Patents

Literature

56results about How to "Frequent maintenance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

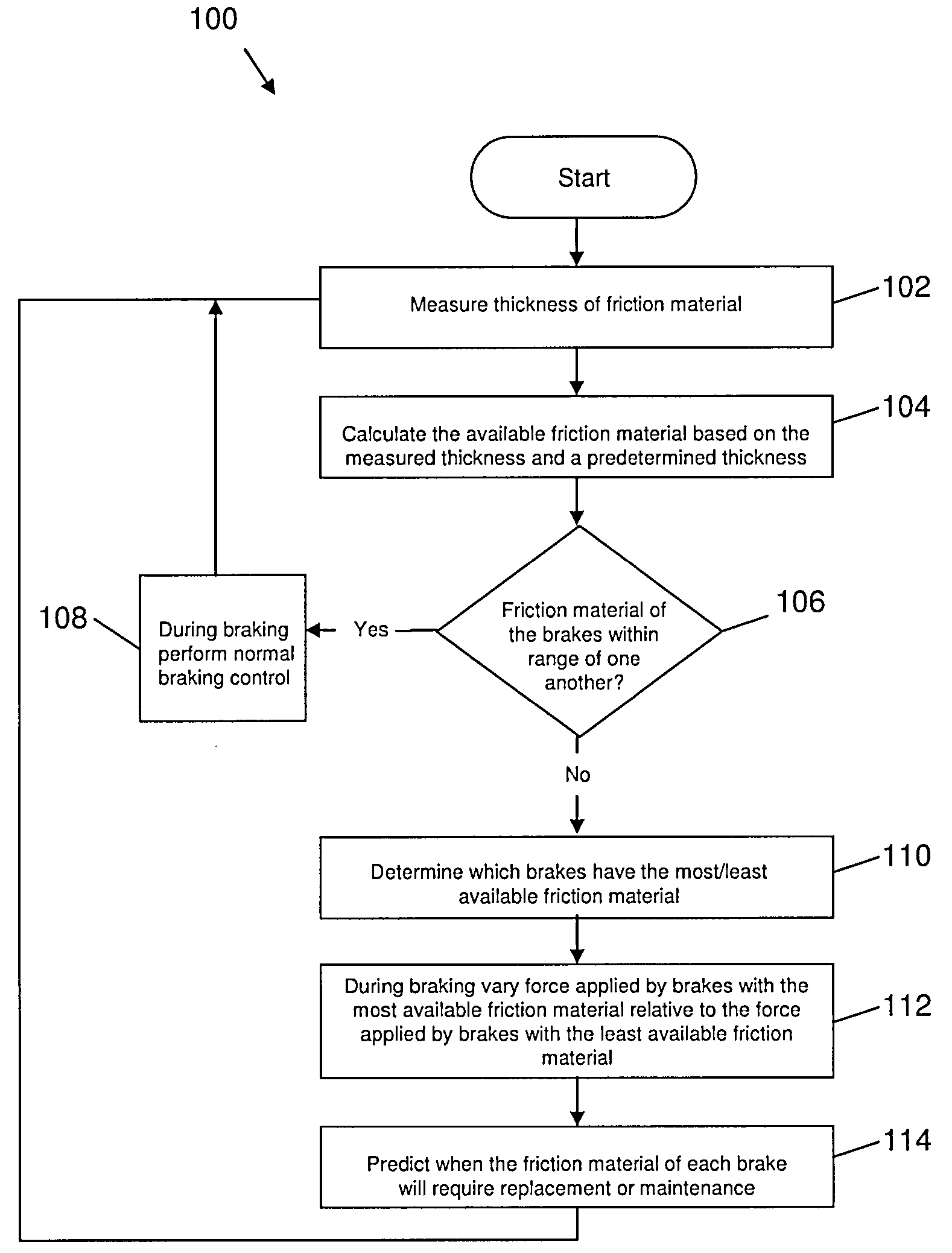

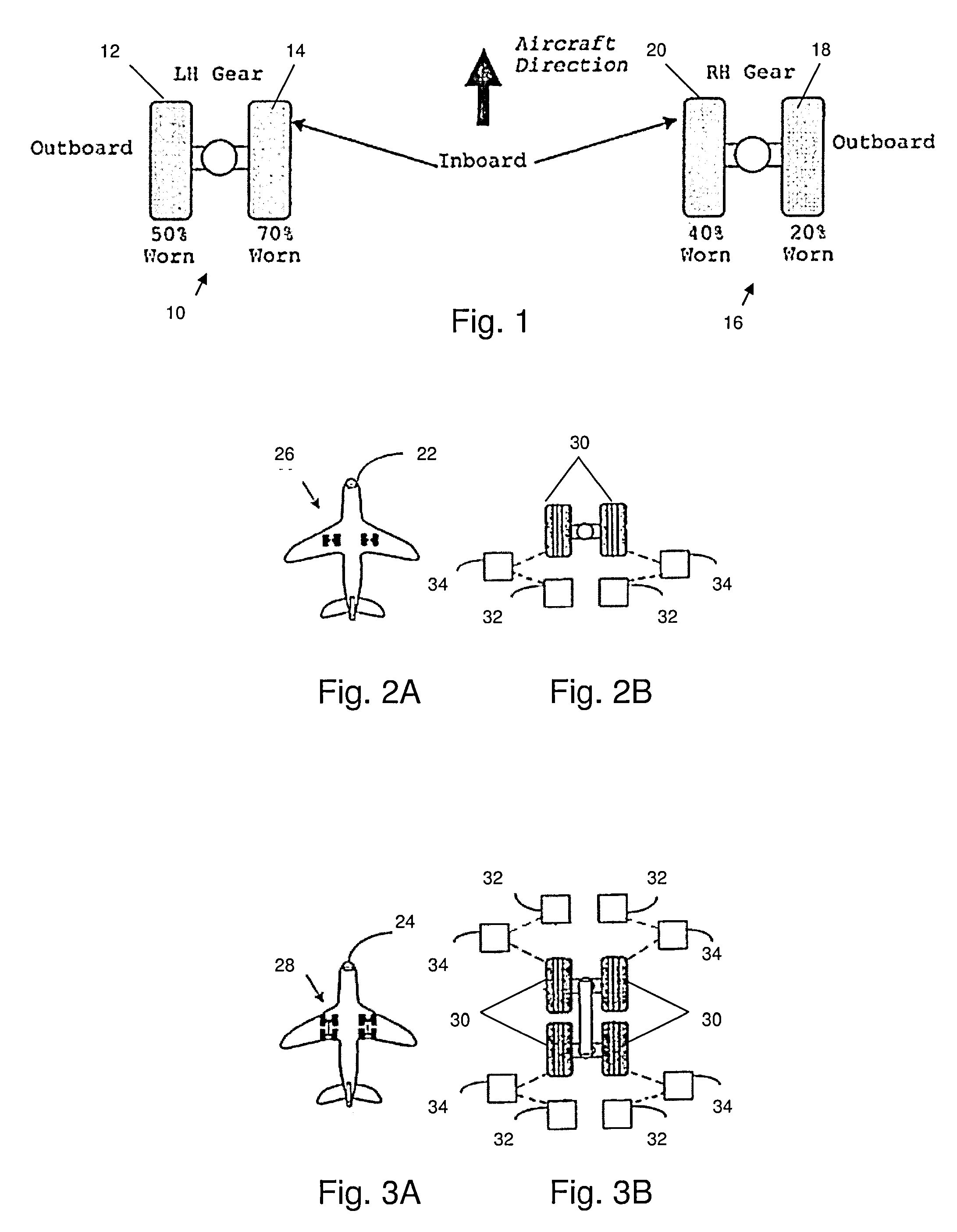

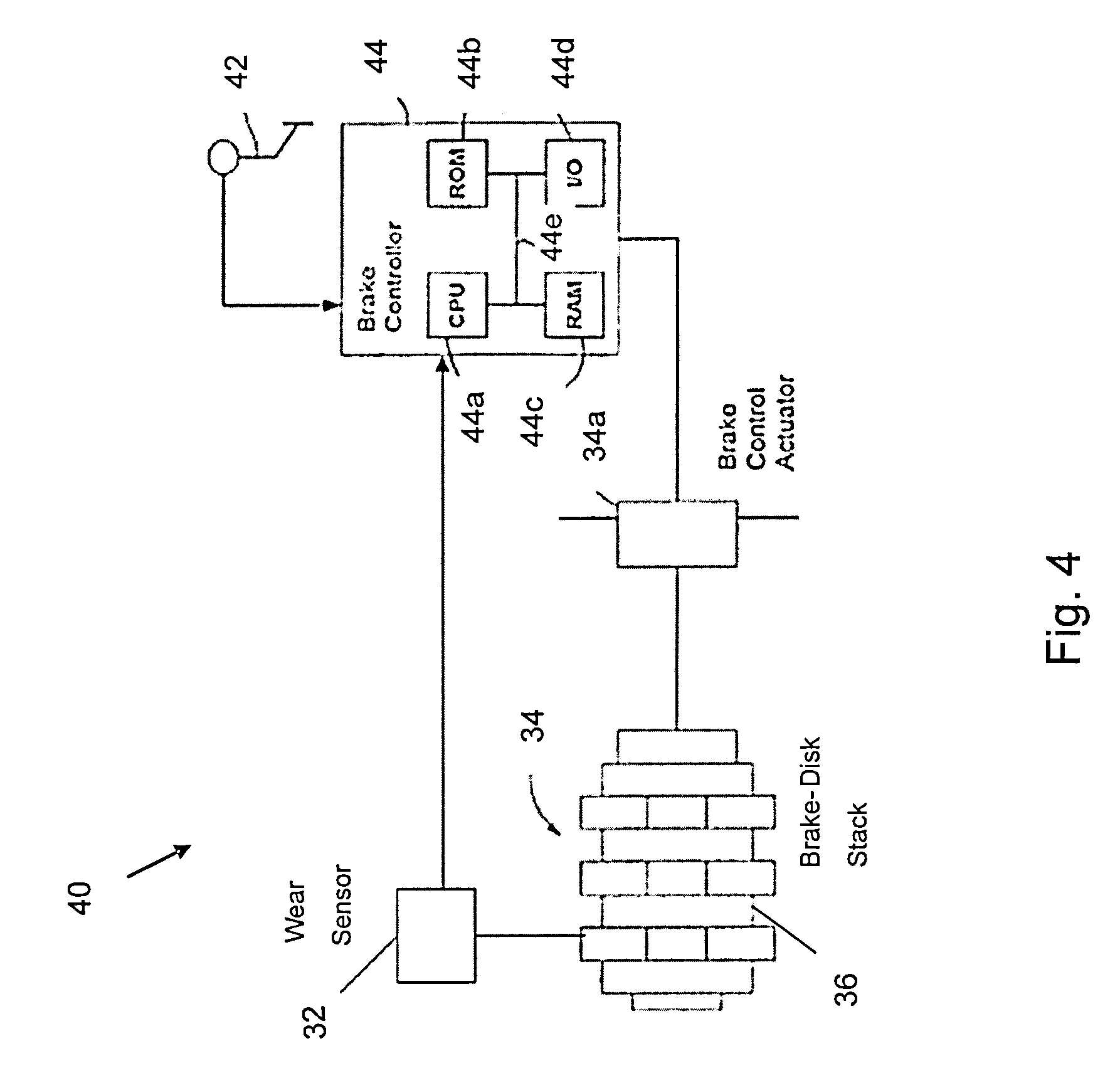

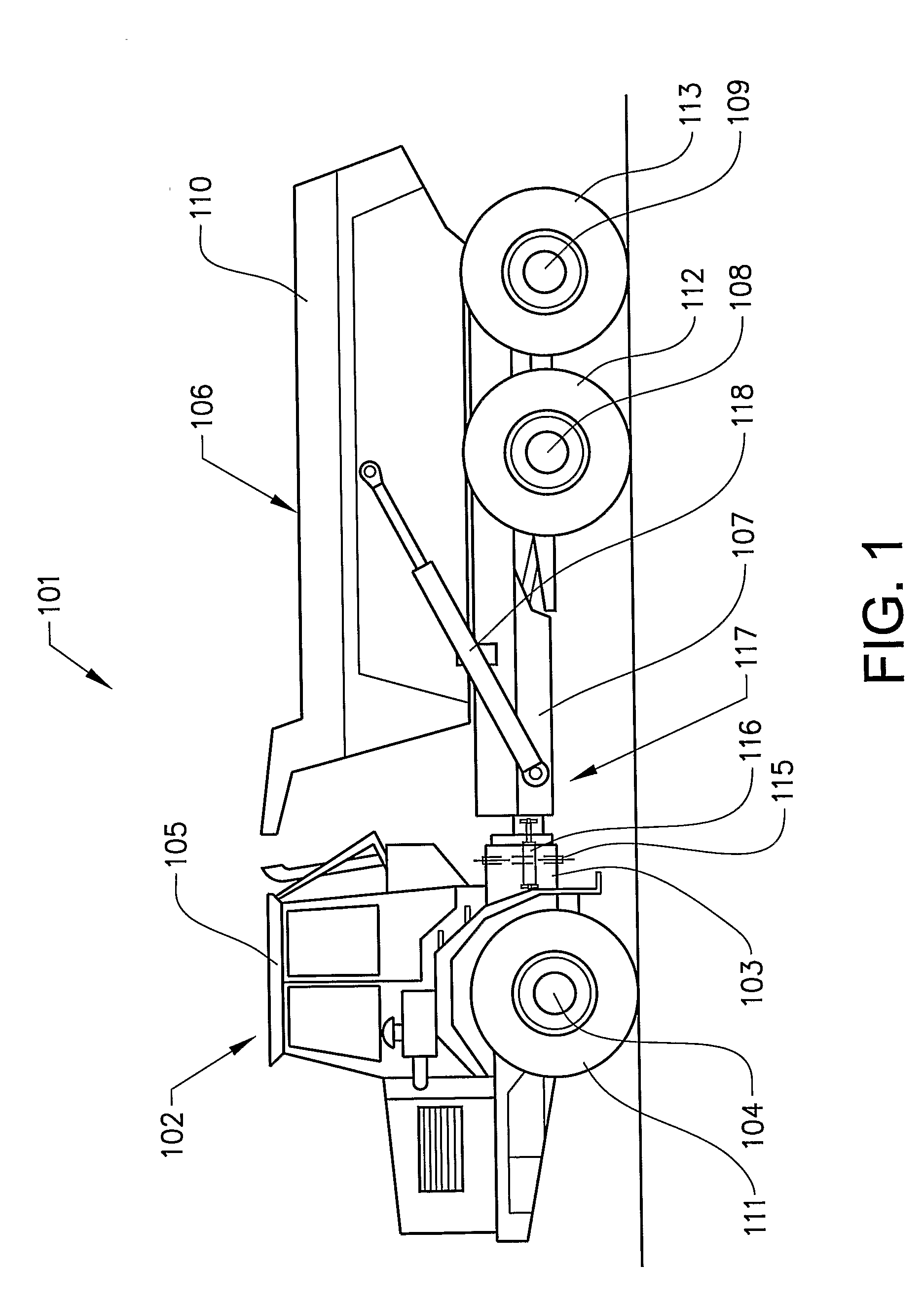

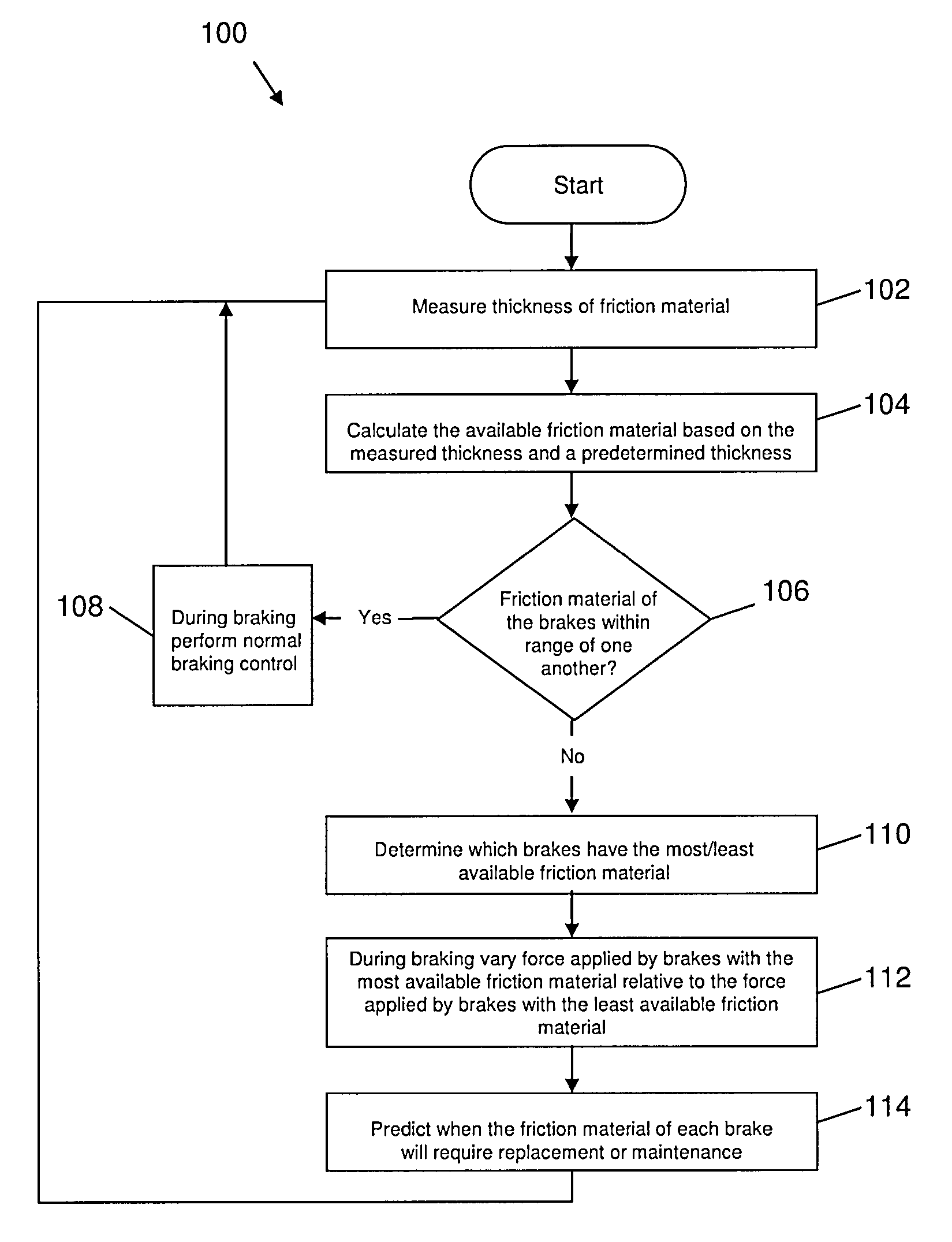

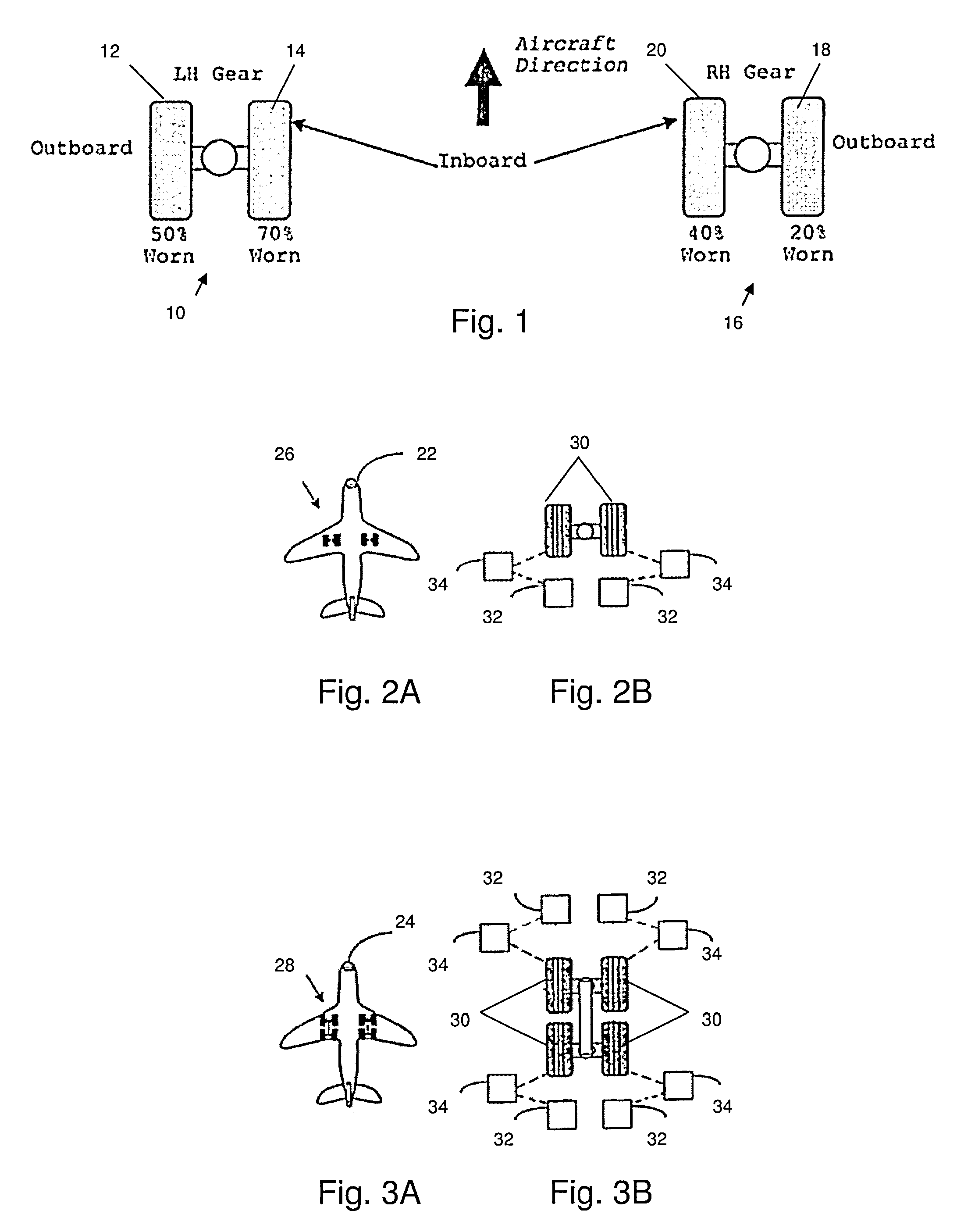

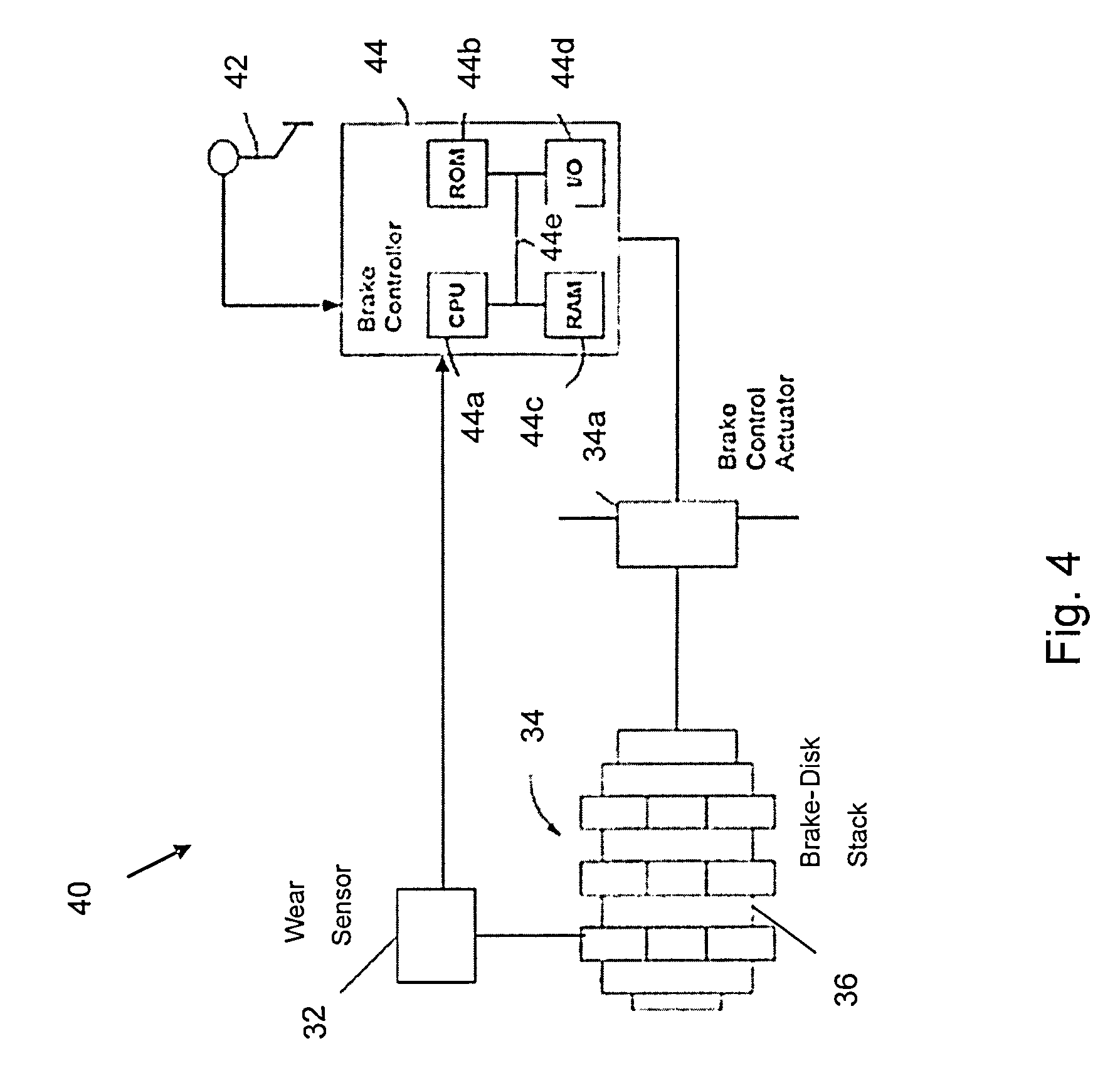

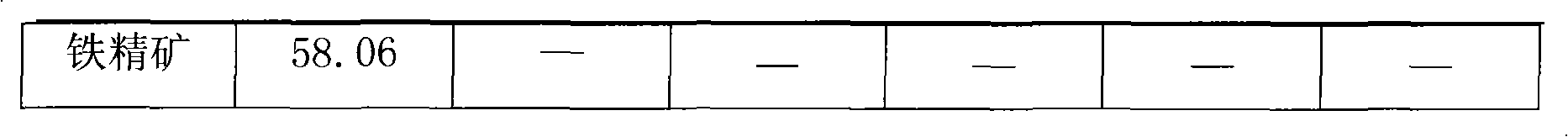

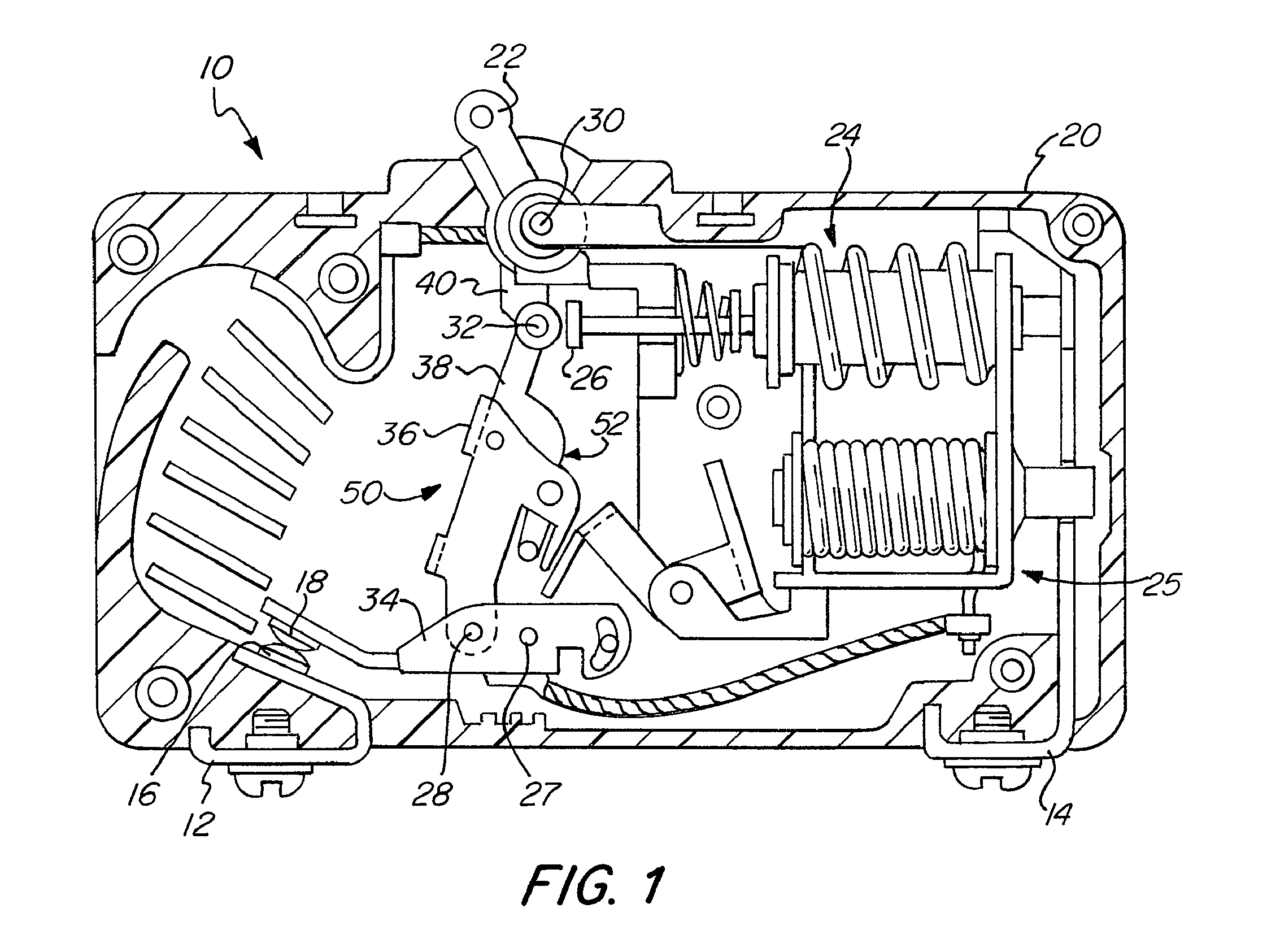

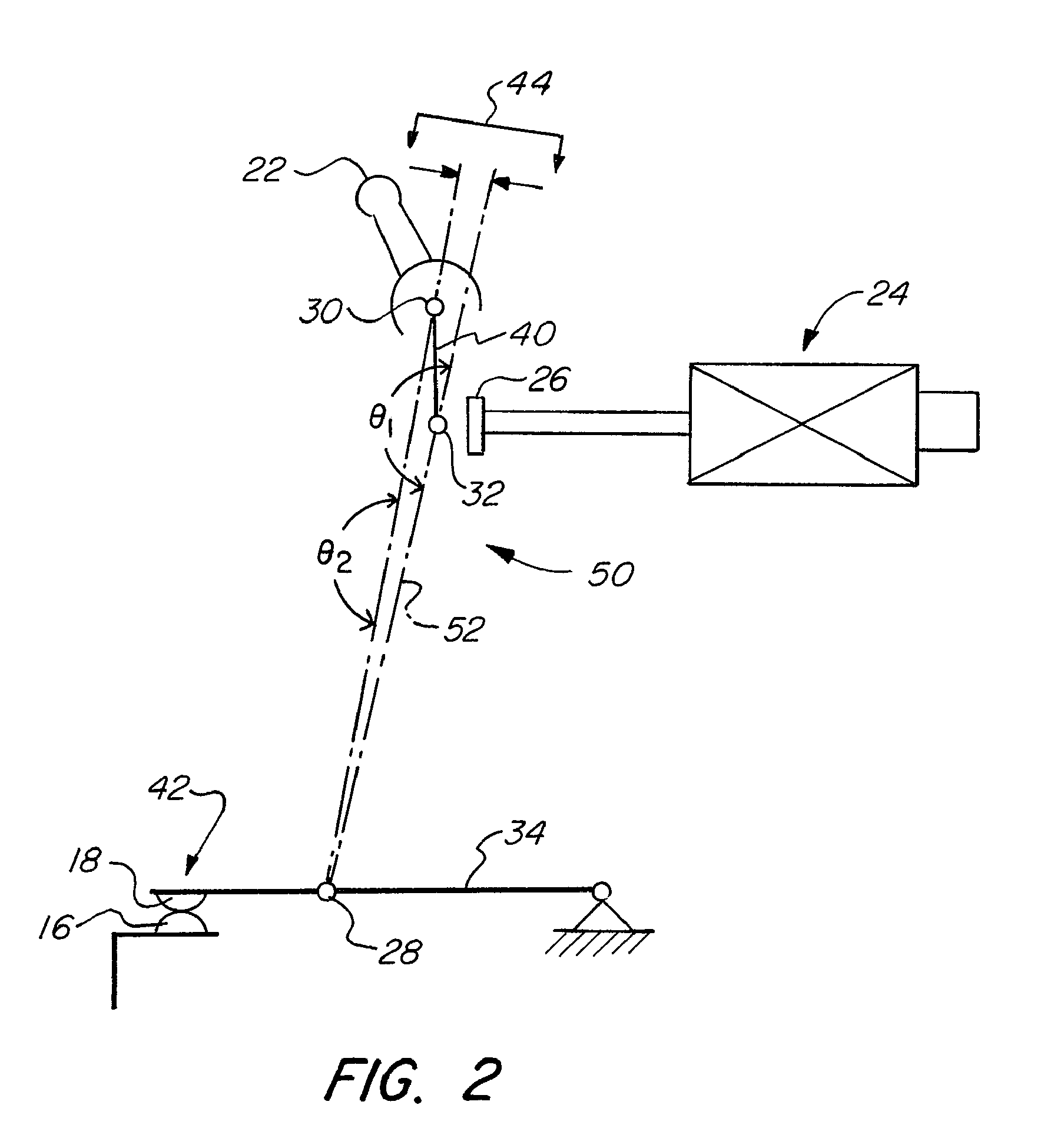

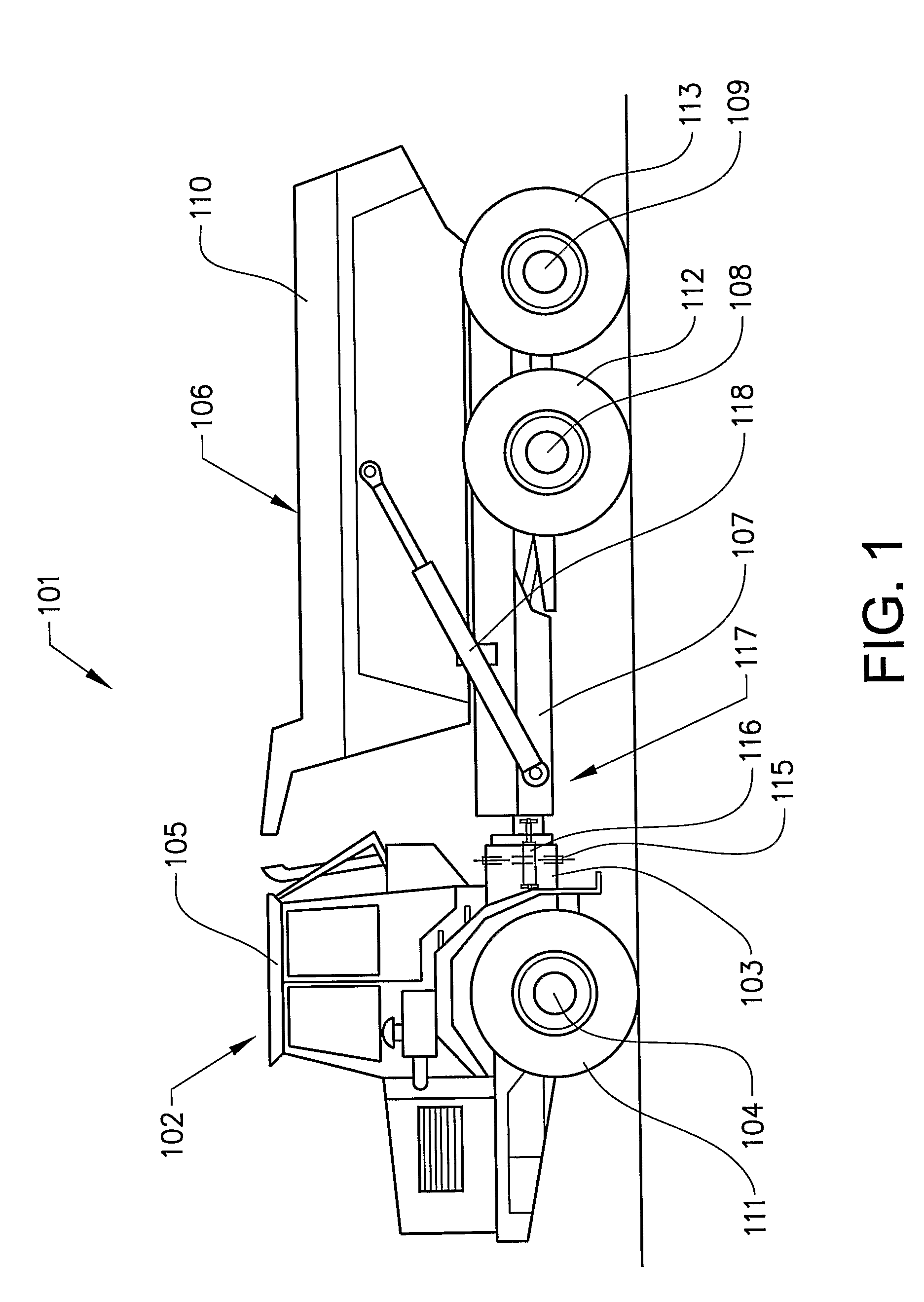

Brake wear control system

ActiveUS20100286881A1Lost revenueFrequent inspection and maintenanceAnalogue computers for trafficAxially engaging brakesBrake forceMechanical engineering

A system, apparatus and method provide a means for managing wear of brake friction material such that even friction material wear is experienced between brakes. The available friction material of each brake is monitored to determine an amount of wear. Based on the amount of wear, a braking force applied by each brake may be varied to ensure even wear between brakes.

Owner:THE BF GOODRICH CO

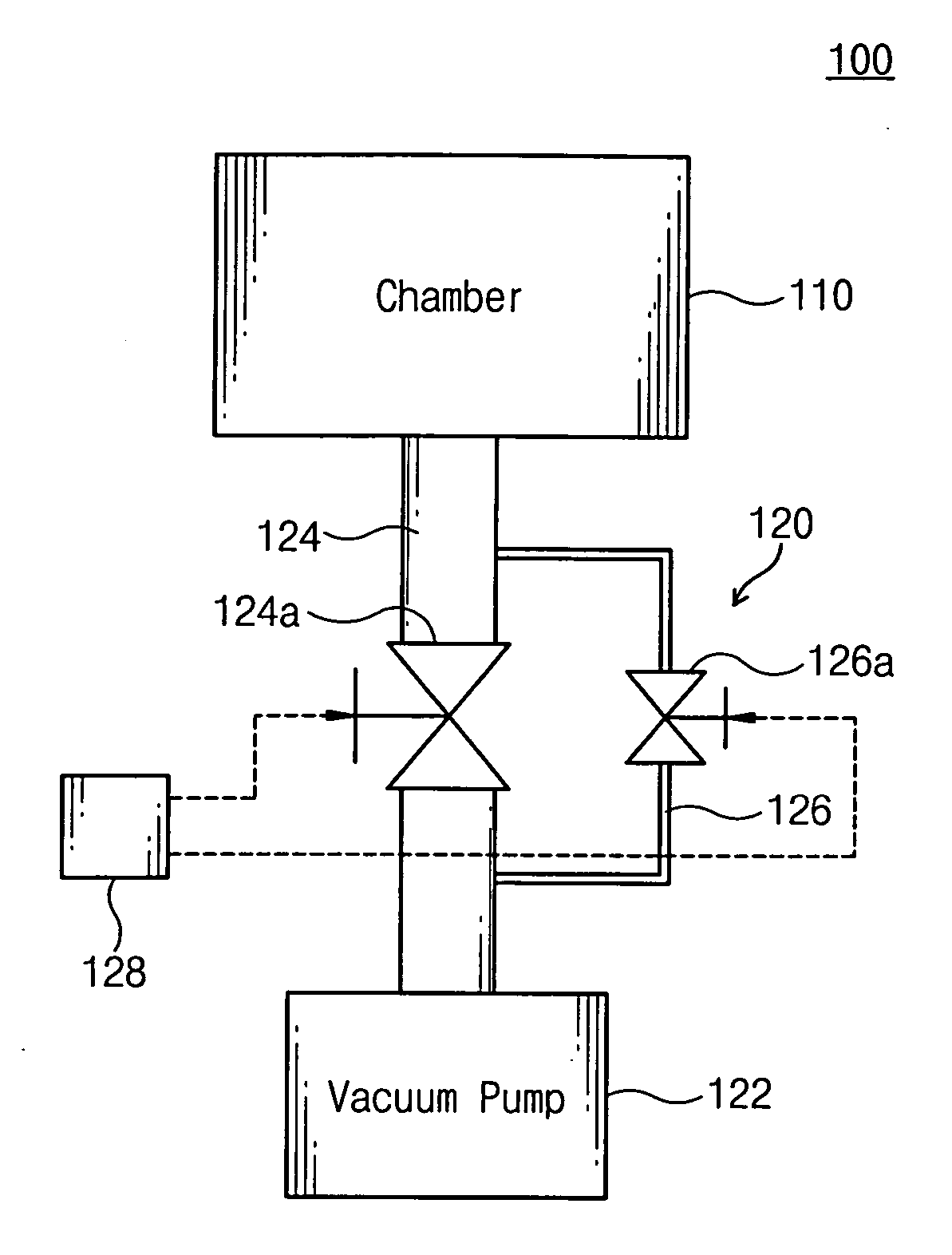

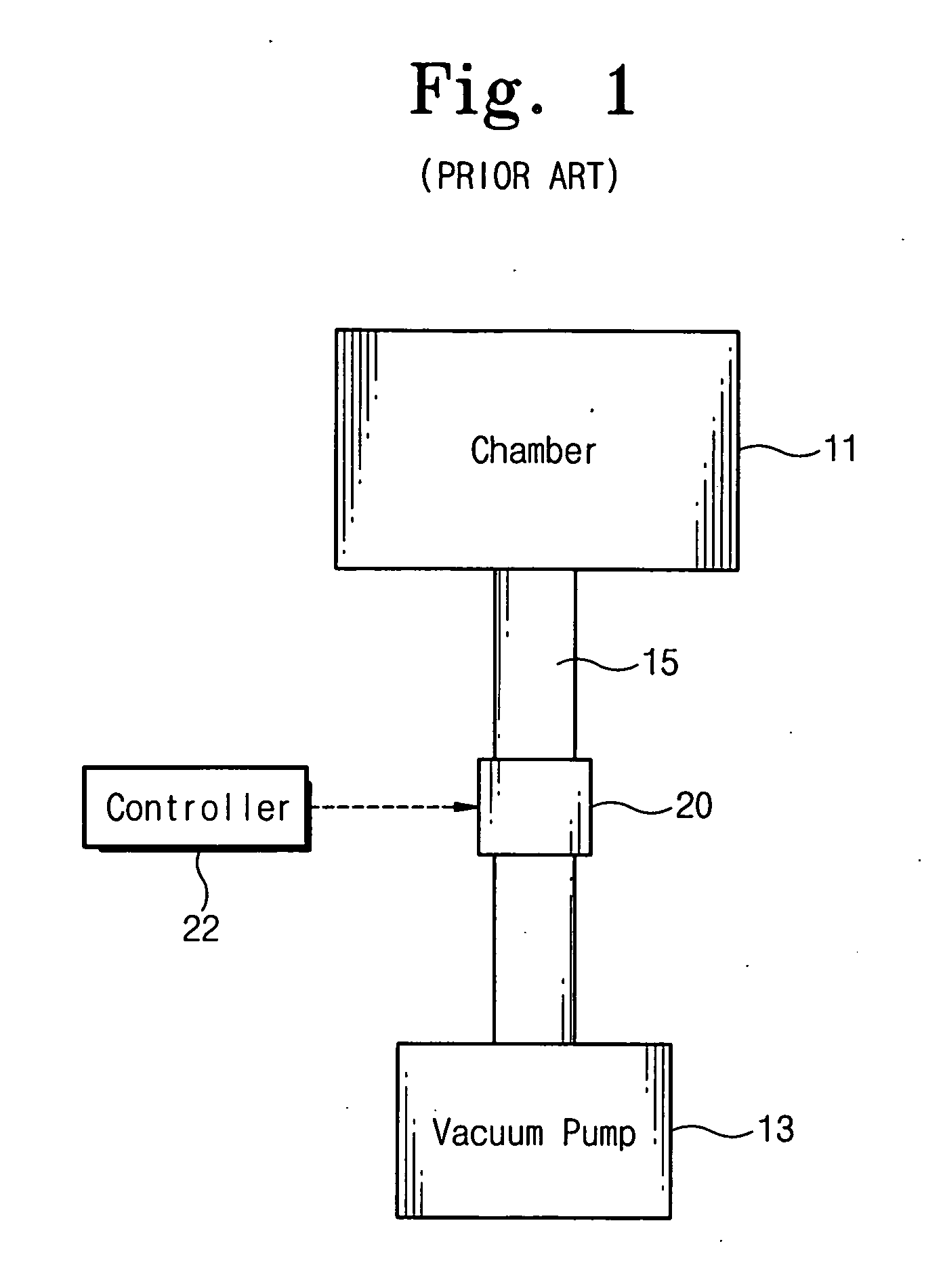

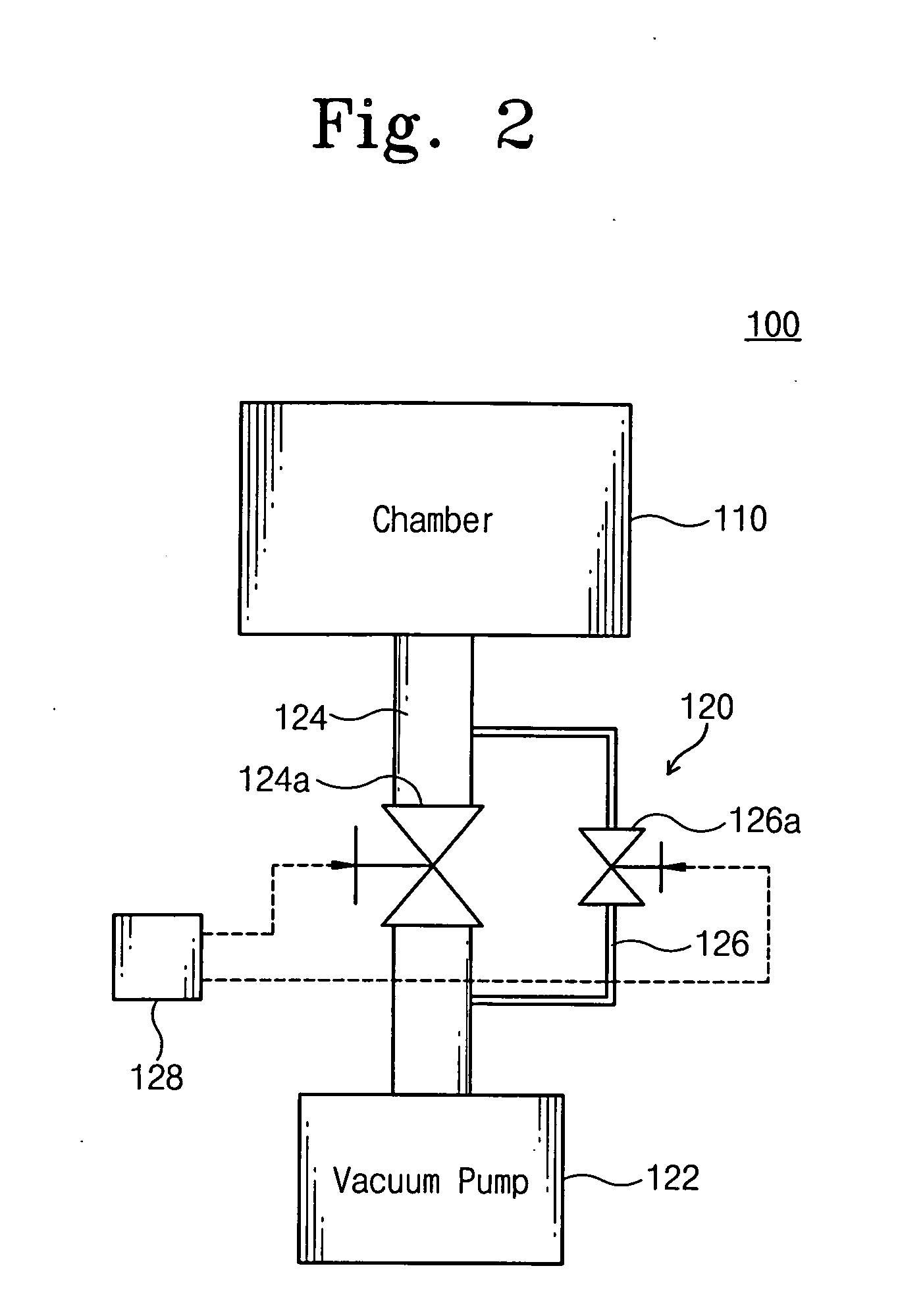

Semiconductor fabrication equipment and method for controlling pressure

InactiveUS20060175012A1Easy to adjustFrequent maintenanceWing accessoriesSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

Provided are semiconductor fabrication equipment and a related method of controlling pressure in a process chamber associated with the equipment. Multiple connected vacuum lines, each having a controllable valve, are used to exhaust gas from the process chamber.

Owner:SAMSUNG ELECTRONICS CO LTD

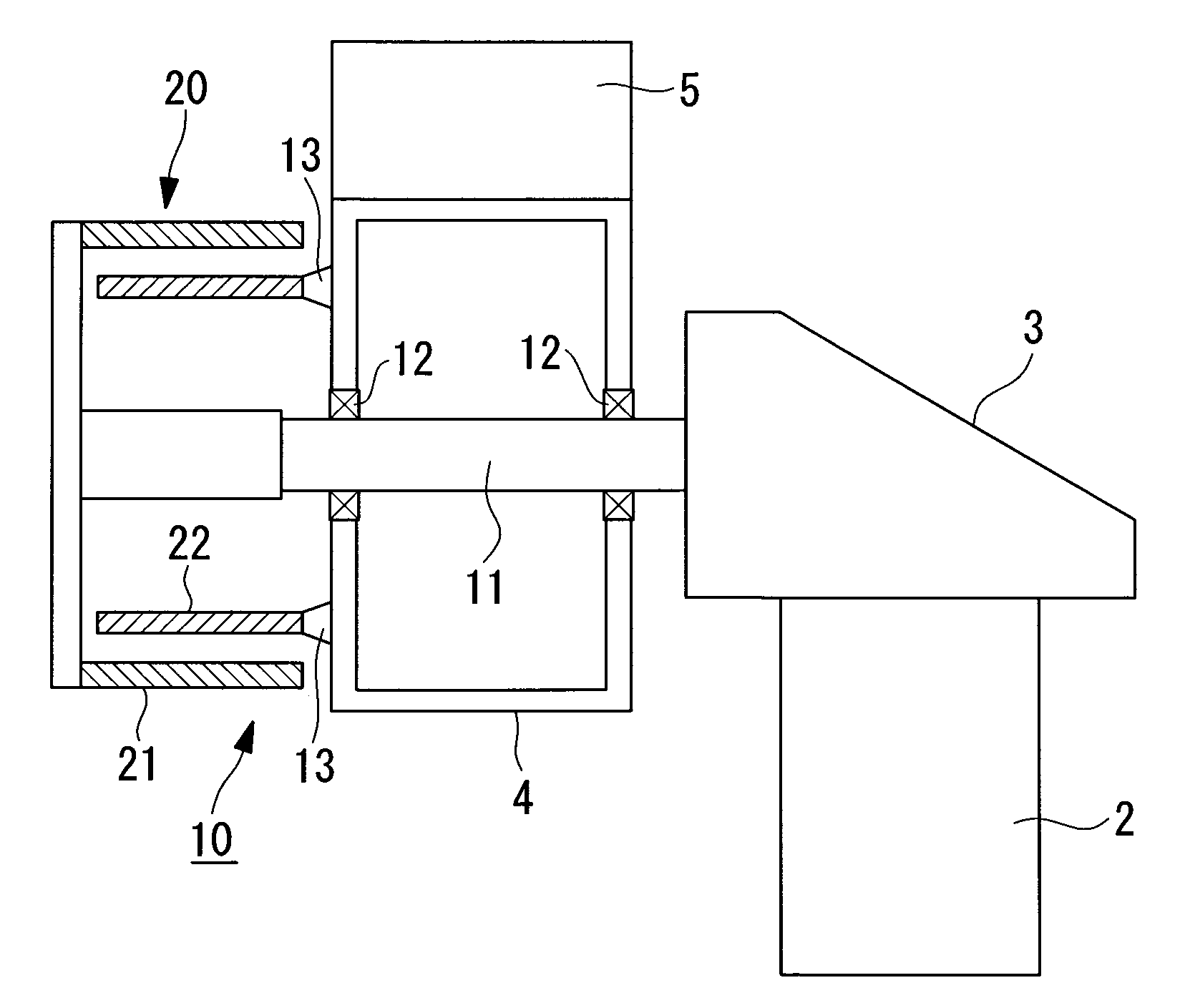

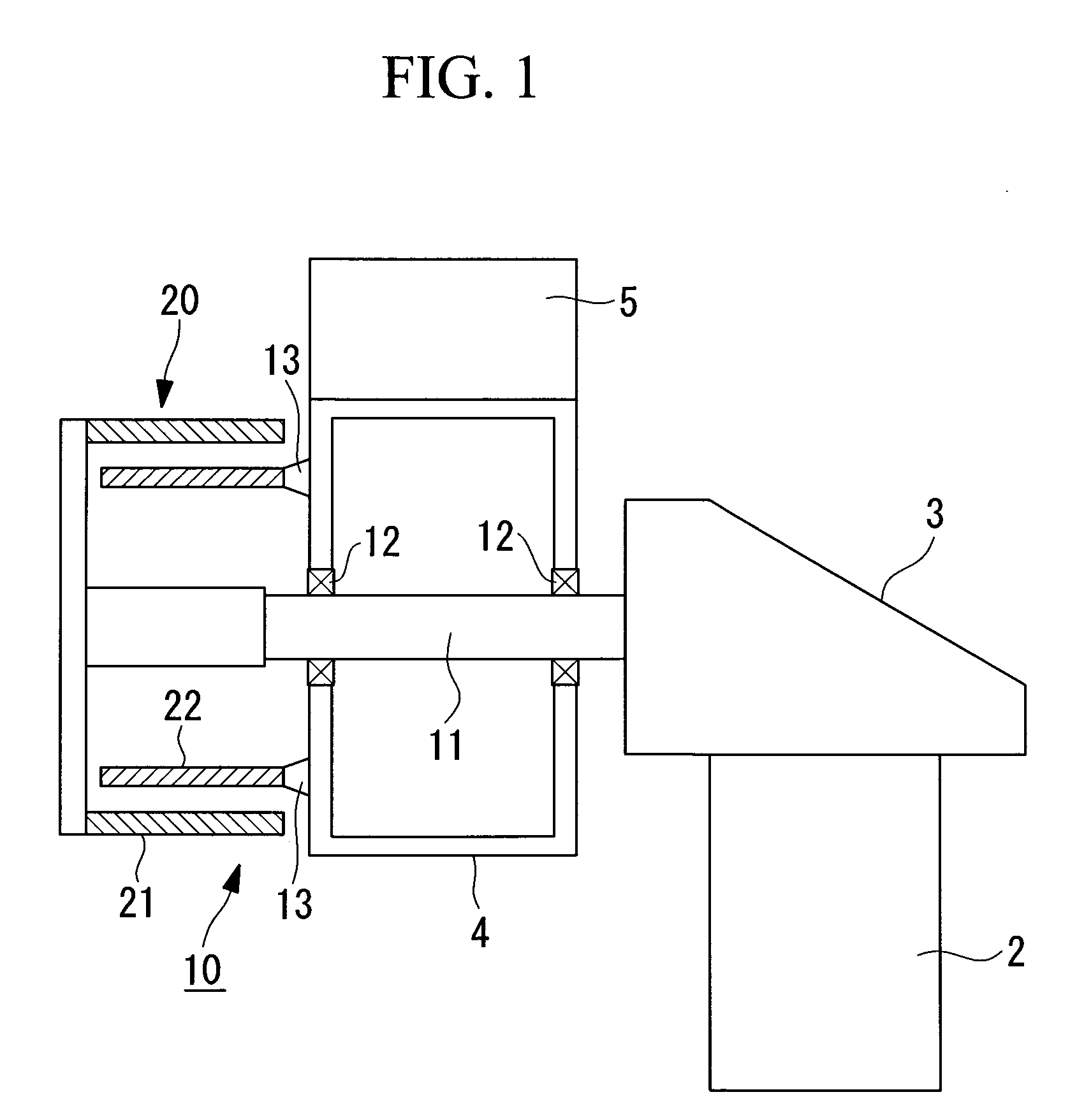

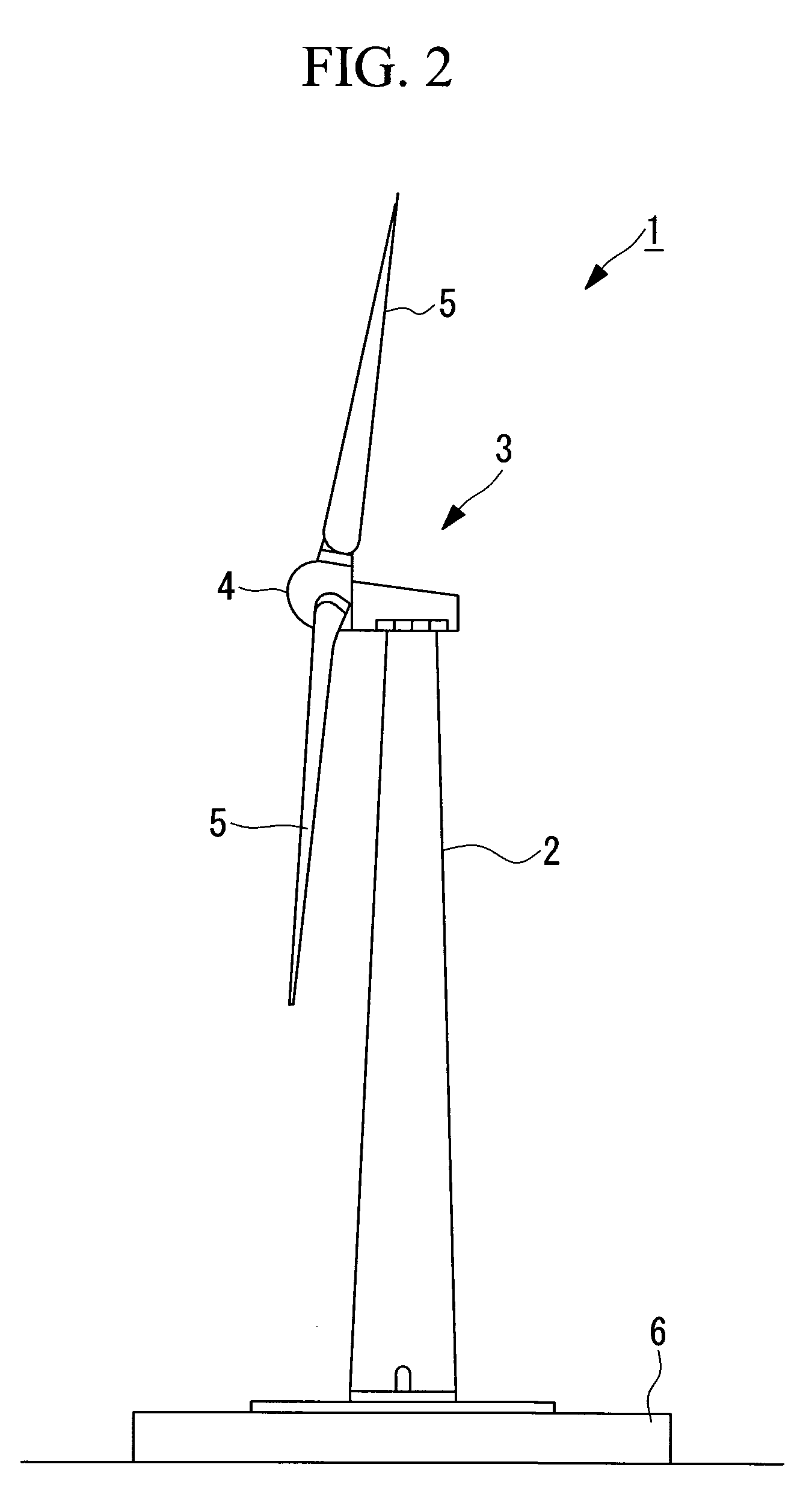

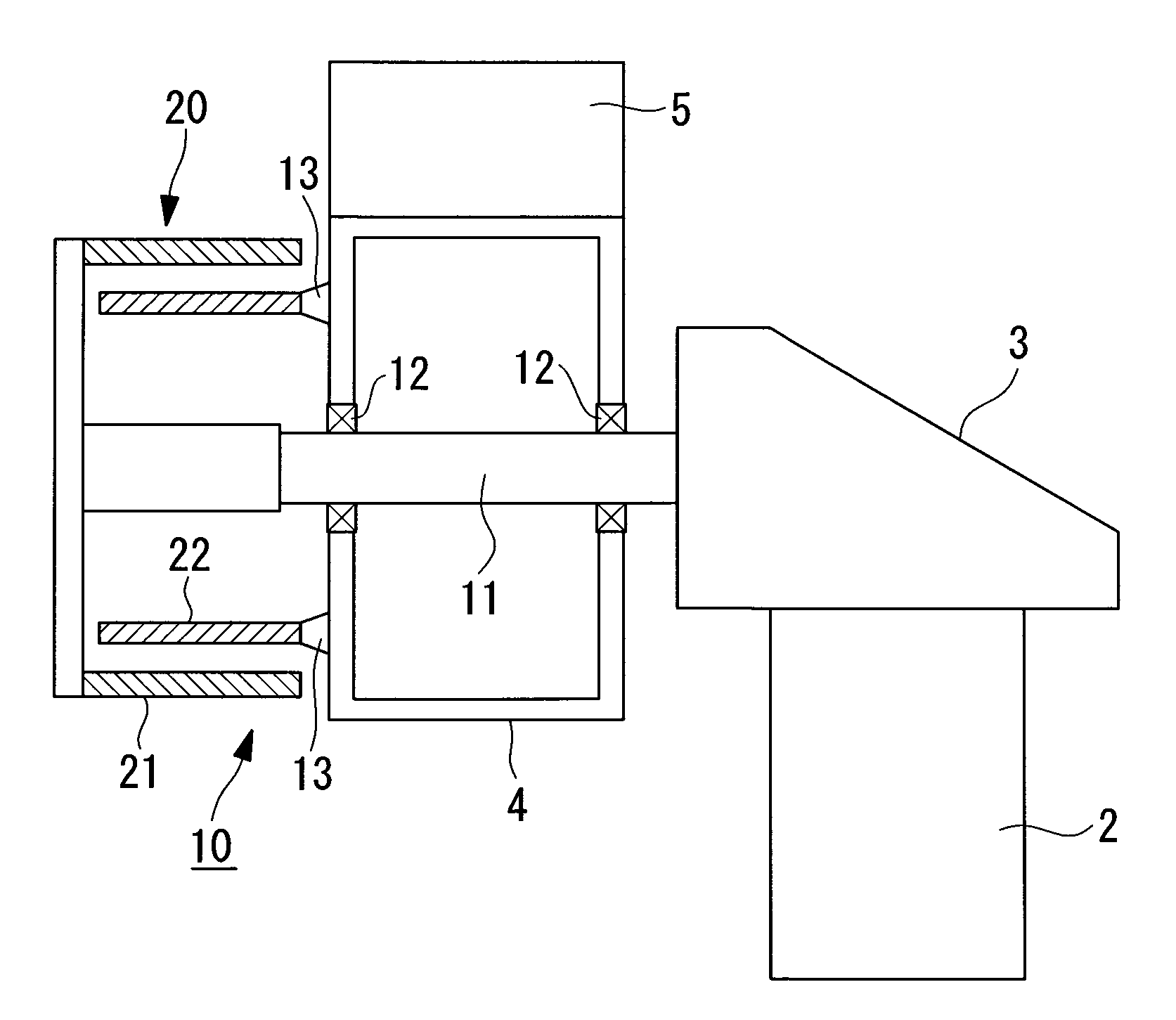

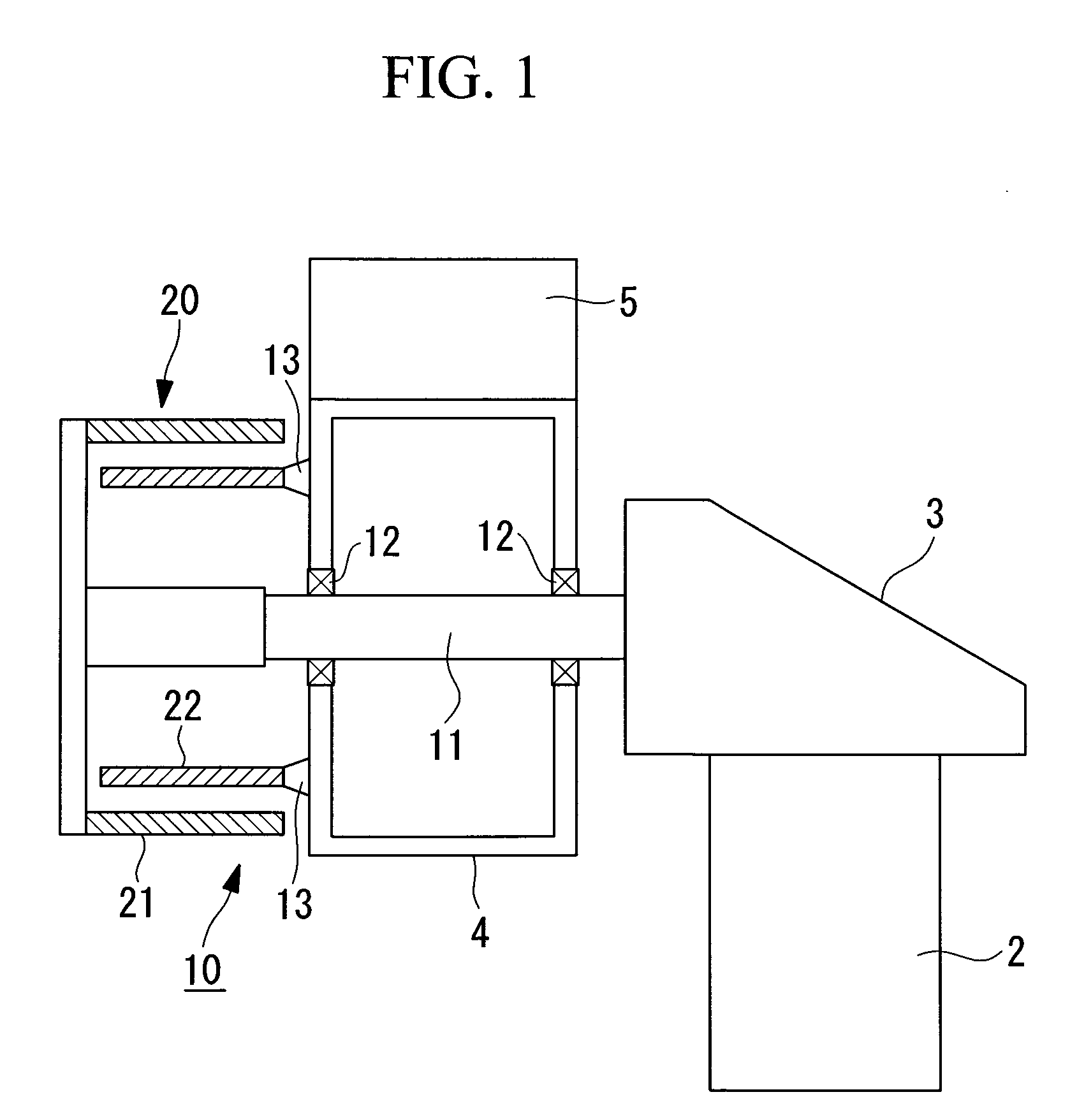

Wind turbine generator

A wind turbine generator that allows for size and weight reduction of a nacelle bedplate and that enables easier maintainability, such as device replaceability, is provided. In a wind turbine generator that generates electricity by driving a generator connected, via a drive train, to a rotor head that has wind-turbine rotor blade attached thereto and rotates together therewith, at least a part of the drive train that transmits torque from the rotor head to the generator is disposed on a front side of the rotor head opposite a nacelle.

Owner:MITSUBISHI HEAVY IND LTD

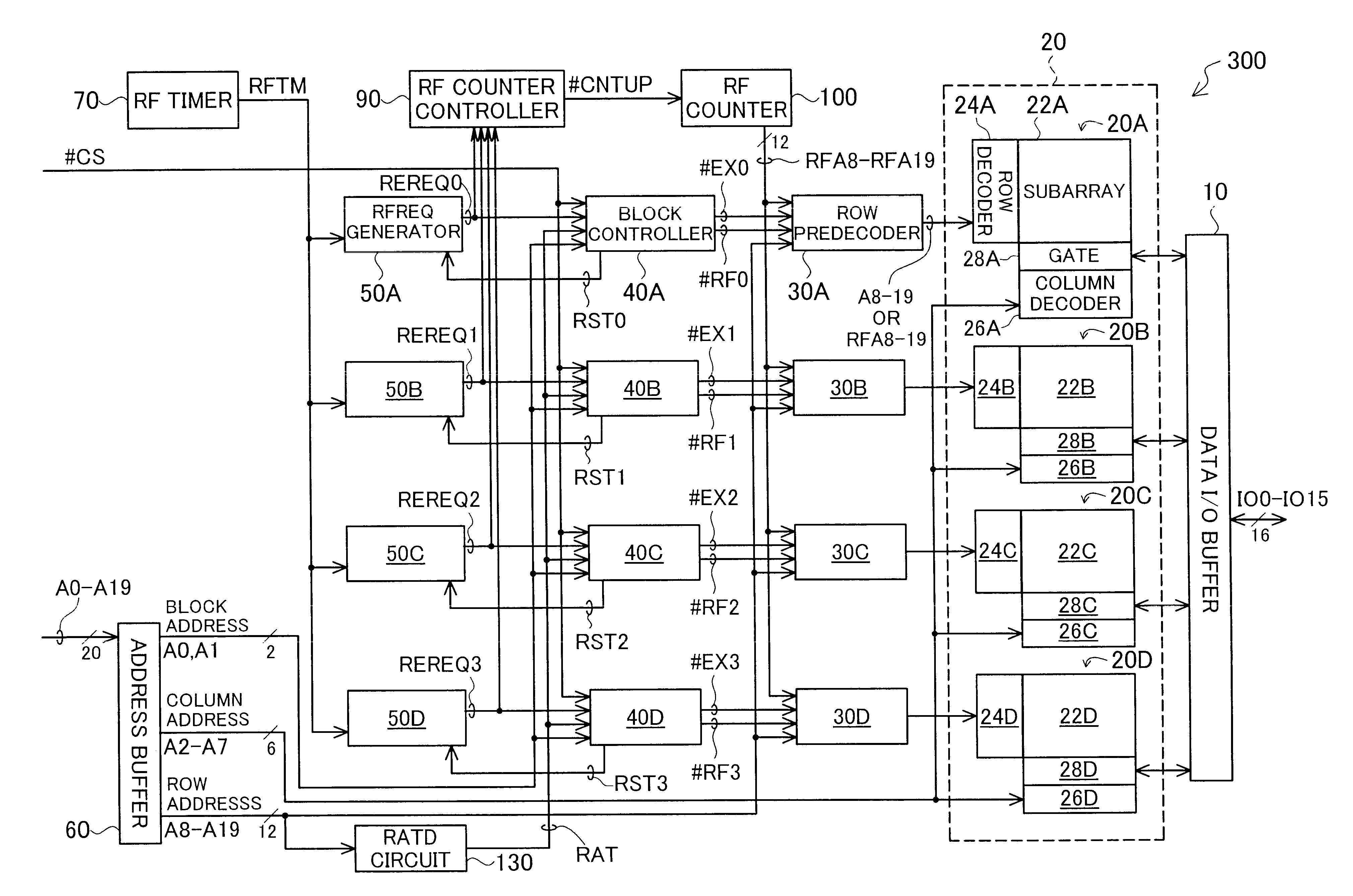

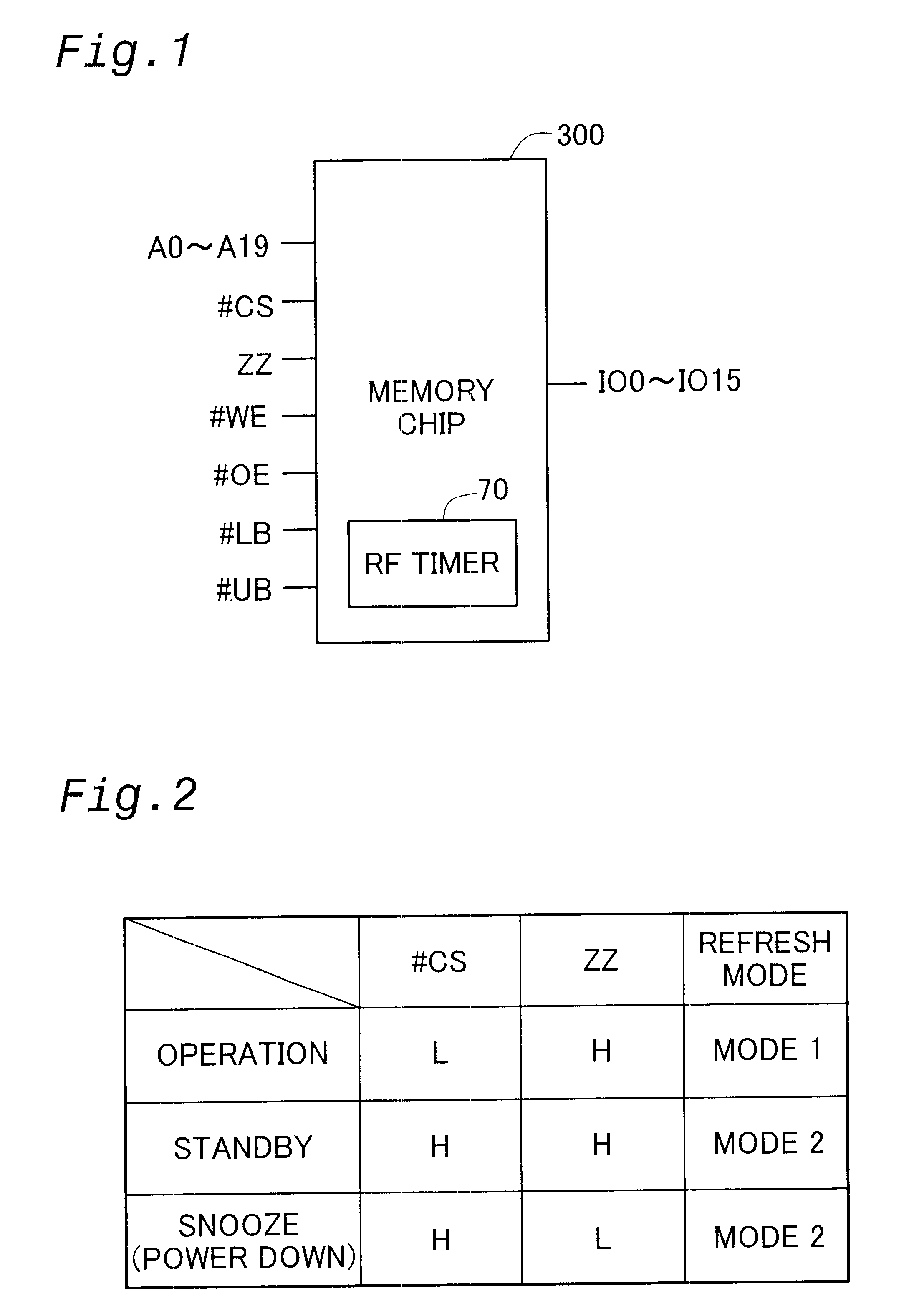

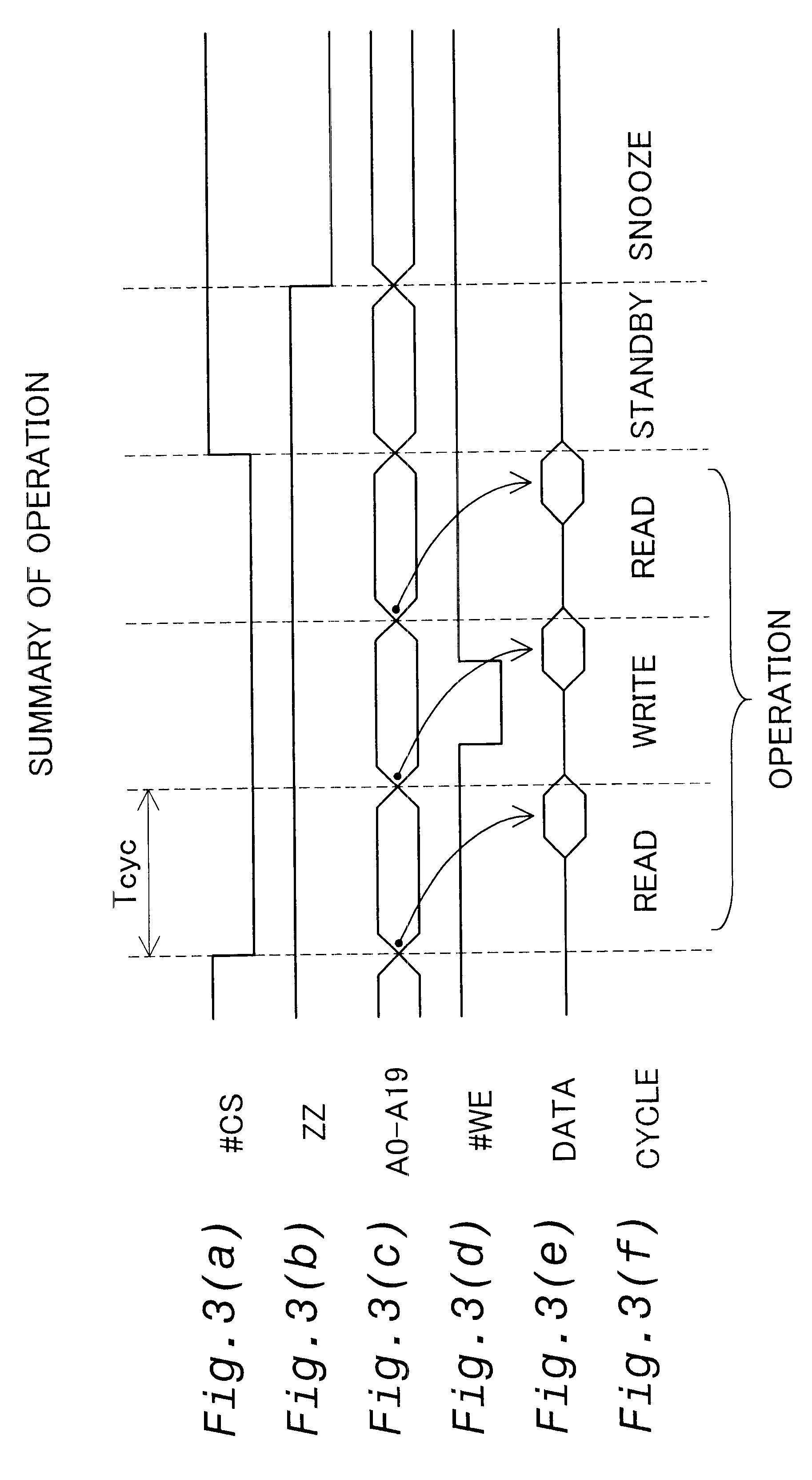

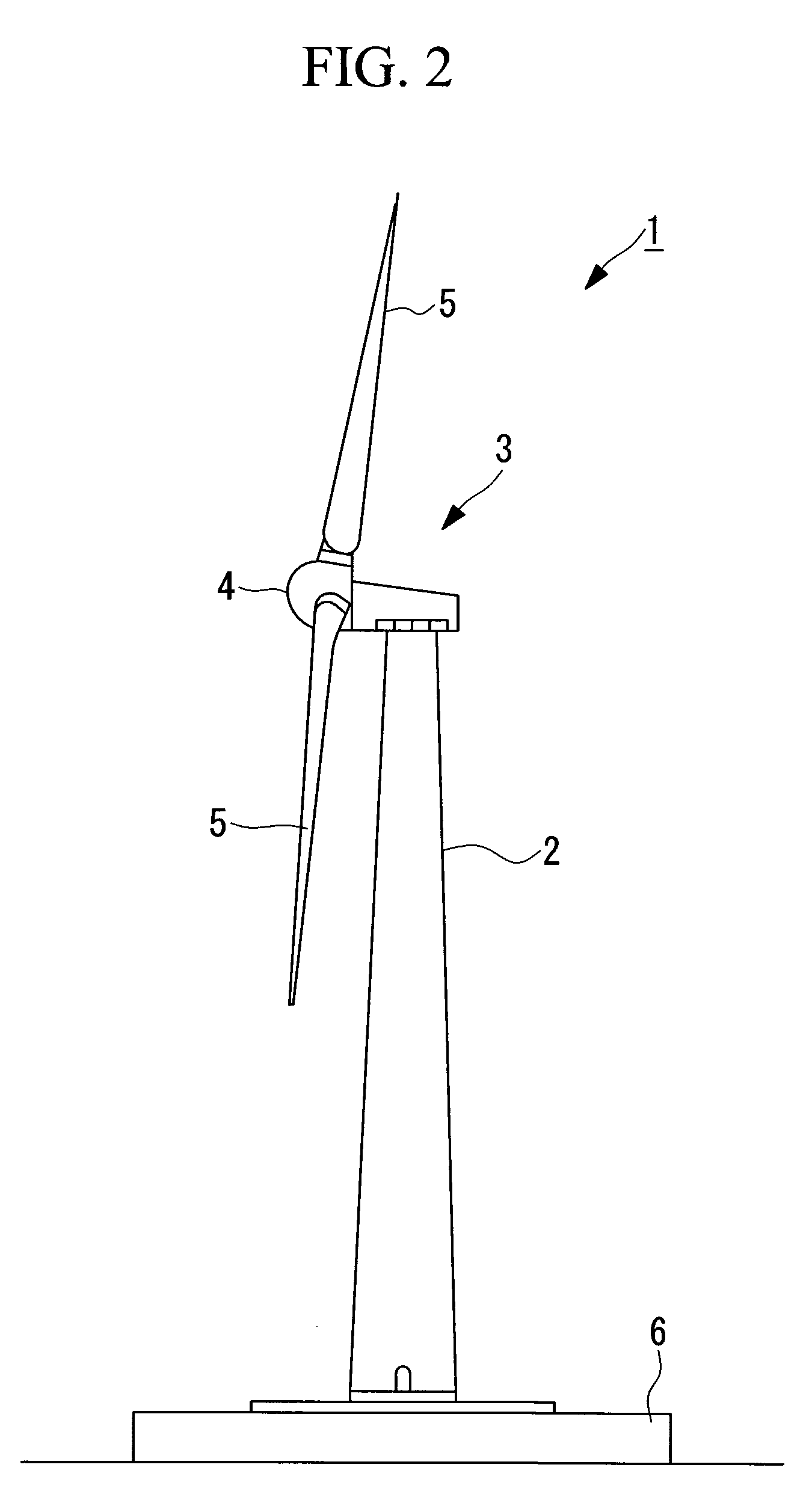

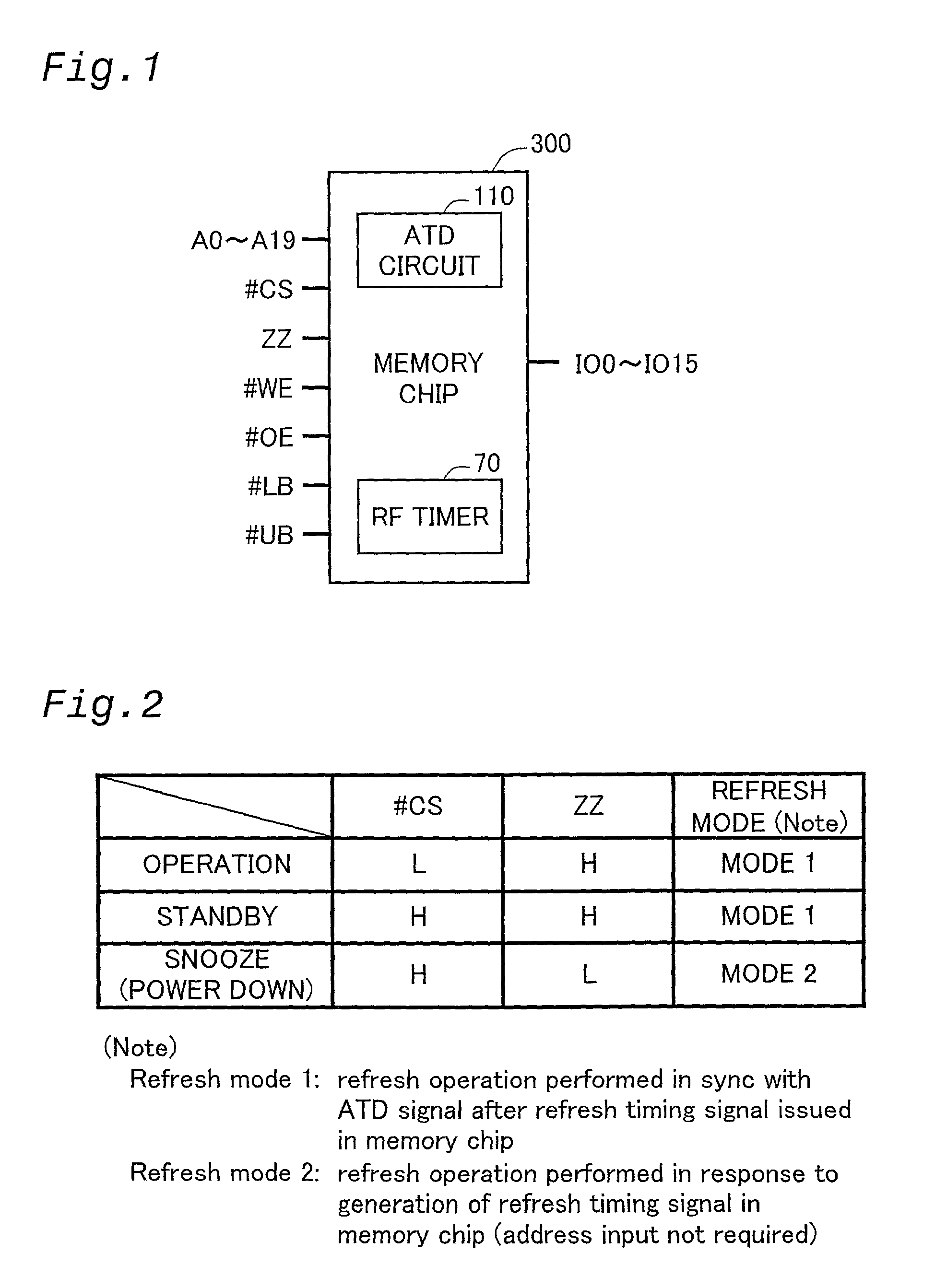

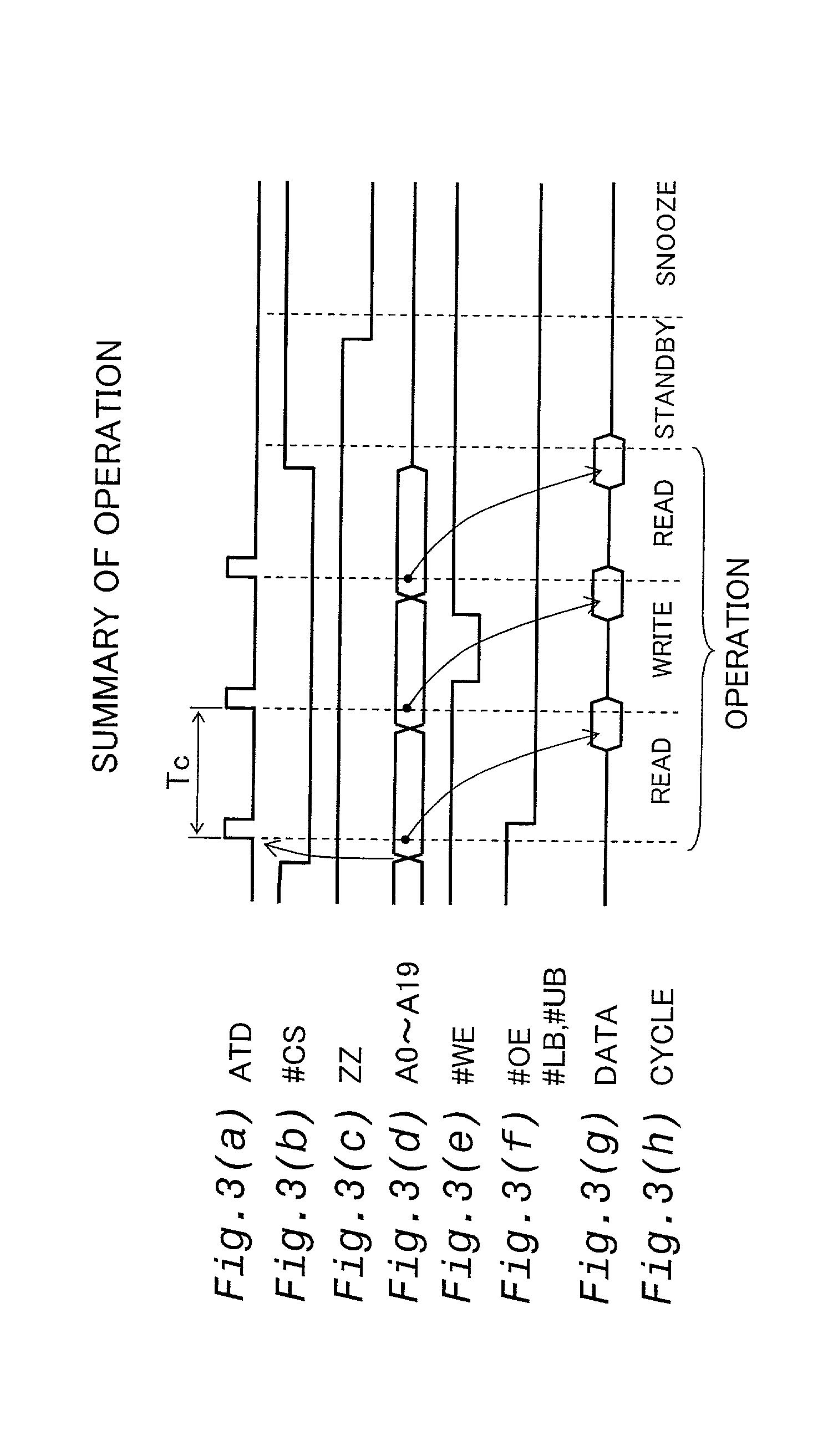

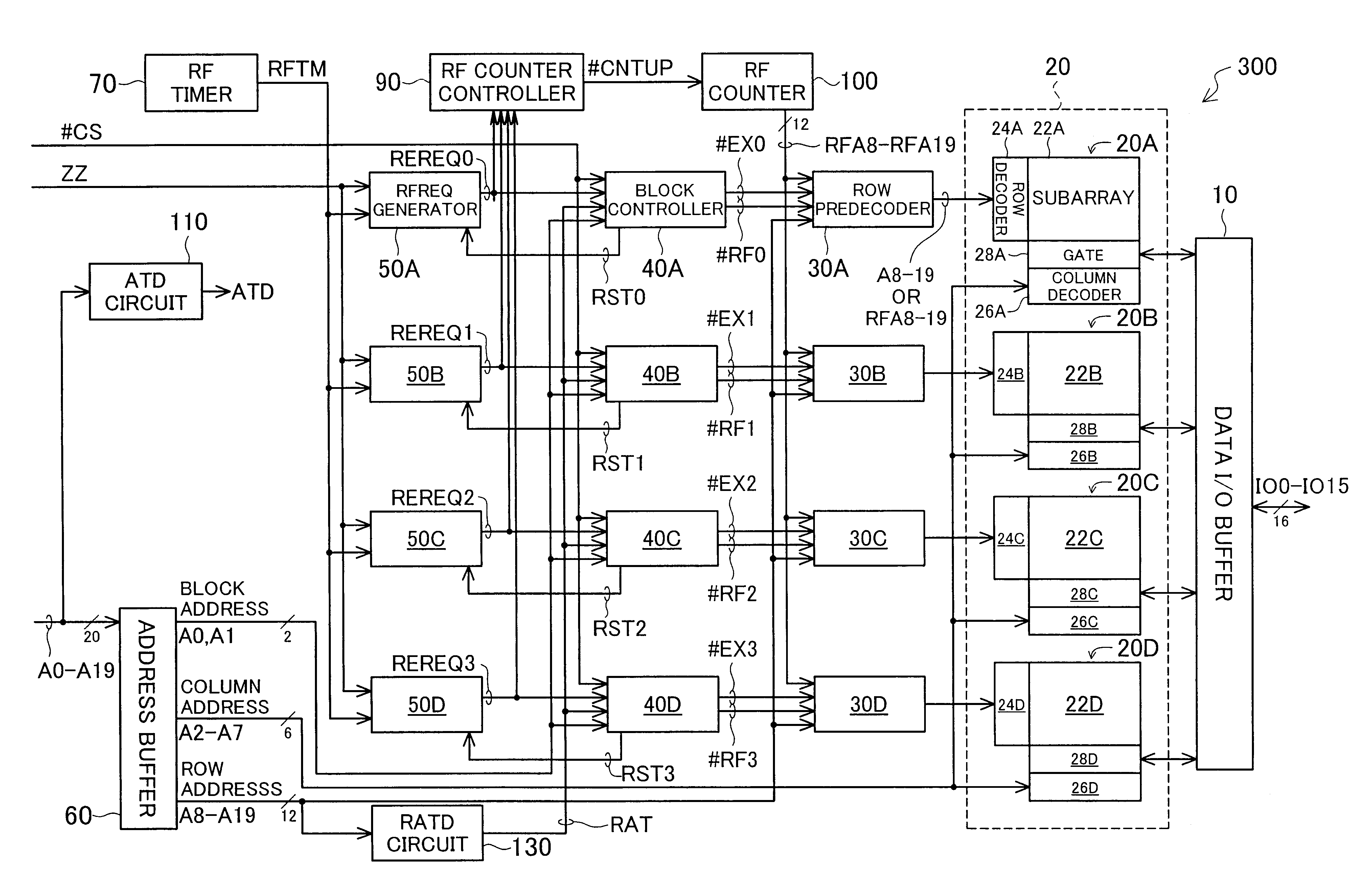

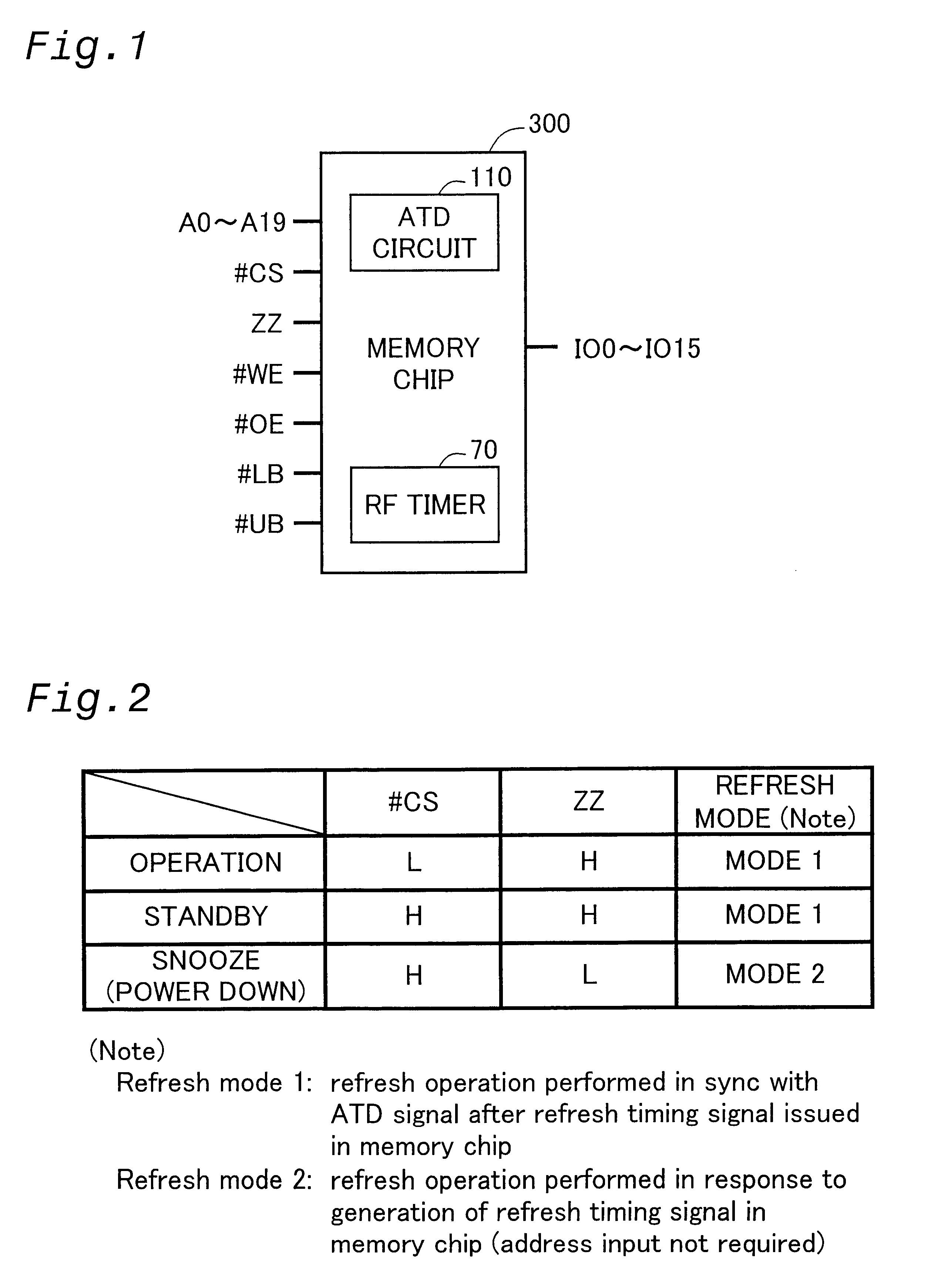

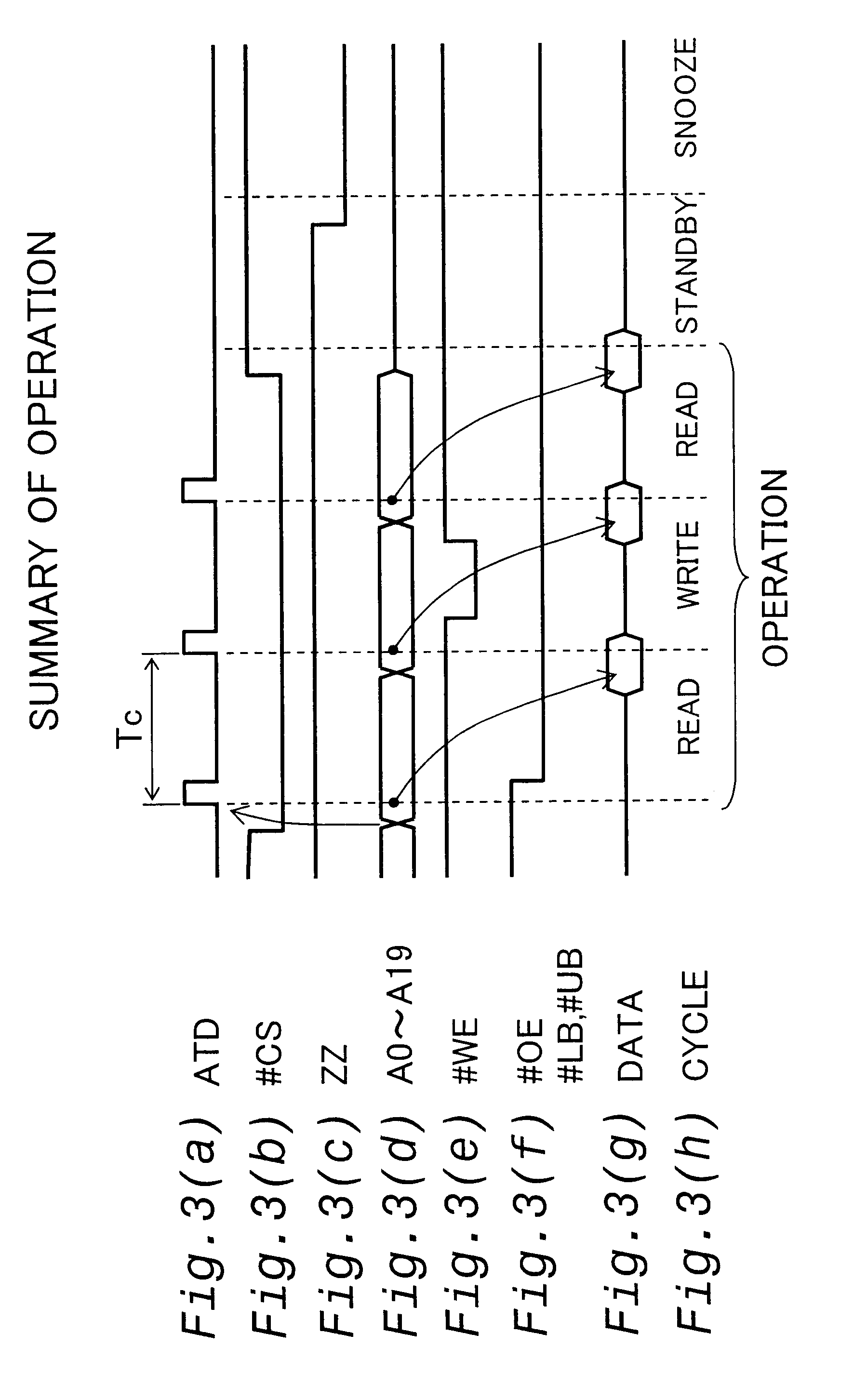

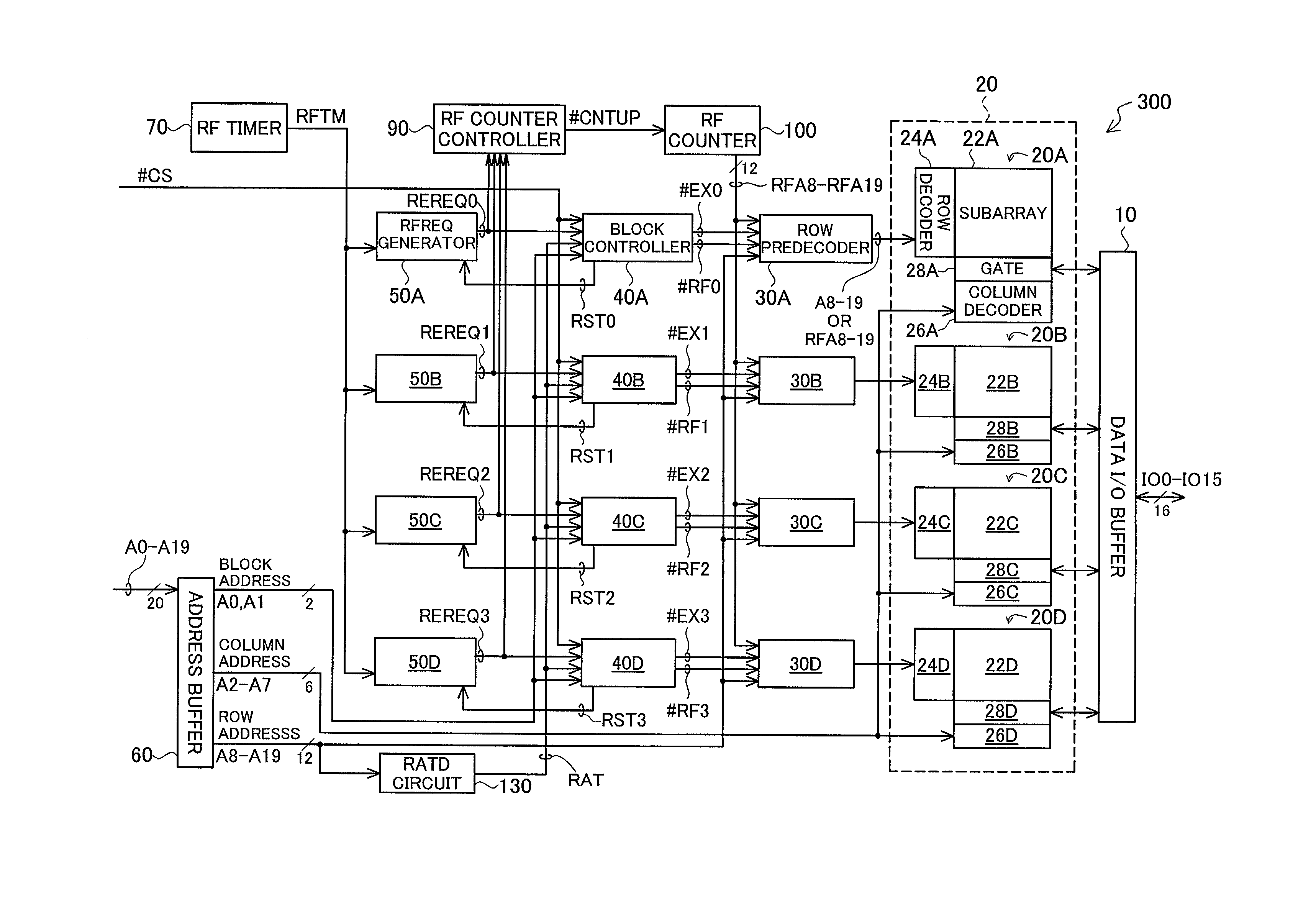

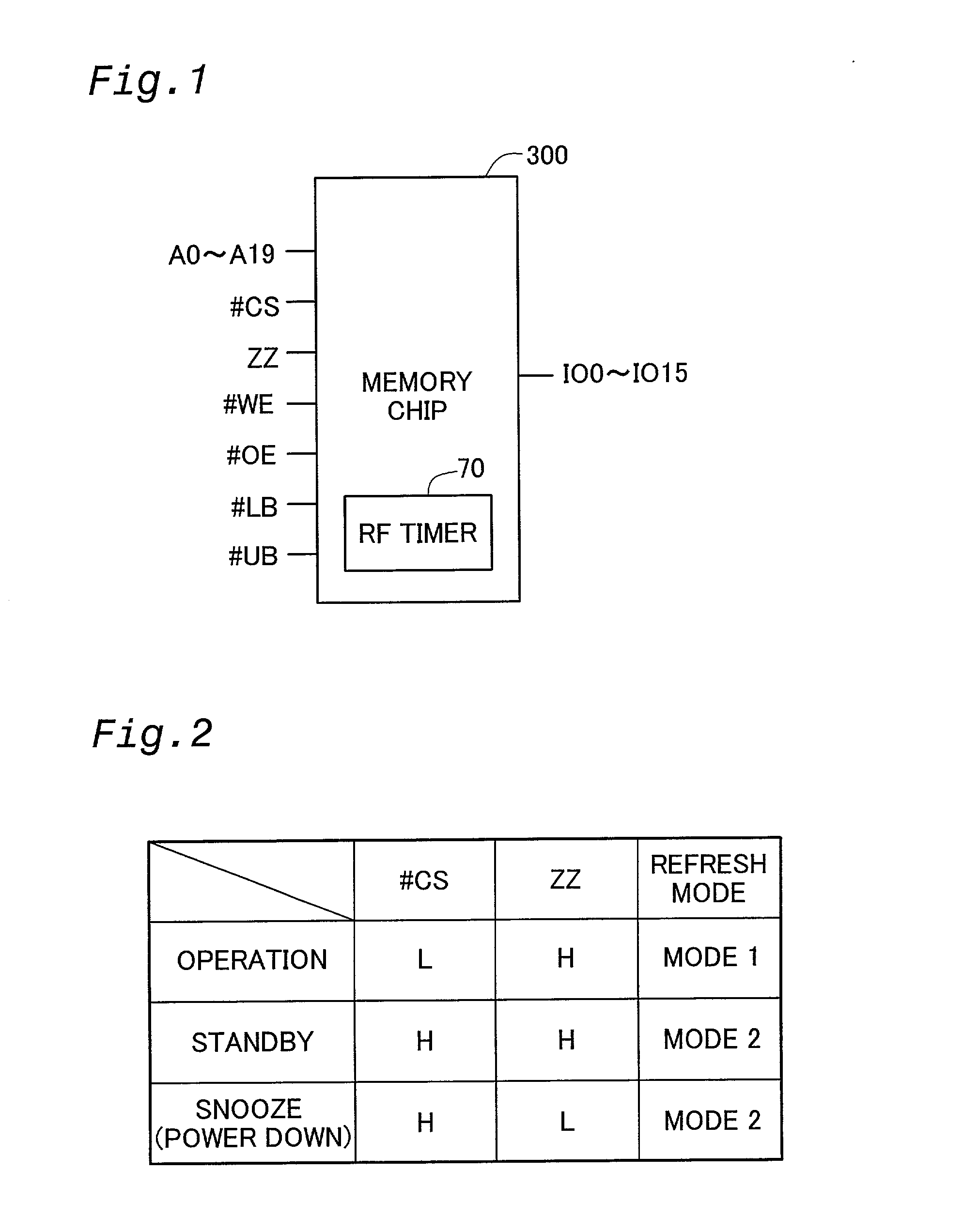

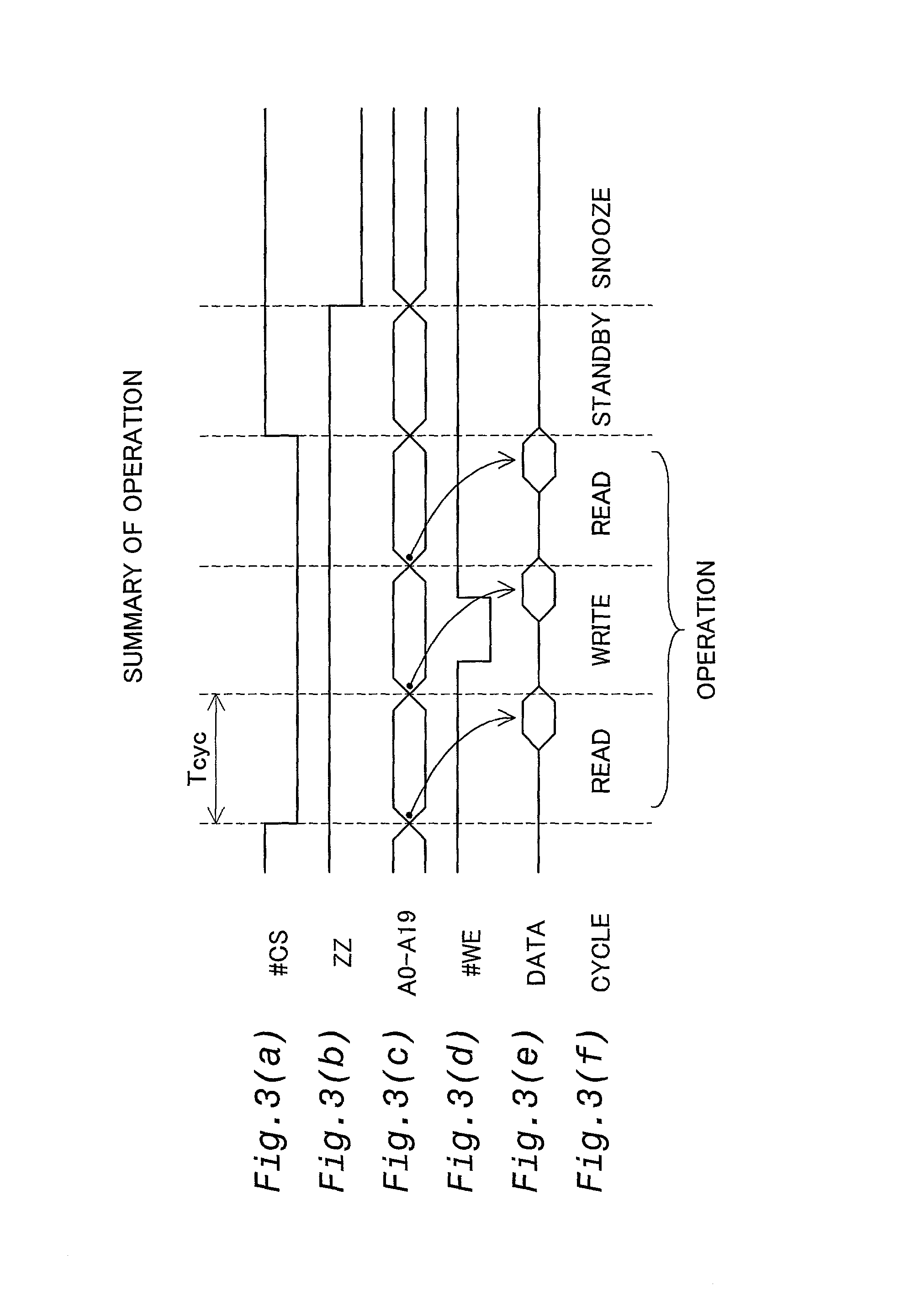

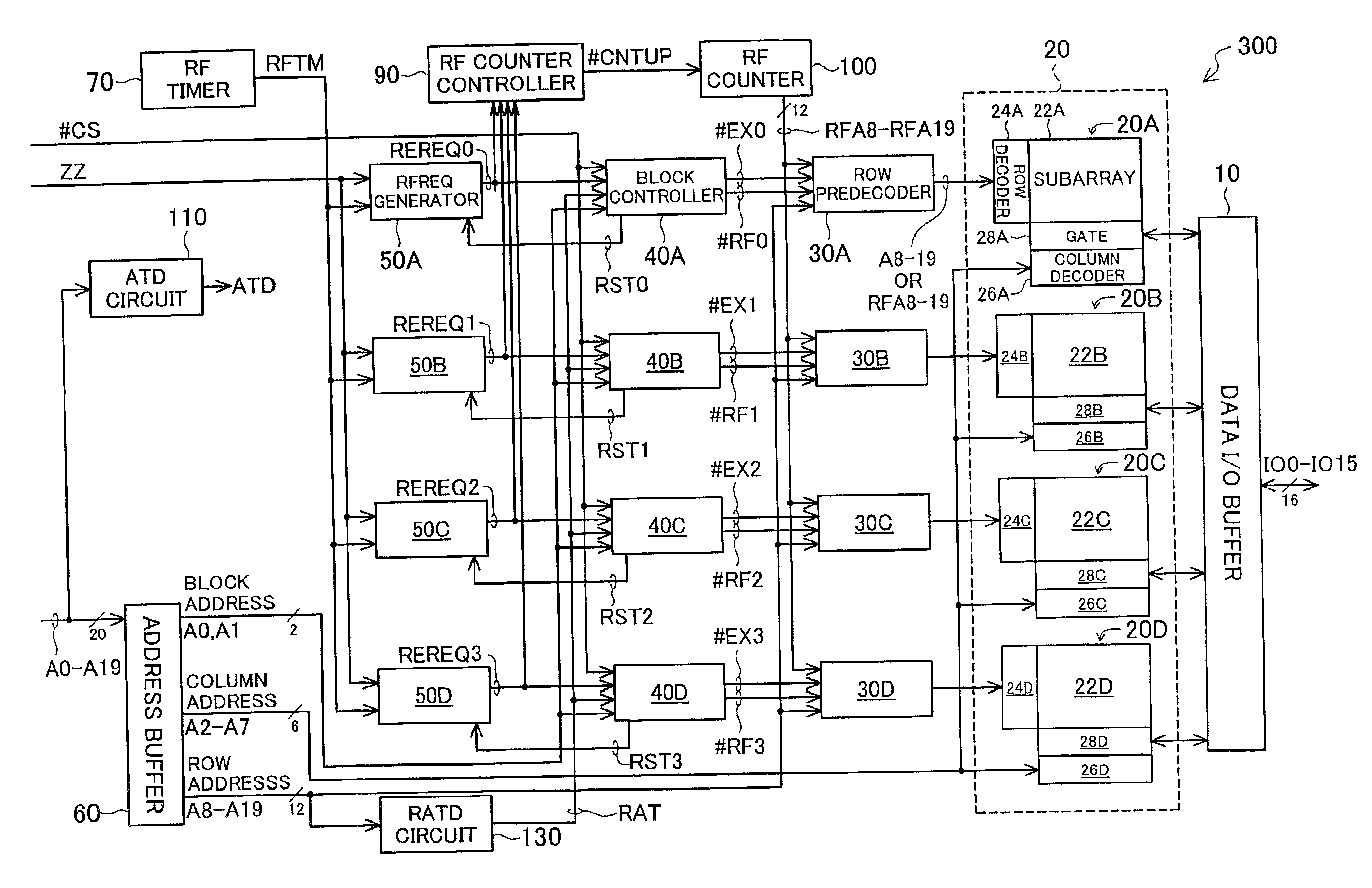

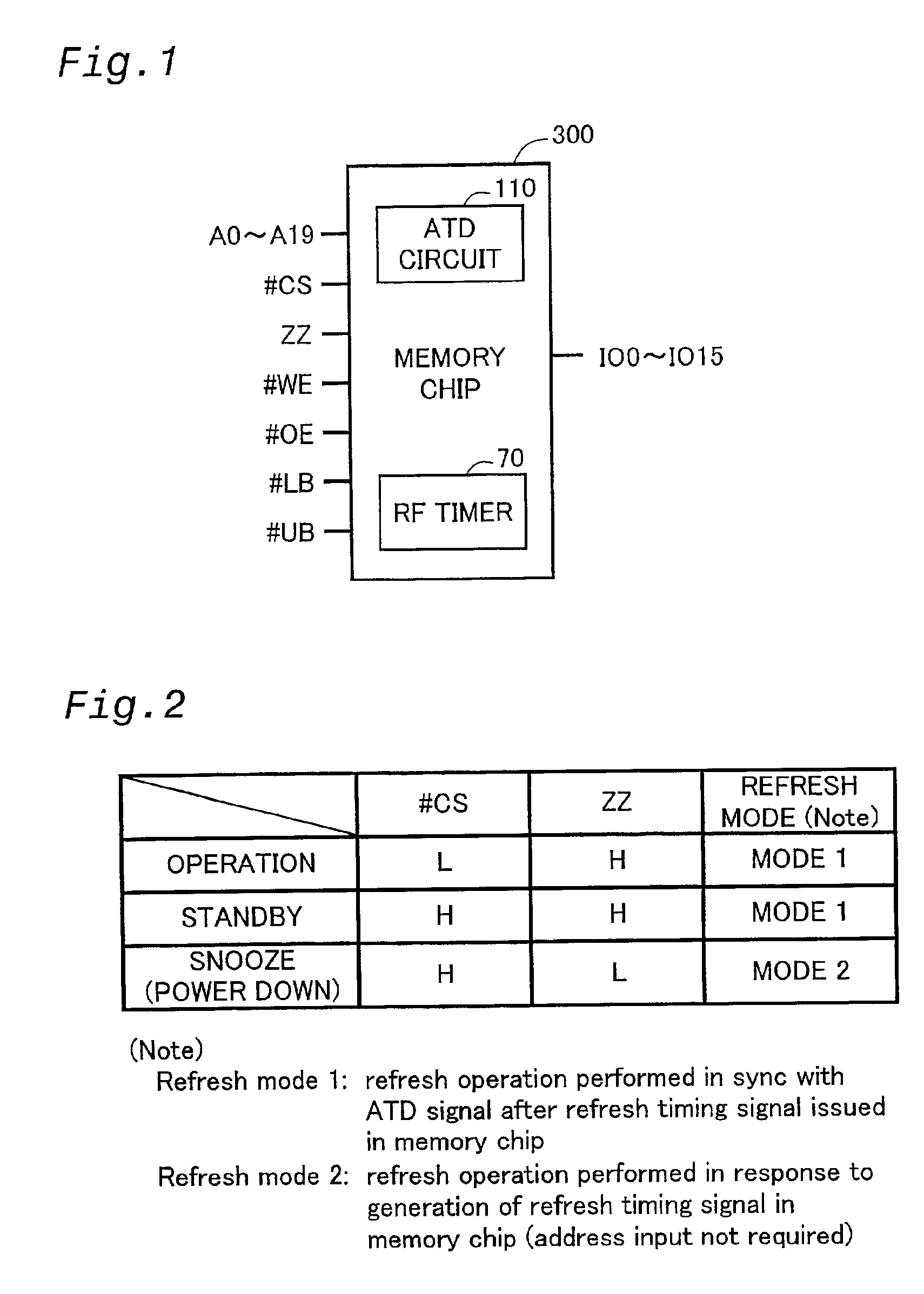

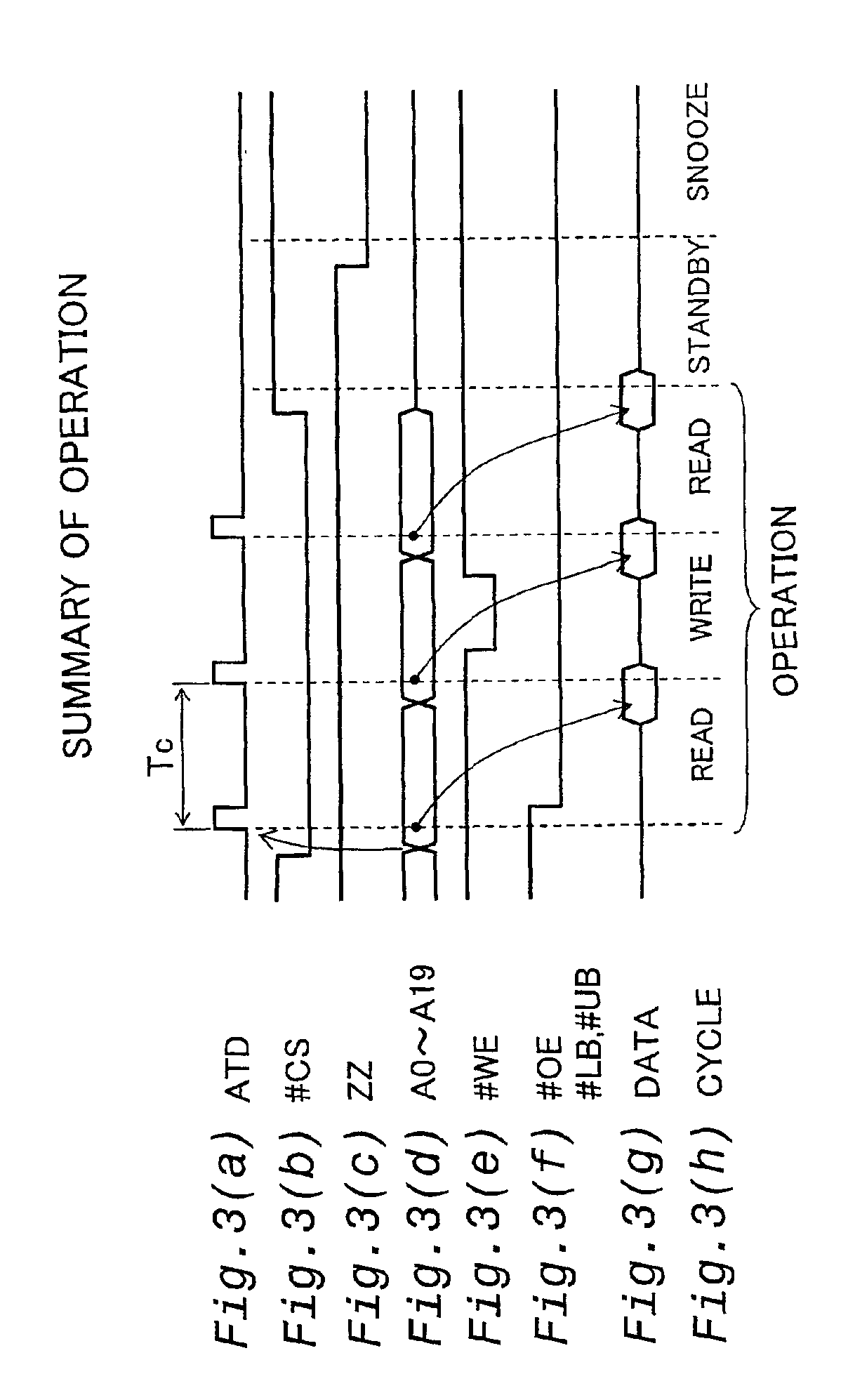

Activation of word lines in semiconductor memory device

InactiveUS6545943B2Reduce power consumptionFrequent maintenanceDigital storageBiological activationContinuous operation

To provide a technique for reducing the power consumption associated with word line activation in a semiconductor memory device. The semiconductor memory device is provided with a word line activation controller for controlling word line activation. Where consecutive operation cycles use multiple-bit addresses that include an identical row address, the controller maintains an activated state of a word line without deactivation thereof until the row address changes. In the event of a refresh request when a word line in a certain block is in an activated state, the controller can deactivate the word line, with the proviso that no external access is currently being performed in the block. Where a request for external access to the block is made within a predetermined period after the refresh request, the refresh operation for the block is suspended, and the word line for external access is activated.

Owner:SEIKO EPSON CORP

Wind turbine generator

InactiveUS8198749B2Simple working processImprove work efficiencyEngine fuctionsWind motor supports/mountsElectricityNacelle

A wind turbine generator that allows for size and weight reduction of a nacelle bedplate and that enables easier maintainability, such as device replaceability, is provided. In a wind turbine generator that generates electricity by driving a generator connected, via a drive train, to a rotor head that has wind-turbine rotor blade attached thereto and rotates together therewith, at least a part of the drive train that transmits torque from the rotor head to the generator is disposed on a front side of the rotor head opposite a nacelle.

Owner:MITSUBISHI HEAVY IND LTD

Activation of word lines in semiconductor memory device

InactiveUS20020054523A1Reduce power consumptionFrequent maintenanceDigital storageBiological activationContinuous operation

To provide a technique for reducing the power consumption associated with word line activation in a semiconductor memory device. The semiconductor memory device is provided with a word line activation controller for controlling word line activation. Where consecutive operation cycles use multiple-bit addresses that include an identical row address, the word line activation controller maintains an activated state of a word line activated during an initial cycle of the consecutive cycles, without deactivating it until a final cycle of the consecutive cycles.

Owner:SEIKO EPSON CORP

Activation of word lines in semiconductor memory device

InactiveUS6525989B2Reduce power consumptionFrequent maintenanceDigital storageBiological activationComputer science

To provide a technique for reducing the power consumption associated with word line activation in a semiconductor memory device. The semiconductor memory device is provided with a word line activation controller for controlling word line activation. Where consecutive operation cycles use multiple-bit addresses that include an identical row address, the word line activation controller maintains an activated state of a word line activated during an initial cycle of the consecutive cycles, without deactivating it until a final cycle of the consecutive cycles.

Owner:SEIKO EPSON CORP

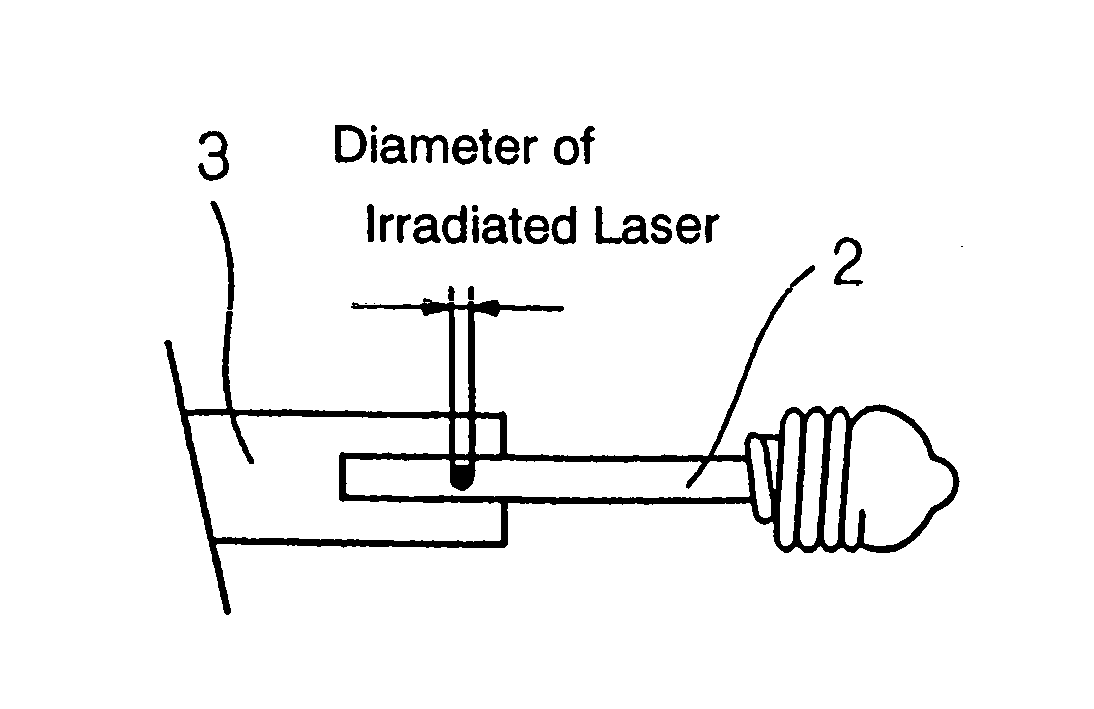

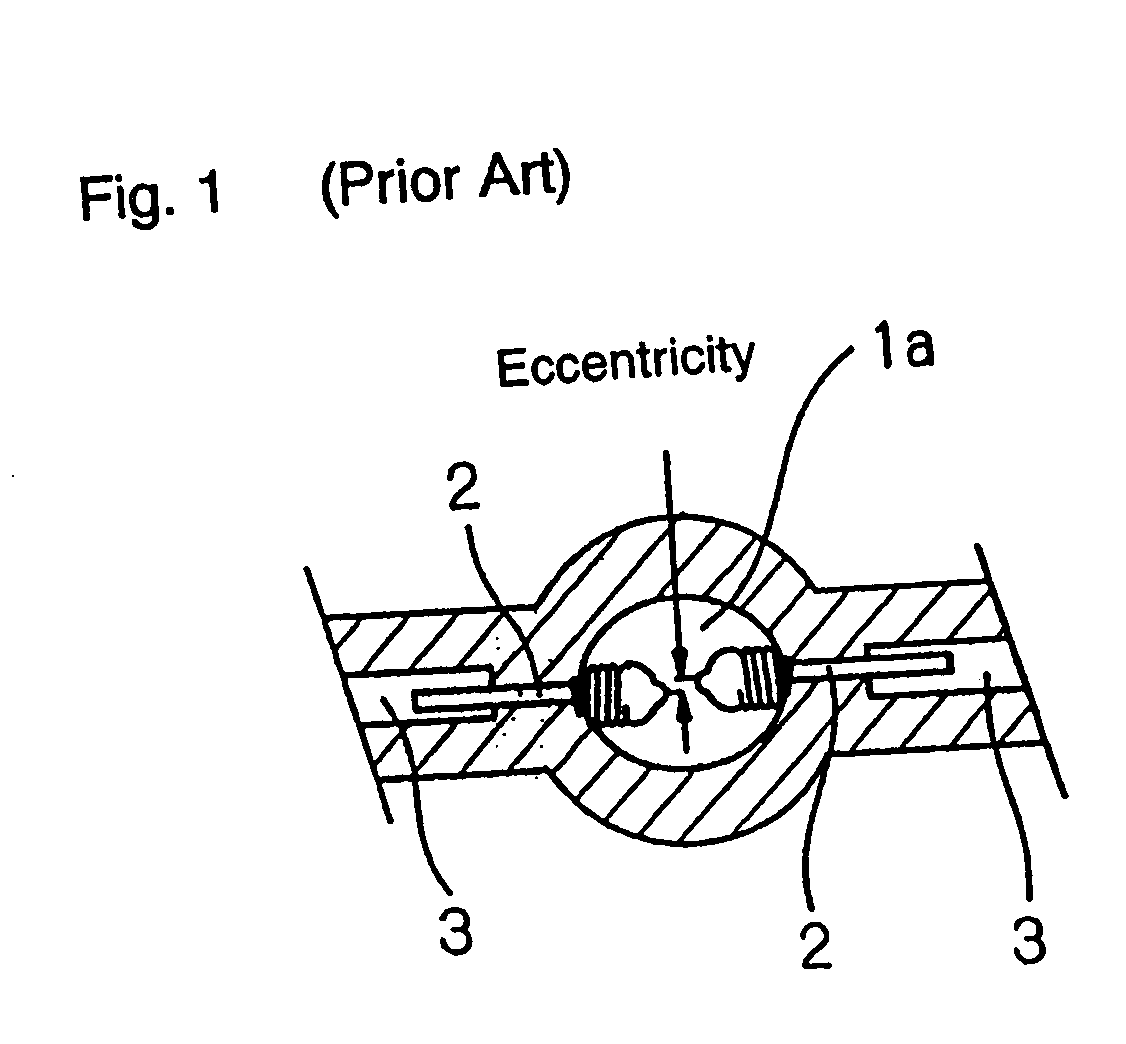

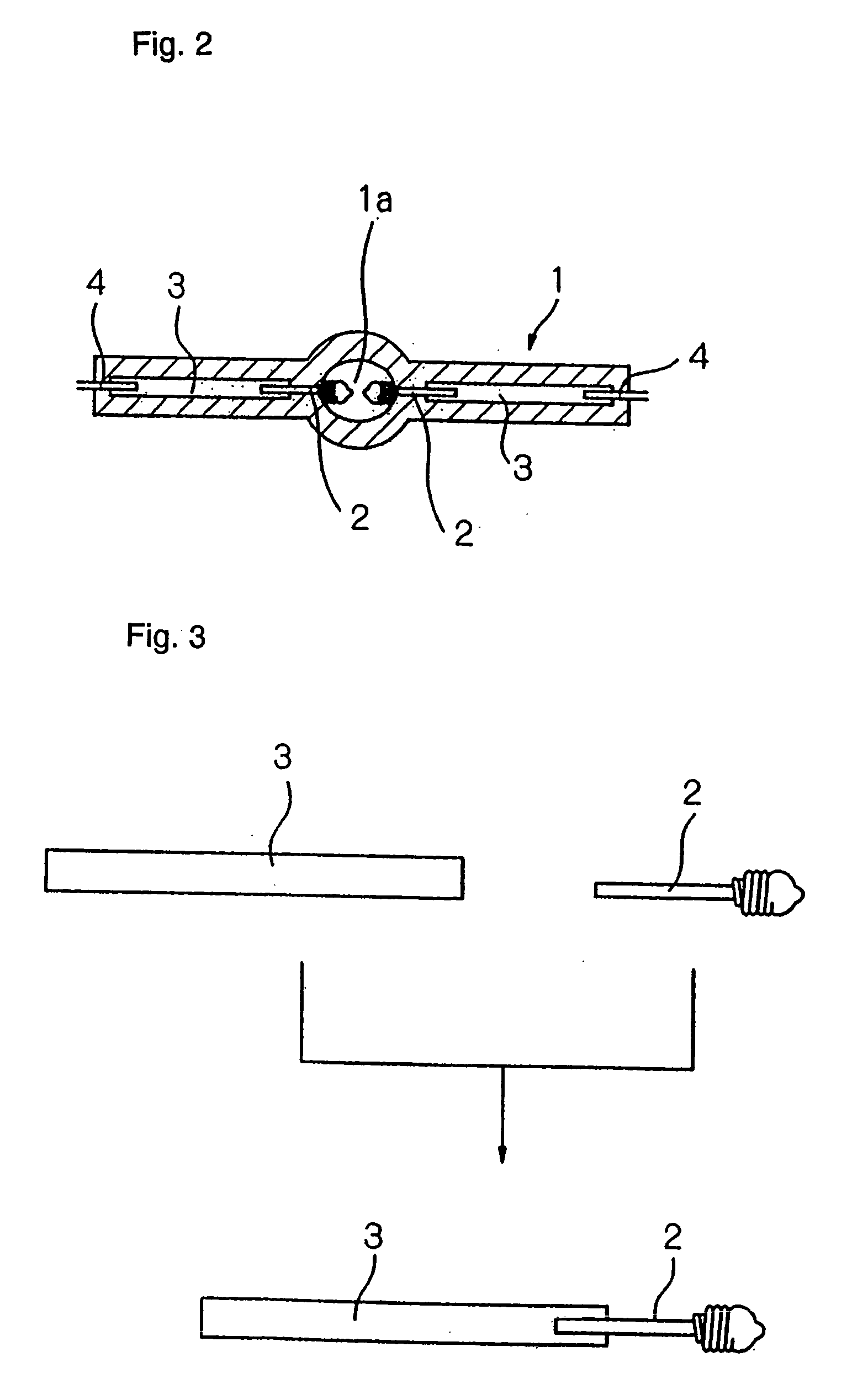

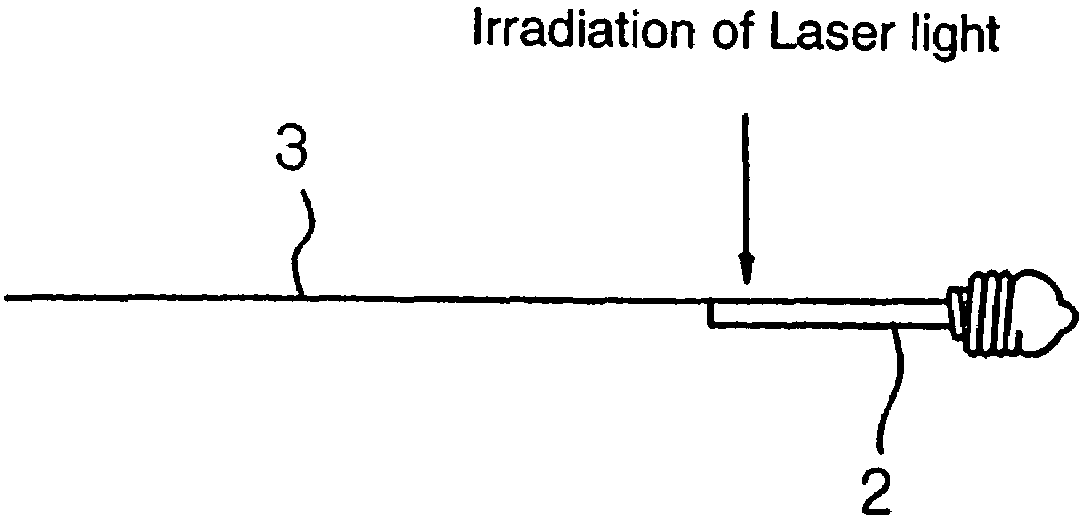

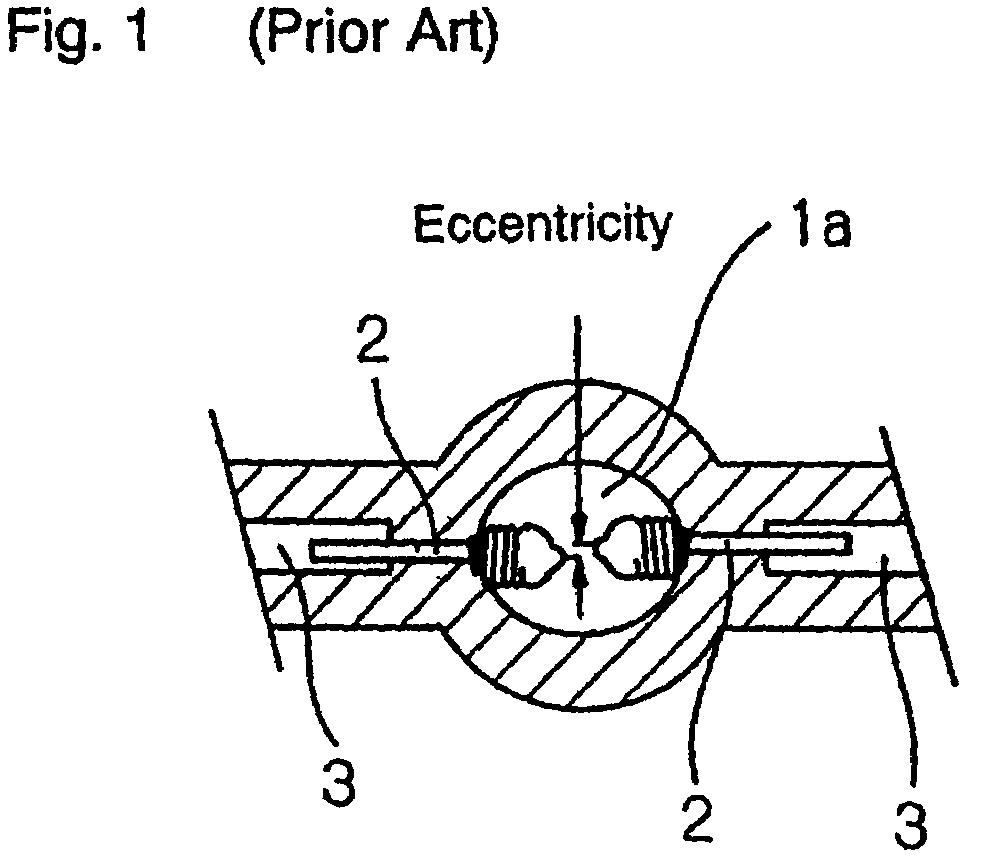

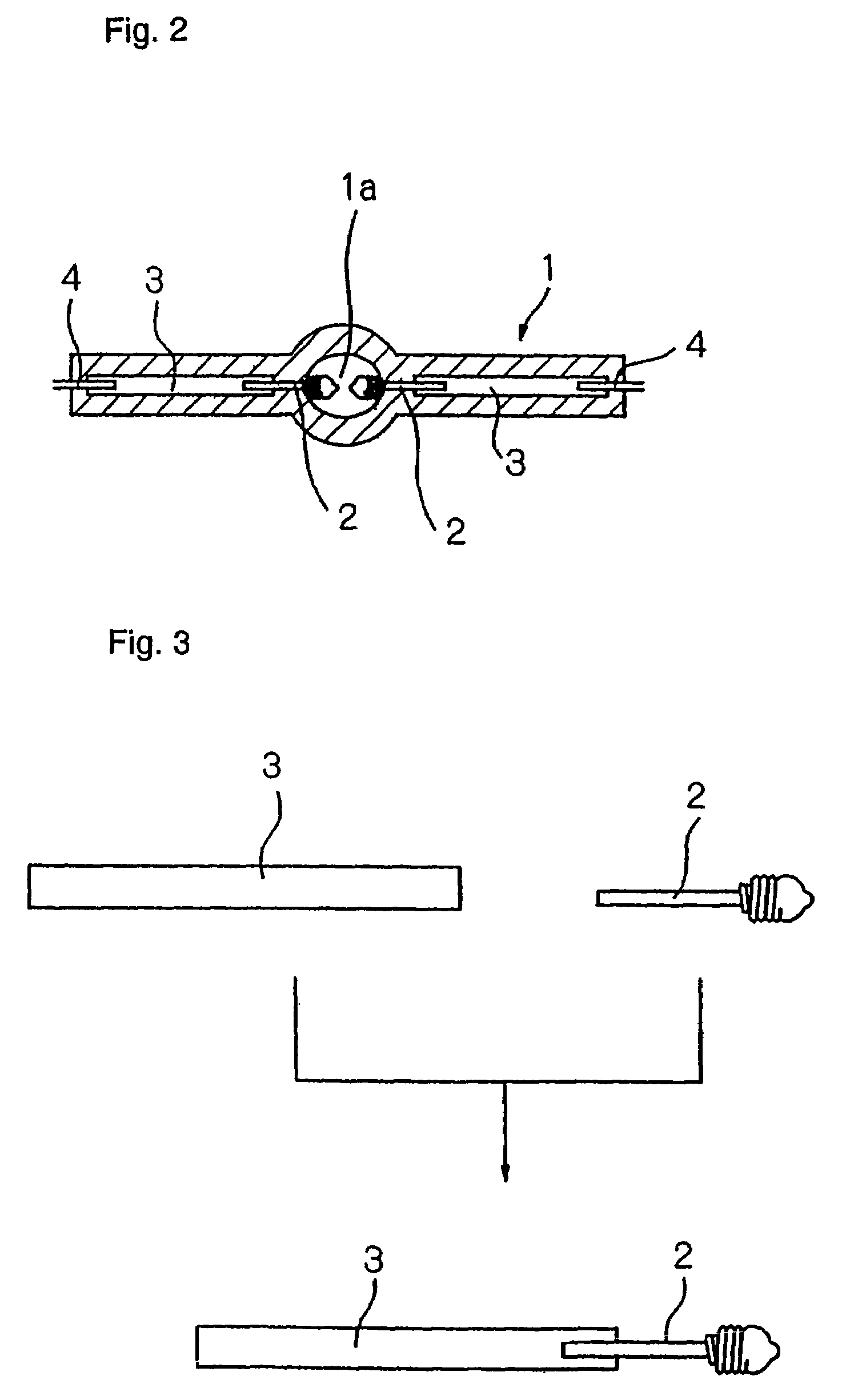

Method of manufacturing a high-pressure discharge lamp

InactiveUS20050003729A1Improve reliabilityEliminate disadvantagesTube/lamp screens manufactureElectroluminescent light sourcesLaser lightLength wave

For manufacturing a high-pressure discharge lamp, a tungsten electrode is welded to a molybdenum foil by bringing a shaft of tungsten electrode into close contact with the molybdenum foil, and by irradiating a laser light, having a metal melting wavelength, to a junction of the molybdenum foil with the tungsten electrode from a location closer to the molybdenum foil to melt both the molybdenum foil and the shaft of the tungsten electrode for bonding.

Owner:USHIO DENKI KK

Activation of word lines in semiconductor memory device

InactiveUS20020057607A1Reduce power consumptionFrequent maintenanceDigital storageBiological activationContinuous operation

To provide a technique for reducing the power consumption associated with word line activation in a semiconductor memory device. The semiconductor memory device is provided with a word line activation controller for controlling word line activation. Where consecutive operation cycles use multiple-bit addresses that include an identical row address, the controller maintains an activated state of a word line without deactivation thereof until the row address changes. In the event of a refresh request when a word line in a certain block is in an activated state, the controller can deactivate the word line, with the proviso that no external access is currently being performed in the block. Where a request for external access to the block is made within a predetermined period after the refresh request, the refresh operation for the block is suspended, and the word line for external access is activated.

Owner:SEIKO EPSON CORP

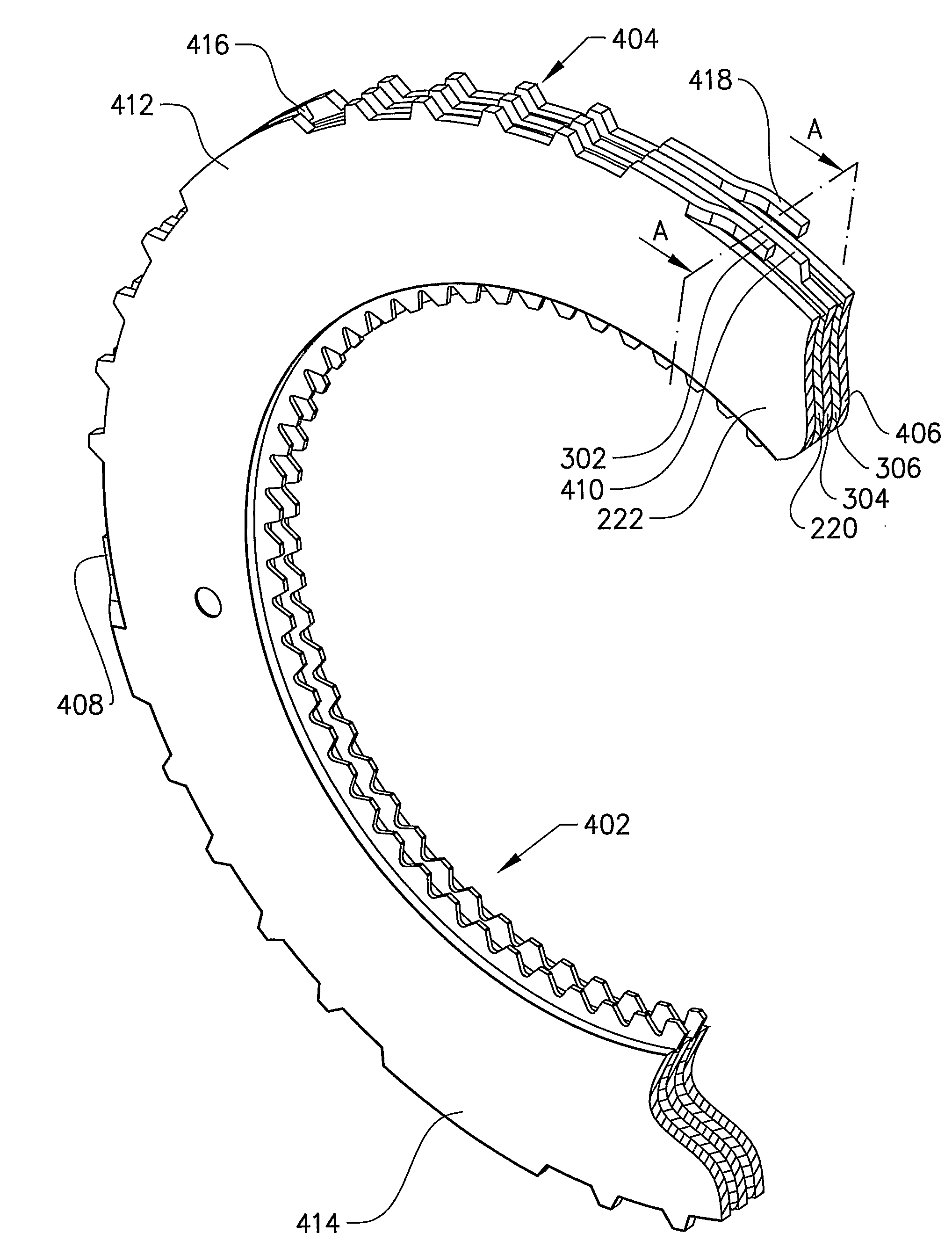

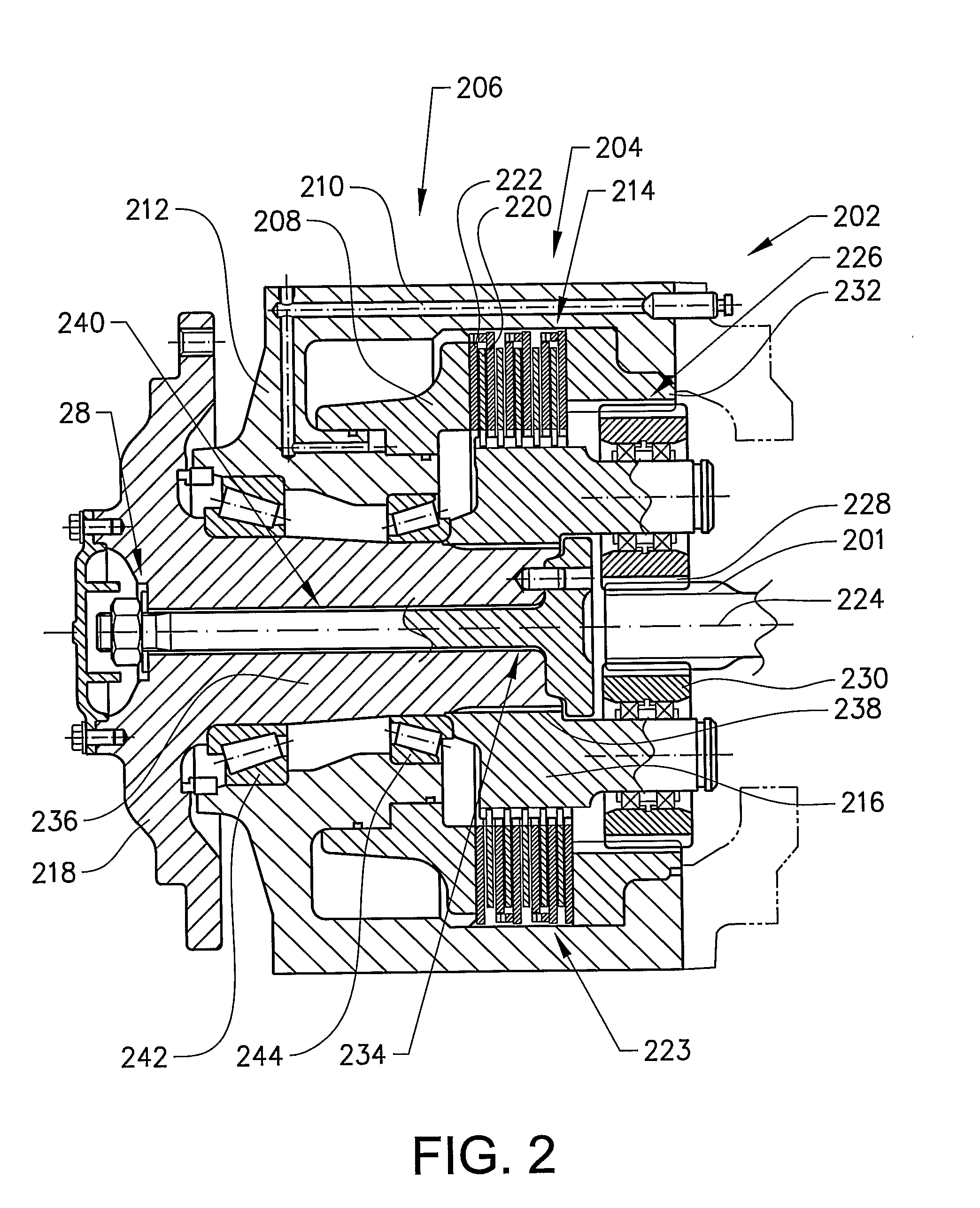

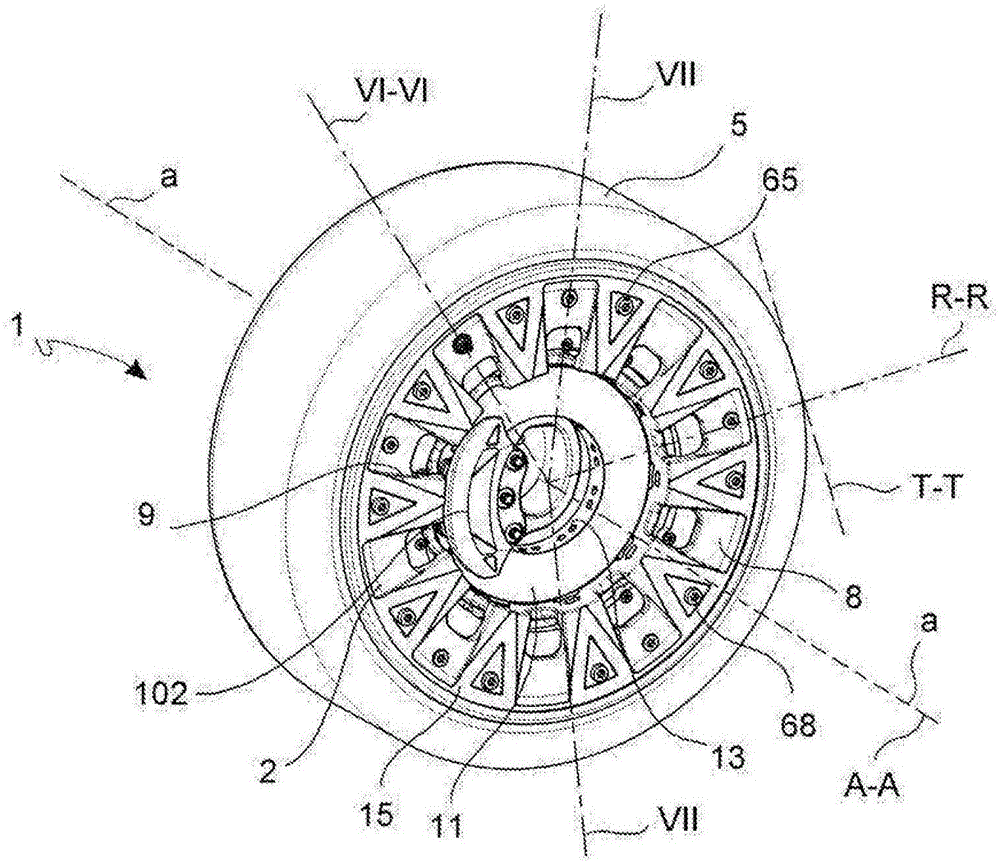

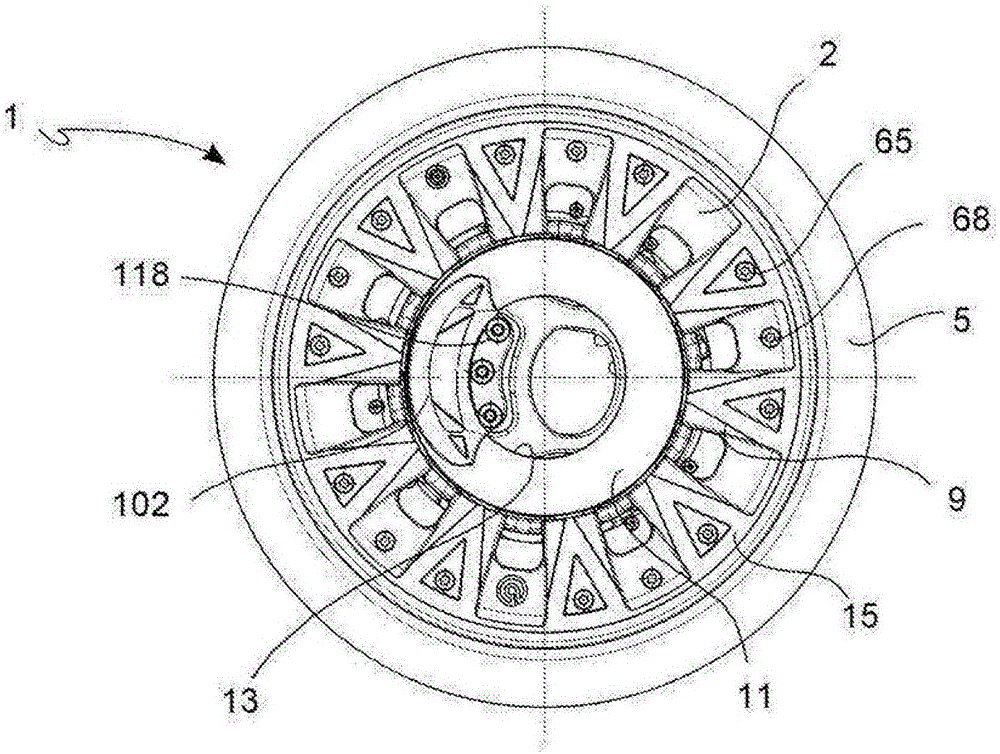

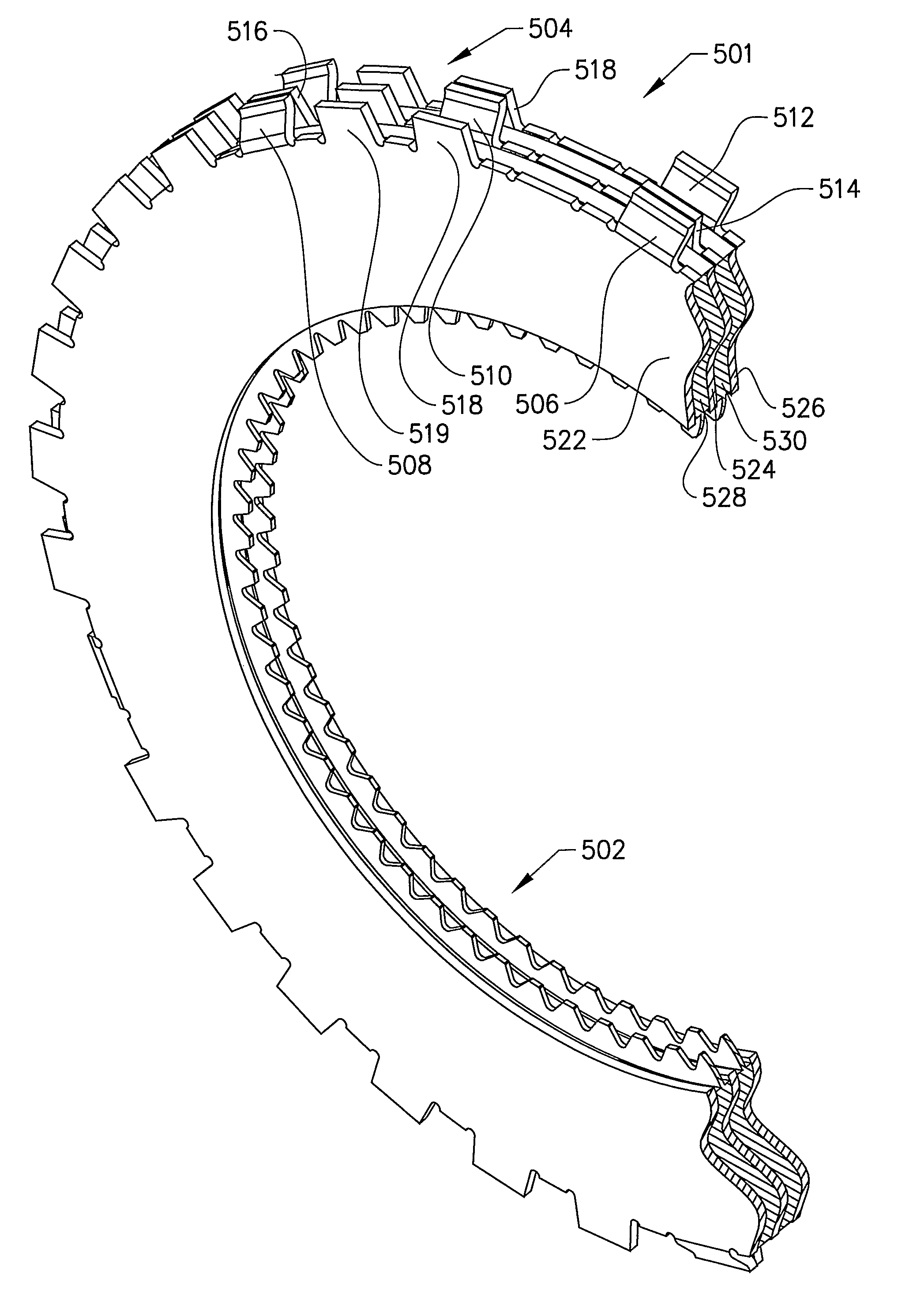

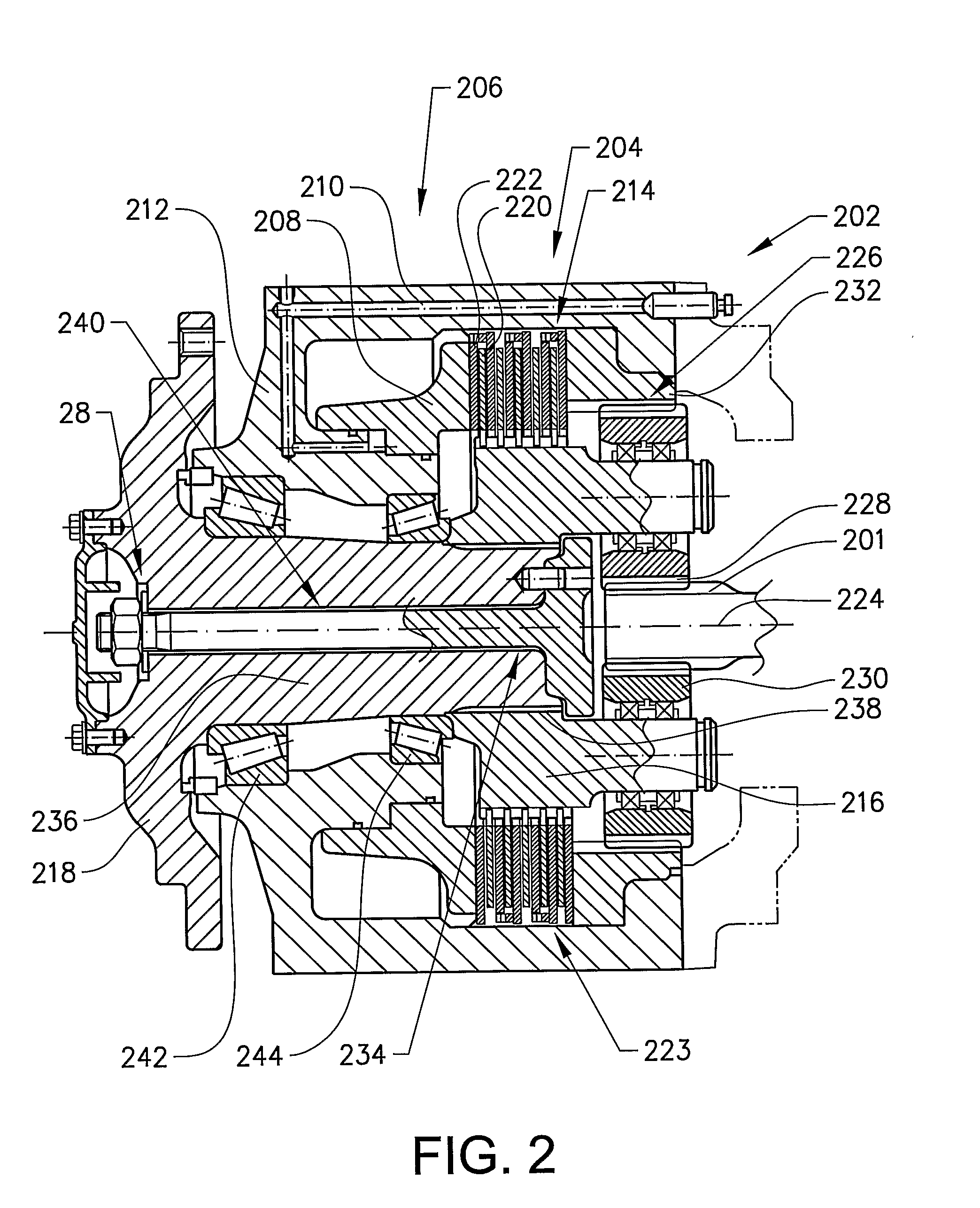

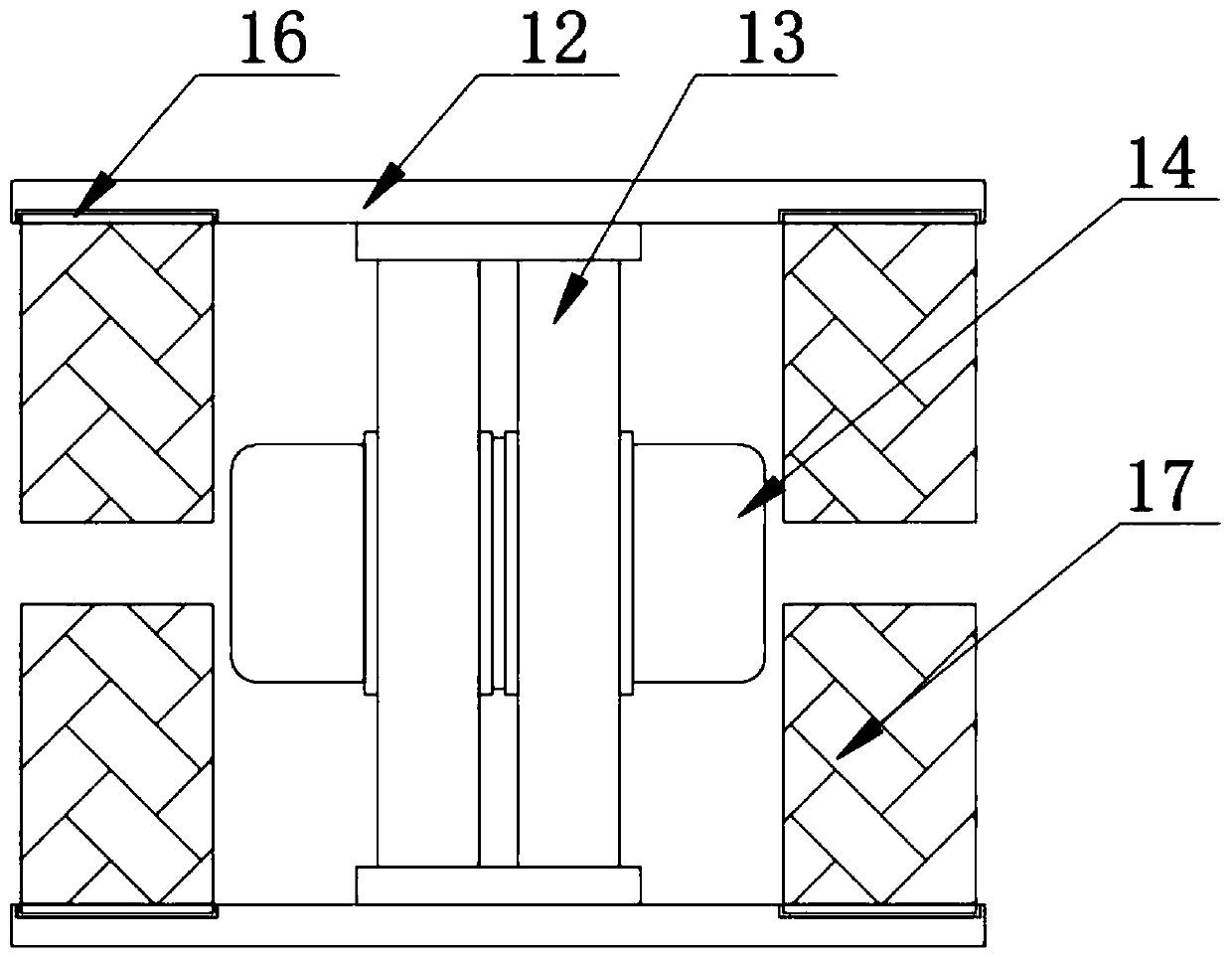

Wheel brake for a vehicle and a vehicle comprising the wheel brake

InactiveUS20090101458A1Reduce material costsSave spaceAxially engaging brakesBraking discsMechanical engineering

A wheel brake for a vehicle including a brake disc unit adapted to brake the rotation of a rotation element, which is adapted to be drivingly connected to the wheel . The brake disc unit includes a first set of discs and a second set of discs arranged in an alternating manner in an axial direction. The discs in the first disc set are adapted to be rotationally rigidly connected to the rotation element. The brake disc unit includes at least one separator element, which is adapted to keep a sufficient distance between two adjacent discs of one of the disc sets for an intermediate disc from the other disc set to rotate at least substantially freely relative to the spaced discs when the brake disc unit is in a deactivated condition.

Owner:VOLVO CONSTR EQUIP

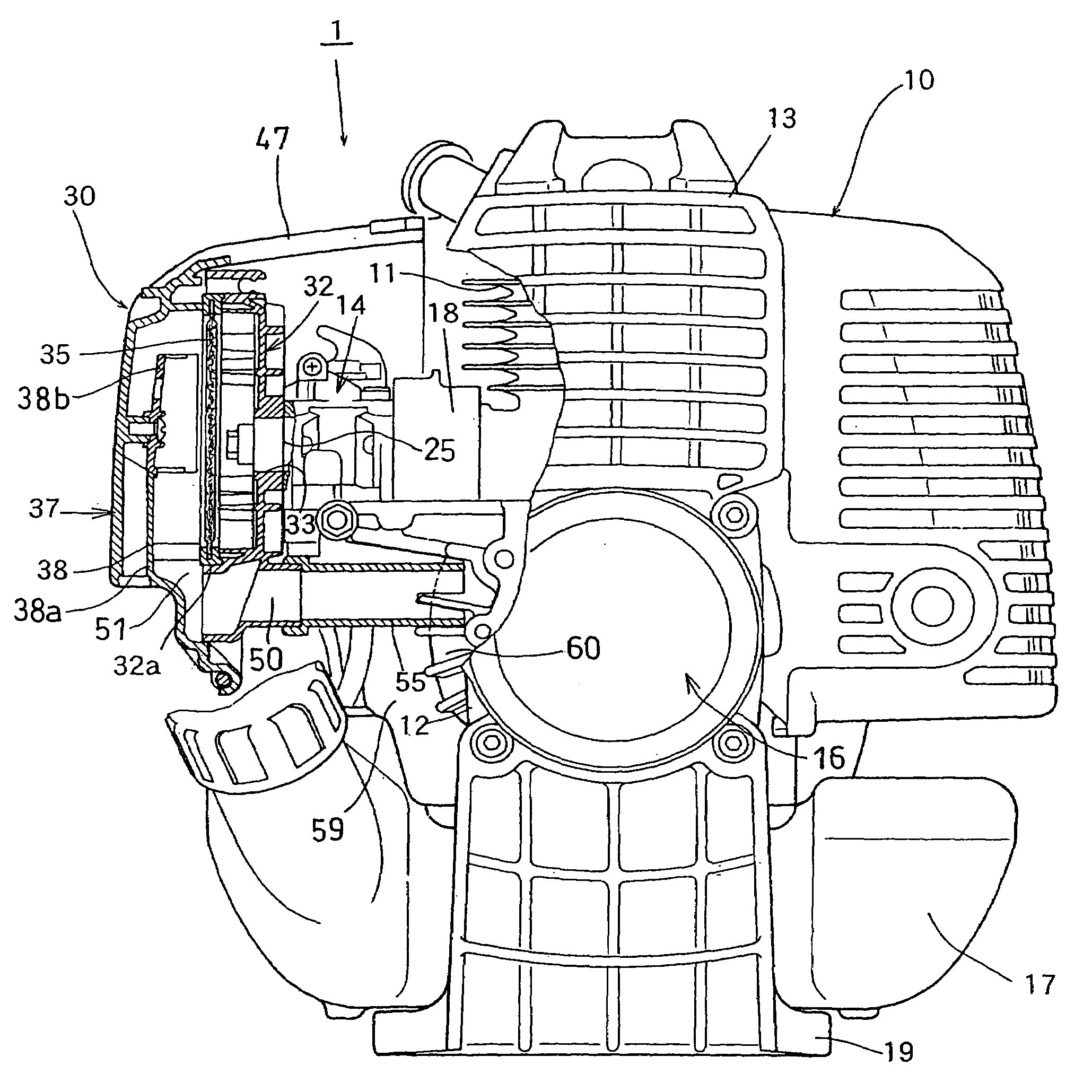

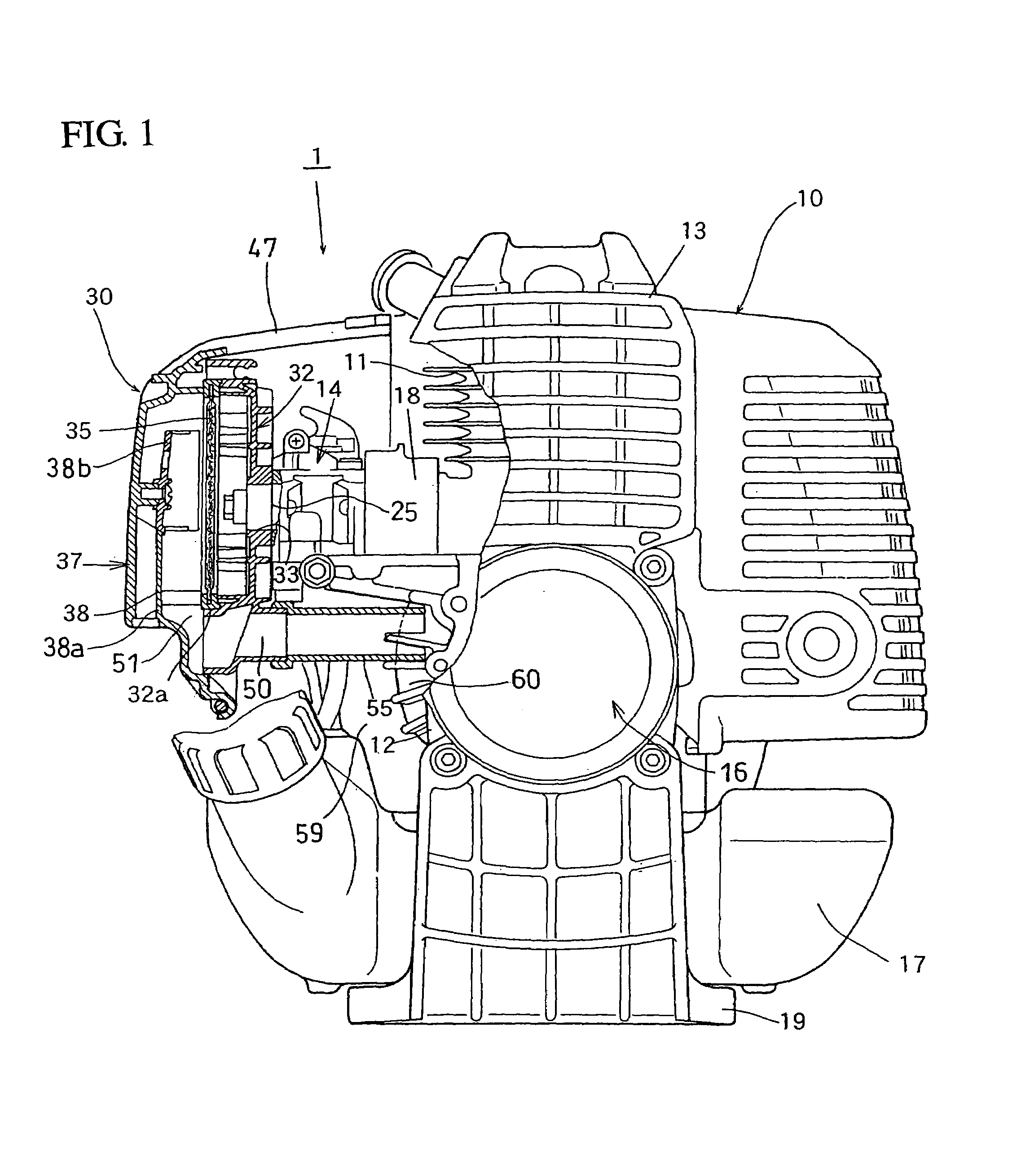

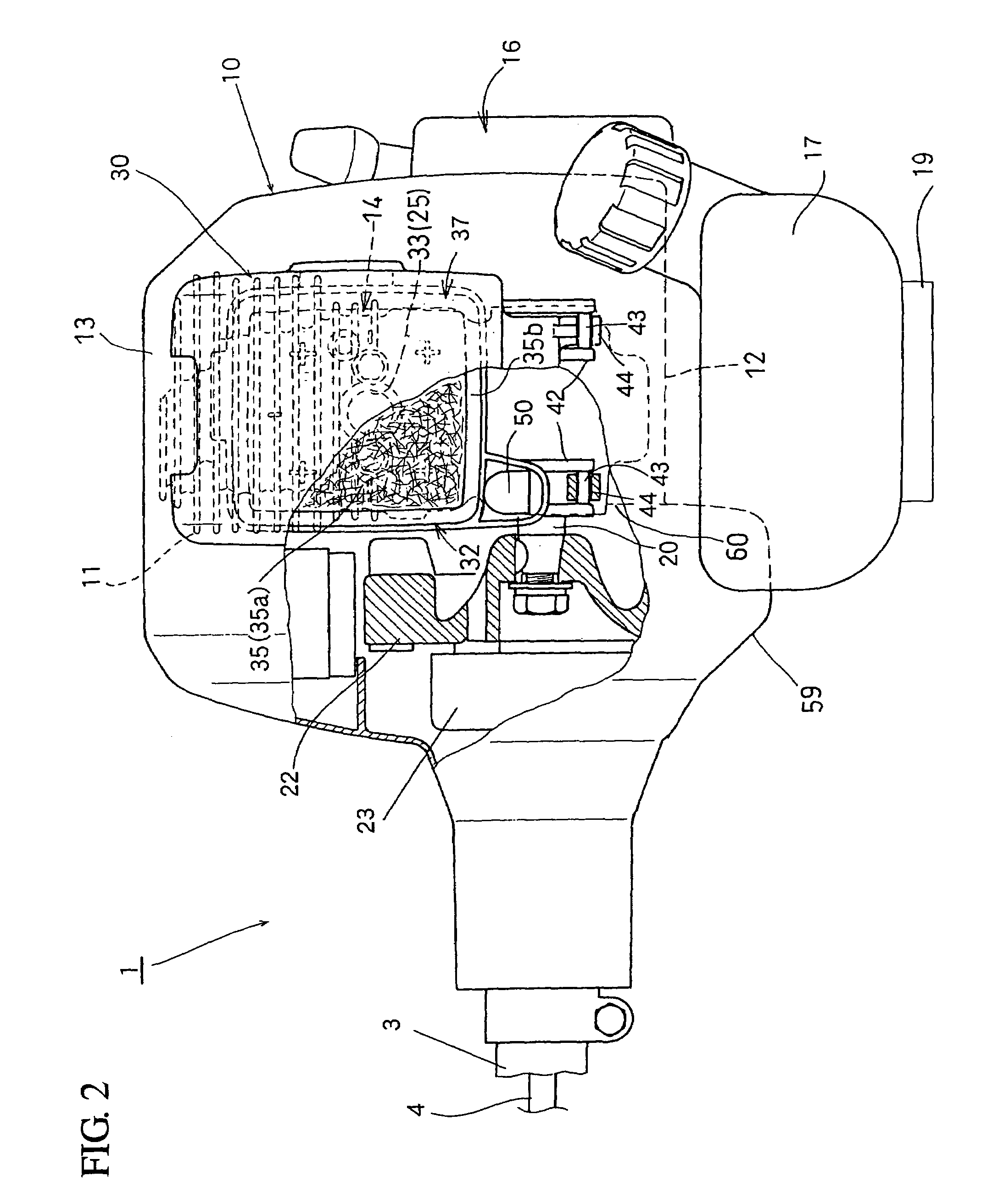

Portable power working machine

ActiveUS7007660B2Frequent maintenanceConvenience to workCombination devicesLiquid degasificationPortable powerEngineering

A portable power working machine is disclosed, which is capable of effectively minimizing the clogging of the air cleaner, thereby dispensing with frequent maintenance. This portable power working machine comprises an air cleaner (30) having a base body case (32) provided with a clean air discharge port (33) for introducing the air cleaned into an intake port (25) of a carburetor (14), a filter (35) which is mounted on a filter mounting opening (32a) of base body case (32) so as to seal it, and a cleaner cover (37) which is attached onto the filter (35) so as to cover the filter (35) and to guide outside air toward the filter (35), while giving a predetermined directionality to the outside air. The air cleaner (30) is also configured to include a suction port (50) and a suction guiding member (55) both designed to discharge the dust out of the air cleaner (30) through a space formed between the filter (35) and the cleaner cover (37) as the dust adhered to the outside air side of the filter (35) is sucked out by taking advantage of a negative pressure to be generated by a fan (22).

Owner:KIORITZ

Brake wear control system

ActiveUS8634971B2Frequent inspectionFrequent maintenanceMechanically actuated brakesDigital data processing detailsControl systemEngineering

Owner:THE BF GOODRICH CO

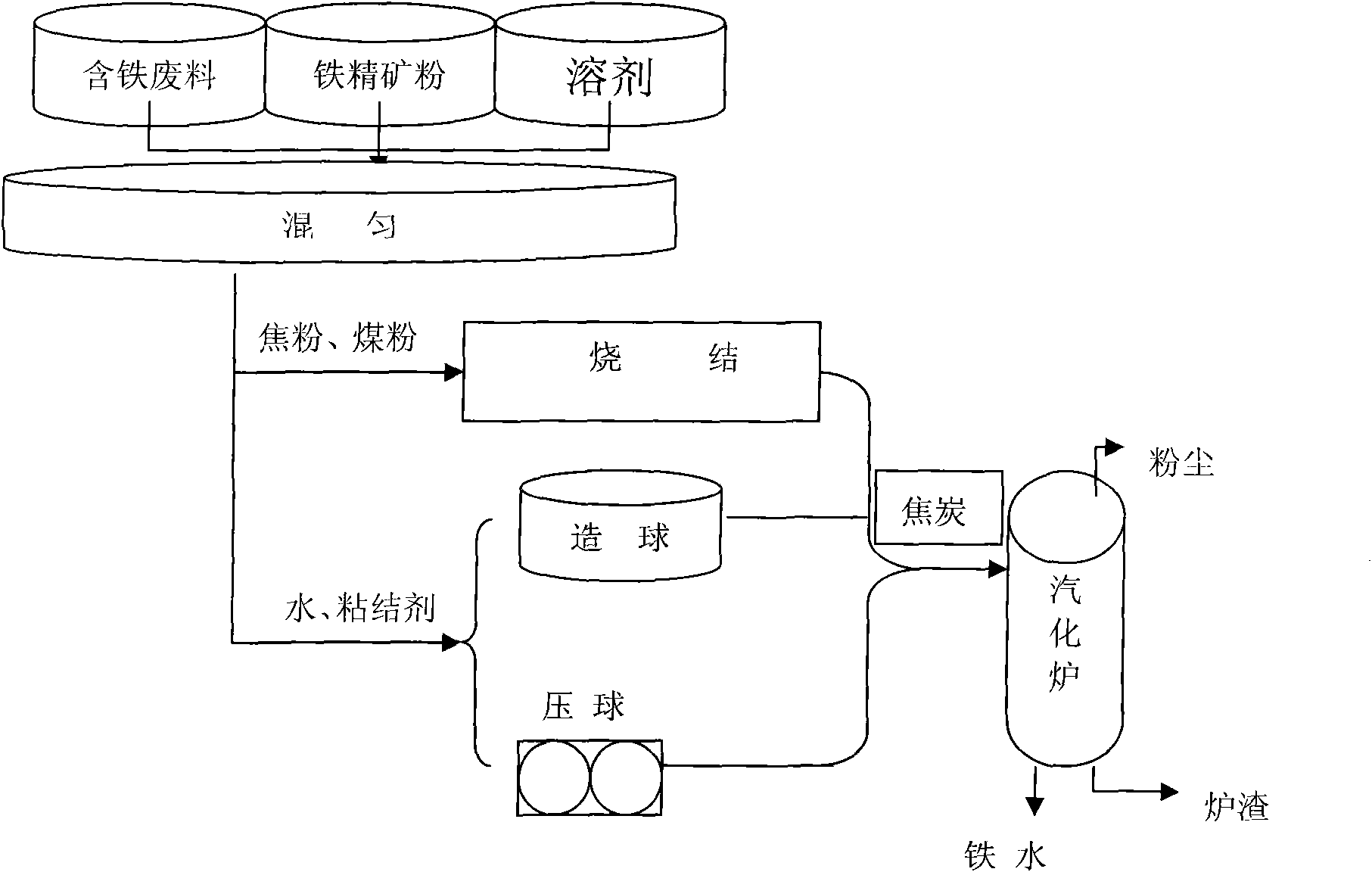

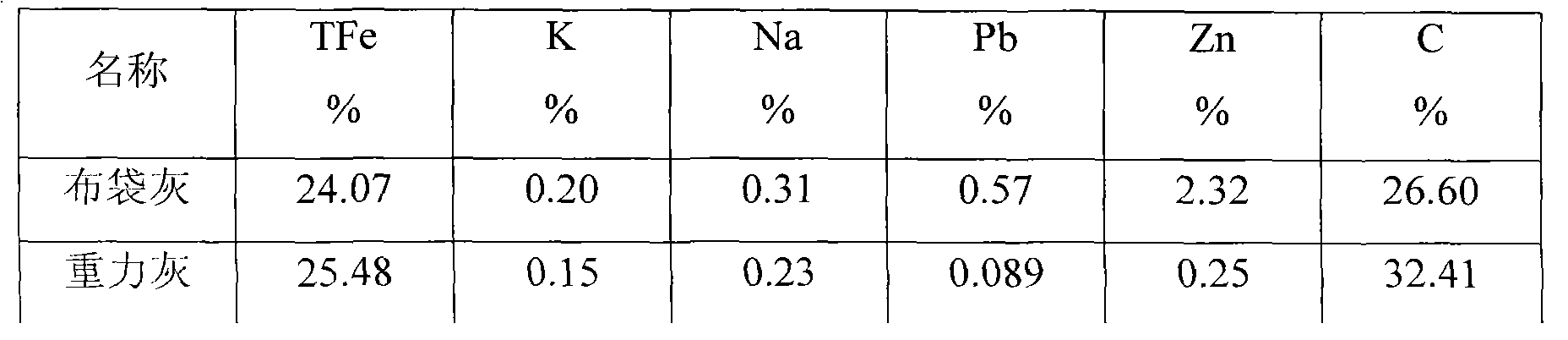

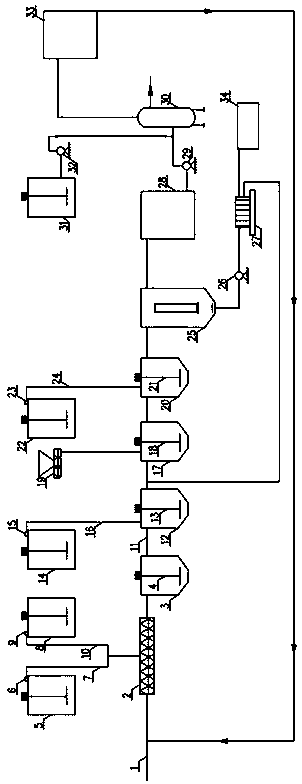

Method for treating iron-containing dusts in steel plant by using melting gasification furnace

The invention discloses a method for treating iron-containing dusts in a steel plant by using a melting gasification furnace, which comprises the following steps of: preparing uniformly mixed raw materials, namely mixing various iron-containing dusts in the steel plant, iron ore concentrate powder, adhesive and flux in a certain proportion to form the uniformly mixed raw materials; preparing lumps, namely preparing the uniformly mixed raw materials into the lumps by a cold bond agglomeration method or a hot-state agglomeration method; and smelting in a blast furnace, namely adding the prepared lumps and a certain amount of coke into the high-wind-temperature melting gasification furnace to perform melting, and finally obtaining molten iron by melting. The method for treating the iron-containing dusts in the steel plant can effectively solve the pollution problem of the iron-containing dusts, can obtain qualified molten iron, and makes full use of valuable elements such as carbon, iron and the like in wastes.

Owner:UNIV OF SCI & TECH BEIJING

Method for treating coking biochemical effluent by microwave-oxidation-coagulation technology

ActiveCN101767912AReduce usageImprove processing efficiencyWater/sewage treatment by magnetic/electric fieldsMultistage water/sewage treatmentSludge cakeMicrowave oven

The invention provides a method for treating coking biochemical effluent by microwave-oxidation-coagulation technology, which comprises the following steps of: A, adding a mixed reagent consisting of H2O2 and Fe2+ into the coking biochemical effluent until the mass concentration of hydrogen peroxide in water is between 0.01 and 1 percent, and controlling the pH to between 2.0 to 6.0; B, delivering the mixed liquid into an industrial microwave oven for processing for 5 to 60s; C, regulating the pH value of the mixed liquid to between 6.0 and 6.5 or 7.5 and 8.5, and carrying out oxidation treatment for 1 to 4 hours under an aeration condition that the aeration rate is 10 to 40m<3> / h; D, adding a coagulant into the liquid until the mass concentration of the coagulant in the liquid is betweenone millionth and one hundred thousandth; E, precipitating and separating; F, filtrating the liquid to obtain process effluent for recycling; and G, collecting sludge, separating the liquid from the sludge; and returning the liquid to the step D, and filter-pressing the sludge to obtain sludge cakes. The method realizes recycling, does not discharge sewage, and effectively solves the problem thatpresent coking sewage is difficult to treat and to recycle.

Owner:云南天朗环境科技有限公司

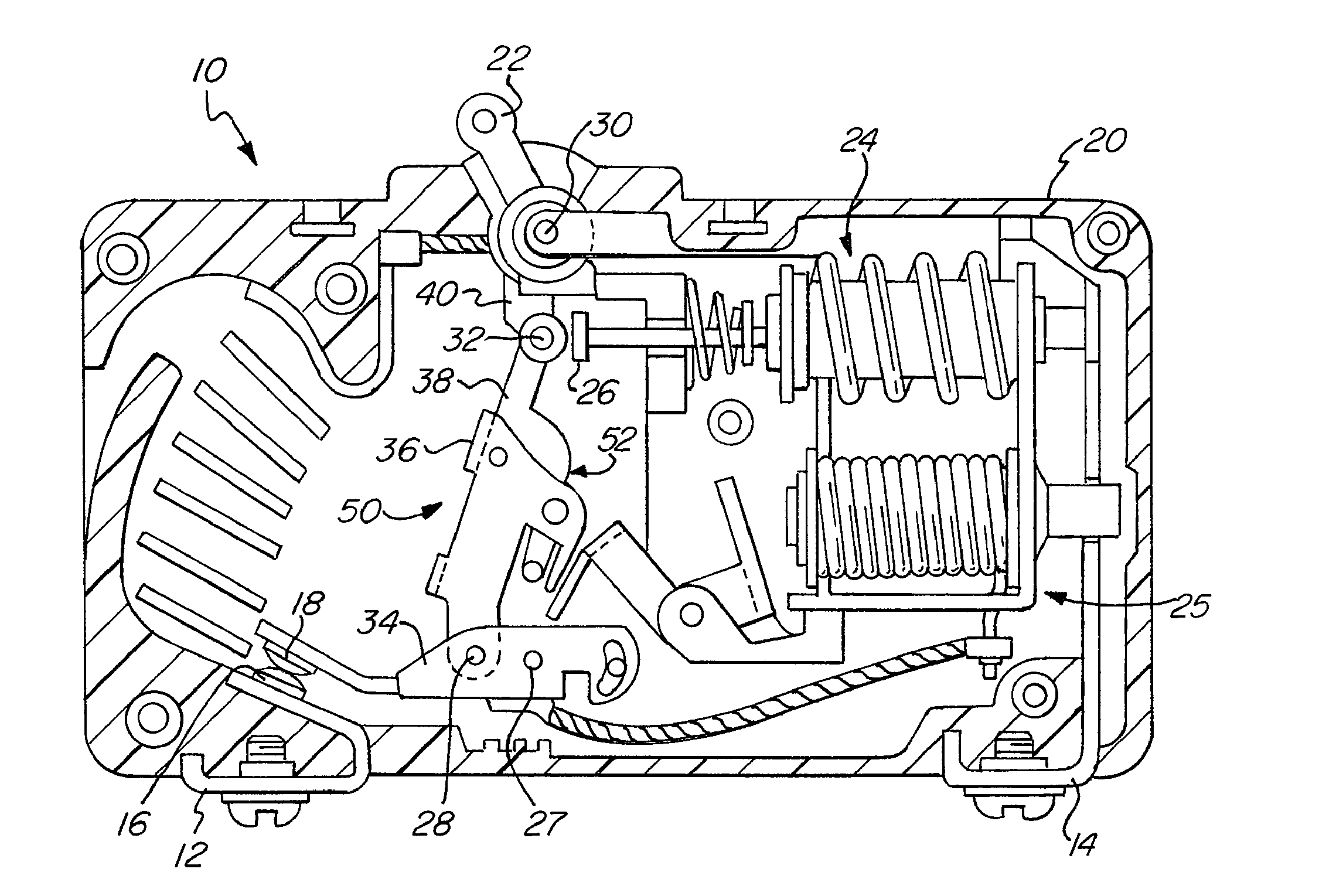

Circuit Breaker with Current Limiting and High Speed Fault Capability

ActiveUS20160379789A1Quick tripOpen fastSwitch operated by falling currentEmergency protection detectionCurrent limitingTime delays

A circuit breaker arraignment including at least two trip mechanisms the first trip mechanism acting to immediately trip to open contacts of the circuit breaker upon reaching a first threshold current level, and the second trip mechanism acting to trip to open the contacts once both a second current threshold is reached and a time delay has elapsed, the contacts moved by a linkage assembly that is held under mechanical advantage such that when acted on by one of the two trip mechanisms, the mechanical advantage is released to rapidly open the contacts.

Owner:CARLING TECH

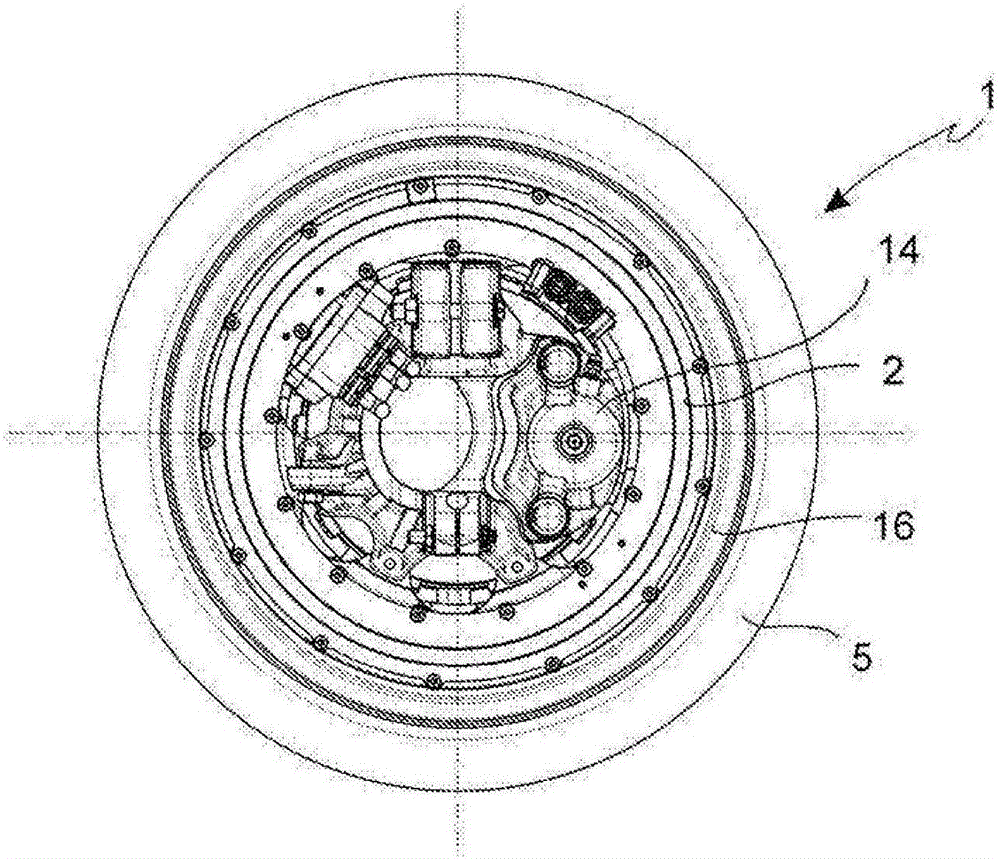

Wheel assembly with motor and vehicle braking device

ActiveCN106103166ASimple structureSmall sizeBraking element arrangementsElectric devicesEngineeringCalipers

Owner:FRENI BREMBO SPA

Electroless plating with nanometer particles

InactiveUS20060024514A1Increase hardnessImprovement to overall physical structureMaterial nanotechnologyLiquid surface applicatorsElectroless platingCorrosion

The addition of nanometer particles to electroless metal plating baths reduces or eliminates seeding in the electroless plating baths. The reduced seeding results in less inclusions or pitting in the coating. Usually the maintenance and frequent tank-cleaning schedule can be increased beyond the normal 2-3 day. The properties of the coating can be improved by the co-deposition of the particles into the bath. Properties such as hardness, corrosion resistance, and wear resistance were improved.

Owner:MCCOMAS EDWARD

Activation of word lines in semiconductor memory device

InactiveUS6842392B2Reduce power consumptionFrequent maintenanceDigital storageBiological activationComputer science

To provide a technique for reducing the power consumption associated with word line activation in a semiconductor memory device. The semiconductor memory device is provided with a word line activation controller for controlling word line activation. Where consecutive operation cycles use multiple-bit addresses that include an identical row address, the word line activation controller can maintain an the activated state of a word line activated during an initial cycle of the consecutive cycles, without deactivating it until a final cycle of the consecutive cycles. If a refresh operation is to be performed during a cycle among the consecutive cycles after the initial cycle, the word line activation controller can deactivate the activated word line prior to performing the refresh operation.

Owner:SEIKO EPSON CORP

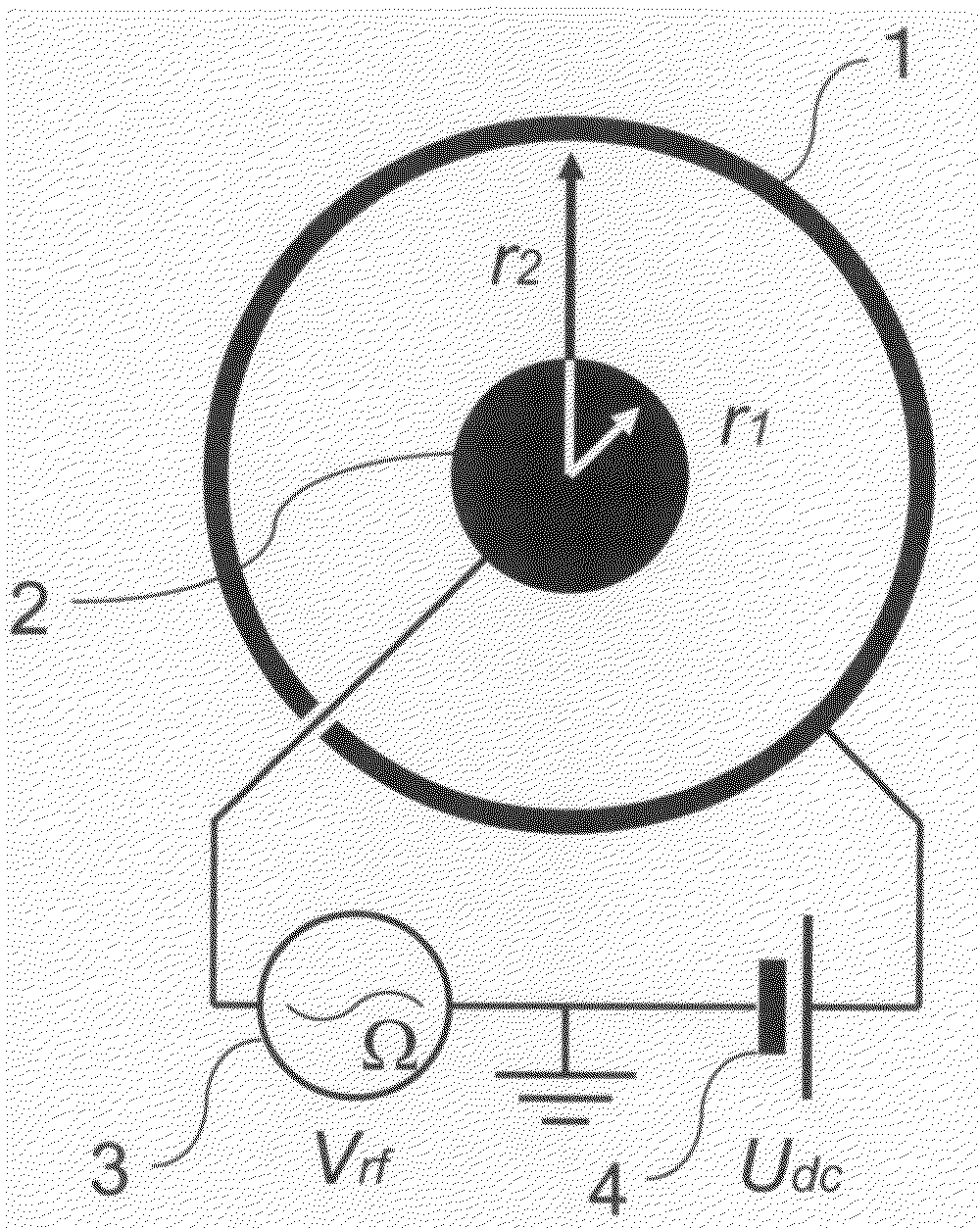

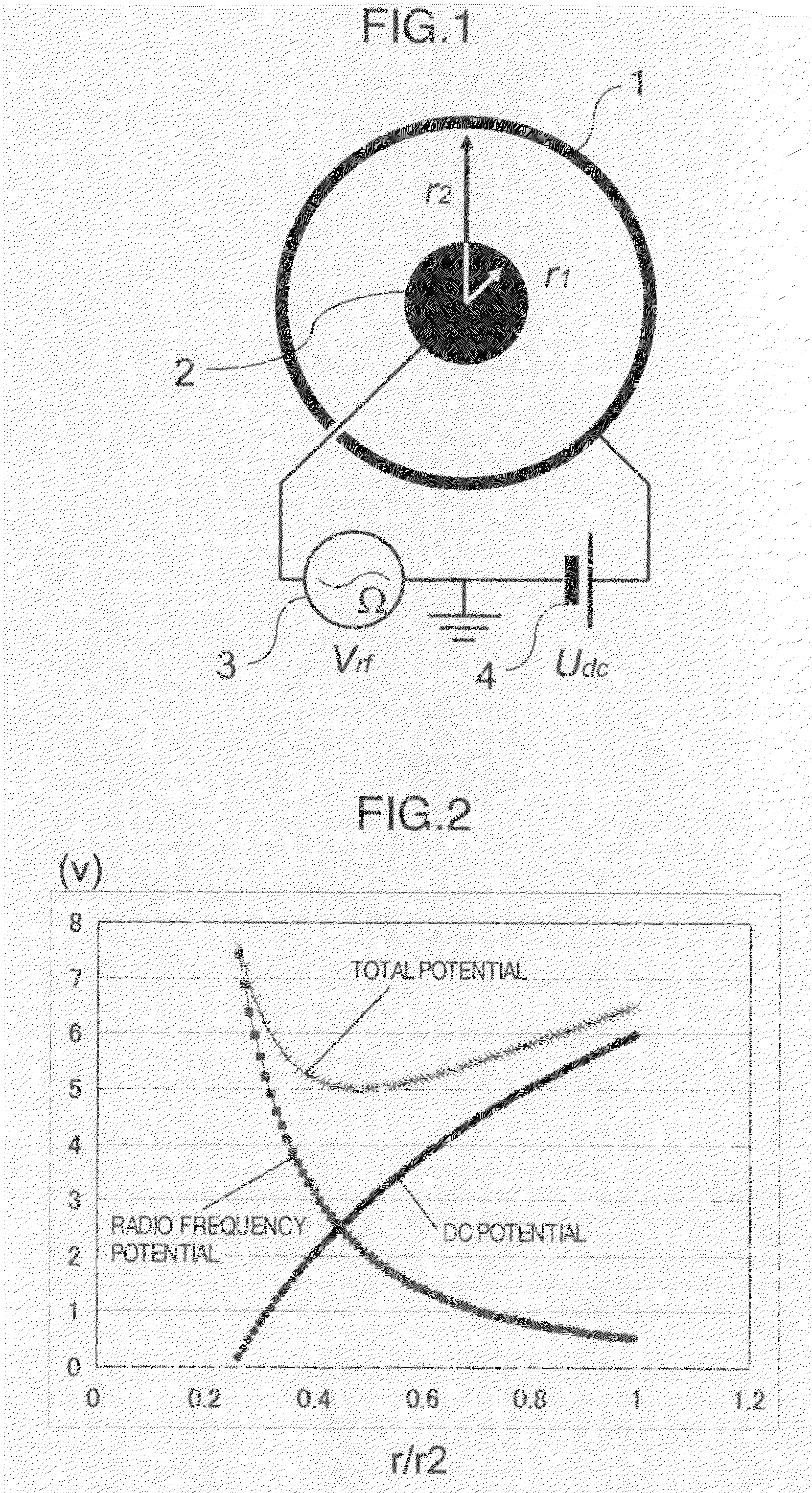

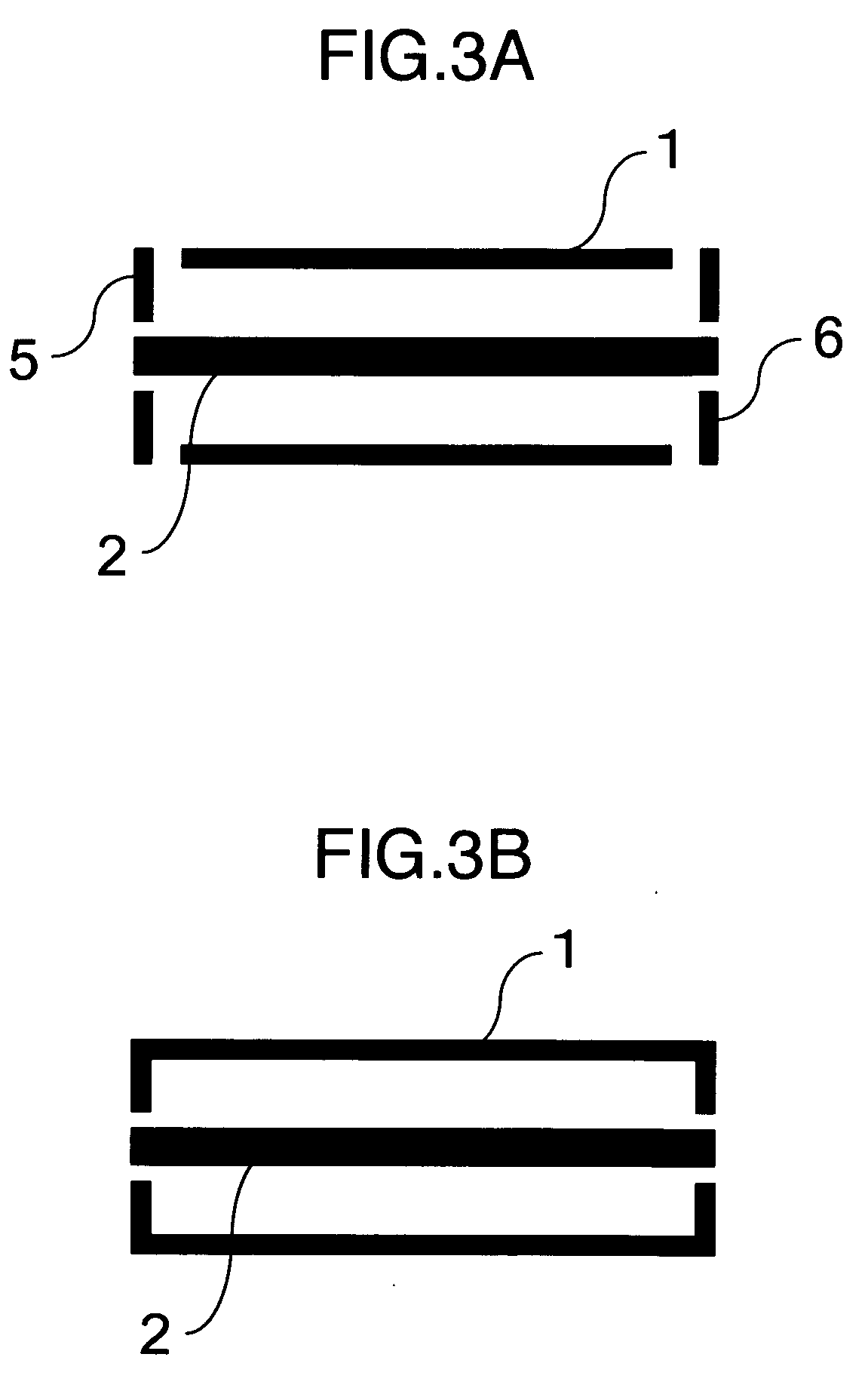

Ion trap, mass spectrometer and ion mobility analyzer using the ion trap

InactiveUS20090001265A1Increase usageAccurate ion trajectoryMaterial analysis by electric/magnetic meansIsotope separationIon trap mass spectrometryMass analyzer

A mass spectrometer using a one-dimensional ion trap is disclosed. The mass spectrometer having the one-dimensional ion trap can trap a great amount of ions, and the provision of a mass spectrometric analyzer capable of operation in a low vacuum eliminates the need of a high vacuum.

Owner:HITACHI LTD

Wheel brake for a vehicle and a vehicle comprising the wheel brake

InactiveUS8047337B2Increased heat generationIncrease demandAxially engaging brakesFriction clutchesEngineeringMechanical engineering

A wheel brake for a vehicle including a brake disc unit adapted to brake the rotation of a rotation element, which is adapted to be drivingly connected to the wheel. The brake disc unit includes a first set of discs and a second set of discs arranged in an alternating manner in an axial direction. The discs in the first disc set are adapted to be rotationally rigidly connected to the rotation element. The brake disc unit includes at least one separator element, which is adapted to keep a sufficient distance between two adjacent discs of one of the disc sets for an intermediate disc from the other disc set to rotate at least substantially freely relative to the spaced discs when the brake disc unit is in a deactivated condition.

Owner:VOLVO CONSTR EQUIP AB

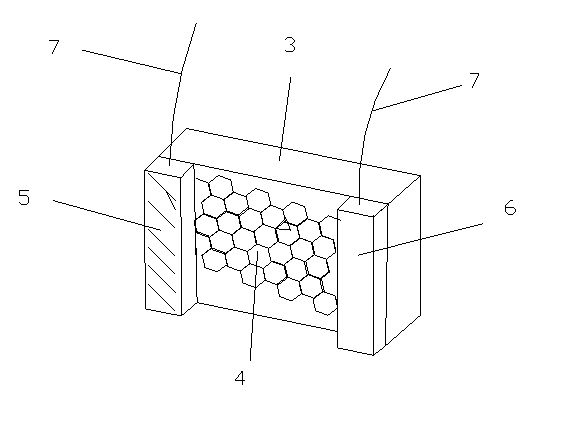

Movable fluorine-containing wastewater treatment method and device

PendingCN107698092AHigh fluoride removal capacityLow investment costWater treatment parameter controlSpecific water treatment objectivesFlocculationPhysical chemistry

The invention discloses a movable fluorine-containing wastewater treatment method and device. The pH value of high-concentration fluorine-containing wastewater is regulated to be neutral or alkaline,CaCl2, PAC, magnetic seeds and PAM are added sequentially for treatment, precipitation is performed, and effluent is adsorbed. The device comprises a pipeline mixer, a NaOH dissolving tank, a calciumchloride dissolving tank, a mixing reaction tank, a chemical coagulation tank, a magnetic seed coagulation tank, a flocculation coagulation tank, a settling tank, a middle pool, an aluminosilicate adsorption tower, a regenerated wastewater storage tank, a coagulant dissolving tank connected with the chemical coagulation tank, a magnetic seed adding device connected with the magnetic seed coagulation tank and a flocculant dissolving tank connected with the flocculation coagulation tank, wherein the mixing reaction tank, the chemical coagulation tank, the magnetic seed coagulation tank, the flocculation coagulation tank, the settling tank, the middle pool, the aluminosilicate adsorption tower and the regenerated wastewater storage tank are sequentially connected with the pipeline mixer. Thedevice has the characteristics that the device occupies little land, is high in treatment capacity, takes effect rapidly and is low in energy consumption, easy to maintain and the like.

Owner:KUNMING ENG & RES INST OF NONFERROUS METALLURGY +2

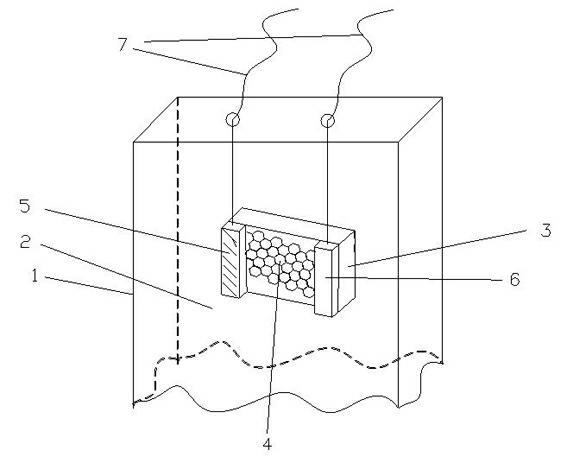

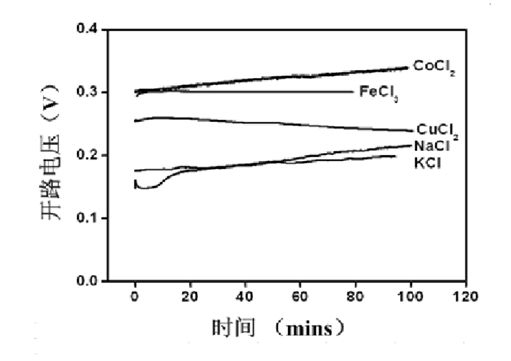

Power generation method adopting ionic thermal motion principle and graphene battery manufactured by power generation method

InactiveCN102496675AReduce security risksReduce performanceThermoelectric device detailsElectricityWork function

The invention discloses a power generating method adopting an ionic thermal motion principle. The power generating method comprises the following steps of: firstly, transferring graphene to a substrate and bonding a graphene film on the substrate; secondly, depositing a conducting material with a work function higher than that of the graphene at one end of the graphene film to obtain a first electrode and depositing a conducting material with a work function lower than that of the graphene at the other end of the graphene film to obtain a second electrode; thirdly, leading out the first electrode and the second electrode at two ends of the graphene film by using two metal wires; and fourthly, holding an ionic salt solution in a container casing, integrally immersing the substrate, the graphene film, the first electrode, the second electrode and the two metal wires in the ionic salt solution and leading the metal wires to the outside of the container casing. The invention also provides a graphene battery manufactured by using the power generating method. The power generating method adopting the ionic thermal motion principle and the graphene battery manufactured by the power generation method have the advantages of safety, reliability, no need of using power for charging, long service life of the graphene battery and no harm to a human body and environment.

Owner:SHENZHEN NATAN TECH

Electroless plating with nanometer particles

InactiveUS20060024447A1High hardnessImprove physical structureMaterial nanotechnologyLiquid surface applicatorsNanoparticleHardness

The addition of nanometer particles to electroless metal plating baths reduces or eliminates seeding in the electroless plating baths. The reduced seeding results in less inclusions or pitting in the coating. Usually the maintenance and frequent tank-cleaning schedule can be increased beyond the normal 2-3 day. The properties of the coating can be improved by the co-deposition of the particles into the bath. Properties such as hardness, corrosion resistance, and wear resistance were improved.

Owner:UCT COATINGS

Medical pad, and method for making and using

InactiveUS20060062829A1Maximize activityRetain activityBiocideGlovesDeep woundsVolumetric Mass Density

A germicidal absorptive material for use in surgical packings, wound bandages, sanitary tampons and bed sore prevention and / or treatment uses is provided by a foam-like matrix of hydrophilic polyurethane polymer to which application-specific loads of a germicidal disinfectant dye have been made. Polyurethane polymer of various densities and thicknesses exhibits an exceptional ability to absorb different levels of a number of disinfectant dyes, both basic and acidic, such as gentian violet and methylene blue, respectively. The relationship between dye-load and application-specific uses permits a totally-bound gentian violet pad to be used as a conventional bandage or pad on a surface wound with the capability of preventing the incursion of external pathogens from entering the wound through the pad, where the pathogens are killed by the bound-dye. The wound exudate is absorbed safely by the pad, where wound-originating pathogens are also killed. When the loaded dye's concentration is saturated by exceeding the bound-dye limit, the limited free-dye is available to be delivered to the wound, particularly deep wounds, to rapidly kill pathogens in the wound. The free dye delivery pad can then be replaced by the bound-dye pad to absorb the wound exudate.

Owner:VIOLET CARE

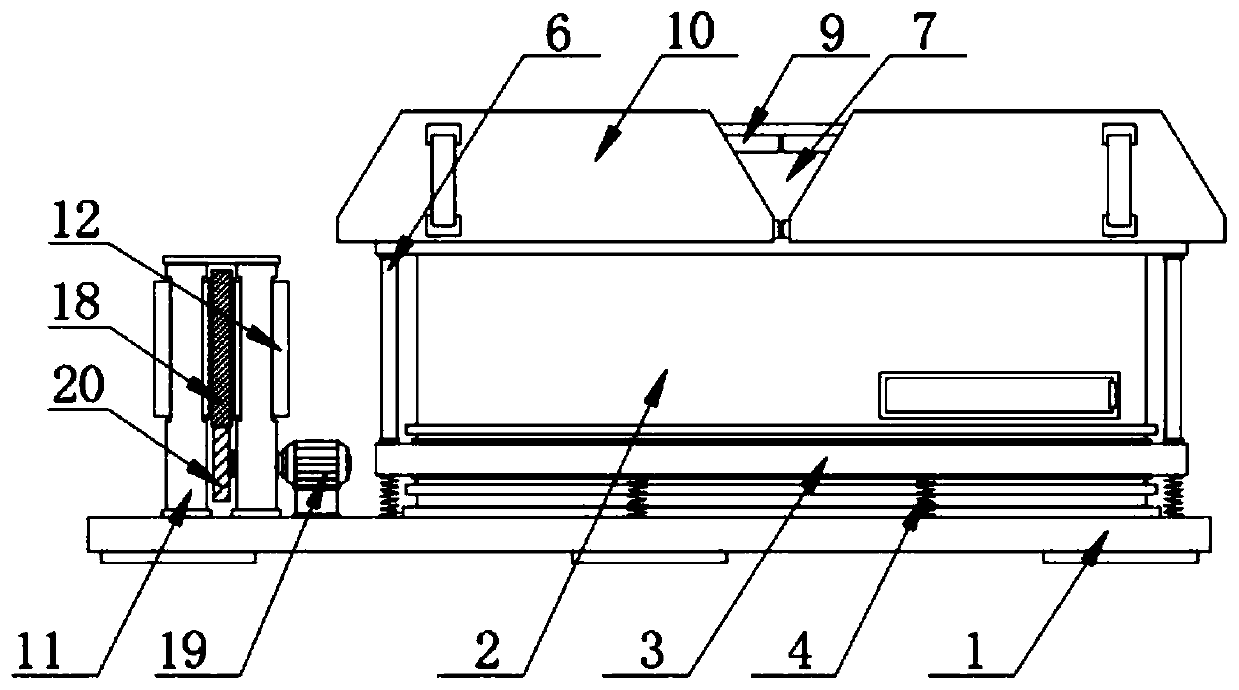

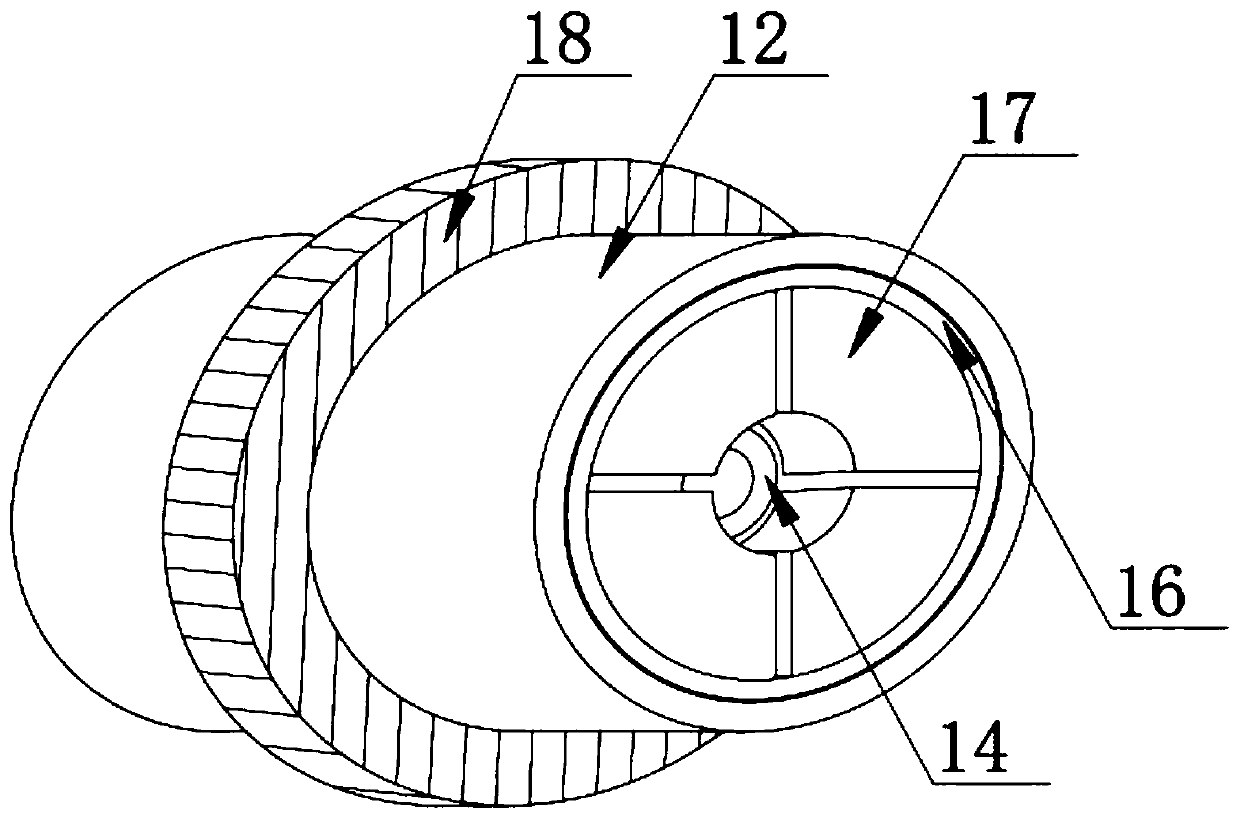

Mining shielding communication cable wrapping machine

ActiveCN110767378AWill not deformGuaranteed aestheticsInsulating conductors/cablesTelecommunicationsStructural engineering

The invention discloses a mining shielding communication cable wrapping machine, which comprises a bottom plate and a wrapping machine, wherein the right side of the top of the bottom plate is fixedlyconnected with the bottom of the wrapping machine; rubber blocks are fixedly connected to the two sides of the top of the wrapping machine; and a baffle is fixedly connected to the top of a connecting rod. According to the mining shielding communication cable wrapping machine which relates to the technical field of communication cable wrapping machines, a to-be-processed communication cable can be thoroughly cleaned once before entering the wrapping machine, the cleaning speed is high, the normal processing is not influenced, and therefore, impurities such as dust are effectively prevented from being attached to the communication cable; and a protective plate extends out of the top of the cleaning position during cleaning, so that the situation of secondary pollution caused by scatteringof dust at the top is avoided, the communication cable entering the wrapping machine is always clean at any time, the cable finally processed by people cannot go wrong, and the use by people is facilitated.

Owner:安徽华上电缆科技有限公司

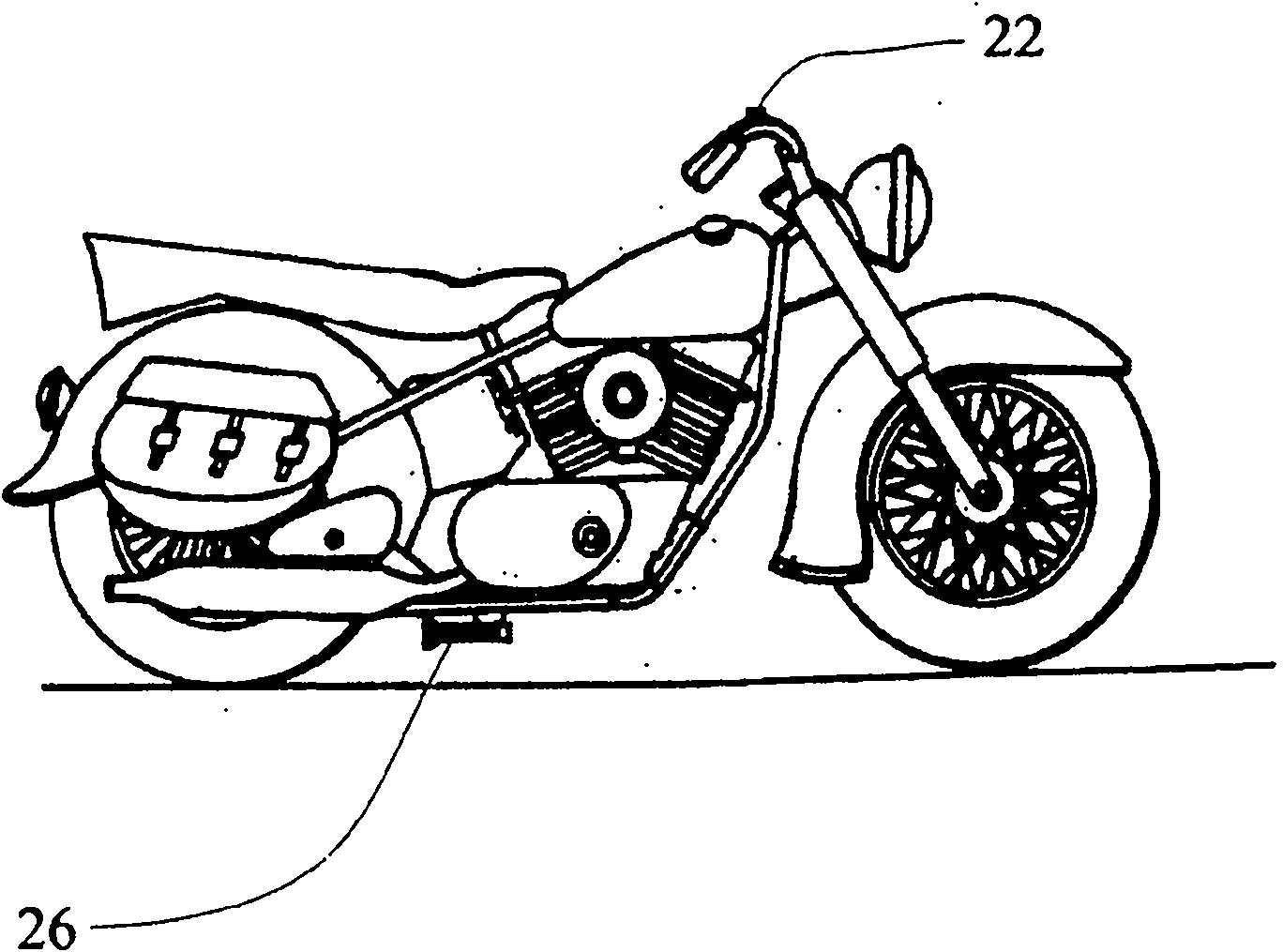

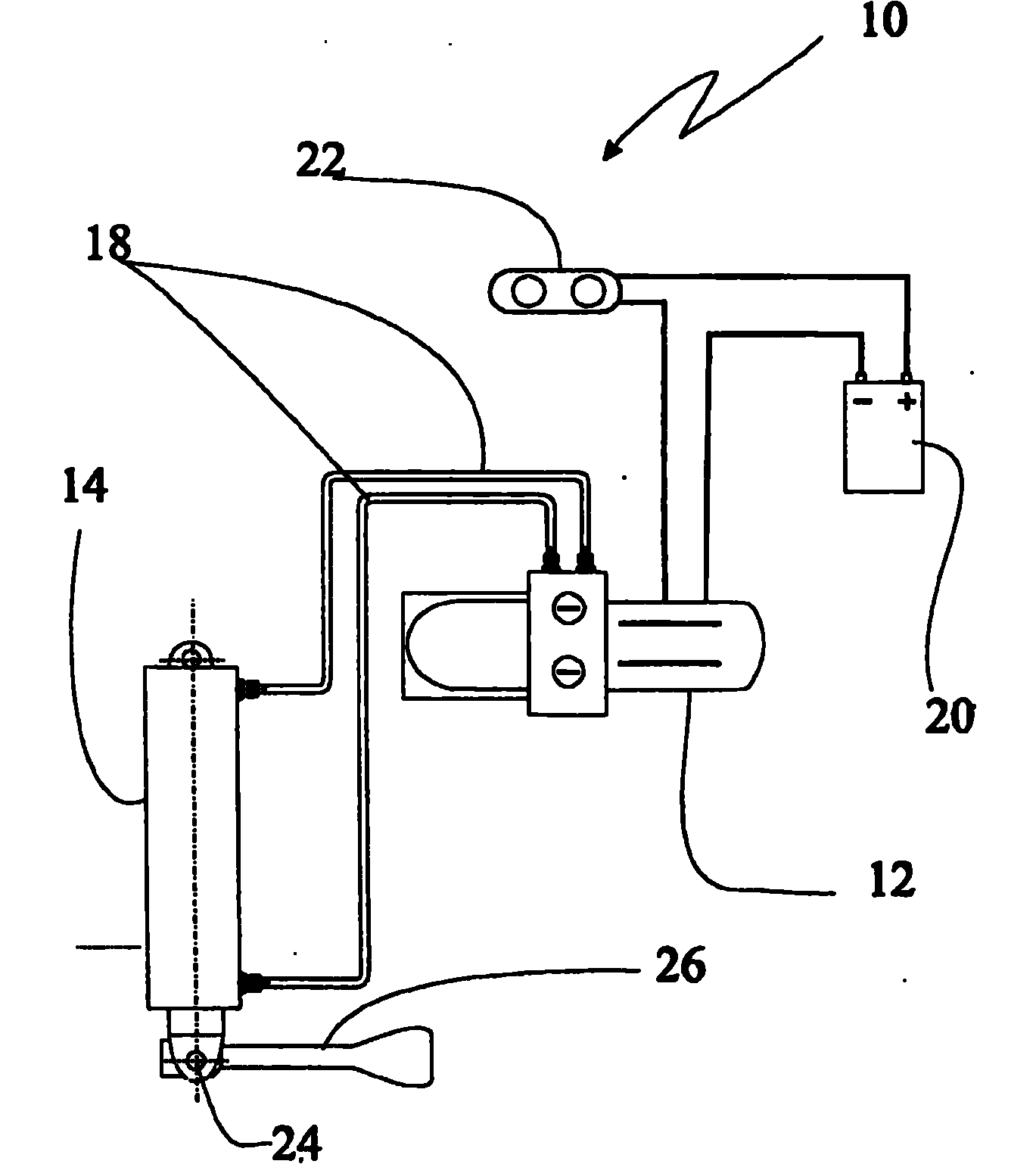

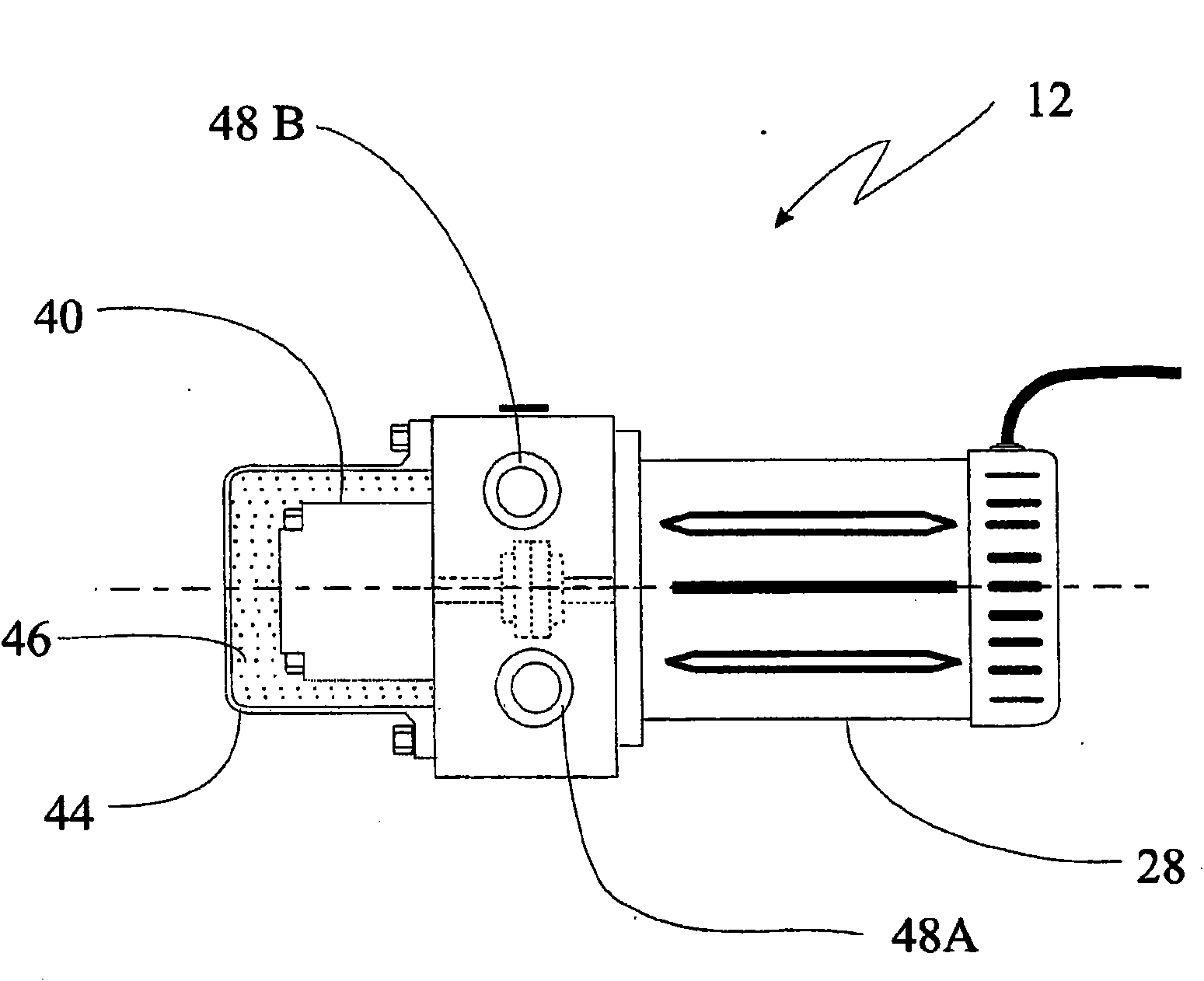

A centre stand for a two wheeled vehicle

A center stand for a two wheeled vehicle comprises leg pieces (72,78) adapted to position the vehicle on a ground surface in an operative vertical position, a hydraulic power pack unit adapted to unfold the leg pieces (72,78) from the horizontal position to the vertical position and further to an operative and extended position, guided locking means (66,86,88) adapted to lock the legs in the operative position, switch means located remotely from the legs to operate the power unit. The center stand can lift the two wheeled vehicle and park it on the ground automatically.

Owner:佩尔韦兹・纳瑞曼・巴鲁查

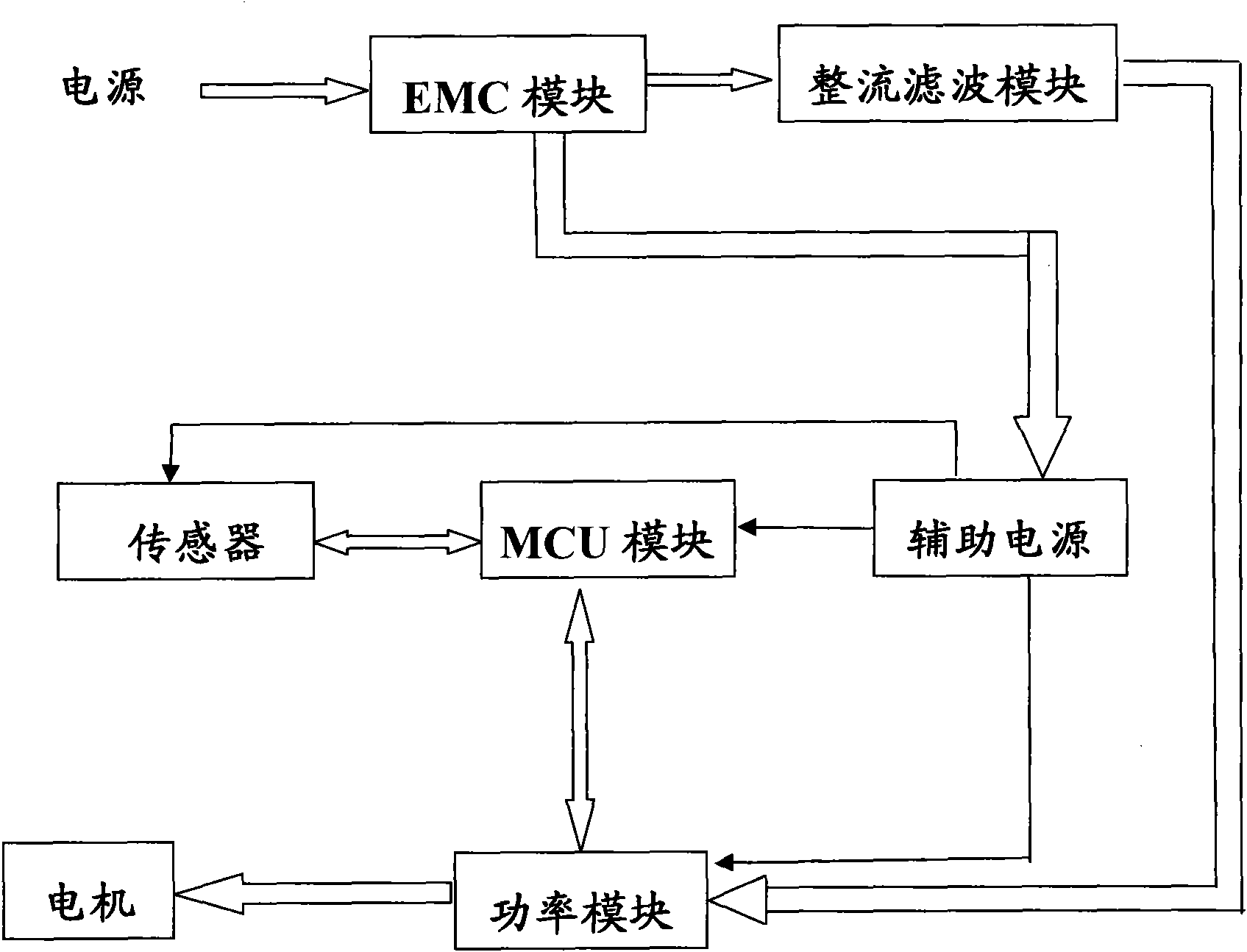

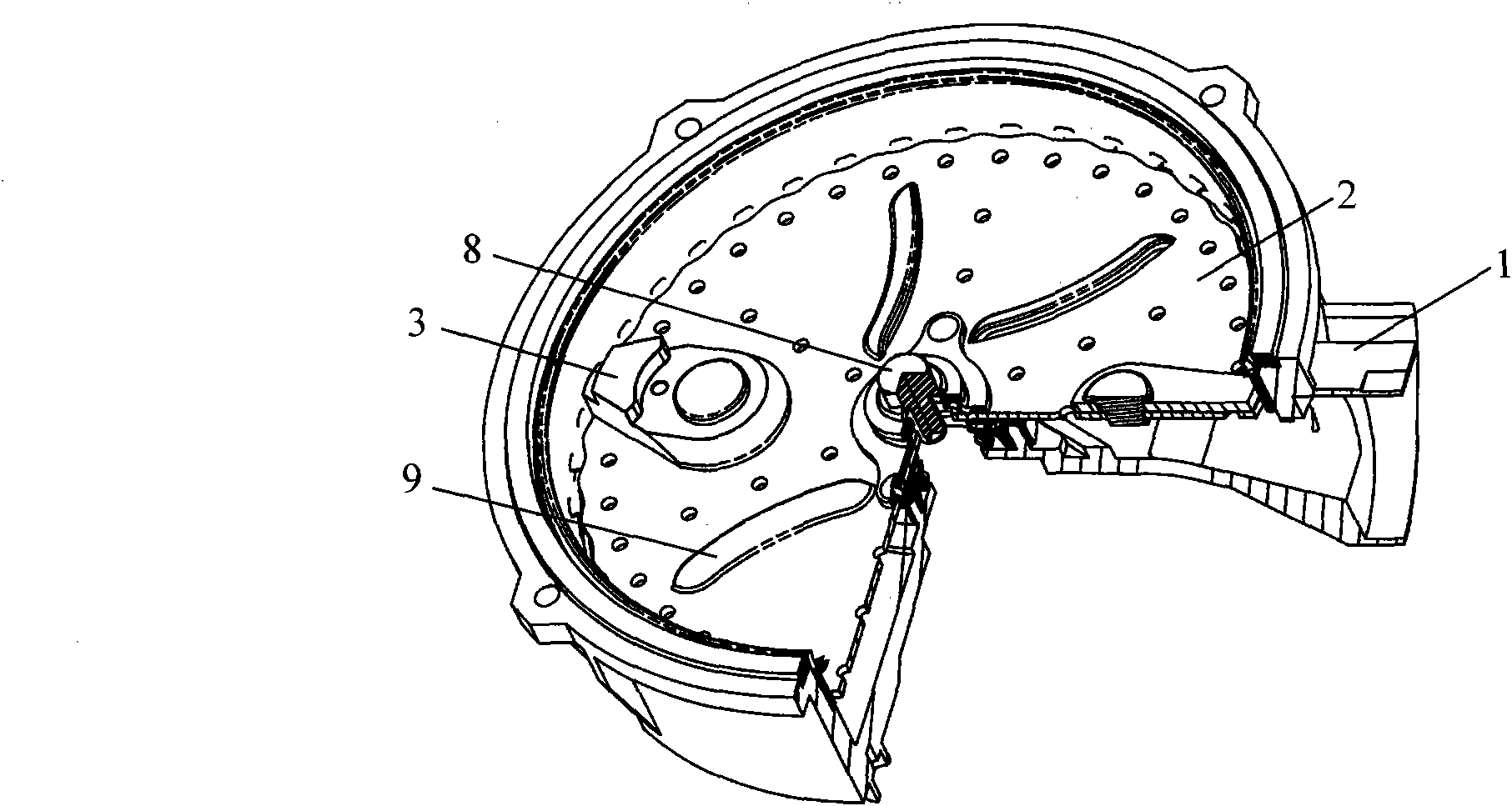

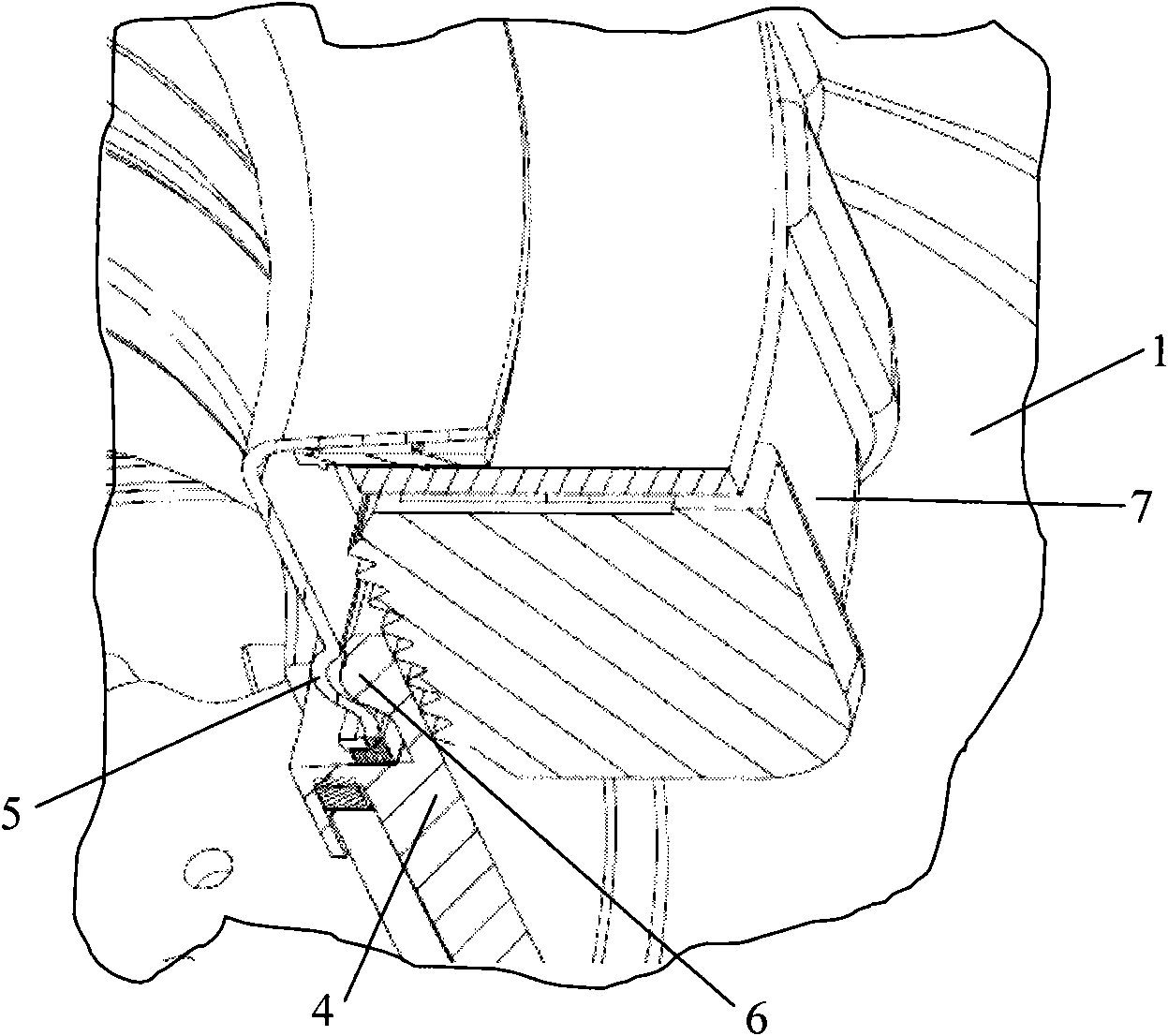

Intelligent food waste disposer

ActiveCN101890421AEasy to operateThe operation is cumbersome and not energy-savingSolid waste disposalBrushless motorsLow noise

The invention relates to an intelligent food waste disposer. The intelligent food waste disposer comprises a shell, a grinding disc positioned in the shell, a grinding head arranged on the grinding disc, a driving mechanism for driving the grinding disc, a control mechanism, an induction mechanism and an automatic water outlet mechanism. The control mechanism is respectively in line connection with the driving mechanism, the induction mechanism and the automatic water outlet mechanism. The induction mechanism is arranged at a joint of the shell. Preferably, an EMC module in the control mechanism is in line connection with a power module by a rectifier filter module; the power module is respectively in line connection with the driving mechanism, an MCU module and the automatic water outlet mechanism; the MCU module is in line connection with the induction mechanism; the induction mechanism is a sensor; the driving mechanism is a DC permanent magnet brushless motor; the grinding head is a grinding impact head; the grinding disc is radially provided with an arc barrier strip; and the shell is a streamline shell. The intelligent food waste disposer has the advantages of ingenious design, simple and convenient operation, good grinding effect, lightness, energy saving, safety, durability, low noise and high reliability.

Owner:SHANGHAI ONEDEAR ENVIRONMENT TECH

Medical pad, and method for making and using

A germicidal absorptive material for use in surgical packings, wound bandages, sanitary tampons and bed sore prevention and / or treatment uses is provided by a foam-like matrix of hydrophilic polyurethane polymer to which application-specific loads of a germicidal disinfectant dye have been made. Polyurethane polymer of various densities and thicknesses exhibits an exceptional ability to absorb different levels of a number of disinfectant dyes, both basic and acidic, such as gentian violet and methylene blue, respectively. The relationship between dye-load and application-specific uses permits a totally-bound gentian violet pad to be used as a conventional bandage or pad on a surface wound with the capability of preventing the incursion of external pathogens from entering the wound through the pad, where the pathogens are killed by the bound-dye. The wound exudate is absorbed safely by the pad, where wound-originating pathogens are also killed. When the loaded dye's concentration is saturated by exceeding the bound-dye limit, the limited free-dye is available to be delivered to the wound, particularly deep wounds, to rapidly kill pathogens in the wound. The free dye delivery pad can then be replaced by the bound-dye pad to absorb the wound exudate.

Owner:VIOLET CARE

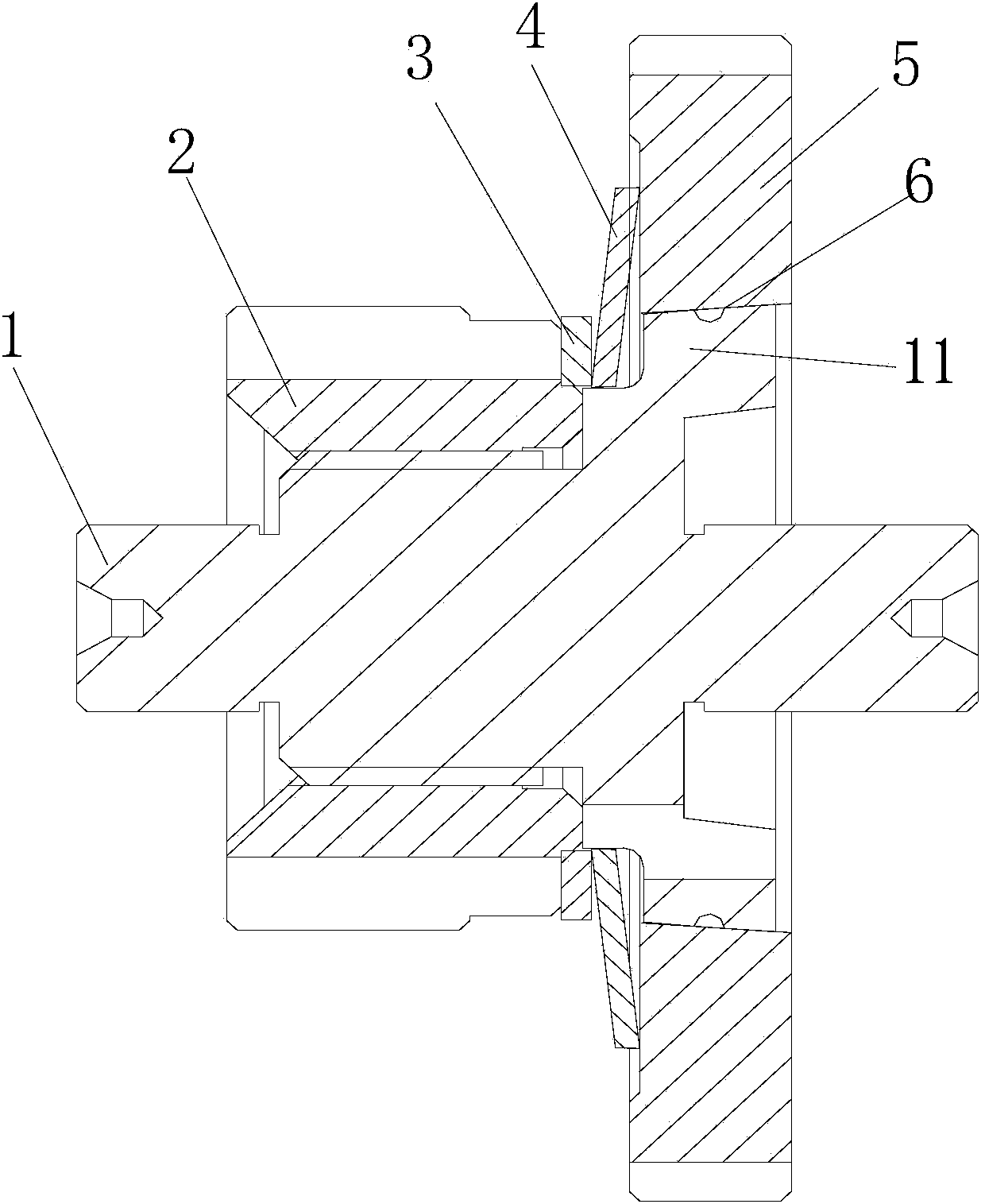

Overload protection type electrical starting duplicate gear and starting system

InactiveCN103726968AGood transmission effectFrequent replacementPortable liftingElectric motor startersElectricityStatic friction

The invention discloses an overload protection type electrical starting duplicate gear and a starting system. The overload protection type electrical starting duplicate gear comprises a duplicate gear shaft, a gear body I and a gear body II, wherein the gear body I and the gear body II are arranged on the duplicate gear shaft in a drive matching mode. The duplicate gear shaft is sleeved with the gear body II so that an inner conical surface of the gear body II and an outer conical surface of the duplicate gear shaft can form a conical surface pair. The gear body II has axial force for locking the conical surface pair and enabling the sliding torsion value of the conical surface pair to be larger than or equal to the electrical starting torsion value. When the reverse dragging phenomenon occurs and the torsion value exceeds the largest static friction force between the conical surfaces due to the fact that an engine suddenly slows down or stops under heavy loads and great inertia in the high-speed running process, the inner conical surface and the outer conical surface can slide, in other words, the gear body II and the duplicate gear shaft can slide relative to each other, and therefore the gear and a starting clutch of the whole electrical starting system can not be damaged, and the overload protection function is achieved. In the use process, the taper angle, the roughness of the conical surfaces and the axial force can be set according to the actual requirements, and therefore the required largest static friction force can be set.

Owner:CHONGQING LONCIN ENGINE

Method of manufacturing a high-pressure discharge lamp

InactiveUS7169002B2Improve reliabilityEliminate disadvantagesTube/lamp screens manufactureElectroluminescent light sourcesLaser lightHigh pressure

For manufacturing a high-pressure discharge lamp, a tungsten electrode is welded to a molybdenum foil by bringing a shaft of tungsten electrode into close contact with the molybdenum foil, and by irradiating a laser light, having a metal melting wavelength, to a junction of the molybdenum foil with the tungsten electrode from a location closer to the molybdenum foil to melt both the molybdenum foil and the shaft of the tungsten electrode for bonding.

Owner:USHIO DENKI KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com