Inkjet print head and inkjet printer

An inkjet print head and nozzle technology, applied in printing and other directions, can solve the problems of not being able to act at the same time, affecting the jetting action of the adjacent groove wall, etc., and achieve the effect of effective jetting action, simple structure and increasing initial speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to make the purpose, technical solution and advantages of the present invention clearer, the present invention will be further described in detail below in conjunction with the accompanying drawings.

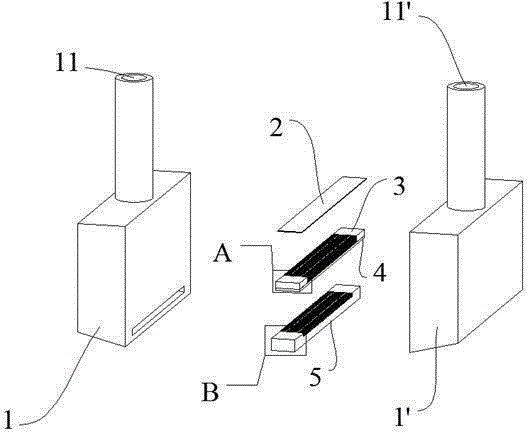

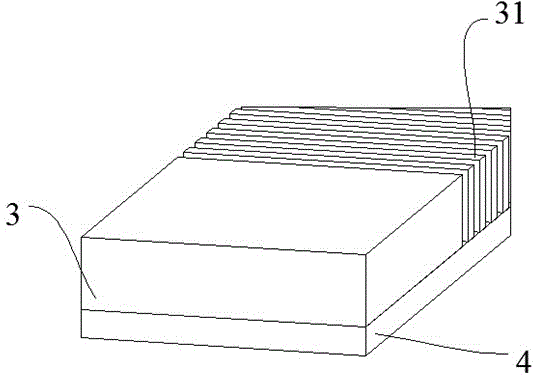

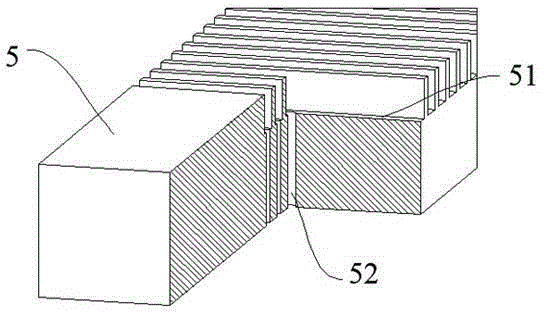

[0055] to combine Figure 1 to Figure 12 , the present invention provides various embodiments of an inkjet printing head, comprising at least one ejection unit, a cover film adapted to the ejection unit, a piezoelectric ceramic actuator and a cover plate, a fluid inflow pipeline, The fluid flows out of the pipeline and the driving circuit device. The cover film, the piezoelectric ceramic actuator, the cover plate and the injection unit are sequentially connected from top to bottom. The cover film is an electrode of the piezoelectric ceramic brake, and also plays a role of protecting the piezoelectric ceramic brake. The cover plate provides physical support and a conductive channel for the piezoelectric ceramic actuator, and serves as another electrode of the pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com