Injection arrangement for injecting water and fuel

A component and fuel technology, applied in the direction of low pressure fuel injection, low pressure fuel injection, fuel injection device, etc., can solve problems such as reducing installation space, and achieve the effect of reducing fuel consumption and reducing knocking tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

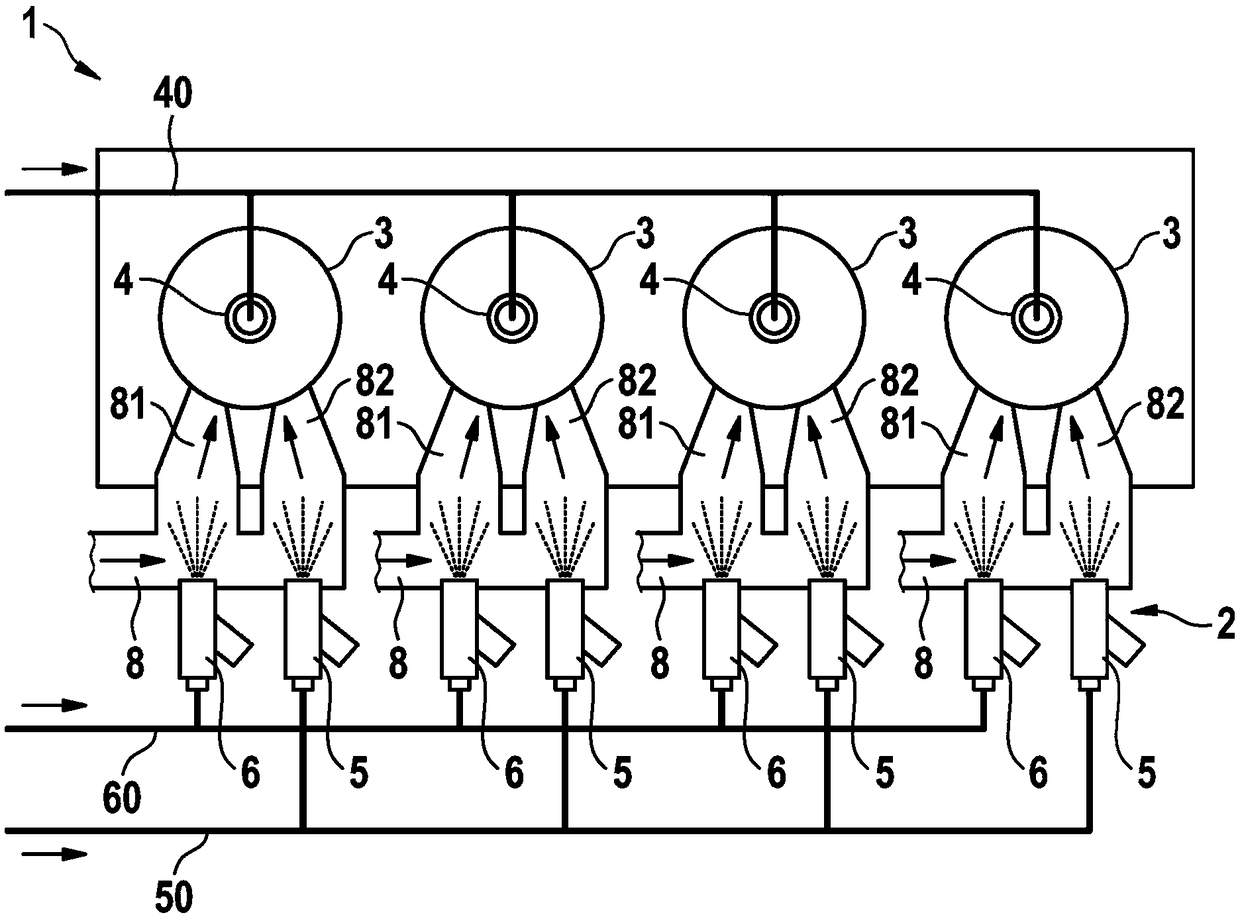

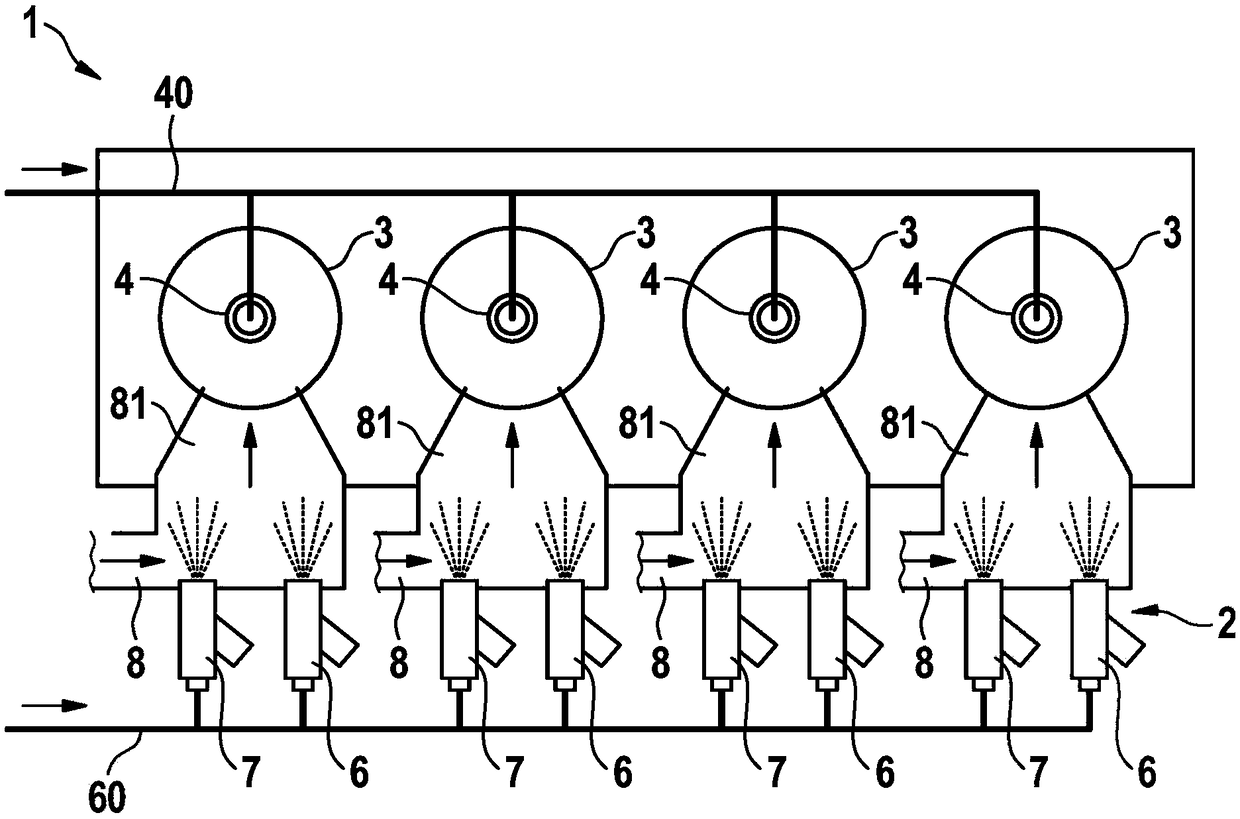

[0016] Refer below figure 1 The jetting assembly 1 according to the first preferred embodiment of the present invention is explained in detail.

[0017] as from figure 1 As can be seen in the figure, the injection system 2 is arranged in an internal combustion engine 1 having four cylinders 3 .

[0018] In this case, exactly three injection valves are provided per cylinder 3 , so that the injection system 2 has a total of twelve injection valves.

[0019] as from figure 1 It can be seen that each cylinder 3 has a first fuel injection valve 4 arranged directly thereon for direct injection. The high-pressure feed line 40 supplies the four fuel injection valves 4 with fuel under high pressure.

[0020] A first intake duct 81 and a second intake duct 82 for each cylinder 3 are arranged on the intake region 8 of the internal combustion engine. Two intake passages 81, 82 respectively connect an intake pipe or the like to the cylinder, wherein the connection between the intake p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com