In-cylinder ion current and urea injection type closed-loop control system for nitrogen oxide emission of internal combustion engine

An ion current, nitrogen oxide technology, applied in the direction of internal combustion piston engine, combustion engine, electronic control of exhaust gas treatment devices, etc., can solve the problem of increasing system production and use costs, urea and ammonia gas escape, affecting vehicle user satisfaction To avoid additional unconventional emissions, reduce system production and use costs, and improve system utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

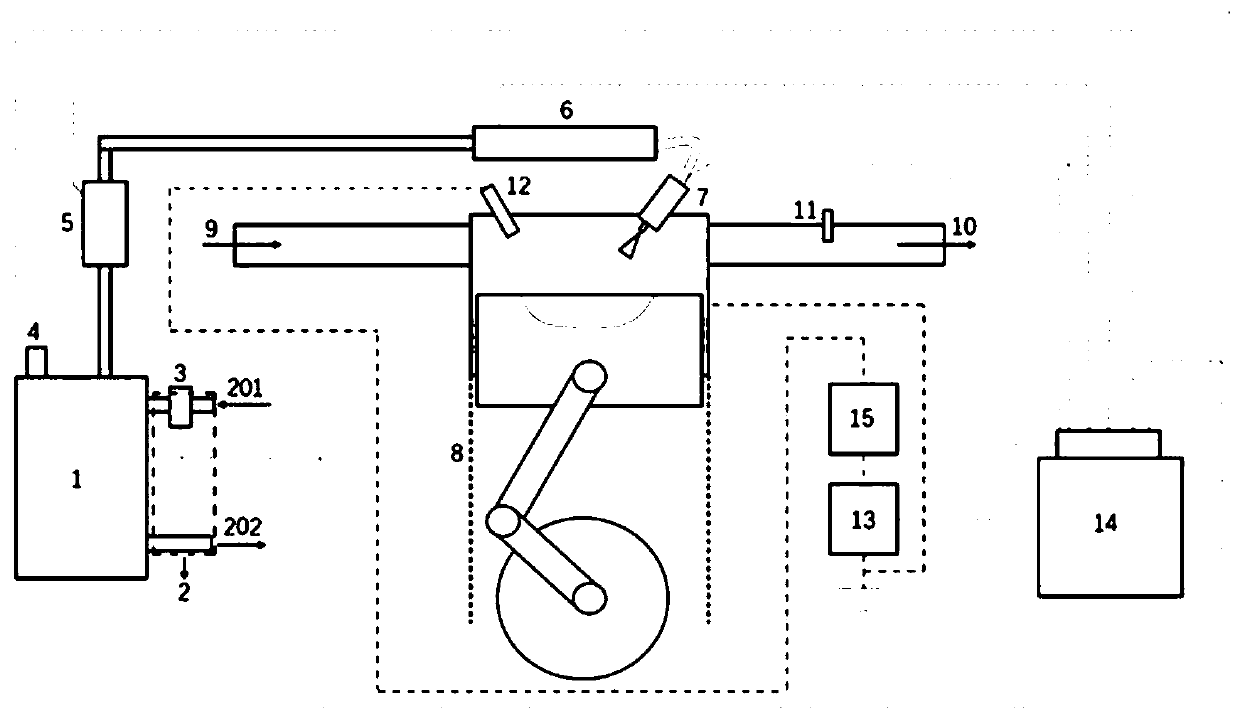

[0052] see figure 1 , a closed-loop control system for internal combustion engine nitrogen oxide emission with in-cylinder ion current and urea injection, characterized in that it includes a urea tank 1, a high-temperature water pipe 2, a heating control valve 3, a liquid level and temperature sensor 4, a high-pressure urea pump 5, High-pressure urea common rail 6, urea direct injection nozzle 7, internal combustion engine body 8, intake manifold 9, exhaust manifold 10, nitrogen oxide sensor 11, ion current sensor 12, ion current signal processing device 13 and closed-loop controller 14 .

[0053] The urea tank 1 is located in the internal combustion engine room, and the normal pressure urea solution is housed in the urea tank 1, and the temperature of the normal pressure urea solution in the urea tank 1 is maintained by the high temperature heat source generated during the working process of the internal combustion engine.

[0054] The high temperature water pipe 2 includes ...

Embodiment 2

[0071] see figure 1 , a closed-loop control system for internal combustion engine nitrogen oxide emission with in-cylinder ion current and urea injection, characterized in that it includes a urea tank 1, a high-temperature water pipe 2, a heating control valve 3, a liquid level and temperature sensor 4, a high-pressure urea pump 5, High-pressure urea common rail 6, urea direct injection nozzle 7, internal combustion engine body 8, intake manifold 9, exhaust manifold 10, nitrogen oxide sensor 11, ion current sensor 12, ion current signal processing device 13 and closed-loop controller 14 .

[0072] The urea tank 1 is located in the internal combustion engine room, and the normal pressure urea solution is housed in the urea tank 1, and the temperature of the normal pressure urea solution in the urea tank 1 is maintained by the high temperature heat source generated during the working process of the internal combustion engine.

[0073] The high temperature water pipe 2 includes ...

Embodiment 3

[0090] The structure of this embodiment is the same as that of Embodiment 1, and further includes a high-voltage ion current power supply device 15 .

[0091] The high-voltage ion current power supply device 15 supplies power to the ion current sensor 12, and applies high voltage to the combustion chamber and the cylinder through the ion current sensor 12.

[0092] Further, the ion current signal processing device 13, the closed-loop controller 14 and the high-voltage ion current power supply device 15 are powered by a vehicle battery.

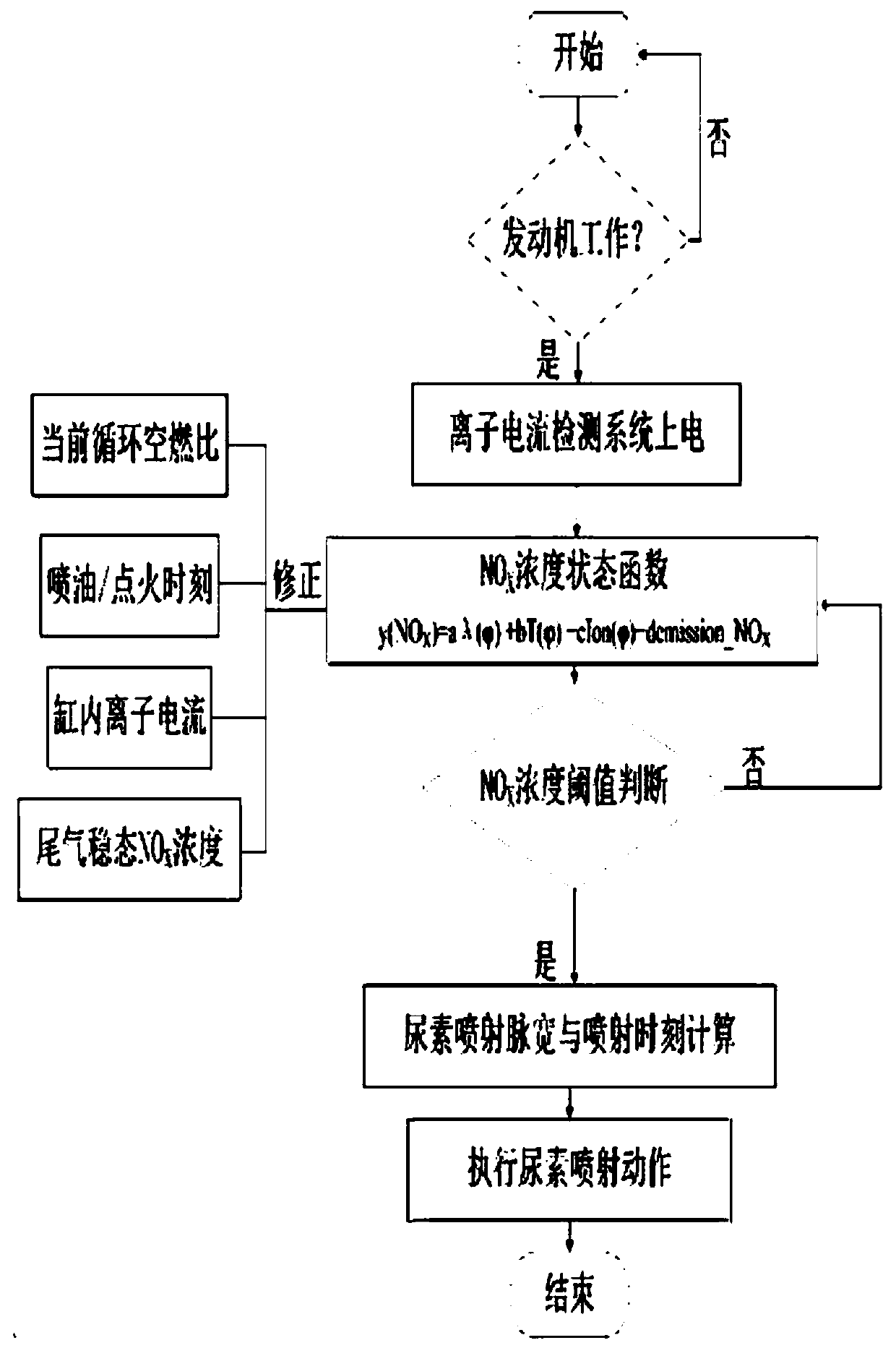

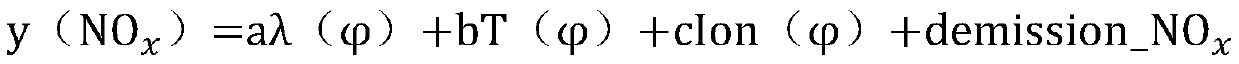

[0093] Further, during the working process of the internal combustion engine, the ion current sensor 12 collects the generation of nitrogen oxides in the cylinder by detecting the ion current signal in the cylinder, including the following steps:

[0094] 1) The high-voltage ion current power supply device 13 applies the 50-300V DC voltage required for ion current detection to the combustion chamber and the cylinder block.

[0095] 2) During ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com