A jet mechanism of single crystal carbide material processing equipment

A technology of carbonized materials and processing equipment, applied in the direction of electrolysis components, electrolysis process, etc., can solve the problems of processing efficiency, electrolyte waste, and increase processing cost, etc., to improve spraying accuracy, increase spraying area, and facilitate recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] In order to make the content of the present invention more clearly understood, the present invention will be further described in detail below based on specific embodiments and in conjunction with the accompanying drawings.

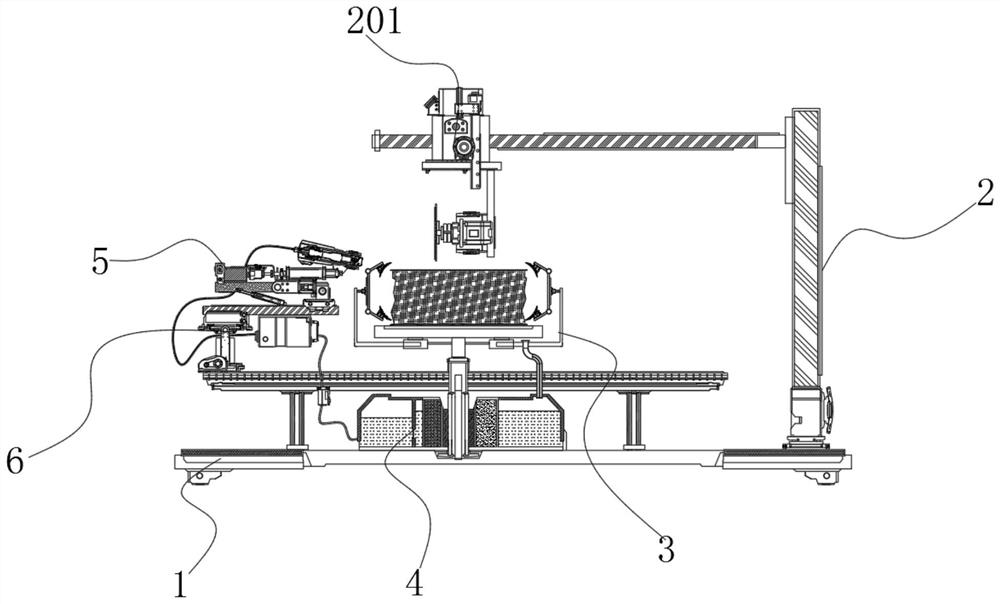

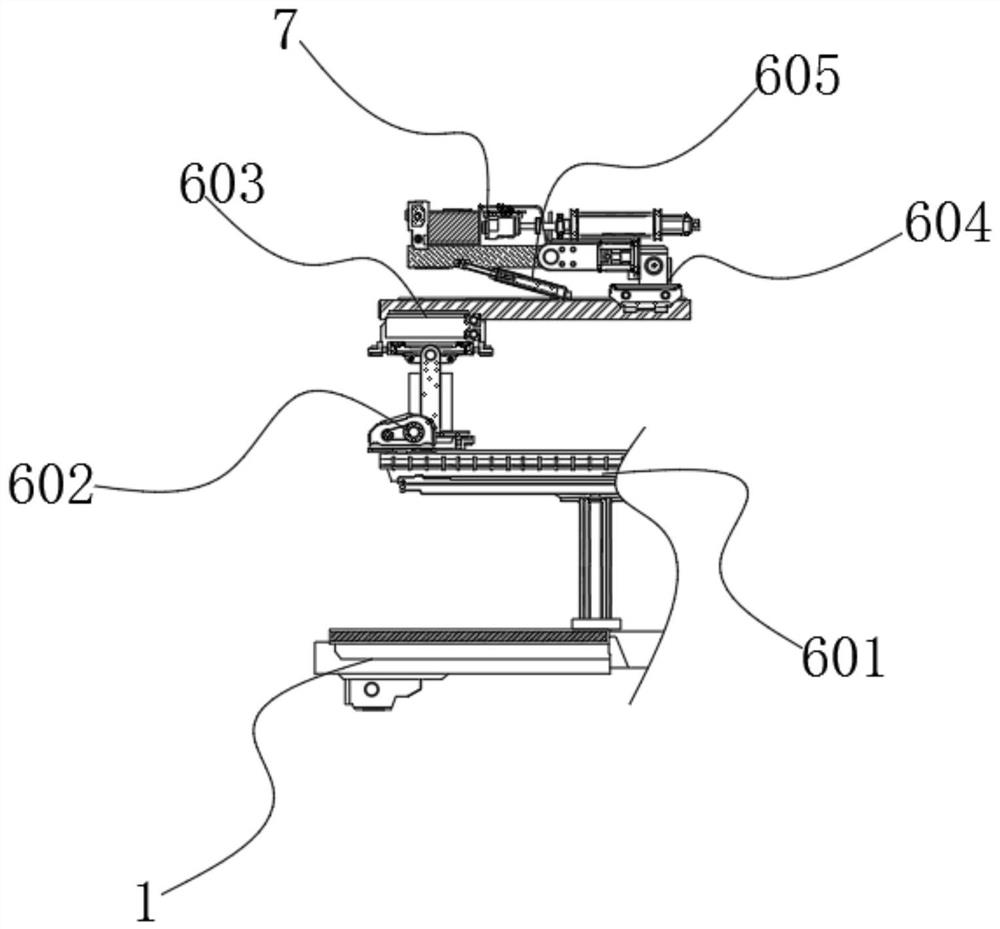

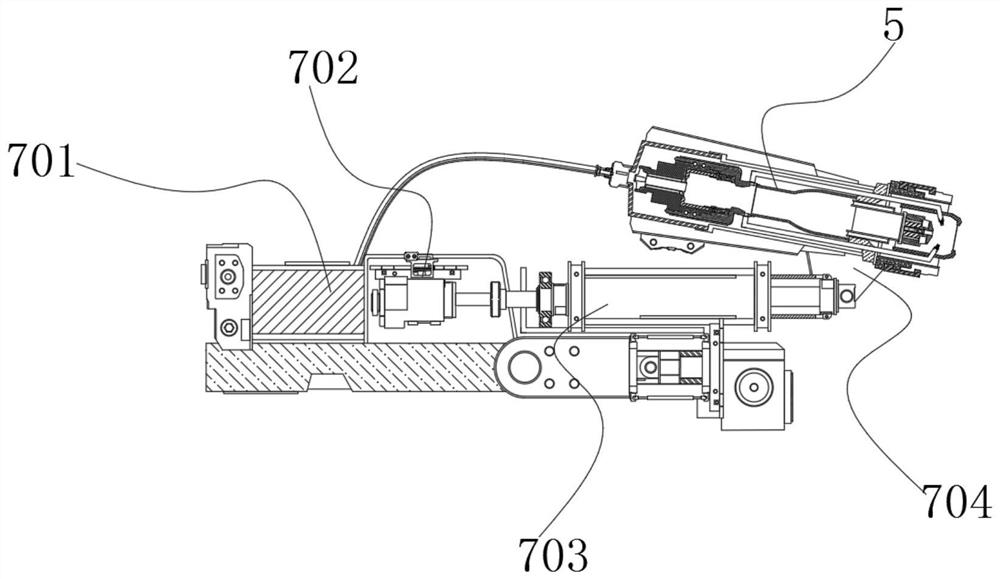

[0027] Such as Figure 1-7As shown, in this embodiment, a fluidic mechanism of single crystal carbide material processing equipment, it consists of a support base 1, a fixed frame 2, a processing device 201, a carrier plate seat 3, a fluidic assembly 5, a main adjustment frame body 6 and The filter and purification assembly 4 is composed of a fixed frame 2 vertically fixed on one side of the upper end surface of the support base 1, and a processing device 201 is installed on the fixed frame 2, and the processing device 201 is used for die-cutting the single crystal; the center of the upper end surface of the support base 1 The position is supported and fixed by the support column with the bearing plate base 3, and the clamping part for clamping and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com