Micro drop jetting method and device

A droplet ejection and liquid ejection technology, which is applied to ejection devices, liquid ejection devices, etc., can solve the problems of affecting droplet ejection accuracy, inability to effectively control droplets, and droplet unevenness, etc., and achieves improved droplet ejection accuracy, Avoid the effect of extra droplet ejection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

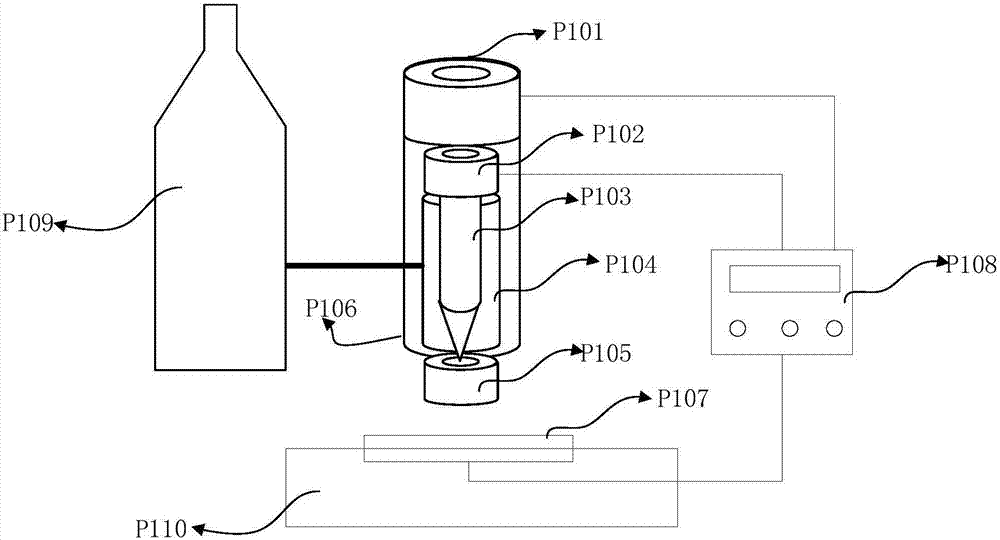

[0030] refer to figure 1 , a droplet spraying device, the device includes a brake P101, a vibrator P102, a cavity P104, a vibrating rod P103, a nozzle P105, a housing P106, a mobile platform P107, a controller P108, a liquid storage tank P109, and a fixed platform P110.

[0031] The brake P101 is above the vibrator P102, the vibrator P102 is connected to the vibrating rod P103, and the vibrating rod P103 is inserted into the cavity P104; the nozzle P105 is connected to the lower end of the cavity P104; the brake P101, the vibrator P101, the cavity P104, the vibrating rod P103, and the nozzle P105 Placed inside the shell P106; the controller P108 outputs a PWM signal which is amplified by the amplifier circuit and then sent to the brake P101. Driven by the PWM signal, the brake P101 pushes the vibrating rod P103 to make intermittent reciprocating linear motions, closing the nozzle P105 or opening The nozzle P105; the controller P108 outputs a PWM signal which is amplified by th...

Embodiment 2

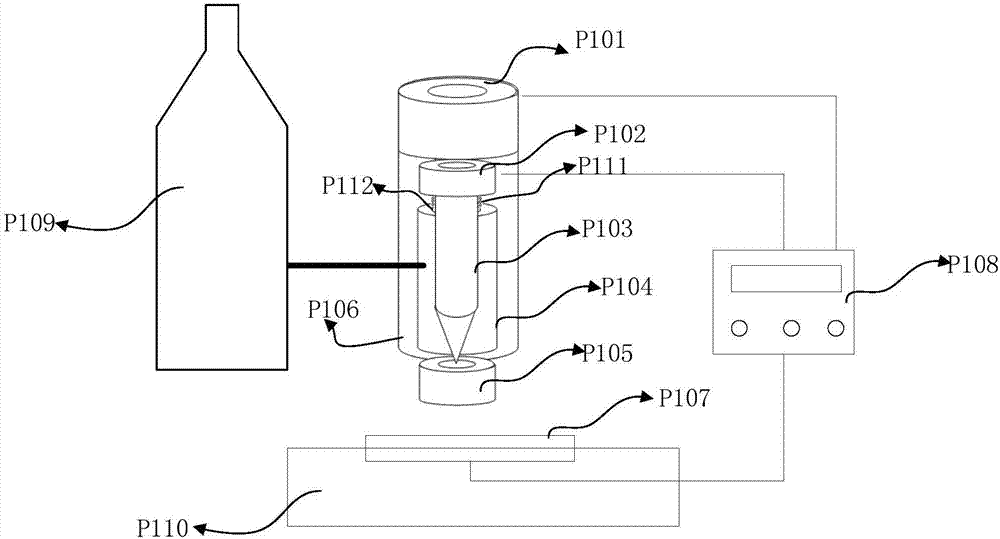

[0039] refer to figure 2 In this embodiment, on the basis of Embodiment 1, a spring P111 is placed on the top of the vibrating rod P103 and below the vibrator P102. The elastic force of the spring P111 can push up the vibrating rod P103 when the brake P101 is not pushed down, thereby opening the nozzle P105.

[0040]Before the controller P108 needs to control the movement of the mobile platform P107, if the area does not need to spray droplets, the controller P108 sends the strongest PWM signal in the positive direction to the brake P101, so that the brake P101 pushes the vibrating rod P103 downward to close the nozzle P105, prevent the liquid from overflowing, and stop sending the PMW signal to the vibrator P102 at the same time. At this time, send a PWM signal to the mobile station P107 to move the mobile station to the destination. After the movement is completed, when it is necessary to spray droplets again, the controller P108 stops outputting the PWM signal to the bra...

Embodiment 3

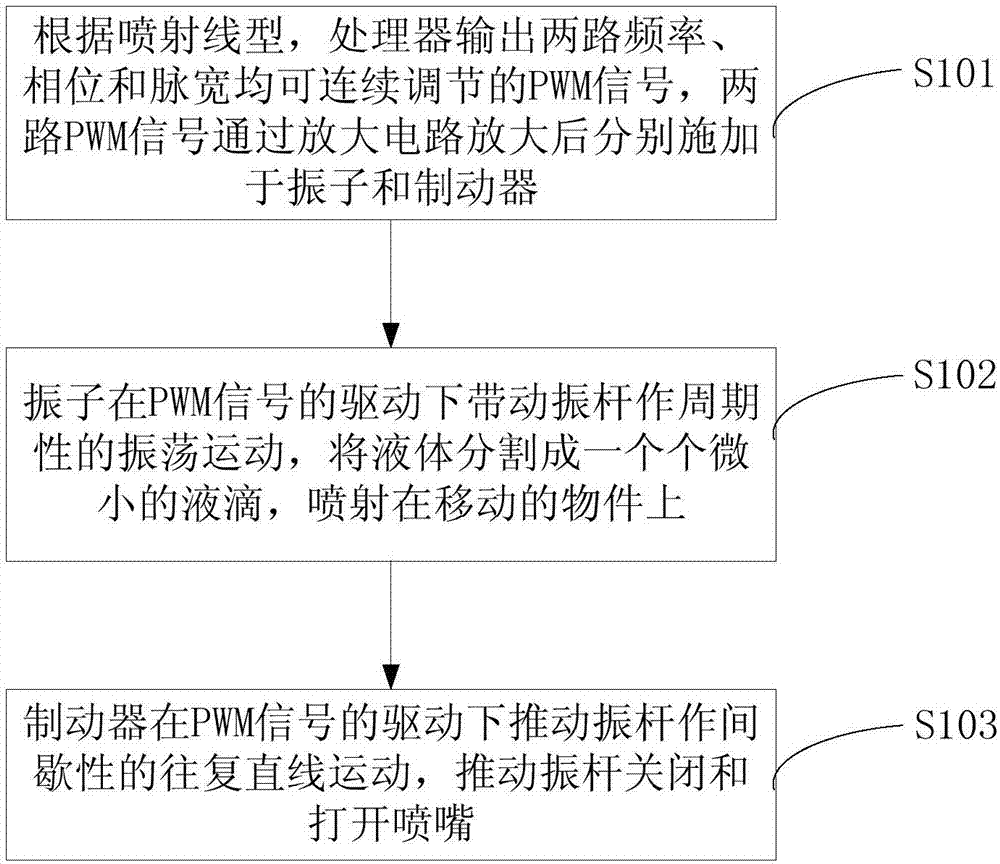

[0044] refer to image 3 , a droplet ejection method, the method comprising:

[0045] S101. According to the injection line pattern, the processor outputs two channels of PWM signals whose frequency, phase and pulse width can be continuously adjusted. The two channels of PWM signals are amplified by the amplifier circuit and applied to the vibrator and the brake respectively.

[0046] The droplet ejection device needs to adjust the PWM signal output by the controller according to the line type (such as a wide dotted line) that needs to be ejected. The signal sent to the vibrator needs to be adjusted according to the width of the line shape. When the droplet needs to be larger, the movement amplitude and frequency of the vibrator need to be smaller; when the droplet is small, the movement amplitude and frequency of the vibrator need to be larger. All of these can be realized by adjusting the PWM signal output by the controller.

[0047] S102. Driven by the PWM signal, the vib...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com