 140, and the middle part is provided with a radial stepped hole 150, radial oil outlet holes 160 and 170, Radial drain holes 180 . The oil outlet holes 160 and 170 and the step hole 150 are located on both sides of the plunger valve hole 140 and communicate with the plunger valve hole 140 respectively. 190 communicates with the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com