Laneway stacker top end braking device and method thereof

A brake device, stacker technology, applied in the direction of storage devices, brake types, mechanical equipment, etc., can solve the problem of spring plate reliability, practicability can not meet the braking requirements of large equipment, reset elastic force is difficult to meet the design requirements, The gap between the fixture and the track becomes larger, so as to achieve the effect of simple and easy braking structure, smooth braking and reduced impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

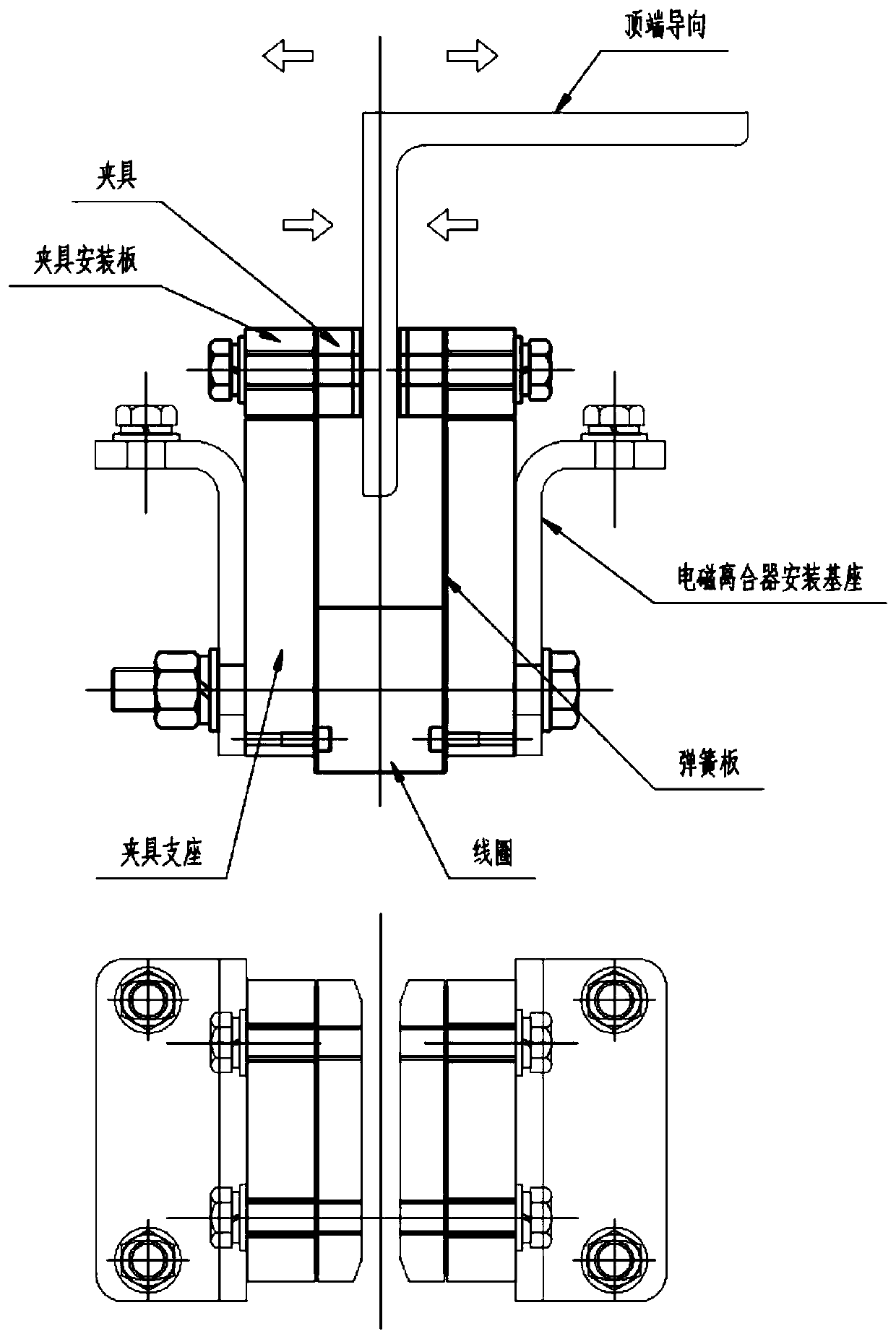

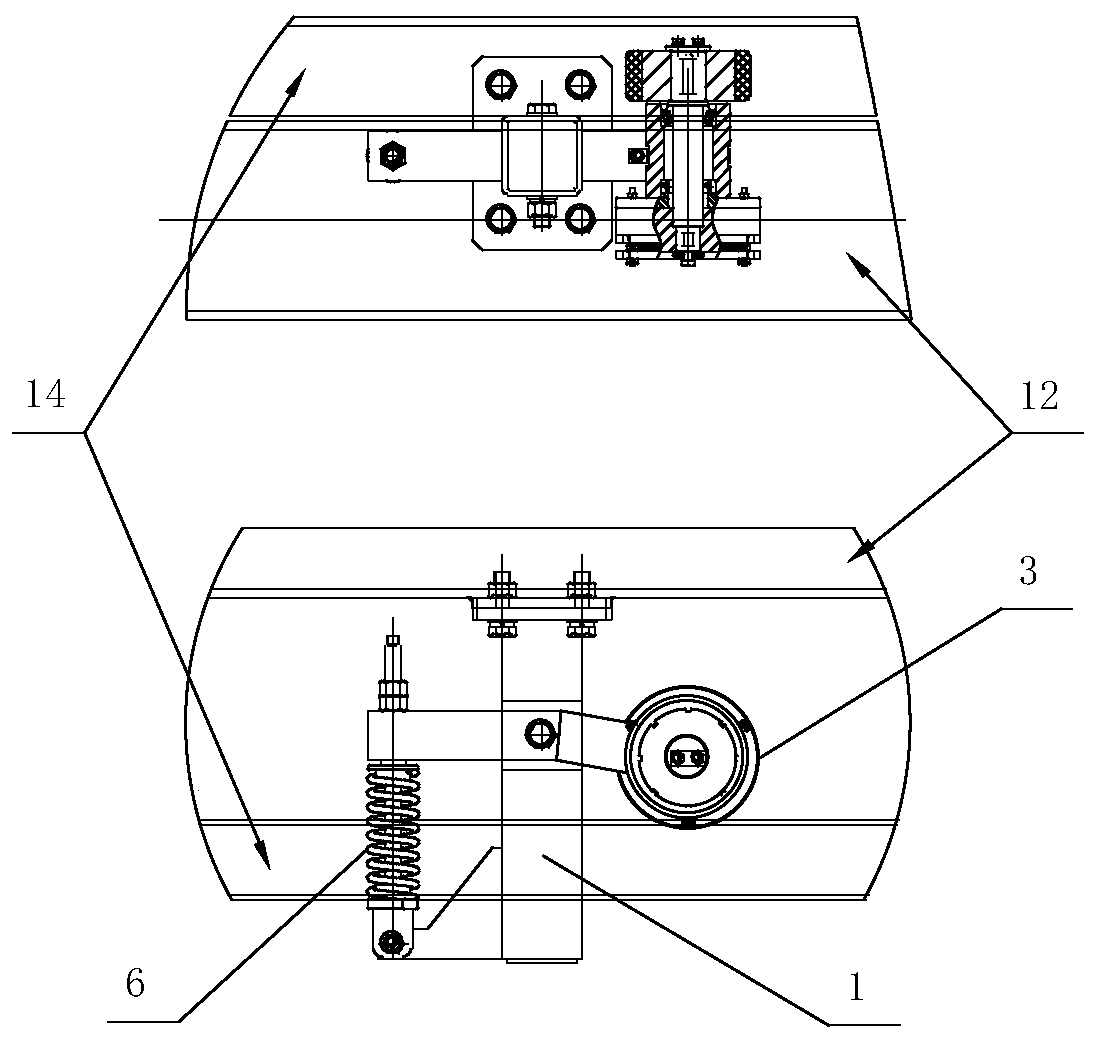

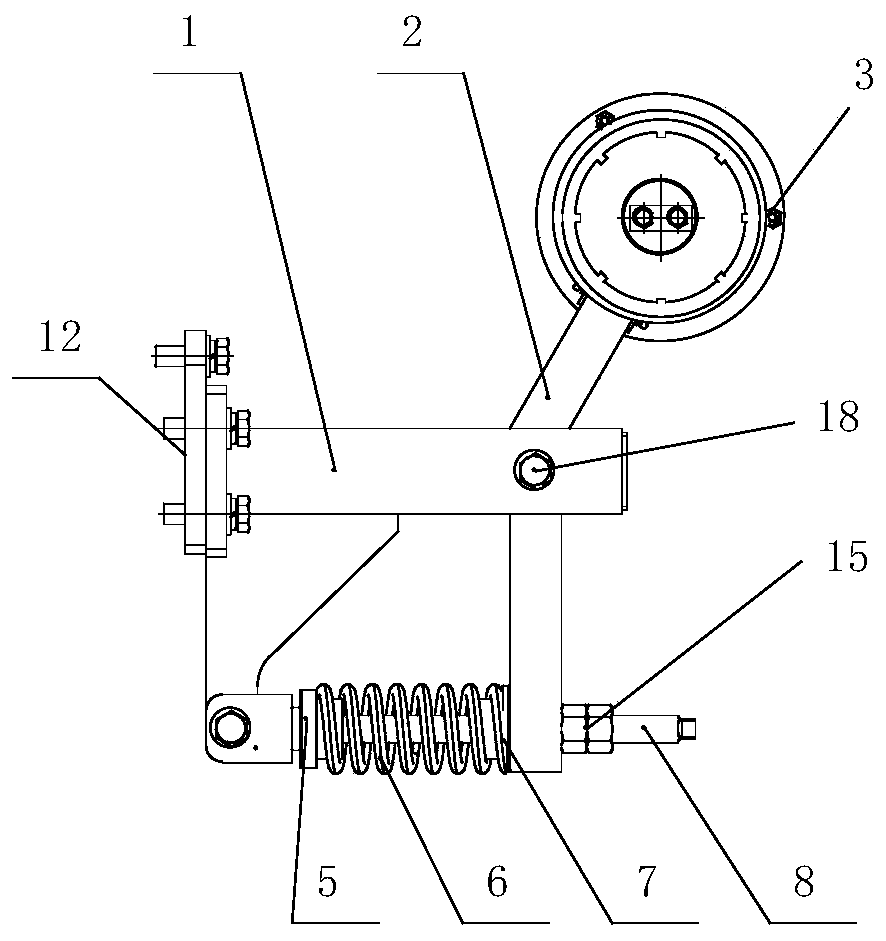

[0030] Example 1, such as Figure 1 to Figure 4 As shown, the braking device at the top of the roadway stacker mainly includes:

[0031] The bracket 1 is fastened to the upper beam 12 of the stacker, and the middle part of the pivot arm 2 is arranged on the bracket 1 through the bolt shaft 18. A clamp 9, the two ends of the clamp 9 are fastened to the rotating arm 2 by bolts; inside the rotating arm sleeve 10, a brake shaft 11, a roller bearing 16, and a deep groove ball bearing 17 are arranged along its axial center ; On one side of the pivoting arm bushing 10, the roller 3 is sleeved on the shaft end of the brake shaft 10, and the two are fastened axially by the end cover and the bolt 13; on the other side of the pivoting arm bushing 10, A flange 19 is provided, the shaft end of the brake shaft 10 passes through the flange 19, and the electromagnetic clutch 4 is fastened to the flange 19 axially through the end cover and bolts 13;

[0032] A screw rod 8 is set between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com