Method for preparing blood vessel stent with polyester medicament eluting coating

A vascular stent and polyester technology, applied in the field of medical devices, achieves the effect of uniform coating, good utilization efficiency, and promotion of healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] The polyester drug-eluting coating of the stent is carried out in the following steps:

[0035] (1) Cleaning of vascular stents

[0036] Stainless steel brackets were cleaned with acetone, absolute ethanol, and deionized water for 5 to 15 minutes by ultrasonic vibration, dried, and set aside; NiTi alloy brackets were first used with hydrofluoric acid:concentrated nitric acid:water=1:8:16~1:2: 7 or glacial acetic acid:concentrated nitric acid=3:7~5:5, corrode for 5~7min, then use absolute ethanol and deionized water to ultrasonically clean for 5~15 minutes, dry and set aside.

[0037] (2) Preparation of coating solution

[0038]According to the ratio of drug: polymer drug-loaded material = 5% to 40%, the two are dissolved in a certain volume of organic solvent, and the concentration is 0.1% to 10% (w / v%, that is, the total amount of polymer and drug) The ratio of weight to solvent volume) uniform coating solution, for subsequent use. Its polymer drug carrier includes ...

Embodiment 2

[0044] (5) Cleaning of vascular stents

[0045] Stainless steel brackets were cleaned with acetone, absolute ethanol, and deionized water by ultrasonic vibration for 15 minutes, dried, and set aside; NiTi alloy brackets were firstly treated with hydrofluoric acid:concentrated nitric acid:water=1:8:16 or glacial acetic acid:concentrated nitric acid= 3:7, corrode for 7 minutes, then wash with absolute ethanol and deionized water with ultrasonic vibration for 15 minutes, dry and set aside.

[0046] (6) Preparation of coating solution

[0047] According to the ratio of paclitaxel: polylactic acid glycolic acid or polylactide glycolide (PLGA) = 35%, the two are dissolved in a certain volume of organic solvent, and the concentration is 1% (w / v%), that is, the polymer and the ratio of the total weight of the drug to the volume of the solvent) for a uniform coating solution, for subsequent use.

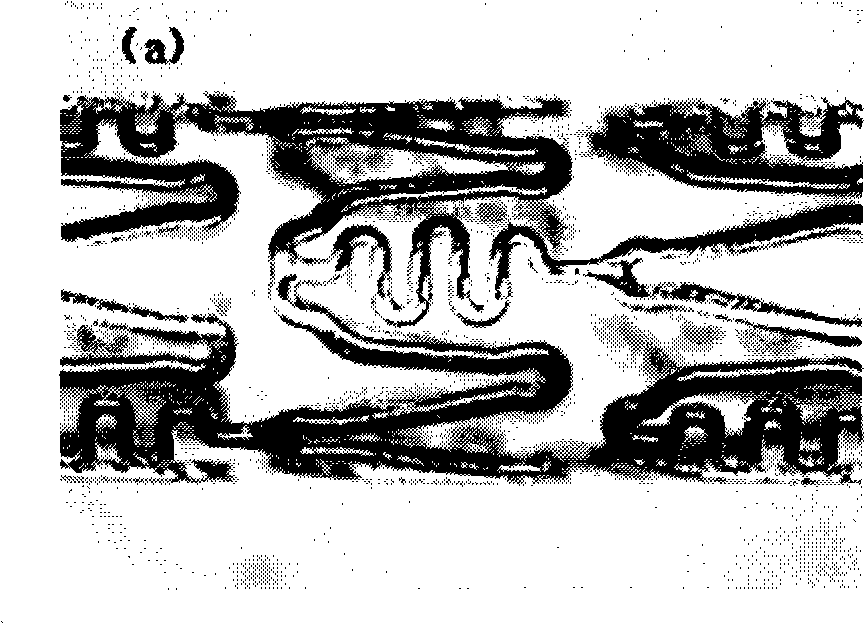

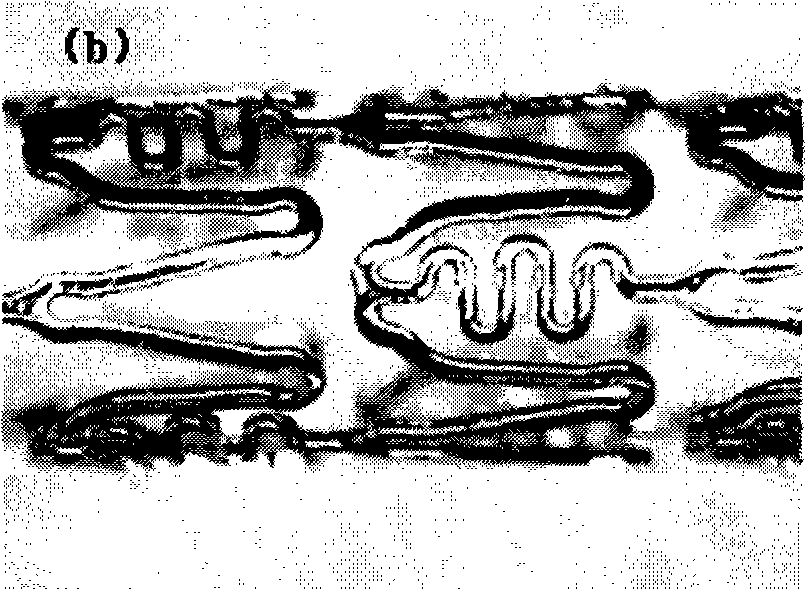

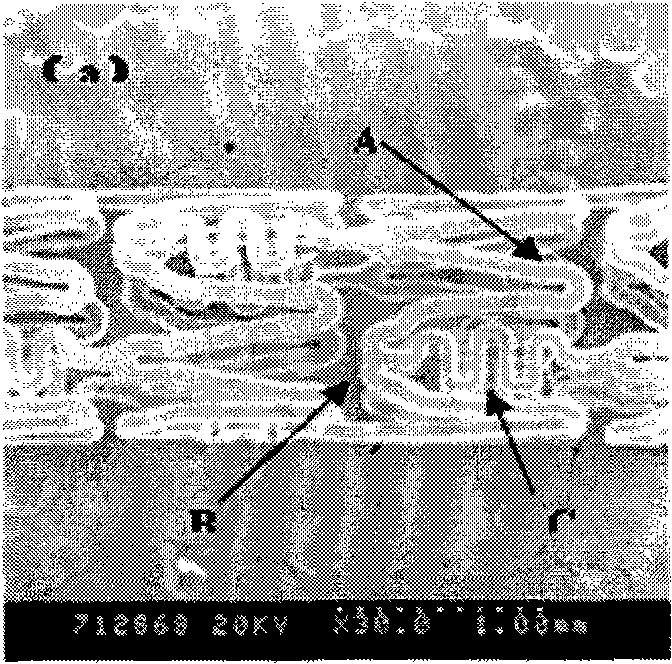

[0048] (7) Spraying of drug-eluting coating

[0049] The drug-eluting coating adopts t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com