Wheel assembly with motor and vehicle braking device

A technology of wheel components and braking devices, applied in the direction of electric power devices, brake components, electrical devices, etc., can solve the problems of impossible replacement of motors, and achieve the effects of easy maintenance, easy independent inspection, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

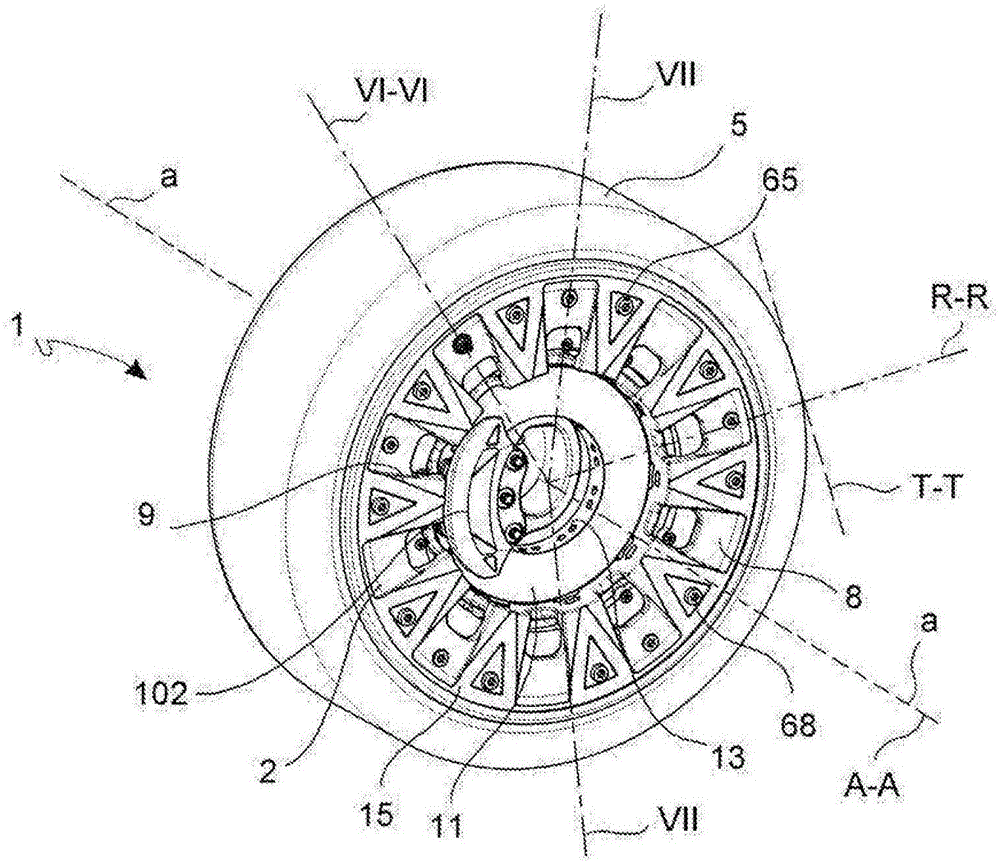

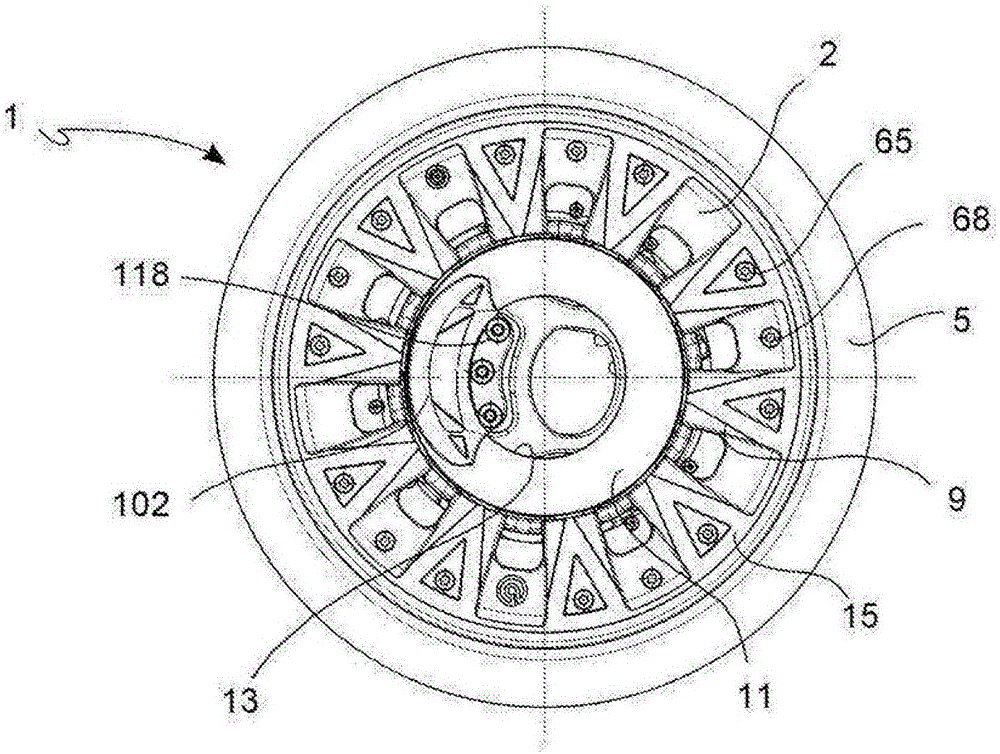

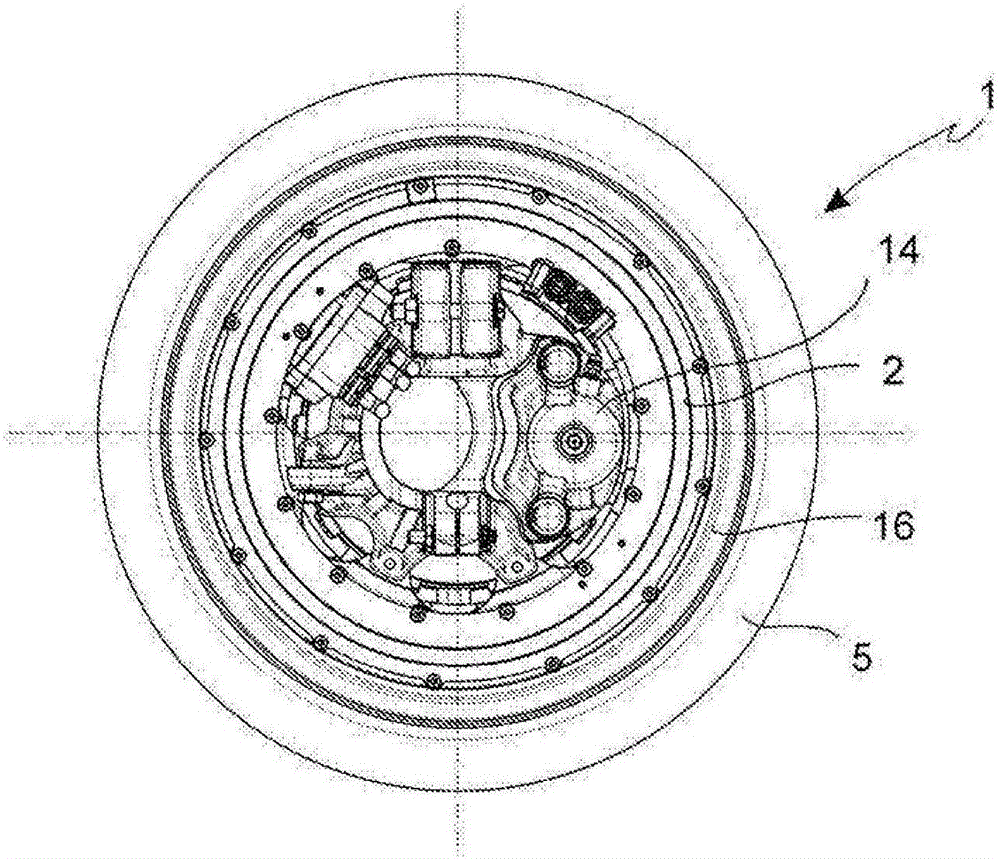

[0082] With reference to the above-mentioned figures and according to a general form of embodiment, a wheel assembly 1 of a vehicle comprises a rim 2 adapted to rotate about an axis of rotation a-a and defines an axial direction A-A parallel to or coincident with said axis of rotation a-a, an orthogonal radial direction R-R and the circumferential direction, the tangential direction T-T orthogonal to the axial direction A-A and the radial direction R-R.

[0083] The rim 2 has a radially outer side, or outer side 3 , facing away from the axis of rotation a-a, and a radially inner side, or inner side 4, facing the axis of rotation a-a. The outside of said rim is adapted to receive a tire 5 and the inside forms a cylindrical rim chamber 54 radially delimited by said inside 4 .

[0084] Furthermore, the wheel assembly includes an electric motor 306 including a rotor 307 and a stator 308 . The rotor 307 is coaxially supported to the stator 308 freely rotatable. The stator is fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com