Hydraulic rotary three-dimensional garage

A technology of three-dimensional garage and hydraulic rotation, which is applied in the direction of buildings, building types, and buildings where cars are parked. It can solve the problems of failure to meet parking needs, inconvenient access to cars, and large floor space. It achieves simple structure, Ease of operation and control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings.

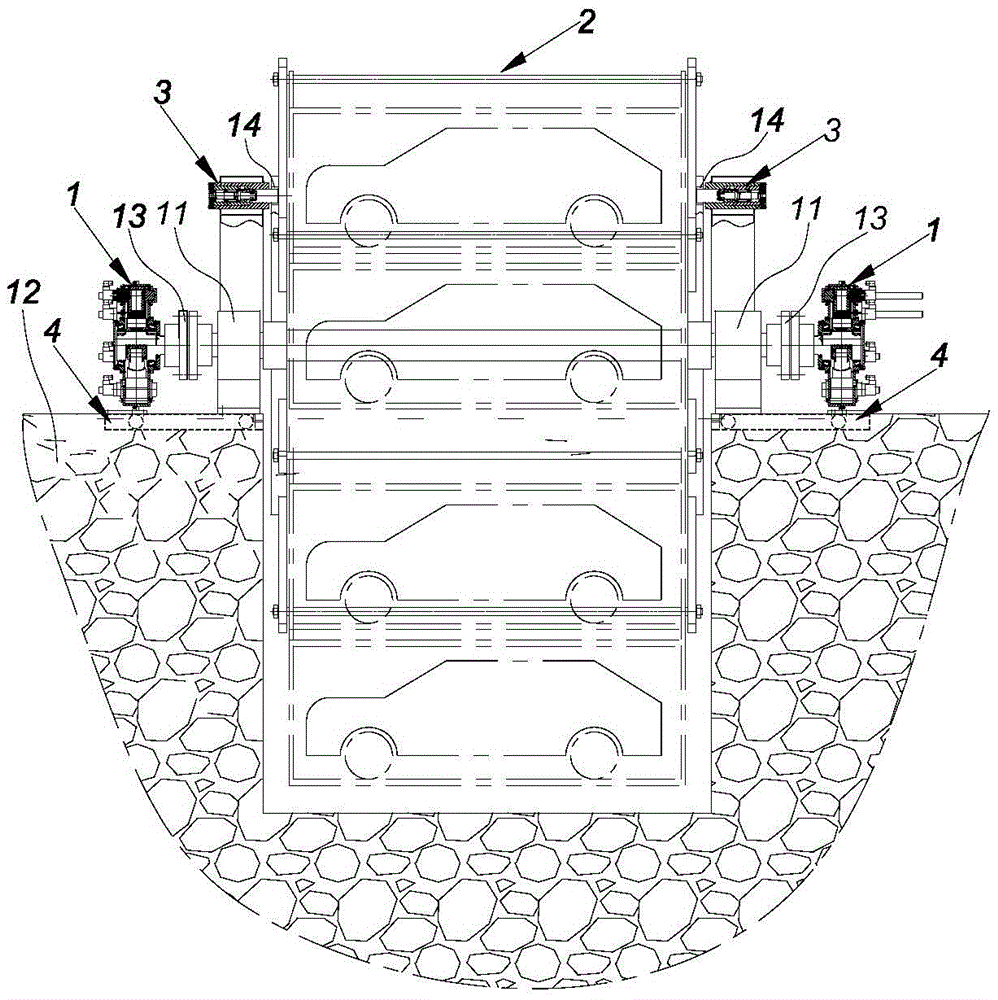

[0028] figure 1 A hydraulic rotary three-dimensional garage according to an embodiment of the present invention is schematically shown.

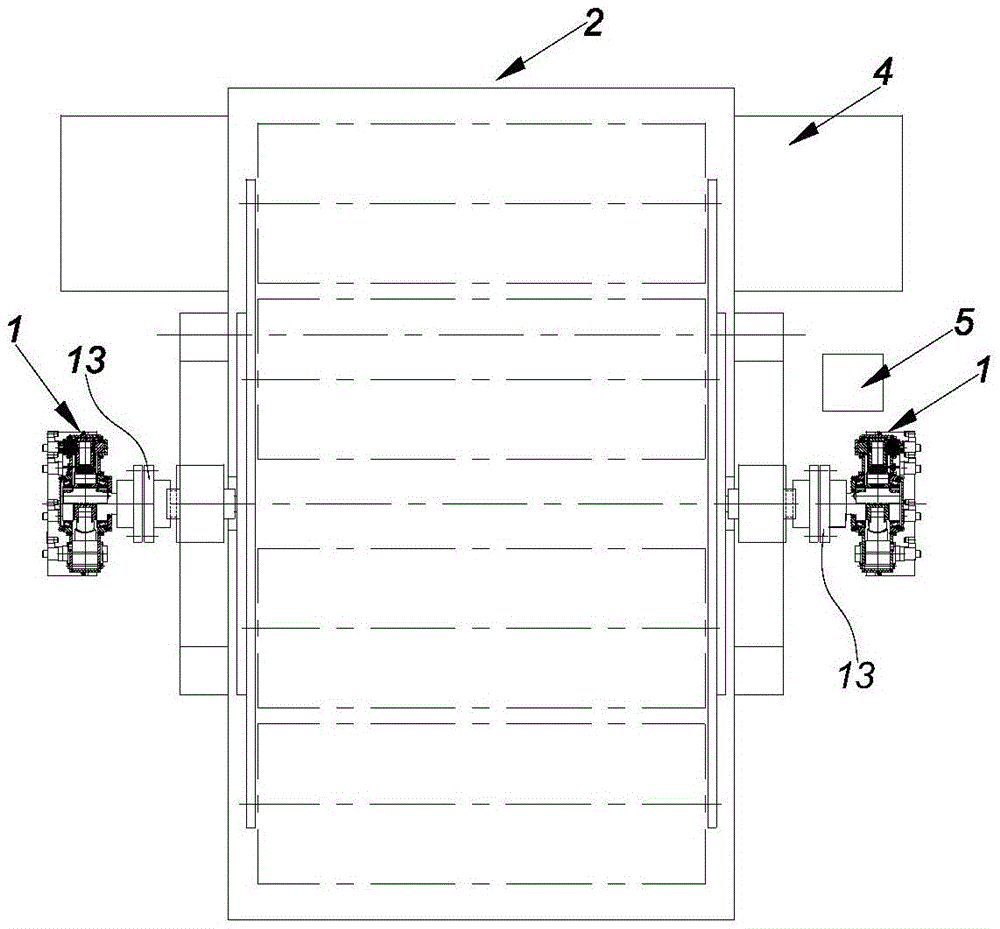

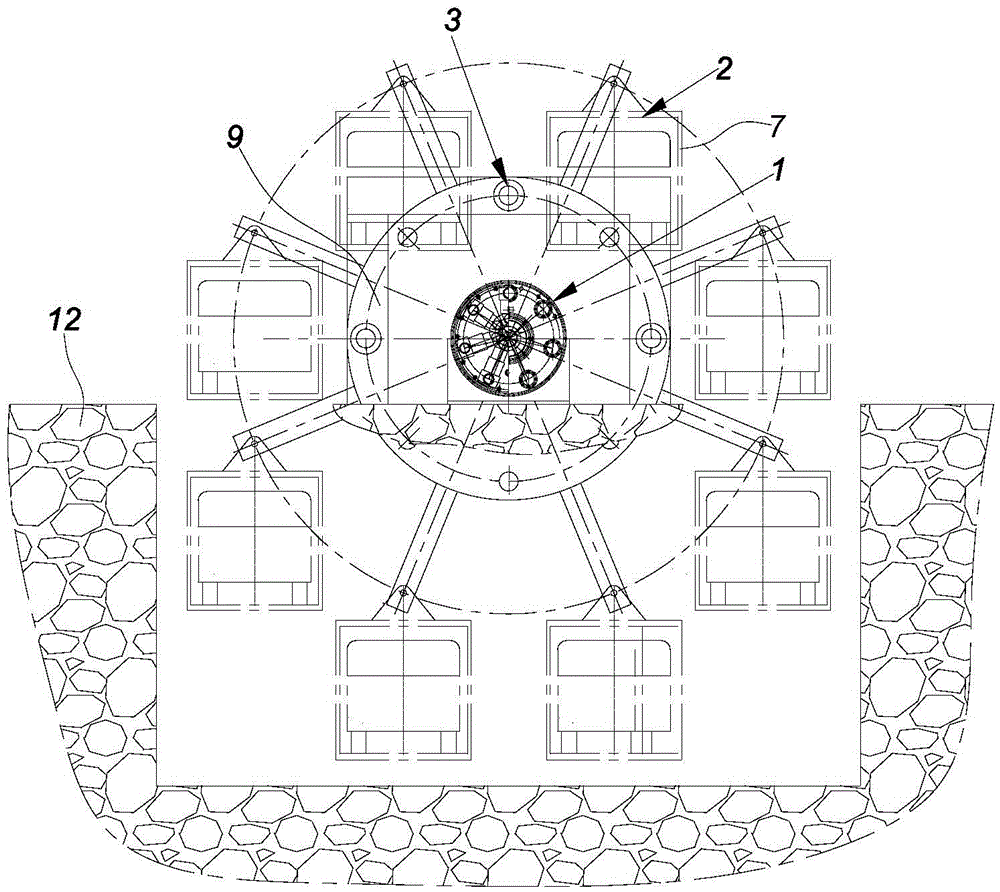

[0029] Such as figure 1 , 2 , 3, the hydraulic rotary three-dimensional garage includes an electro-hydraulic motor 1, a turntable assembly 2, a brake mechanism 3, a bridge mechanism 4 and a hydraulic system 5.

[0030] Such as figure 1 , 4 , 8, the turntable assembly 2 includes a main shaft 6, a vehicle frame assembly 7, a pull rod 8, a left disk 9 and a right disk 10, and the number of the vehicle frame assembly 7 and the pull rod 8 is eight, and each pull rod 8 passes through the left Disk 9, vehicle frame assembly 7, right disk 10 are fixed by bolts, eight vehicle frame assemblies 7 carry eight cars respectively, main shaft 6 passes through and is welded to left disk 9, right disk 10 and fixes, the two ends of main ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com