Manufacturing method for lithium ion battery pole piece

A lithium-ion battery and pole piece technology, which is applied to battery electrodes, circuits, electrical components, etc., can solve the problems of not being able to meet the needs of foam current collector electrode pole pieces, and cannot complete the production of pole pieces, so as to achieve good electrical performance and increase energy density. , the effect of reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

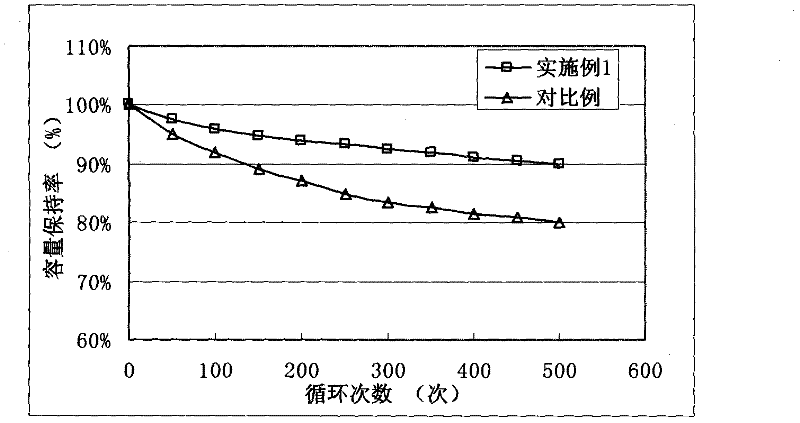

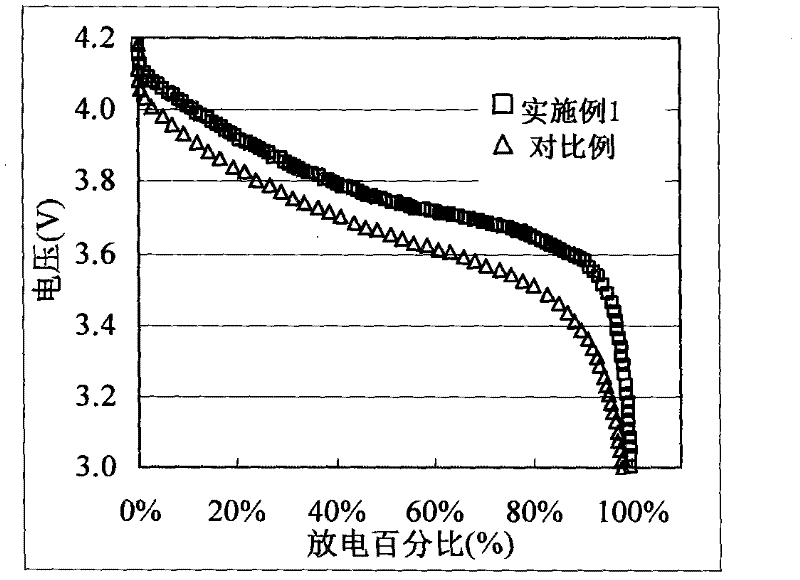

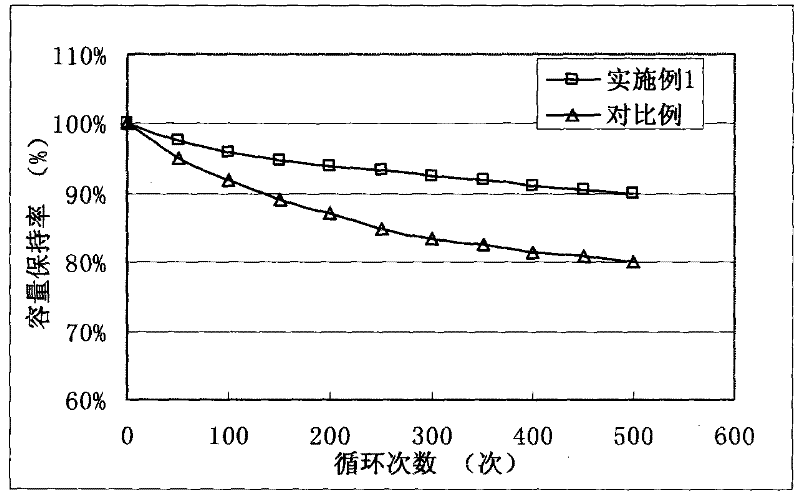

Embodiment 1

[0036] Positive electrode sheet preparation: according to the need to cut the corresponding size of aluminum foam as the positive current collector. The positive electrode current collector is placed in a container, the container has a bottom and four walls, and the height of the four walls is greater than the thickness of the positive electrode body, and the container can be heated. Add LiCoO2 (lithium cobalt oxide), Super-P (superconducting carbon black), PVDF (polyvinylidene fluoride) in a mass ratio of 95.0:2.5:2.5 to NMP, mix and stir evenly to obtain a slurry with certain fluidity. The stirred slurry is poured on the surface of the aluminum foam current collector, so that the slurry is evenly distributed inside and on the surface of the foam current collector to obtain a positive wet electrode sheet. Then dry the positive wet pole piece at 60°C to obtain a dry positive pole piece, cold press the dry positive pole piece, and then weld the positive pole lug made of 0.4mm t...

Embodiment 2

[0044] Positive electrode sheet preparation: according to the need to cut the corresponding size of aluminum foam as the positive current collector. The positive electrode current collector is placed in a container, the container has a bottom and four walls, and the height of the four walls is greater than the thickness of the positive electrode body, and the container can be heated. Add LiMnO2 (lithium manganese oxide), conductive carbon black, and sodium carboxymethylcellulose (CMC) according to the mass ratio of 95.0:2.5:2.5 and add NMP (N-methylpyrrolidone) to mix and stir evenly to obtain a slurry with certain fluidity material. The stirred slurry is poured on the surface of the aluminum foam current collector, so that the slurry is evenly distributed inside and on the surface of the foam current collector to obtain a positive wet electrode sheet. Then dry the positive wet pole piece at 100°C to obtain a dry positive pole piece, cold press the dry positive pole piece, an...

Embodiment 3

[0048] Positive electrode sheet preparation: according to the need to cut the corresponding size of aluminum foam as the positive current collector. The positive electrode current collector is placed in a container, the container has a bottom and four walls, and the height of the four walls is greater than the thickness of the positive electrode body, and the container can be heated. Add LiNiO2 (lithium nickelate), lithium nickel cobalt manganese oxide, conductive carbon black, and styrene-butadiene rubber (SBR) according to the mass ratio of 90.0:5.0:2.5:2.5 and add NMP (N-methylpyrrolidone) to mix and stir evenly to obtain a Certain fluidity slurry. The stirred slurry is poured on the surface of the aluminum foam current collector, so that the slurry is evenly distributed inside and on the surface of the foam current collector to obtain a positive wet electrode sheet. Then dry the positive wet pole piece at 80°C to obtain a dry positive pole piece, cold press the dry positi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com