Microscopic oil displacement chip with displacement fluid injection volume marking scale in flow-guiding flow passage

A technology of diversion channel and displacing fluid, applied in the petroleum field, can solve the problem of inability to precisely control the injection amount of displacing fluid, and achieve the effect of solving the problem of poor repeatability of experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

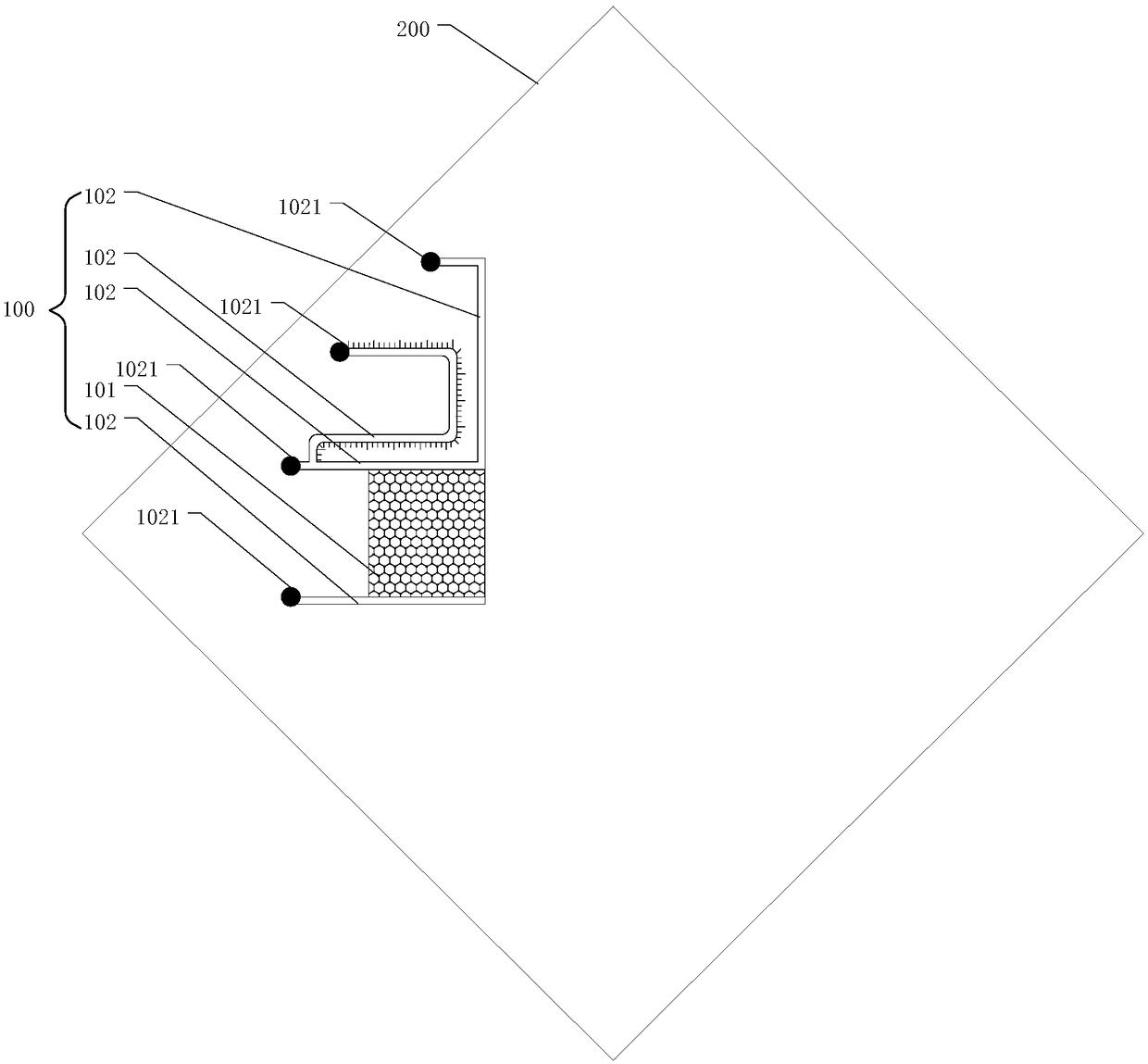

[0023] figure 1 A schematic diagram of a microscopic oil displacement chip provided in the flow channel for marking the injection volume of the displacement fluid provided by the embodiment of the present application.

[0024] Such as figure 1 As shown, the microscopic oil flooding chip provided in this embodiment includes a chip substrate 200 and an oil flooding model 100, and the oil flooding model 100 is used to simulate corresponding water flooding residual oil types and parameters.

[0025] The chip substrate 200 serves as the basis of the entire chip, and its material can be made of hard transparent materials such as glass, so as to observe its seepage and oil displacement process by using its light transmission.

[0026] The oil flooding model includes an oil flooding area 101 and four flow channels 102. One end of the flow channels 102 communicates with the oil flooding area 101, and the other end of each flow channel 102 is connected to the injection port or the prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com