Top end braking method for aisle stacker

A technology of stacker and roadway, which is applied in the direction of transportation, packaging, and storage devices, and can solve the problems of limited mechanical strength, increased production cost, and small thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

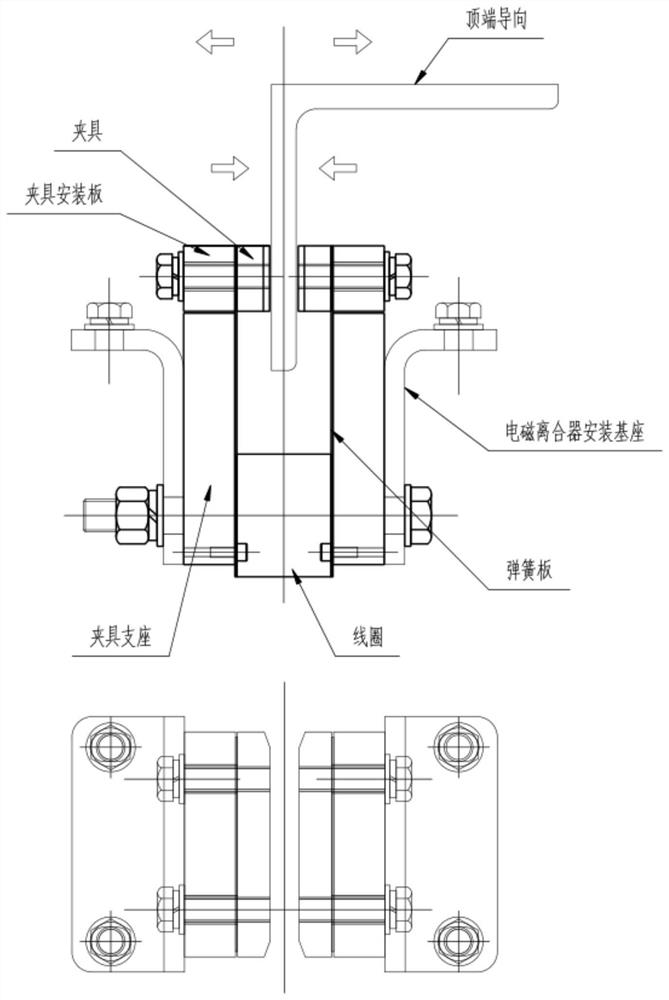

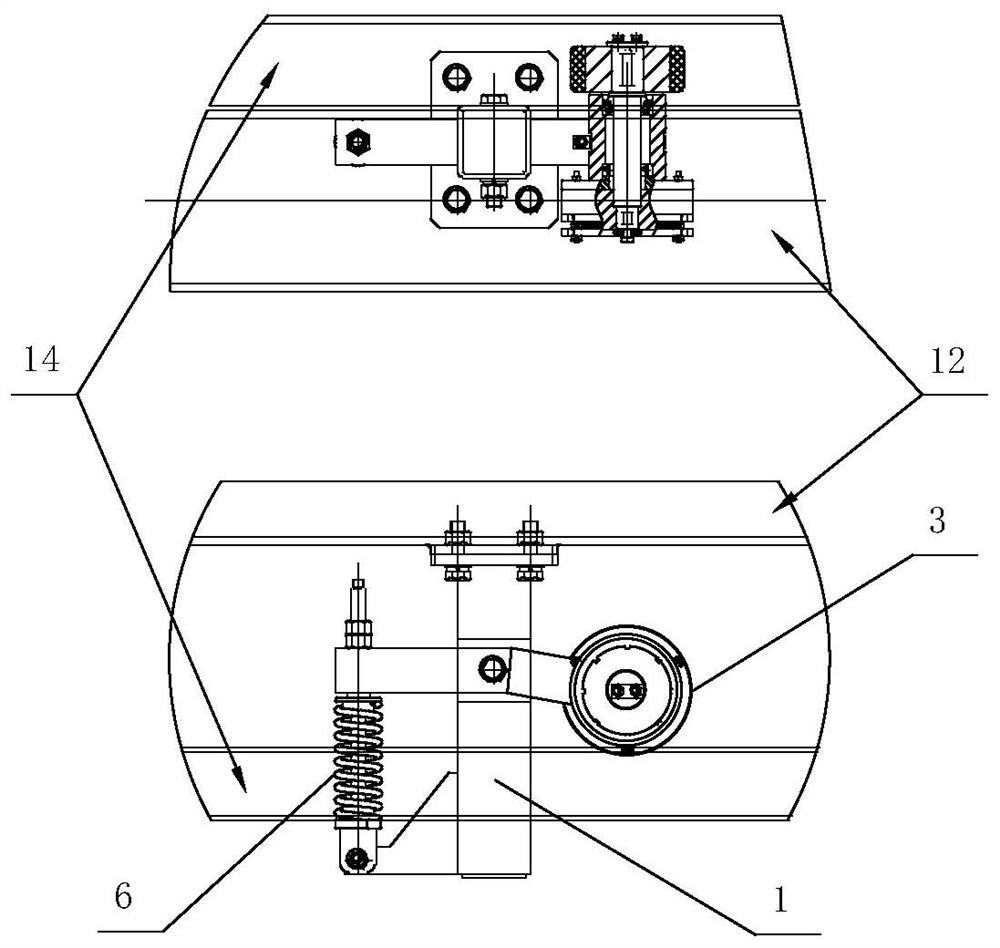

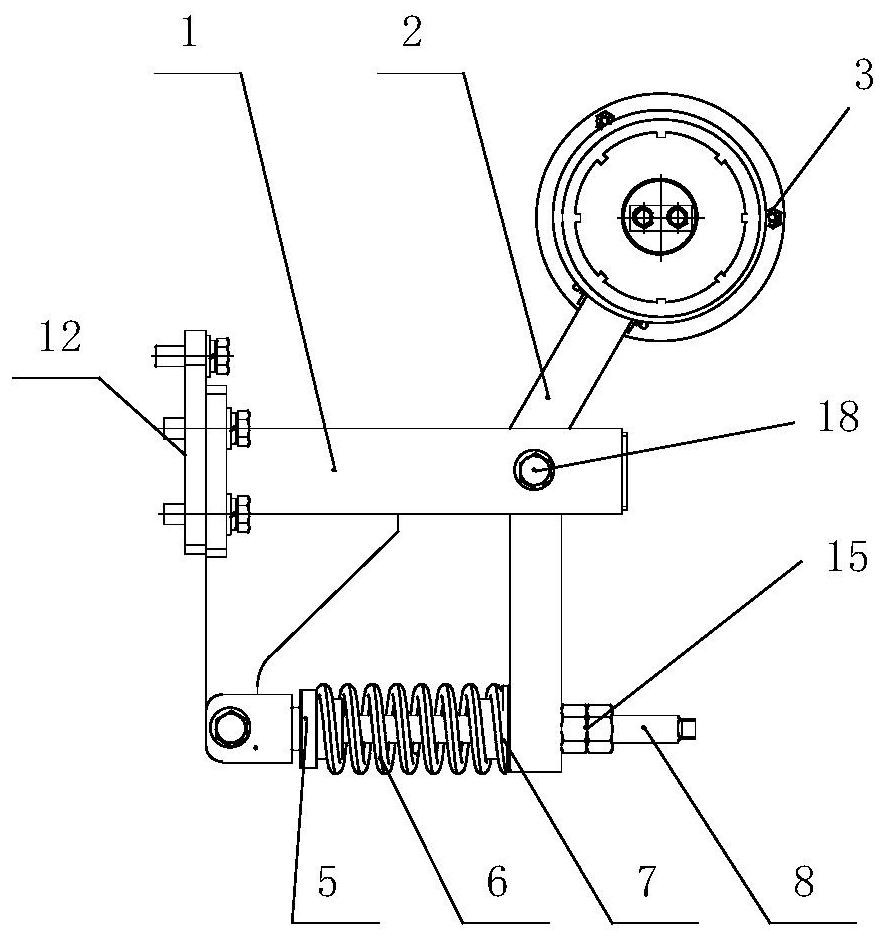

[0020] Example 1, such as Figure 1 to Figure 4 As shown, in order to realize the braking method at the top of the roadway stacker described in the present application, the bracket 1 of the braking device is fastened to the upper beam 12 of the stacker, and the middle part of the rotating arm 2 is arranged on the bracket 1 through the bolt shaft 18, and the rotation The far end of the arm 2 is welded with a pivot arm sleeve 10, and a clamp 9 is arranged on the outer periphery of the pivot sleeve 10, and the two ends of the clamp 9 are fastened to the pivot arm 2 by bolts; 1. A brake shaft 11, a roller bearing 16, and a deep groove ball bearing 17 are arranged along its axial center; on one side of the arm sleeve 10, a roller 3 is sleeved on the shaft end of the brake shaft 10, and passes through the end The cover and the bolt 13 fasten the two in the axial direction; on the other side of the pivot arm sleeve 10, a flange 19 is arranged, the shaft end of the brake shaft 10 pass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com