Method and system for controlling urea solution spraying amount in closed loop mode through SCR system

A technology of SCR system and solution injection, which is applied in the direction of mechanical equipment, engine components, machines/engines, etc., can solve problems such as narrow application range, high NH3 leakage, and poor anti-interference performance of the system, so as to improve conversion efficiency and reduce leakage volume effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

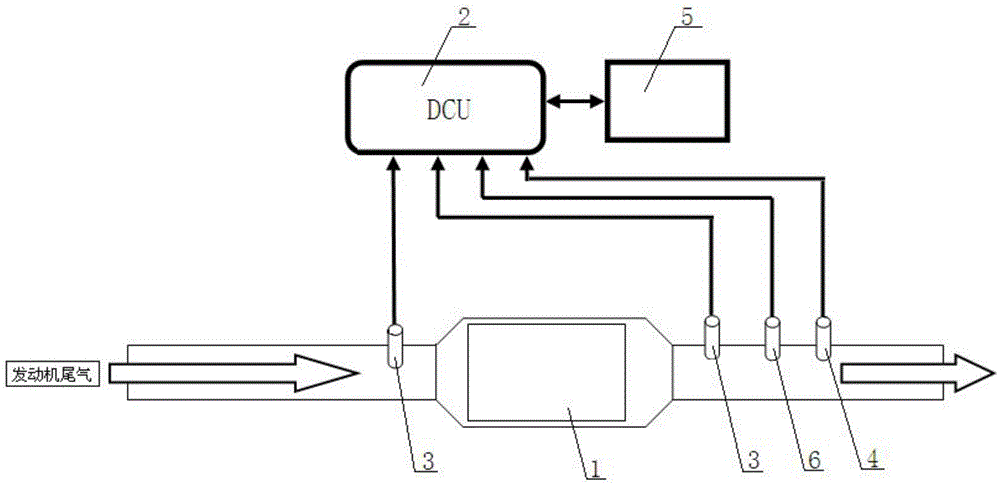

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

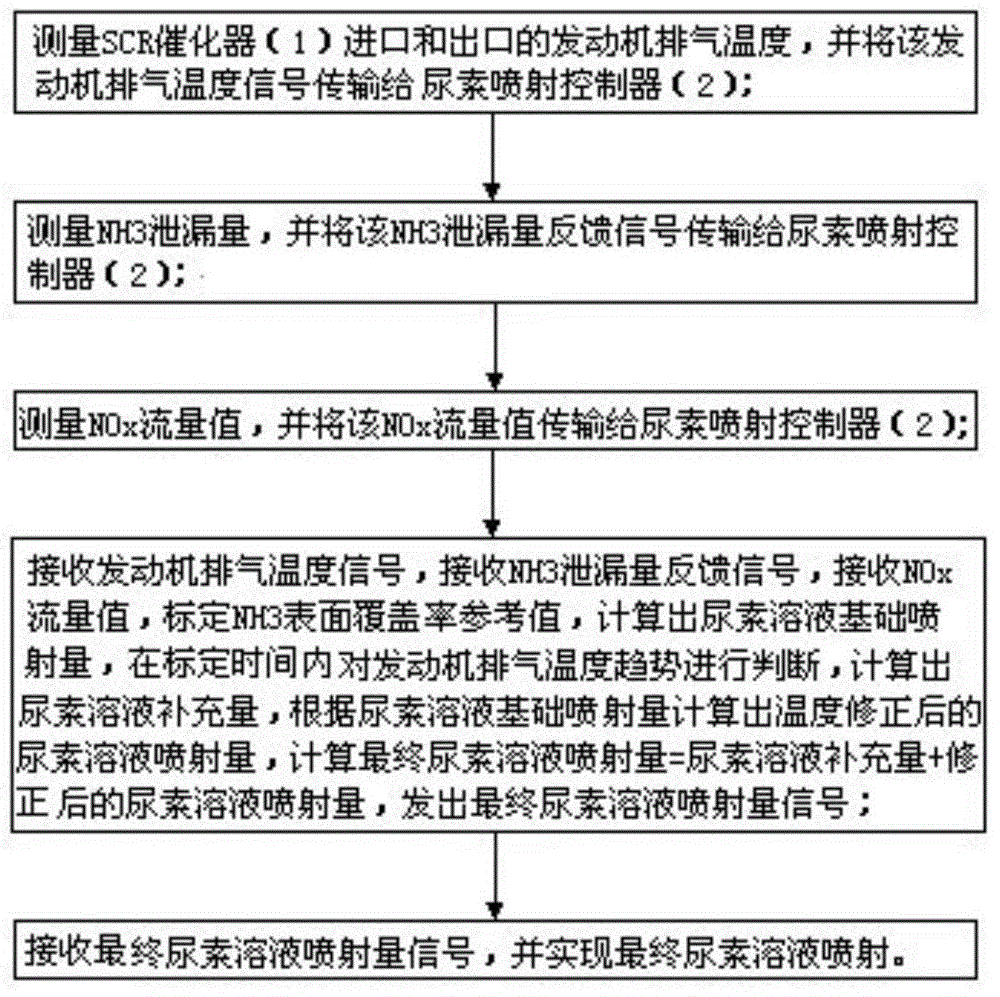

[0026] see figure 1 , a SCR system closed-loop control urea solution injection method, it is characterized in that, comprising the following steps:

[0027] Measure the temperature at the inlet and outlet of the SCR catalytic converter 1, and transmit the temperature signal of the SCR catalytic converter to the urea injection controller 2;

[0028] Measuring the NH3 leakage, and transmitting the NH3 leakage feedback signal to the urea injection controller 2;

[0029] Measure the NOx flow value, and transmit the NOx flow value to the urea injection controller 2;

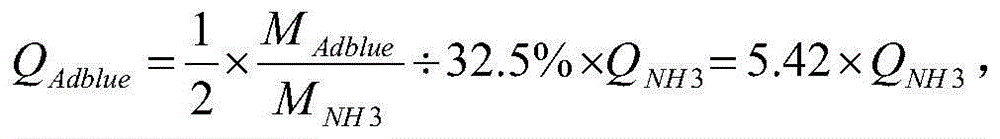

[0030] Receive the SCR catalytic converter temperature signal, receive the NH3 leakage feedback signal, receive the NOx flow value, calibrate the NH3 surface coverage reference value, calculate the basic injection volume of urea solution, judge the SCR catalytic converter t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com