Oil seal coating agent, spraying method thereof and oil seal prepared therefrom

A coating agent and oil seal technology, applied in the field of oil seal coating agent, can solve the problems of affecting the sealing performance, oil seal service life, weak adhesion and high price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Embodiment 1, an oil seal coating agent, is composed of A component, B component, and C component in a mass ratio of 100:7.5:100, wherein, A component is composed of 35wt% graphite powder with a particle size of 20 μm, Composed of 7wt% graphite powder with a particle size of 2μm, 13wt% molybdenum disulfide, and 45wt% polytetrafluoroethylene; component B is a water-based curing agent, 1,6-diisocyanate blocked by polyethylene glycol monomethyl ether Acidohexane homopolymer 96wt% and 1,6-diisocyanatohexane 4wt%; group C consists of polyacrylate XT-1100 40wt% and water-based epoxy resin 60wt%, polyacrylate XT- 1100 is used as a polymer surfactant. First, put it on a three-roller mill and grind it for 2 to 3 times to obtain a batch material. Add the formulated amount of water-based epoxy resin, stir it for 30 minutes by magnetic force, and then ultrasonically disperse it. Mix for 30 minutes to prepare component C; before use, mix component A and component C in proportion, ad...

Embodiment 2

[0015] Embodiment 2, a kind of spraying method of oil seal coating agent, comprises the following steps:

[0016] (1) Coating agent formulation: mix components A, B, and C described in Example 1 in a mass ratio of 100:7.5:100, then magnetically stir, ultrasonically disperse, and concentrate to prepare Coating agent, wherein, the diluent of concentration deployment is distilled water;

[0017] (2) Spraying: Heat treatment on the oil seal assembly that has been activated by plasma, and keep the temperature of the oil seal base material at 95°C, put the evenly mixed coating agent into the spraying equipment, and spray it on the activated fluororubber oil seal, The coating agent is atomized into fine particles through the spray gun and the high-speed air flow of compressed air, which is directly sprayed onto the surface of the main lip and dust-proof lip of the oil seal to form a coating with a thickness of 30 μm;

[0018] (3) Coating curing: bake the coated oil seal in a drying ...

Embodiment 3

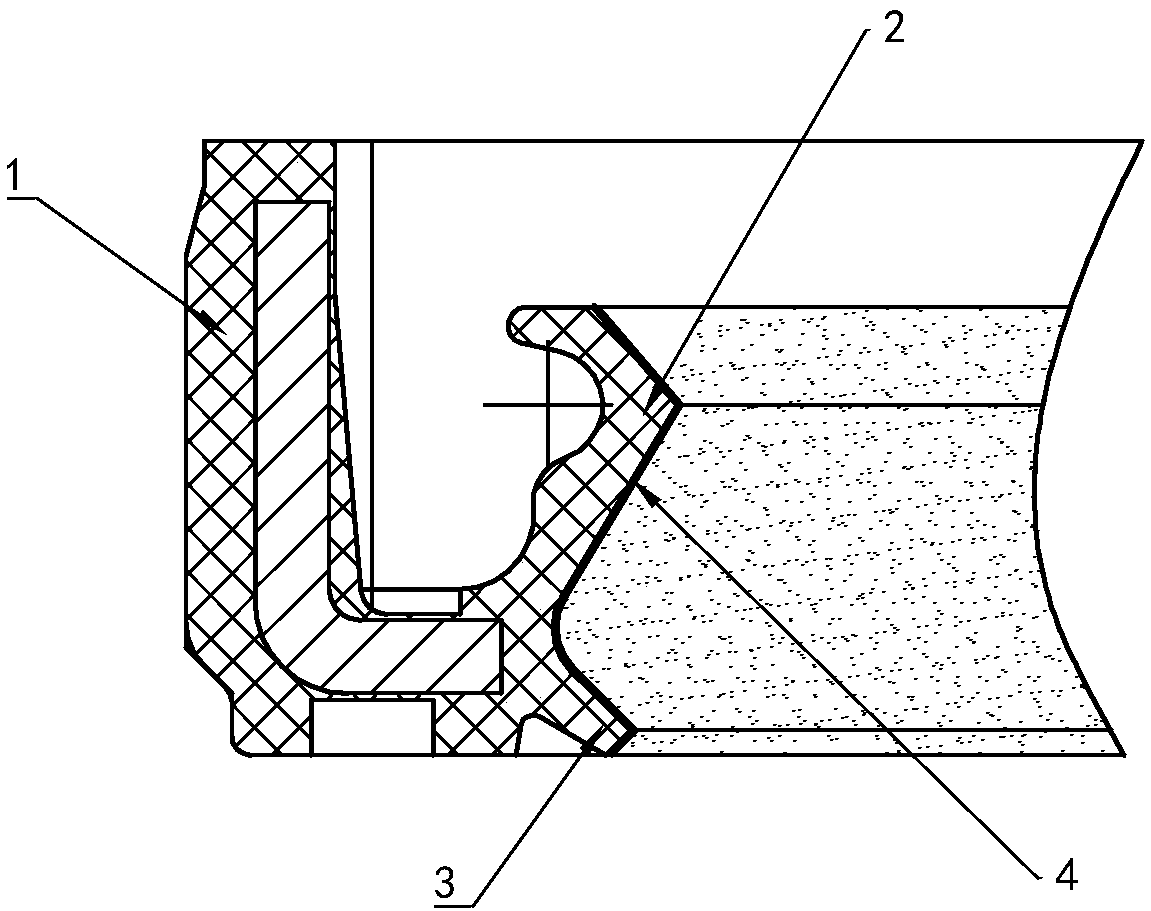

[0019] Embodiment 3, with reference to figure 1 , a coating oil seal, comprising a main lip 2 and a dustproof lip 3, on the surface of the main lip 2 and dustproof lip 3, the coating agent described in Example 1 and the spraying method described in Example 2 are used to coat Overlay coating 4, the thickness of the coating is about 30 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com