Bionic cilium type high-precision nanodrop nozzle device

A high-precision, ciliated technology, used in jetting devices, liquid jetting devices, fiber processing, etc., can solve the problems of low droplet ejection accuracy and large droplet diameter, and achieves improved droplet ejection accuracy, increased ejection speed, and improved Effects of a wide range of materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

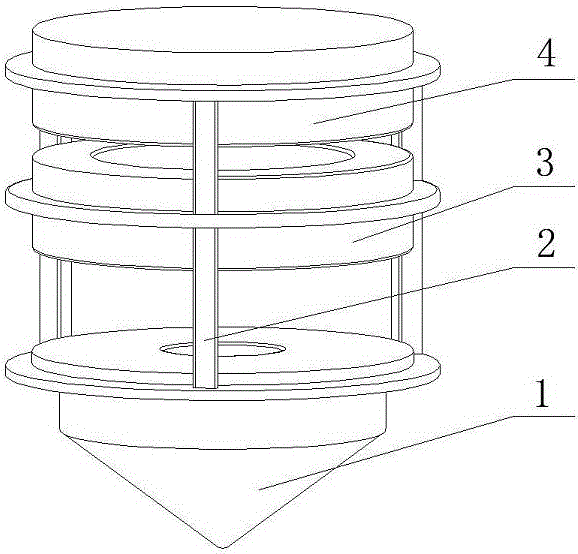

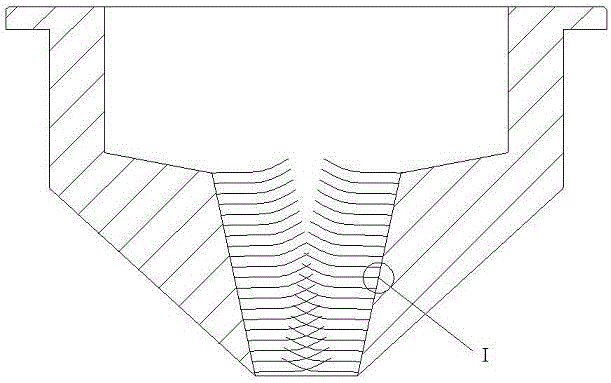

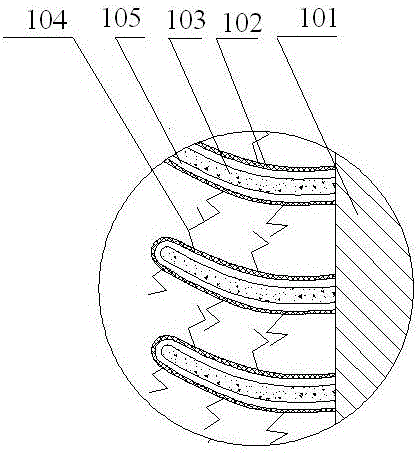

[0039] The polyethylene terephthalate nozzle 1 is installed on the lower part of the bracket 2, the magnetic field coil 3 is installed on the bracket 2 and is located above the polyethylene terephthalate nozzle 1, and the focused ultrasonic transducer 4 is installed on the bracket 2 and located on the magnetic field coil 3, there are bionic cilia on the inner wall below the main body 101 of the polyethylene terephthalate nozzle 1, and the upper part of the main body 101 is a liquid storage chamber;

[0040] The described bionic cilia are prepared by the following steps:

[0041] (1) Mix magnetic powder and silicone resin according to the mass ratio of 1:1, the magnetic powder is cobalt with a diameter of 50nm;

[0042] (2) Add the solvent xylene to the mixture in step (1) at a mass ratio of 1:0.1 to the silicone resin, and use an ultrasonic disperser to ultrasonically disperse at 150W for 6 minutes, and use a mechanical stirrer at a speed of 1200r / min Stir for 10 minutes, add...

Embodiment 2

[0060] The polyethylene terephthalate nozzle 1 is installed on the lower part of the bracket 2, the magnetic field coil 3 is installed on the bracket 2 and is located above the polyethylene terephthalate nozzle 1, and the focused ultrasonic transducer 4 is installed on the bracket 2 and located on the magnetic field coil 3, there are bionic cilia on the inner wall below the main body 101 of the polyethylene terephthalate nozzle 1, and the upper part of the main body 101 is a liquid storage chamber;

[0061] The described bionic cilia are prepared by the following steps:

[0062] (1) Mix magnetic powder and silicone resin according to the mass ratio of 1:2, the magnetic powder is cobalt with a diameter of 125nm;

[0063] (2) Add the solvent xylene to the mixture in step (1) at a mass ratio of 1:0.8 to the silicone resin, and use an ultrasonic disperser to disperse ultrasonically for 8 minutes at a power of 175W, and use a mechanical stirrer at a speed of 1350r / min Stir for 20 ...

Embodiment 3

[0081] The polyethylene terephthalate nozzle 1 is installed on the lower part of the bracket 2, the magnetic field coil 3 is installed on the bracket 2 and is located above the polyethylene terephthalate nozzle 1, and the focused ultrasonic transducer 4 is installed on the bracket 2 and located on the magnetic field coil 3, there are bionic cilia on the inner wall below the main body 101 of the polyethylene terephthalate nozzle 1, and the upper part of the main body 101 is a liquid storage chamber;

[0082] The described bionic cilia are prepared by the following steps:

[0083] (1) Mix magnetic powder and silicone resin according to the mass ratio of 1:3, the magnetic powder is cobalt with a diameter of 200nm;

[0084] (2) Add the solvent xylene to the mixture in step (1) at a mass ratio of 1:1.5 to the silicone resin, and use an ultrasonic disperser to disperse ultrasonically for 10 minutes at a power of 200W, and use a mechanical stirrer at a speed of 1500r / min Stir for 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com