Method and system for controlling emitted dose of urea solution by SCR (Selective Catalytic reduction)

A solution injection and control method technology, applied in the direction of electric control, exhaust treatment, mechanical equipment, etc. of exhaust gas treatment devices, can solve the problems of ammonia gas escape, environmental pollution, secondary pollution, etc. The amount of escape and the effect of improving NOx conversion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] In order to make the above objects, features and advantages of the present invention more comprehensible, specific implementations of the present invention will be described in detail below in conjunction with the accompanying drawings.

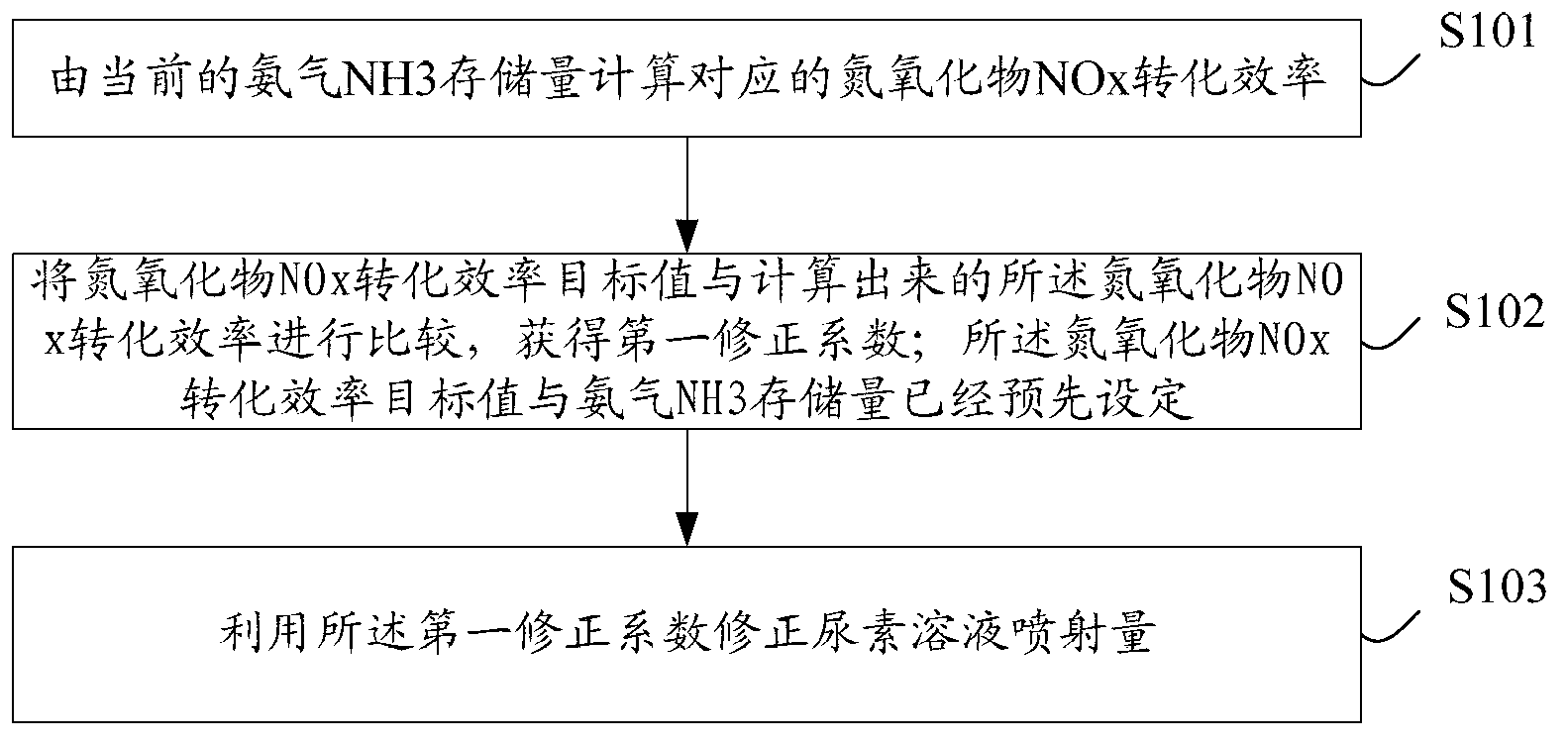

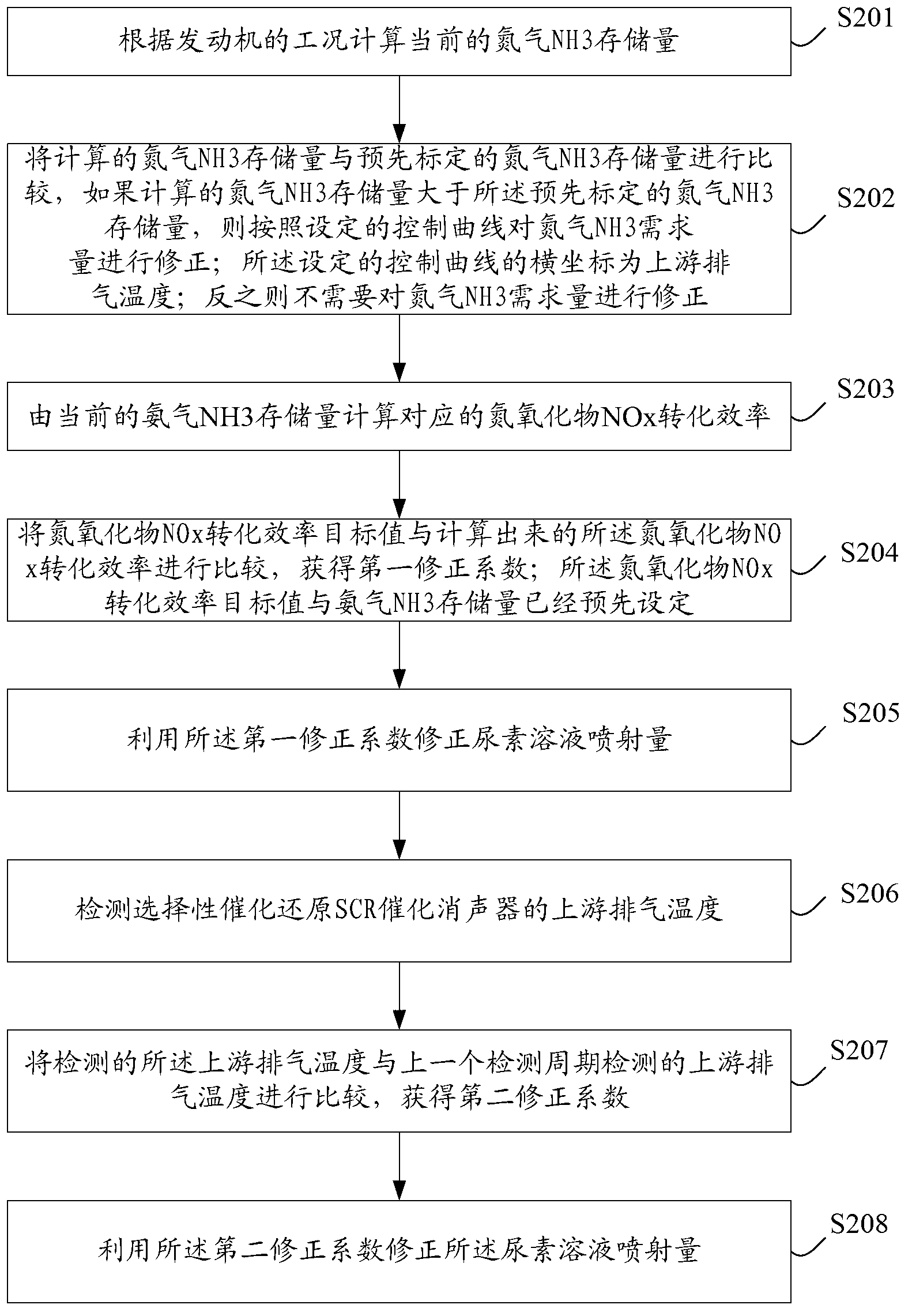

[0056] see figure 1 , which is a flow chart of Embodiment 1 of the method for controlling the injection volume of SCR urea solution provided by the present invention.

[0057] The selective catalytic reduction urea solution injection quantity control method provided in this embodiment includes:

[0058] S101: Calculate the corresponding nitrogen oxides NOx conversion efficiency from the current storage capacity of ammonia NH3;

[0059] The purpose of S101 is to calculate the existing NOx conversion efficiency from the current NH3 storage capacity, because the NH3 attached to the equipment itself can convert a part of NOx, that is, the existing NOx conversion efficiency. In this way, the existing NOx conversion efficiency can be deduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com