Injection moulding method of rubber and plastic electric insulation hand gloves and rubber boots

An injection molding, electrical insulation technology, applied in footwear, other household appliances, household appliances, etc., can solve the problems of prolonged production cycle, low degree of electrical insulation, complex processing technology, etc., and achieve high production efficiency and high degree of electrical insulation. , the effect of good comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

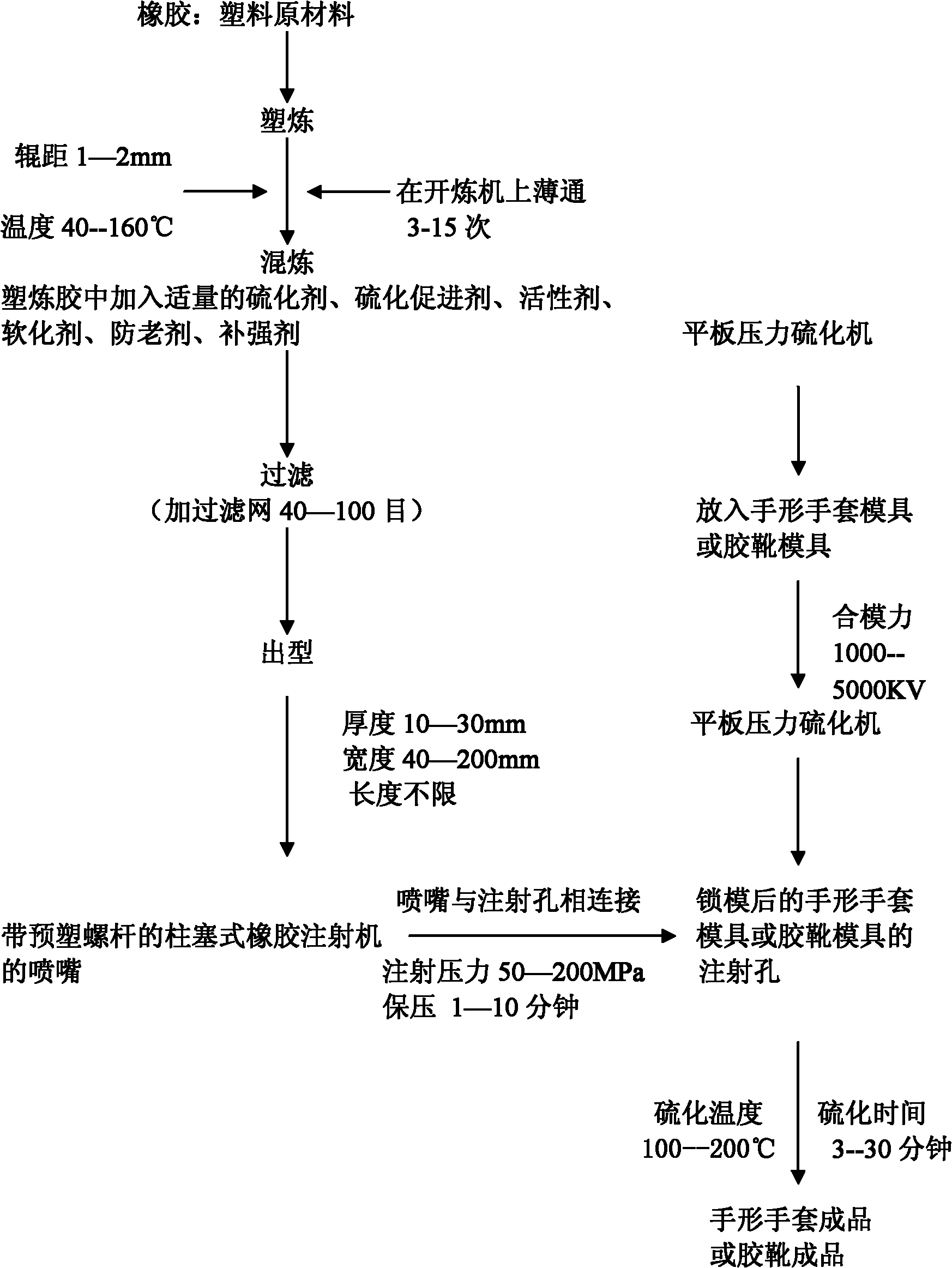

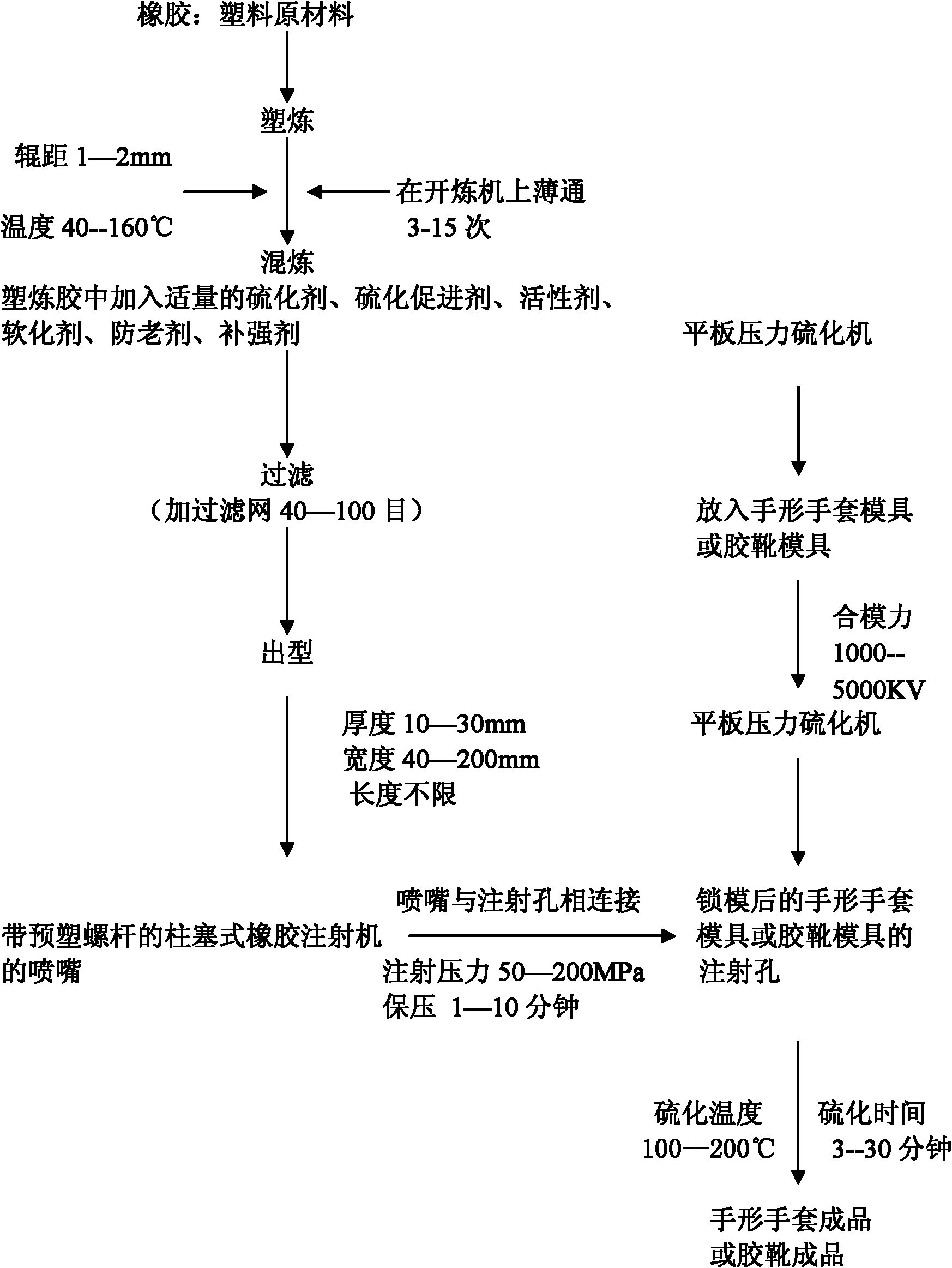

Method used

Image

Examples

Embodiment 1

[0029] The injection molding method of rubber and plastic electrical insulation hand gloves and rubber boots uses rubber and plastic as the main raw material and adopts a movable plunger rubber injection machine with a pre-plastic screw. The injection holes of the mold are connected, and the processing steps are as follows:

[0030] 1. Rubber as the main raw material: In order to meet the different performance requirements of gloves and rubber boots, rubber is used as the main raw material, and a small amount of plastic can be added. Natural rubber, synthetic rubber, or synthetic rubber, natural rubber and plastic may be used alone.

[0031] Raw materials: natural rubber 100Kg, zinc oxide 5 Kg, stearic acid 3 Kg, sulfur 0.6 Kg, accelerator M0.5 Kg, accelerator D0.4 Kg, accelerator DM0.5 Kg, antioxidant RD1 Kg, hydraulic oil 10 Kg, active nano ultrafine calcium 20 Kg.

[0032] 2. Mastication: The rubber is thinly passed in the open mill for 6-8 times, and the roller temperatu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com