Patents

Literature

44results about How to "Various drive methods" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

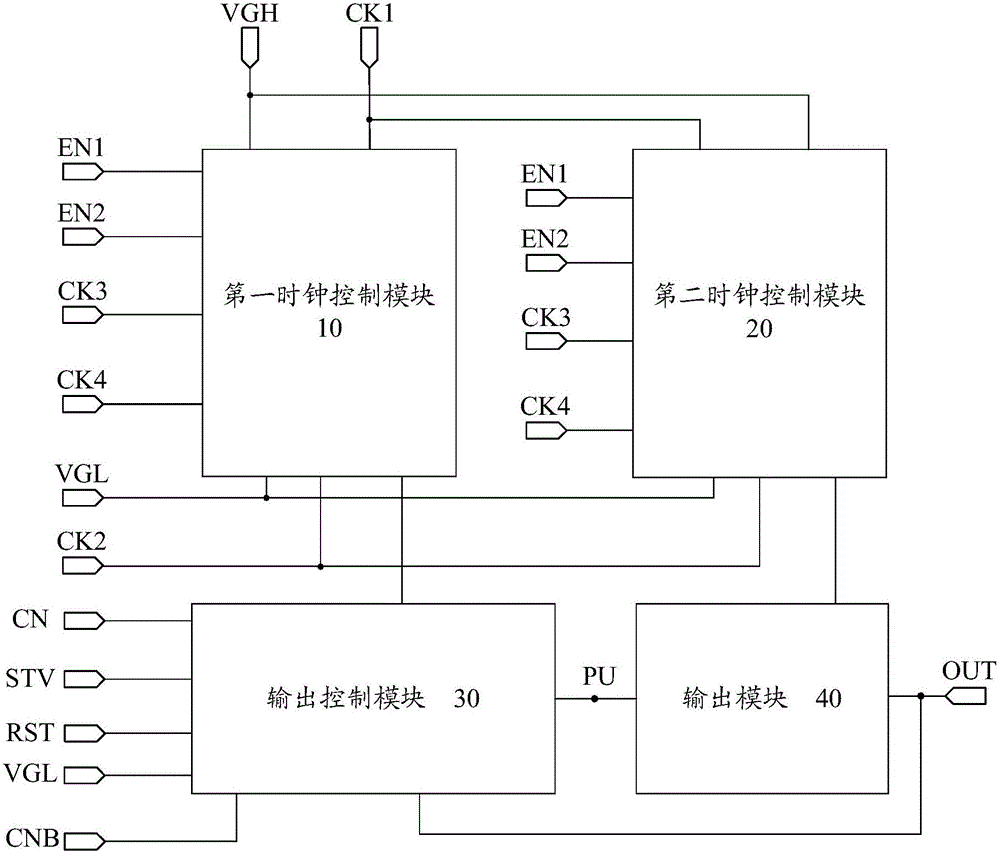

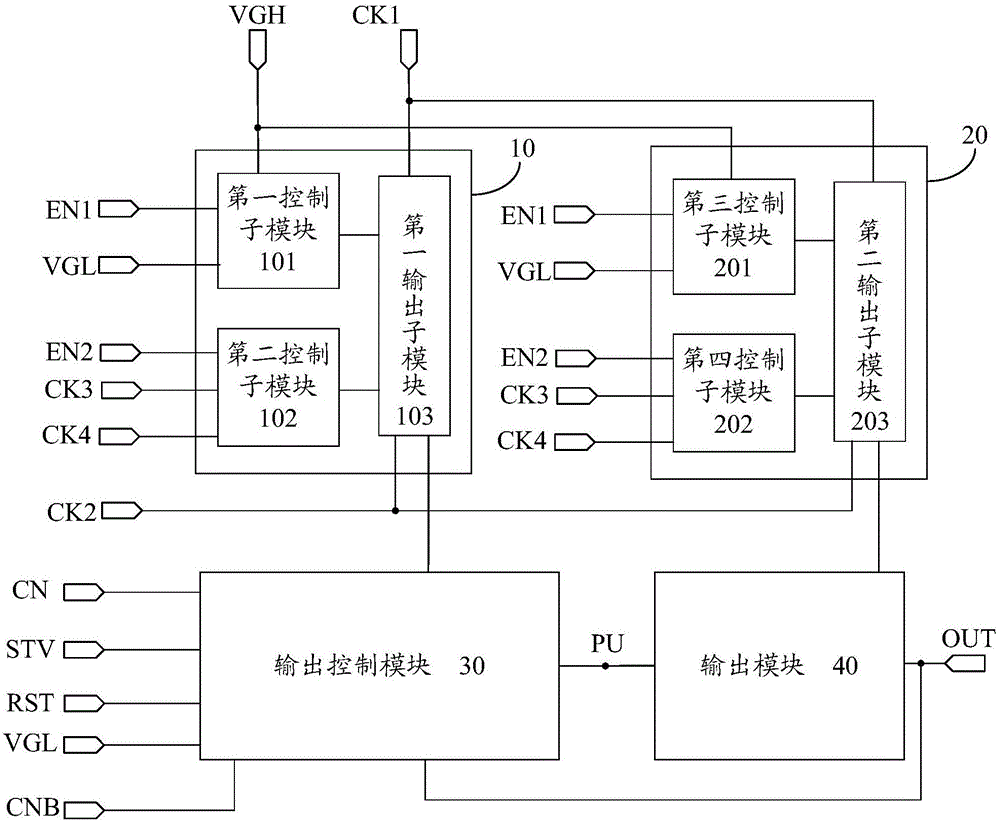

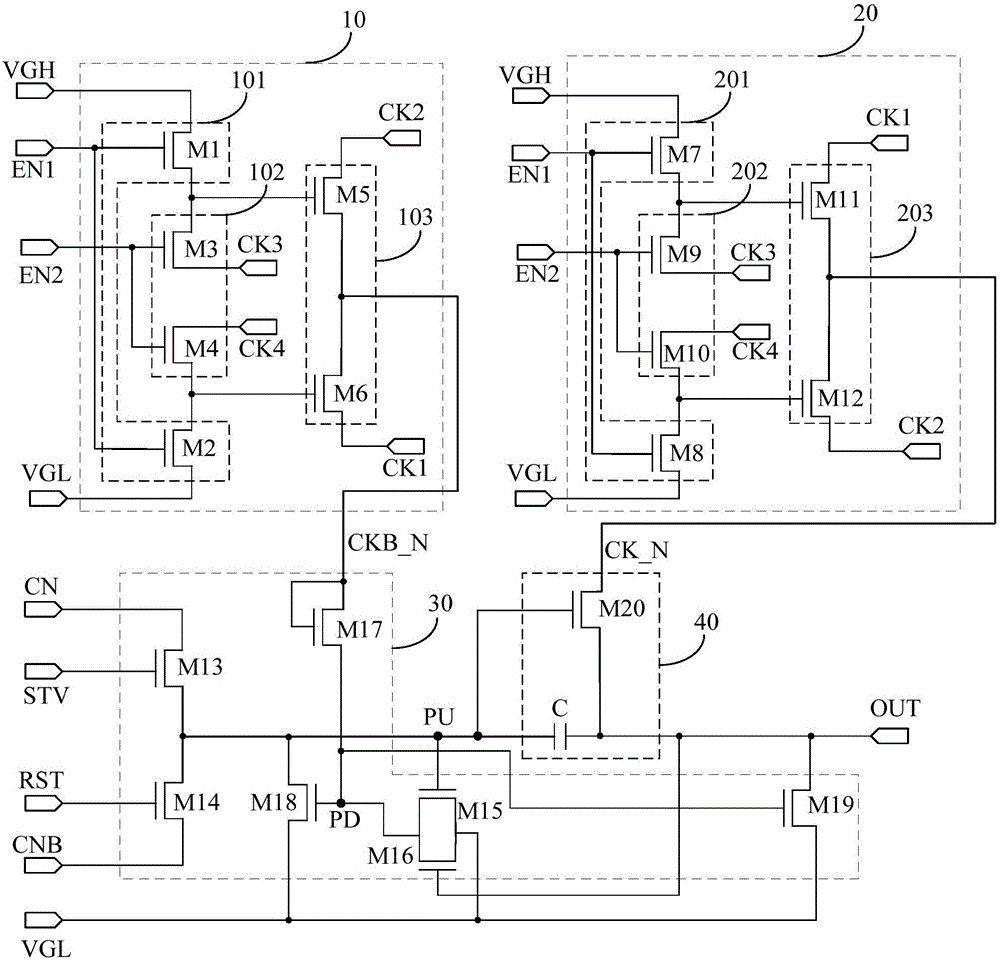

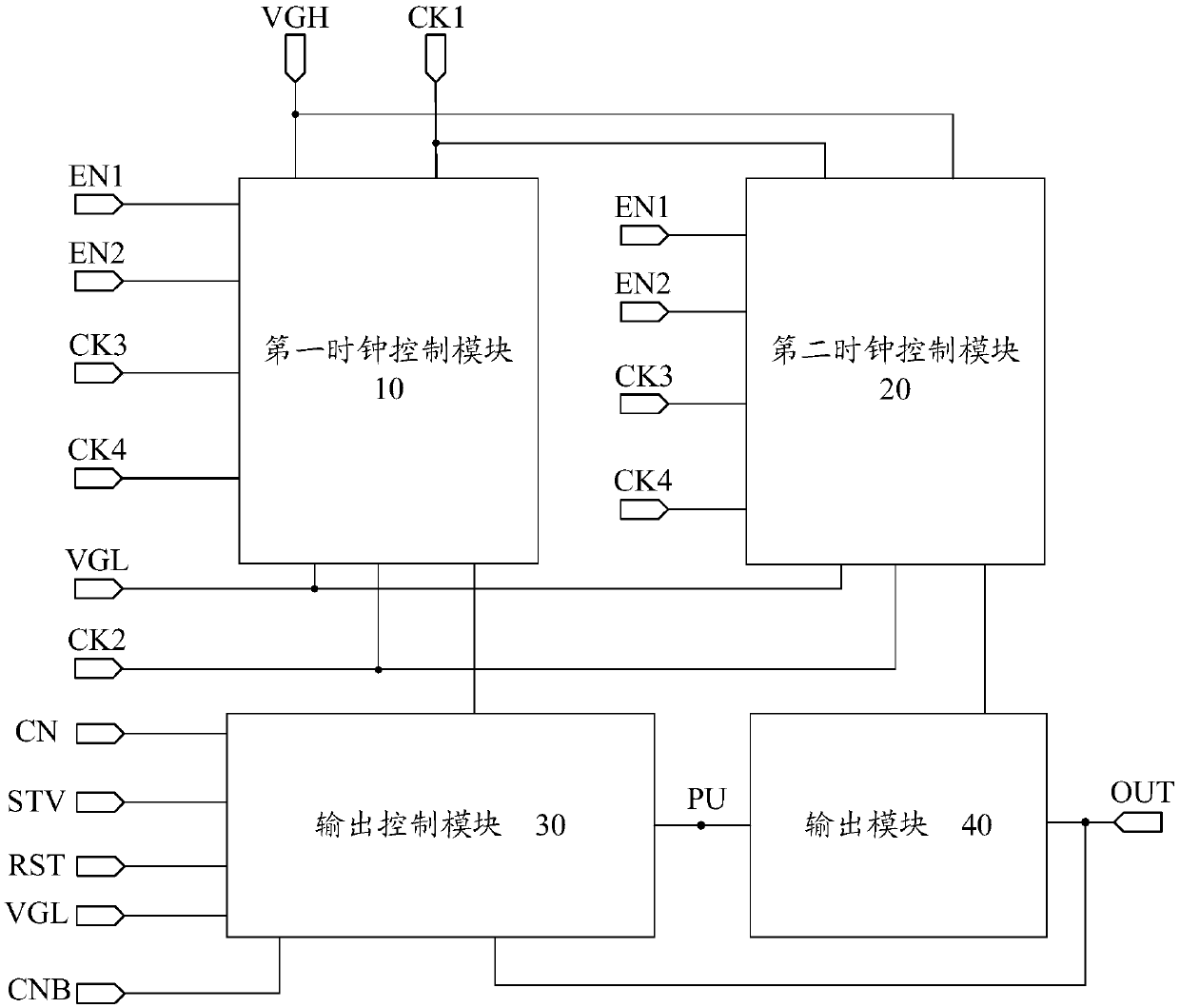

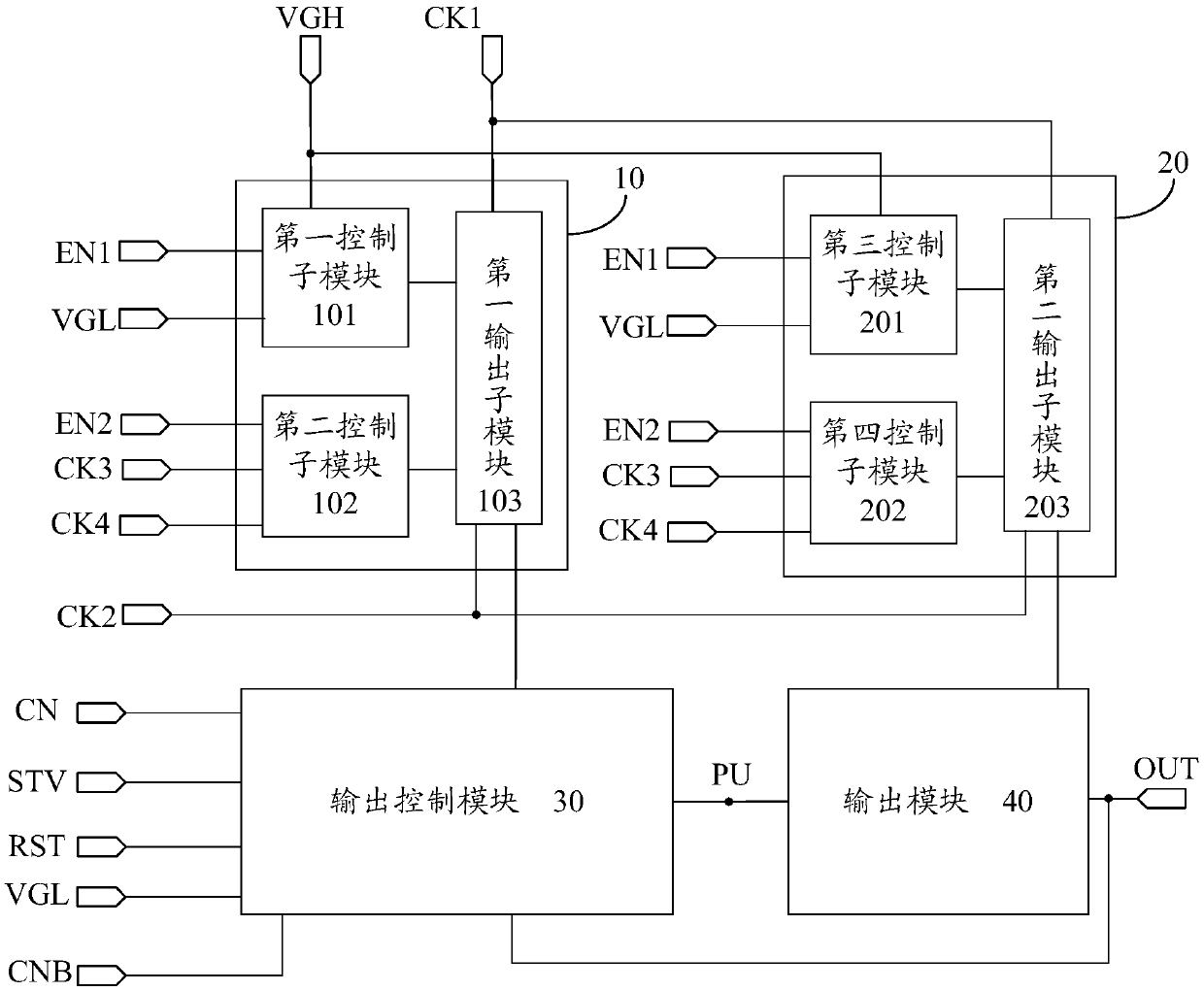

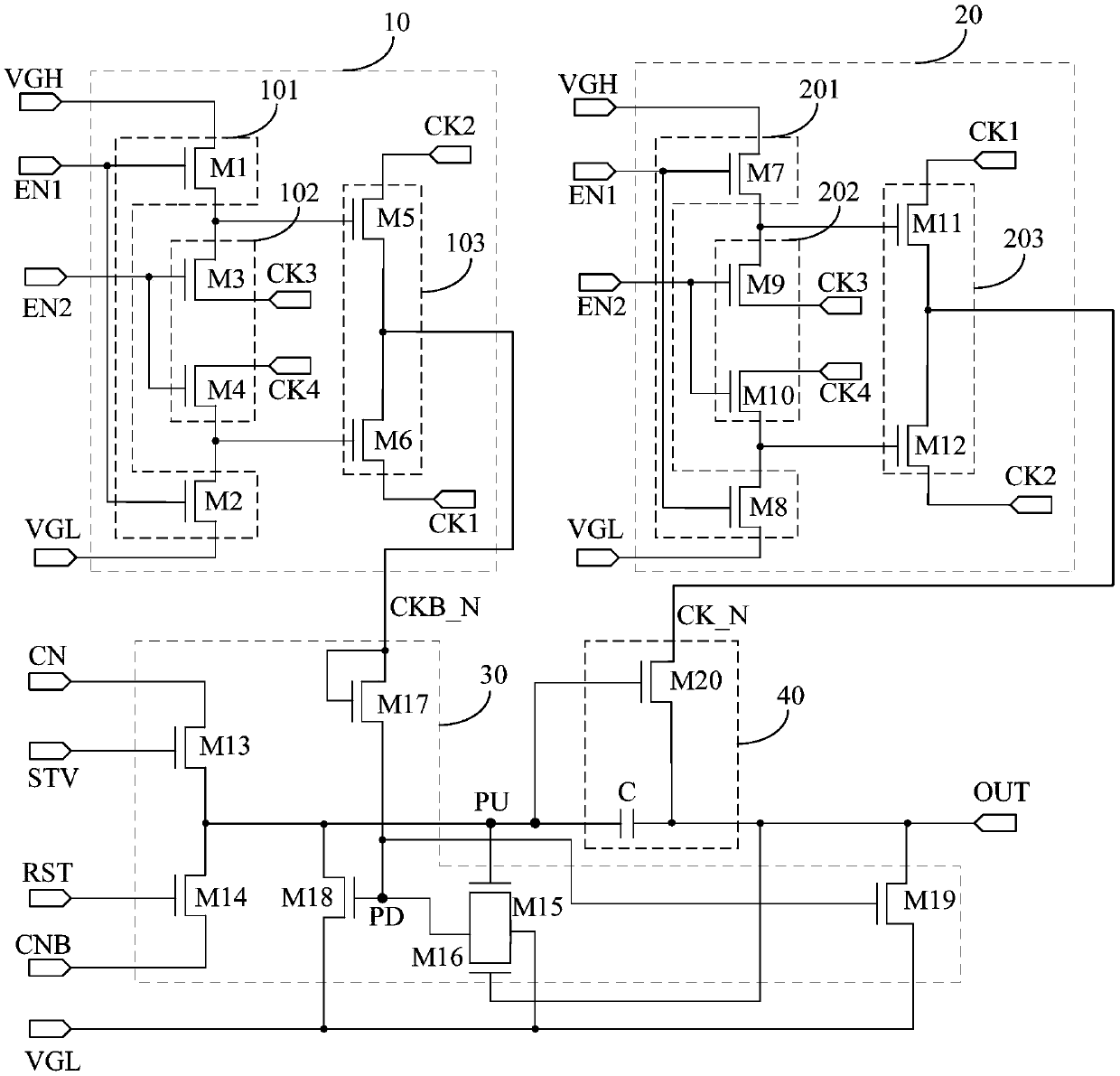

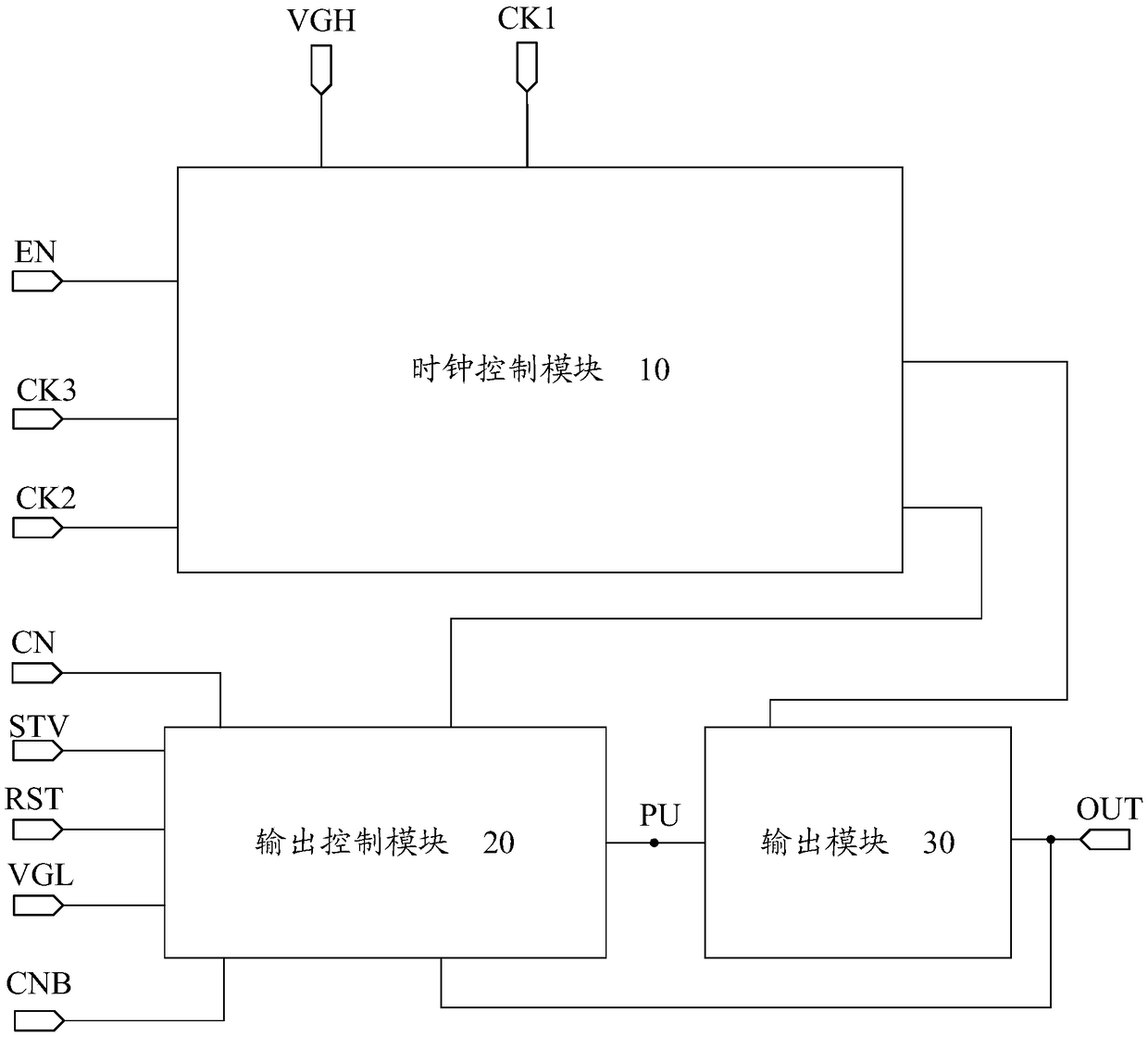

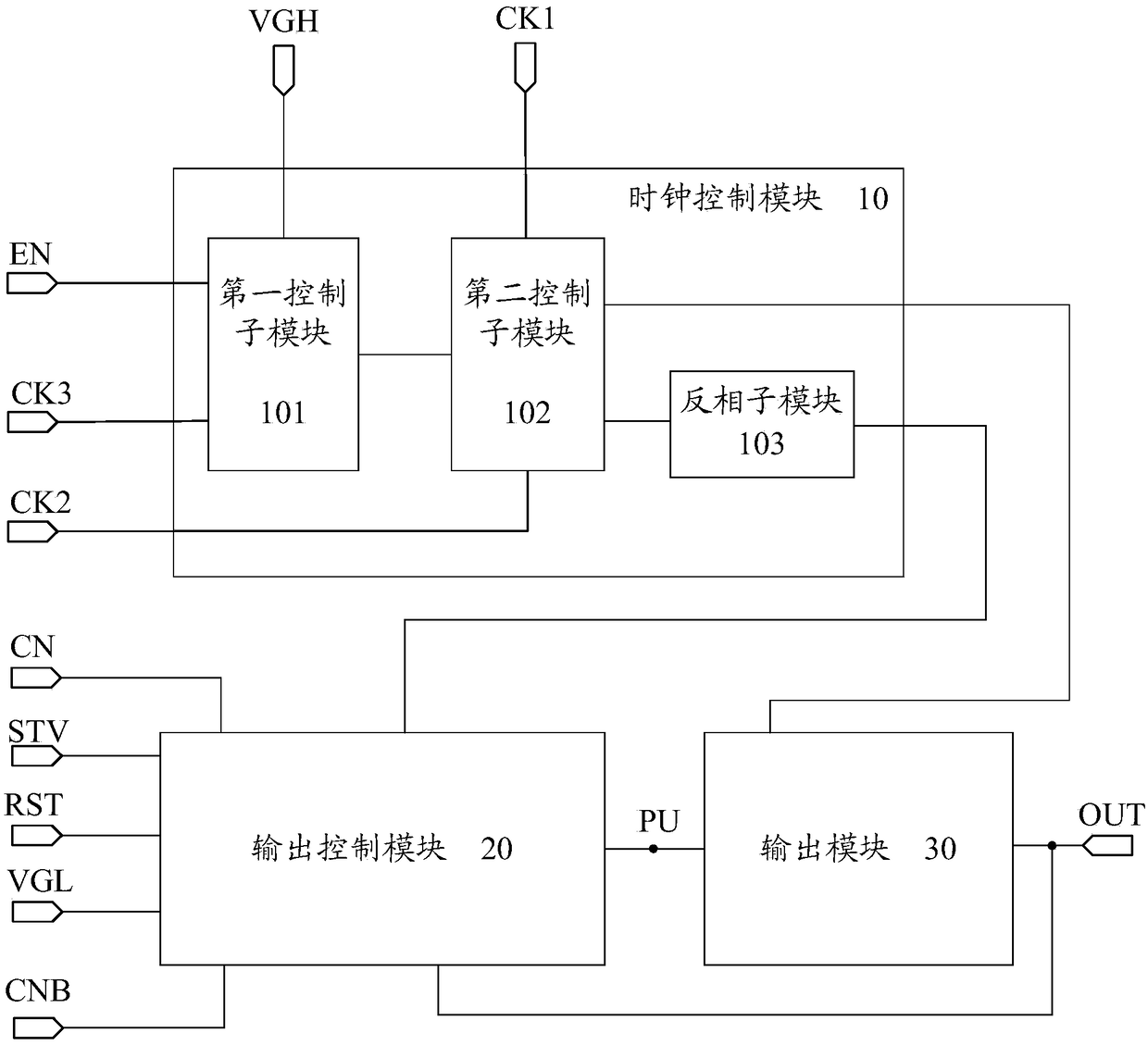

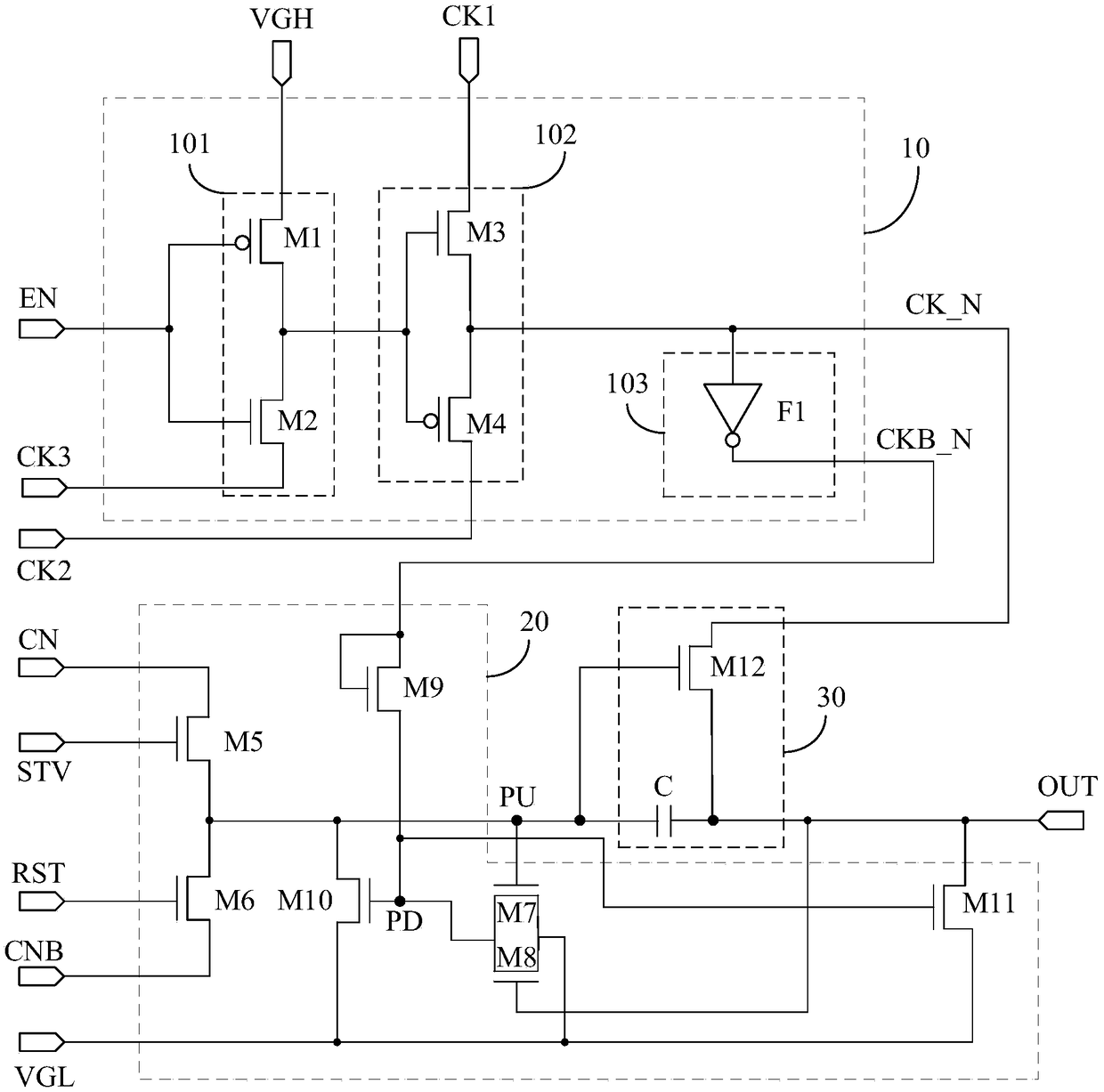

Shifting register unit, driving method, grid drive circuit and display device

ActiveCN106205461AVarious drive methodsAdjust charging timeStatic indicating devicesDigital storageShift registerDisplay device

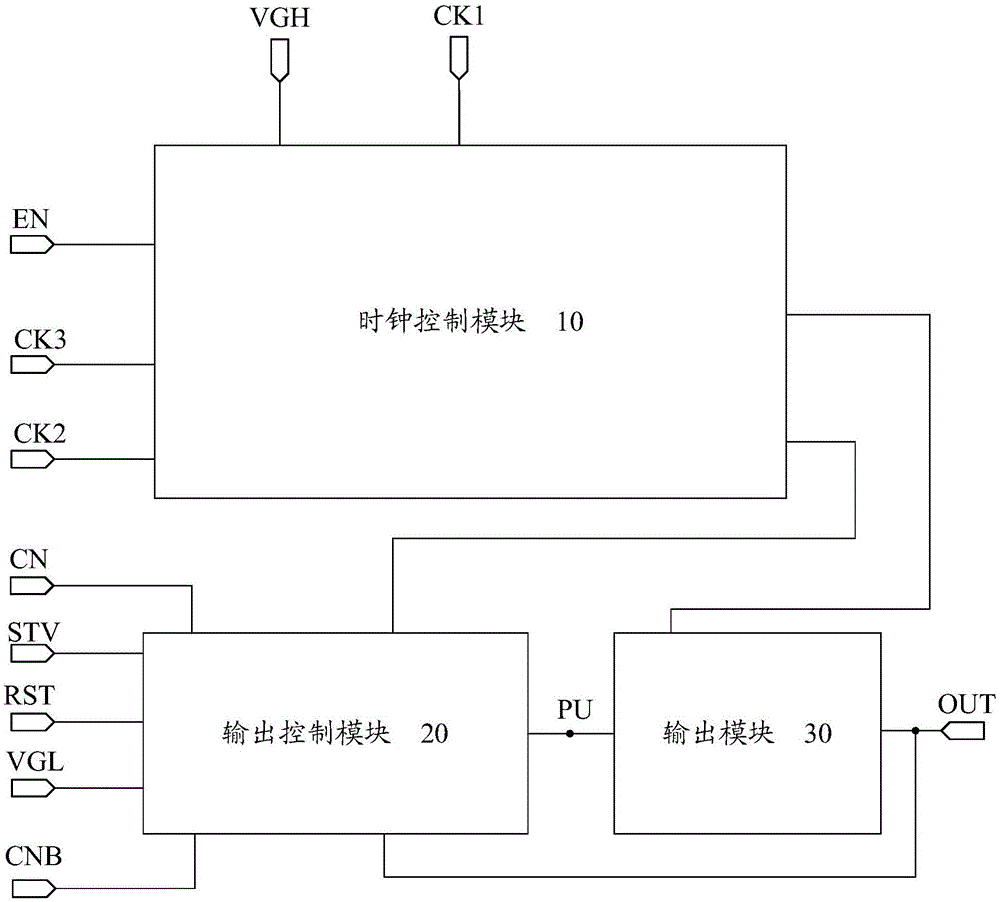

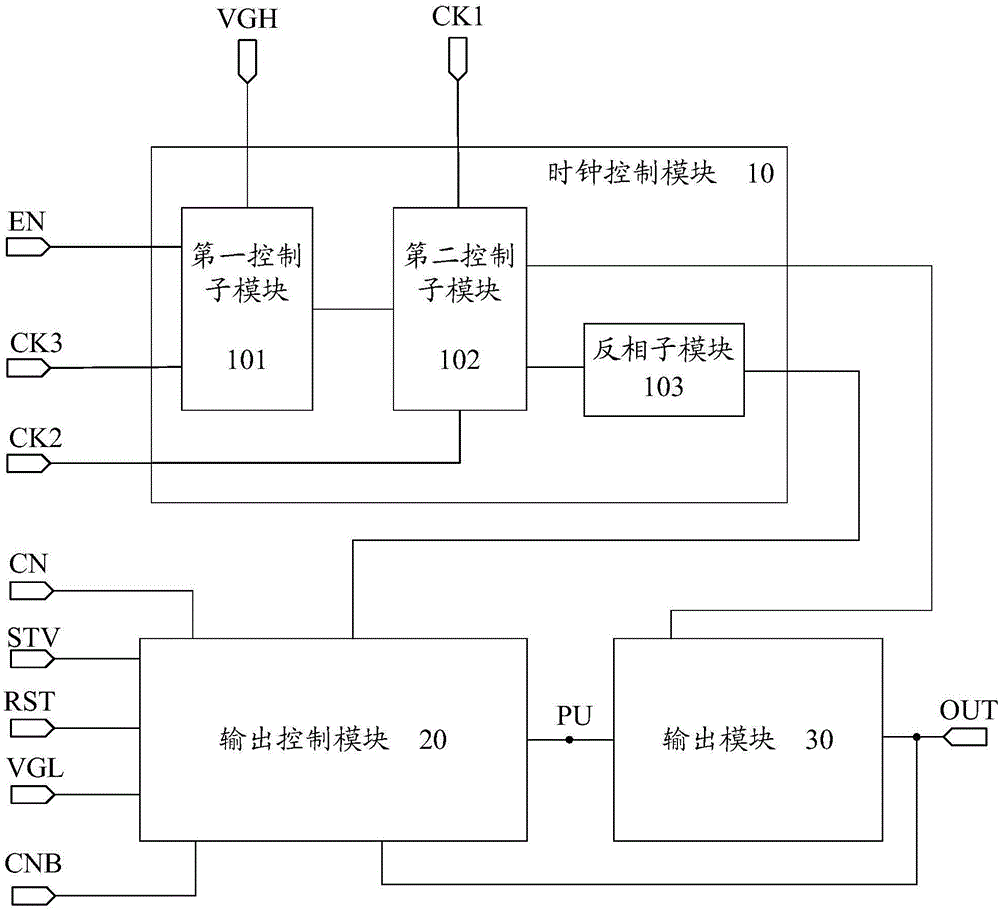

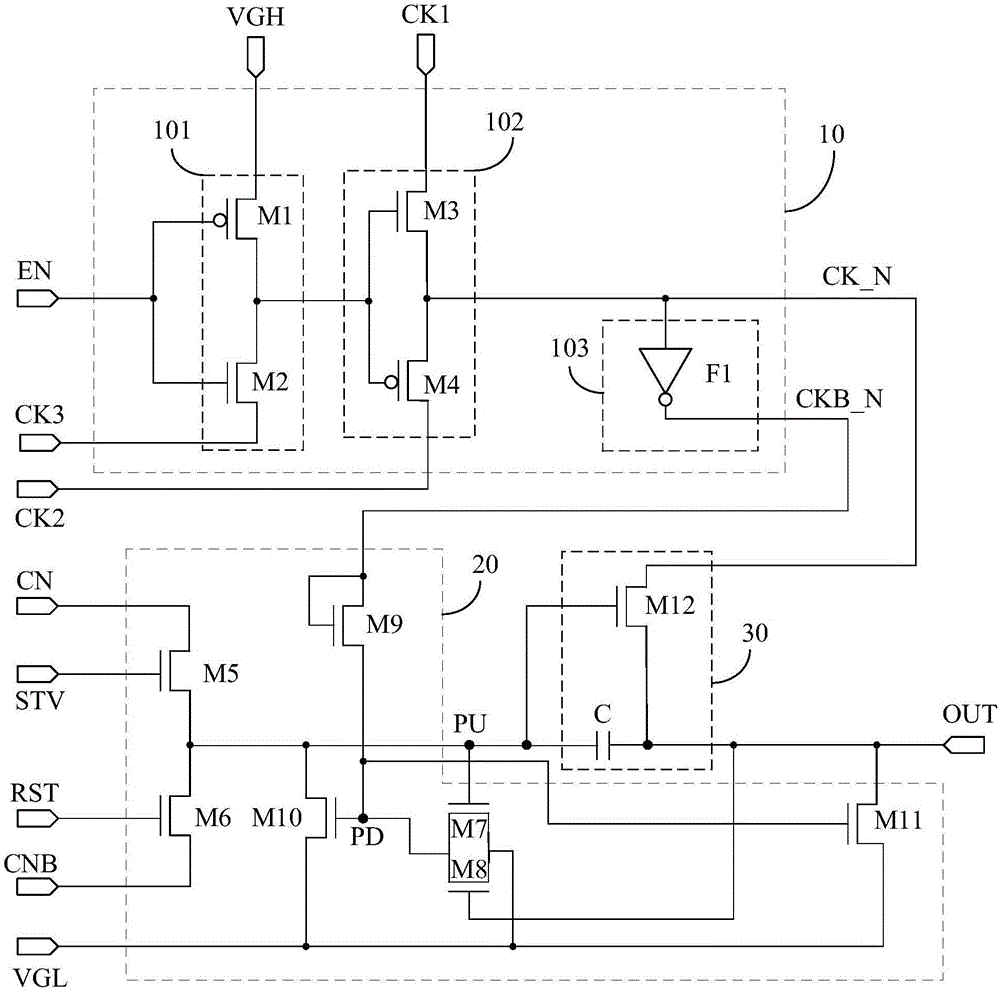

The invention discloses a shifting register unit, a driving method, a grid drive circuit and a display device, and belongs to the technical field of display. The shifting register unit comprises an output control module and an output module, and further comprises two clock control modules. Due to the two clock control modules, clock signals of different frequencies or different duty ratios can be output to the output control module and the output module, the output module can output drive signals of different frequencies or different duty ratios to a pixel unit through the output end, and then the charging time of each row of pixel units can be adjusted; accordingly, the driving modes of the grid drive circuit for the display device are enriched, the drive flexibility is improved, and the display device is used for displaying images.

Owner:BOE TECH GRP CO LTD +1

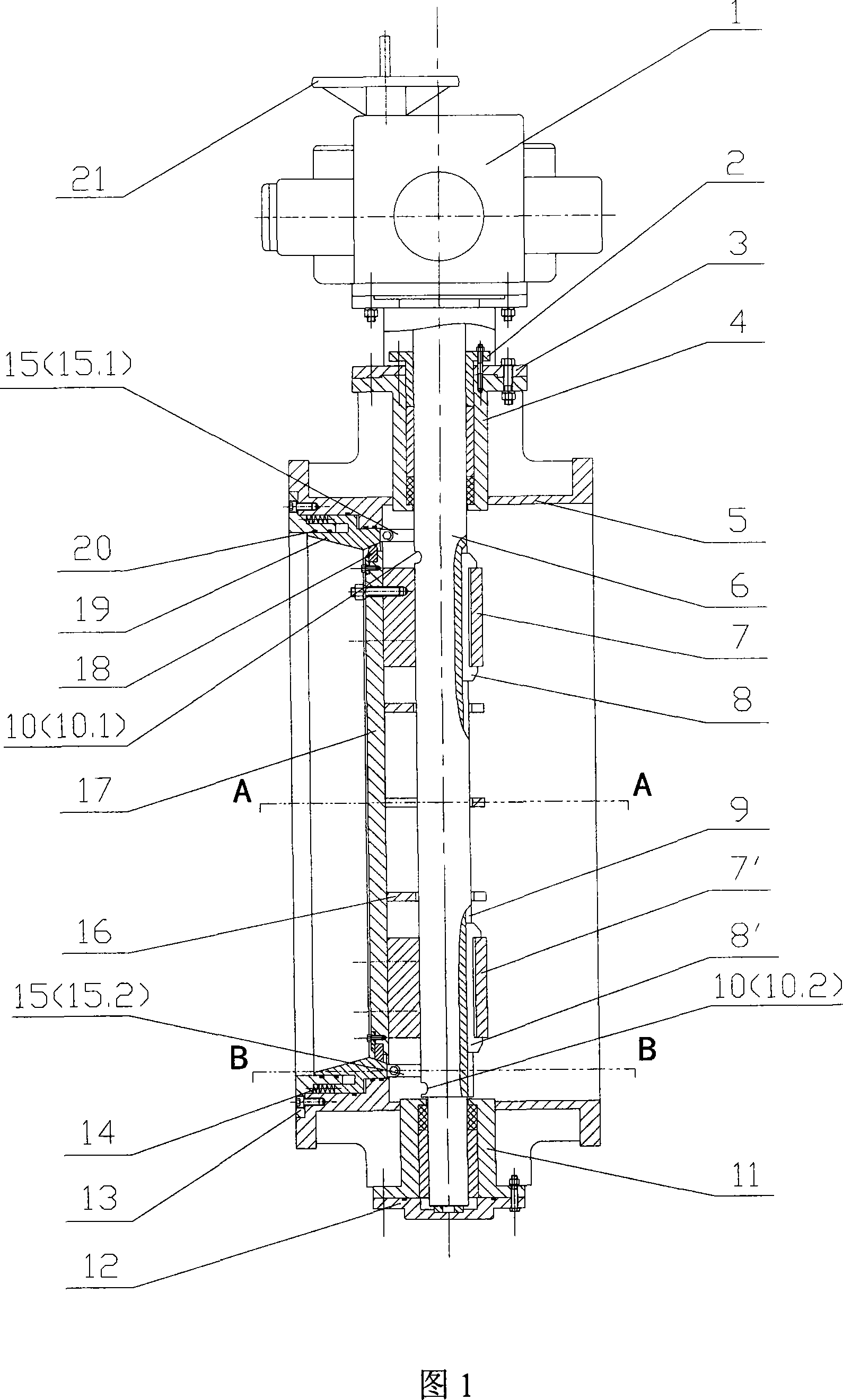

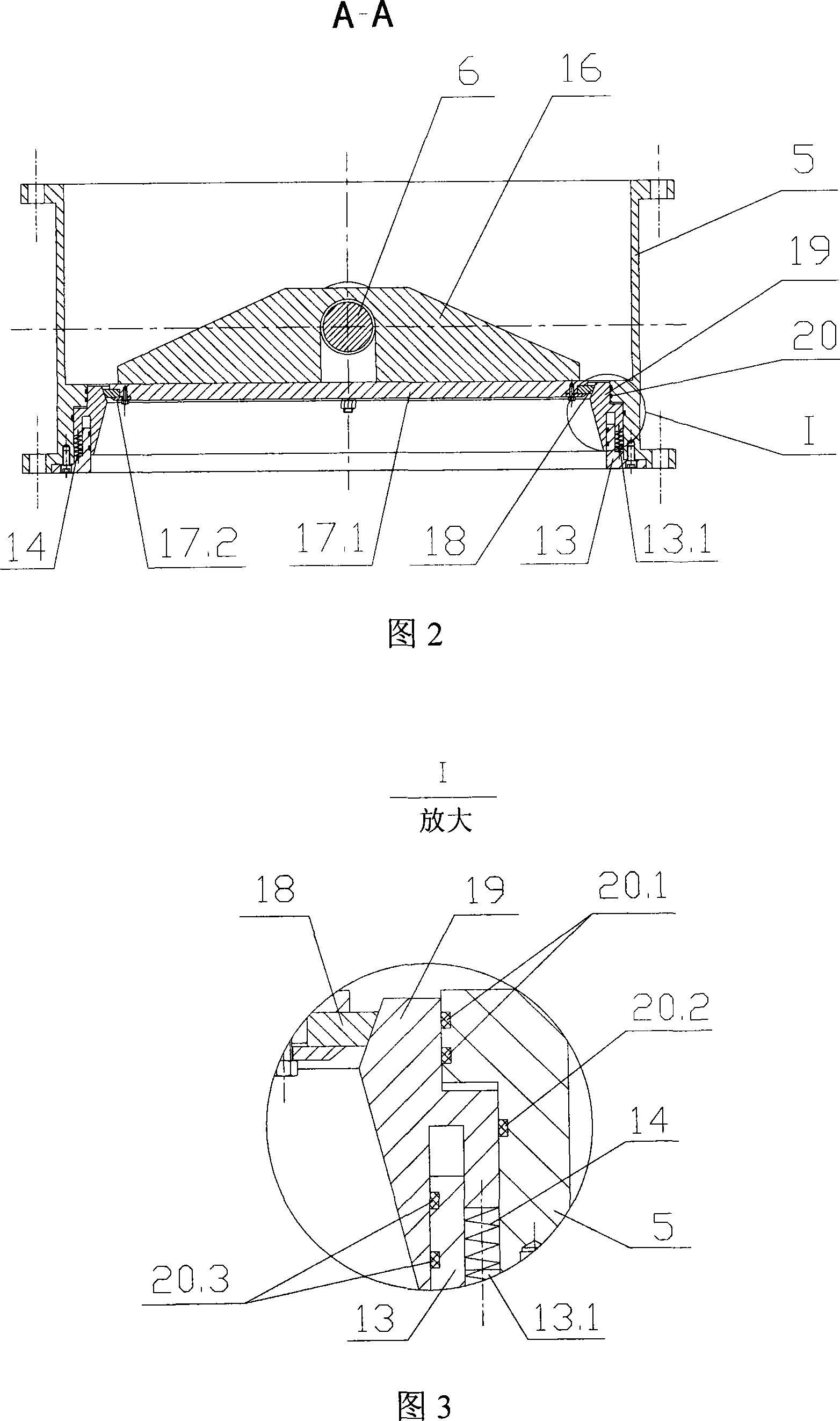

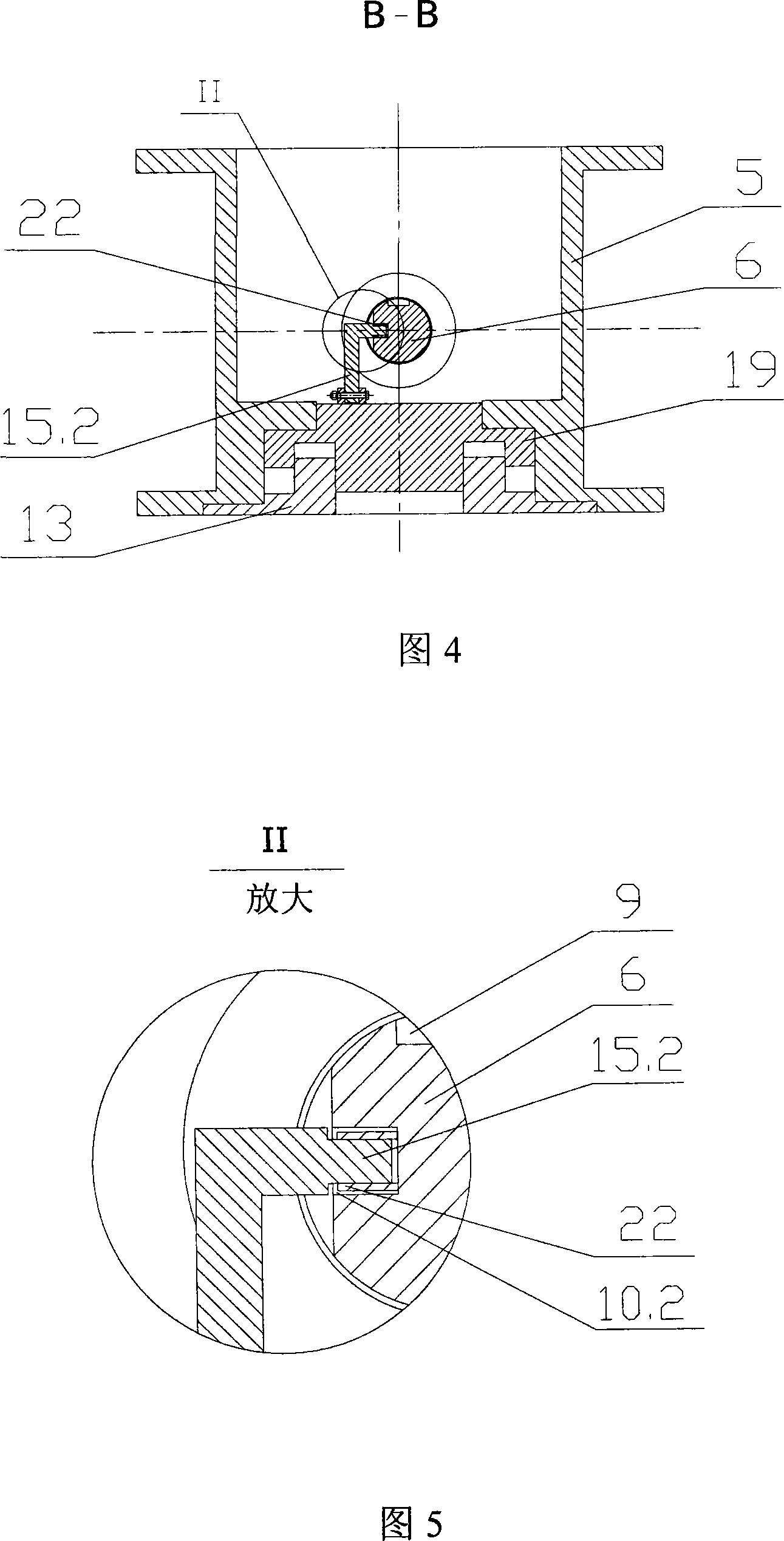

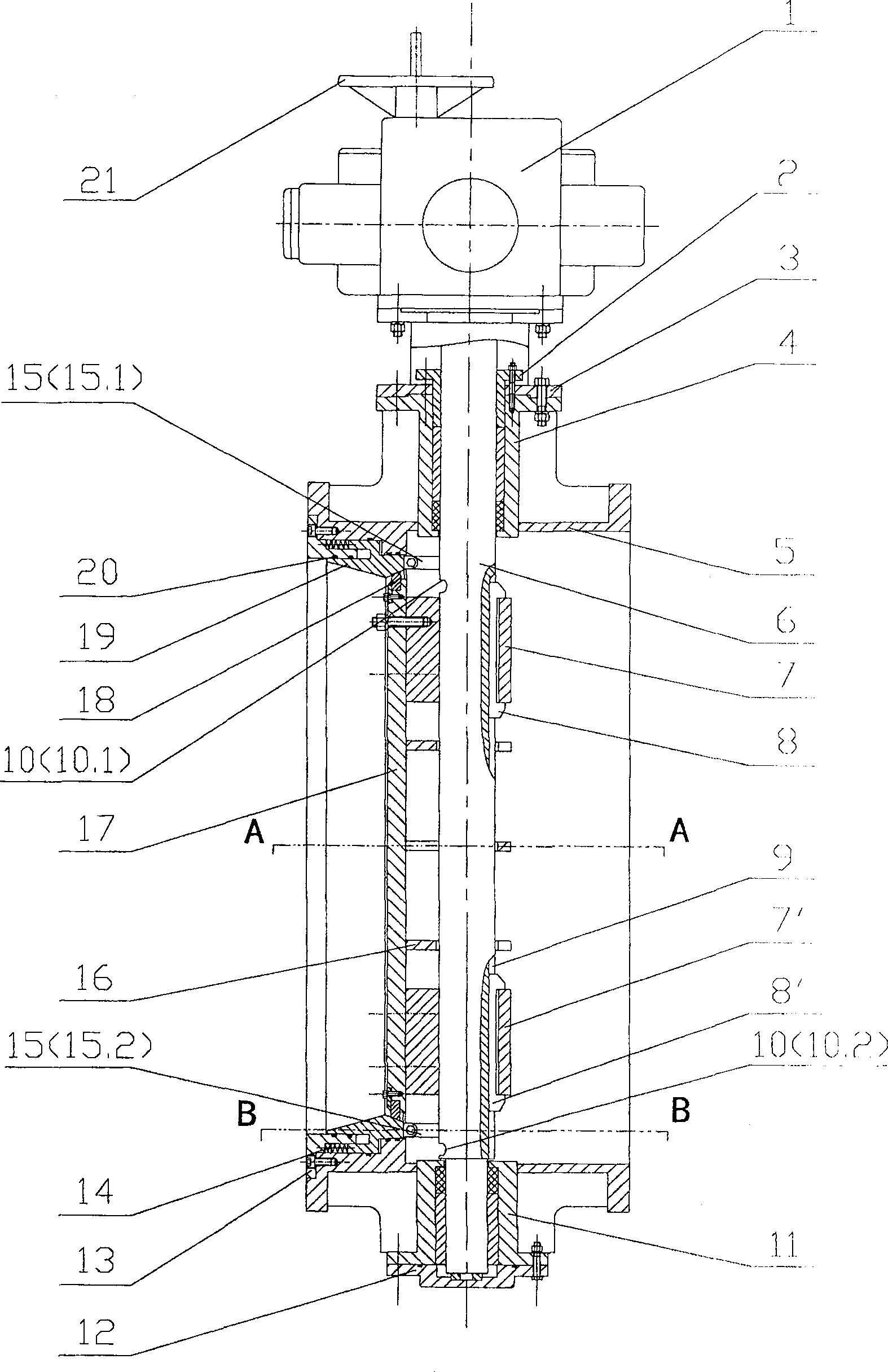

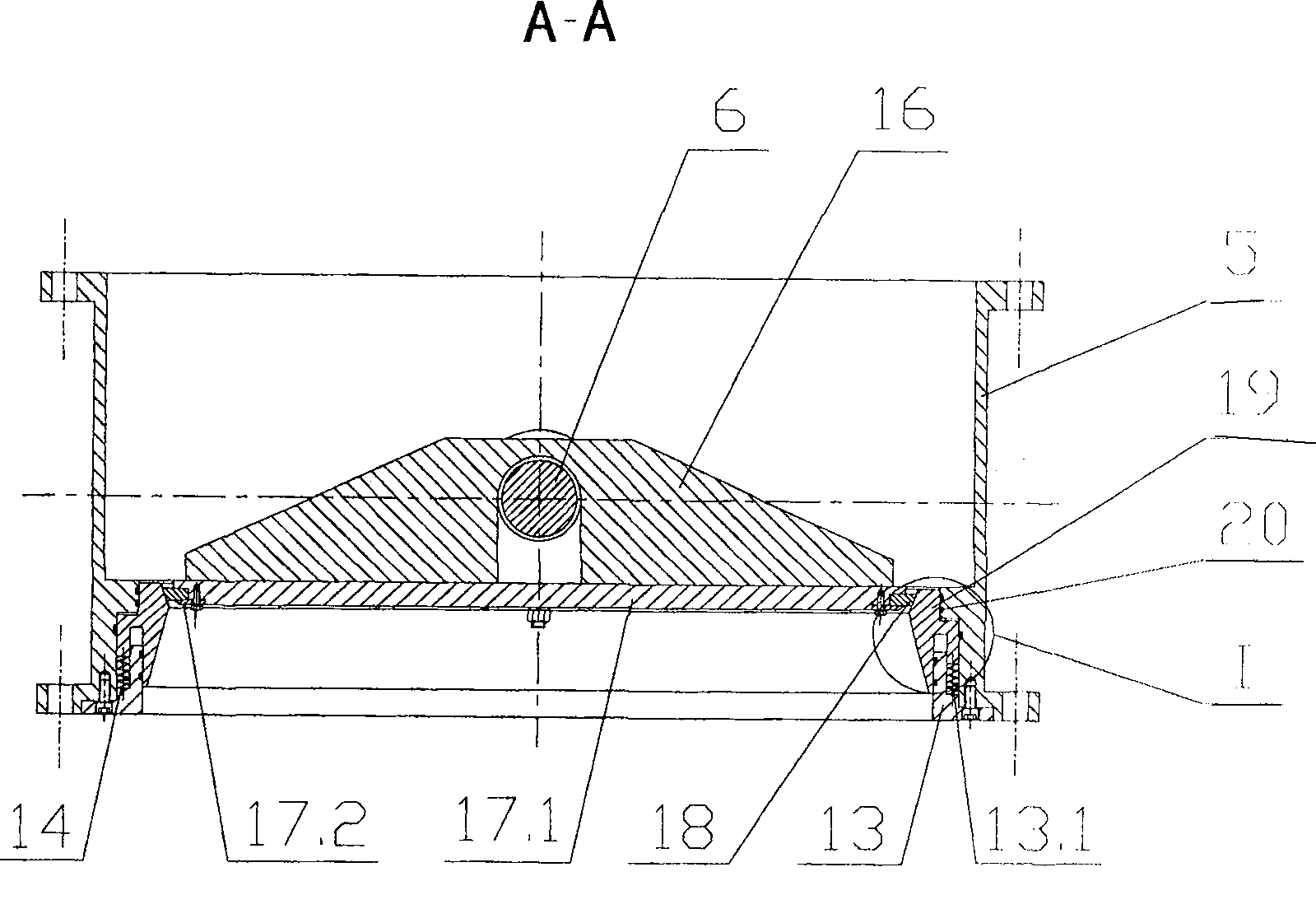

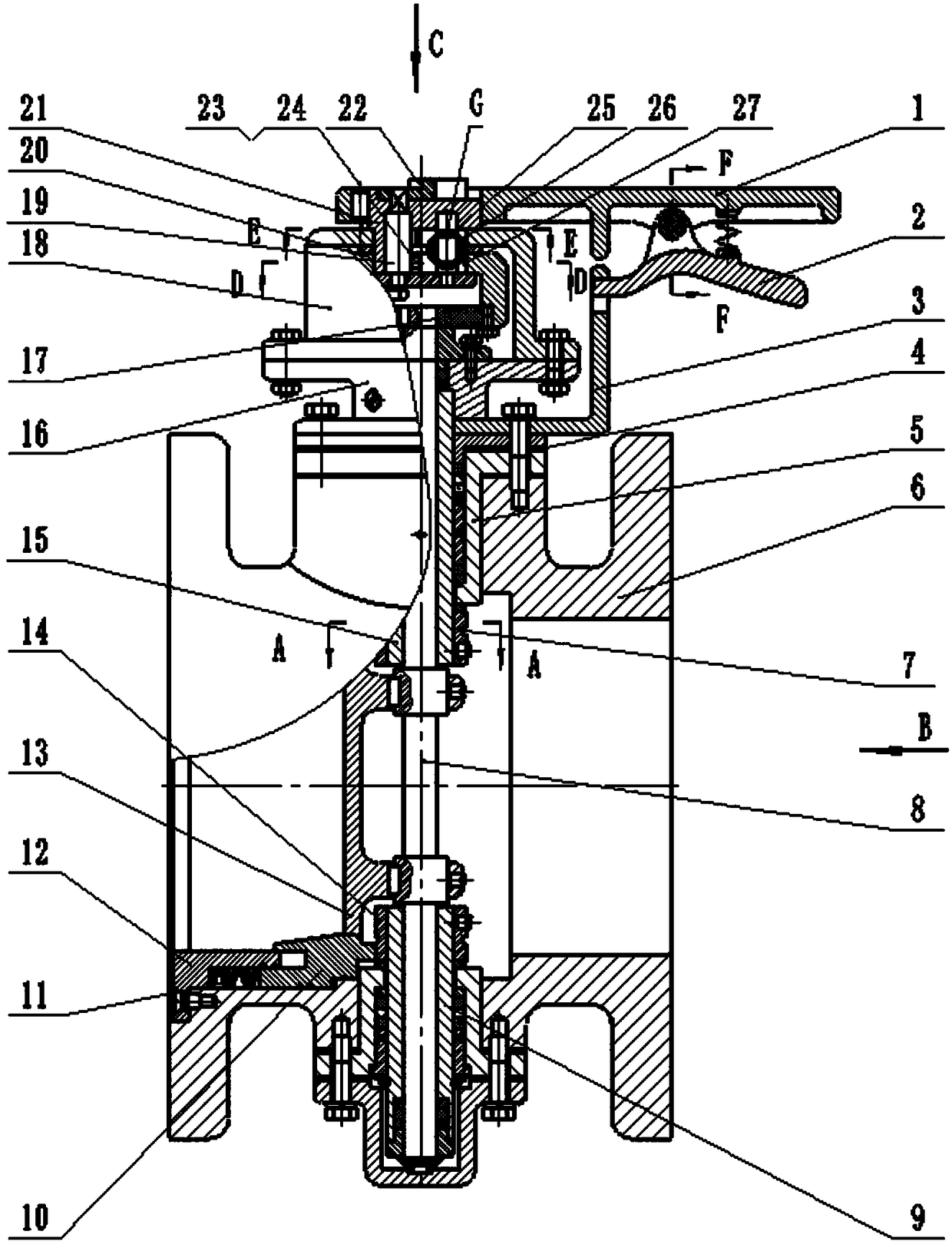

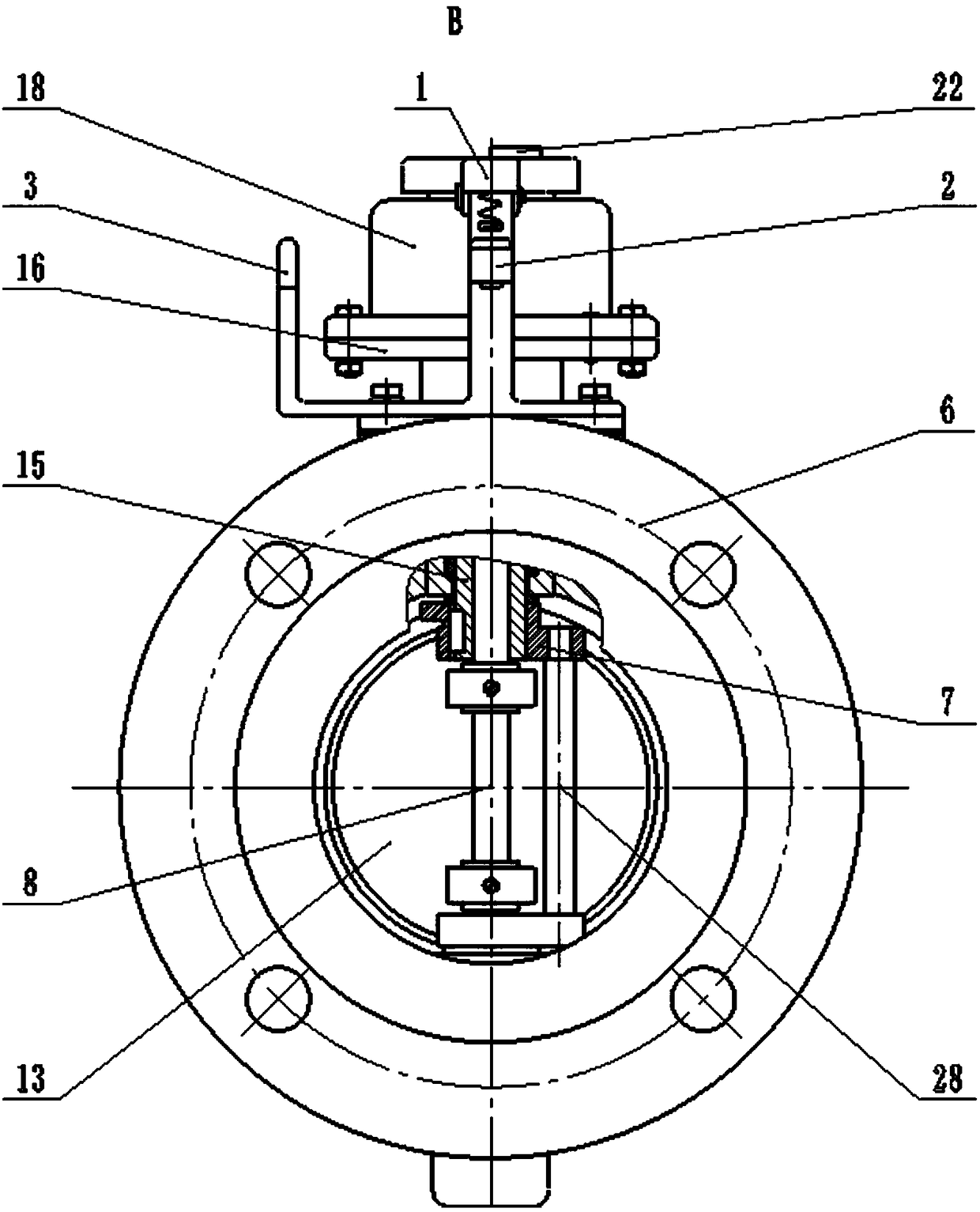

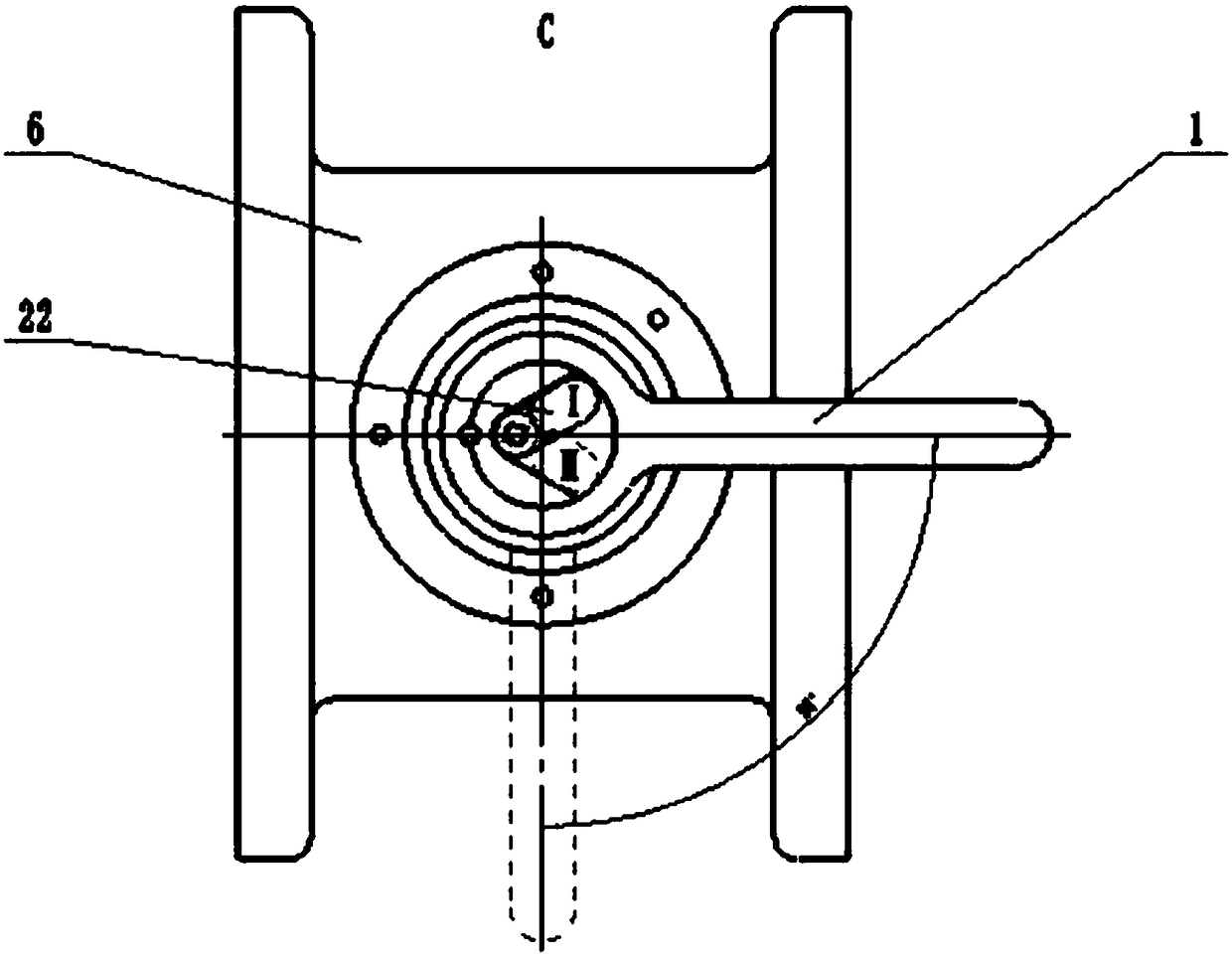

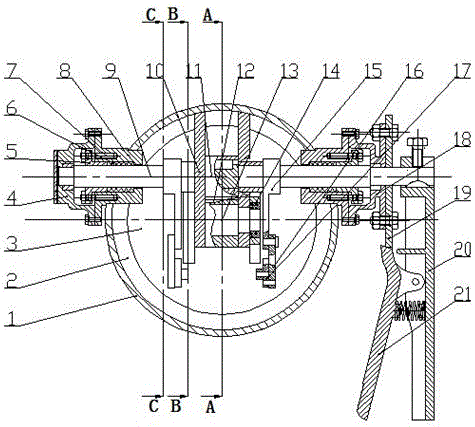

Non-abrasion hard-sealing butterfly valve

The invention relates to a non-loss hard seal butterfly valve which consists of a valve body, a valve rod, a butterfly plate and a valve seat. The invention is characterized in that the valve seat can be a movable valve seat which can axially move along the inner wall of the valve body; one side of the valve body is provided with a lateral body; seal rings are arranged both between the valve seat and the valve body, between the valve seat and the lateral body; a seal component is fixed on a butterfly plate frame; moving fit clearances are reserved between an inner side surface and an outer side surface of the valve seat, between the valve body and the lateral body; a spring is arranged between an outer end surface of the valve seat and the lateral body, an inner end surface of the valve seat is connected with the valve rod through a push rod; an inner end surface of the lateral body is provided with a spring; an upper end and a lower end of the valve rod are respectively provided with a curved slot; an upper curved slot and a lower curved slot are respectively formed by a skewed slot and an arc slot; the middle part of the valve rod is also provided with a long keyway, and an upper sliding key and a lower sliding key which are respectively fixed on an upper connecting seat and a lower connecting seat, and the upper connecting seat and the lower connecting seat are respectively fixed on the butterfly plate; the push rod consists of an upper push rod and a lower push rod, one end of the upper push rod and one end of the lower push rod are both provided with a roller, one end of the lower push rod is embedded in the lower curved slot and capable of sliding, while the other end of the lower push rod is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are symmetrically arranged; a uni-eccentric structure is formed between a butterfly plate rotating axis and a seal pair plane.

Owner:HEBEI UNIV OF TECH

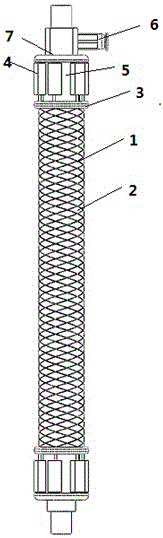

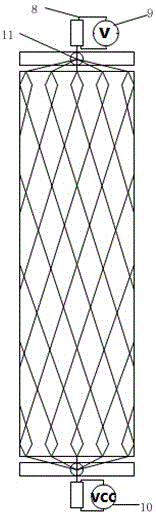

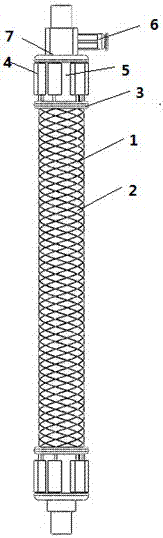

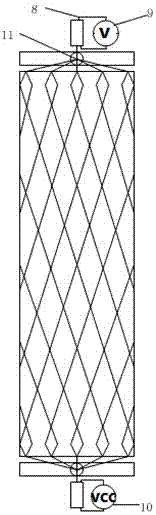

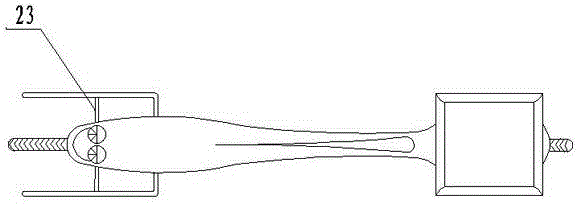

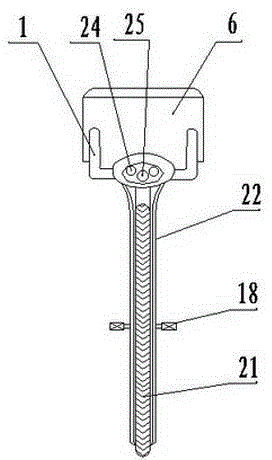

Pneumatic artificial muscle with self-sensing and driving functions

InactiveCN105856219AImprove shrinkageExpand the scope ofProgramme-controlled manipulatorFiberVoltmeter

The invention belongs to the pneumatic artificial technical field and in particular relates to a pneumatic artificial muscle with self-sensing and driving functions. The pneumatic artificial muscle comprises fibers, an elastic hose, a cylindrical sleeve pipe, a fiber collecting hoop, a fiber collecting hole, a piezoelectric body, an electrode, a sensing circuit, a drive circuit, a hoop and an air pipe joint. The pneumatic artificial muscle has the beneficial effects that via the direct piezoelectric effects of the piezoelectric body, the contractility of the fibers can be measured to obtain the external load driving force of the pneumatic muscle; meanwhile, collision of the pneumatic muscle can be self-sensed according to the real-time reading of a voltmeter; via the inverse piezoelectric effects of the piezoelectric body, the amount of contraction of the pneumatic muscle can be increased and the rigidity of the pneumatic muscle can be changed; compared with the same model of pneumatic muscle on the market, the pneumatic muscle provided by the invention can achieve the effects of detecting the external load driving force, self-sensing collision, increasing the amount of contraction of the pneumatic muscle and changing the rigidity of the pneumatic muscle; the properties of the pneumatic muscle are improved and enriched; and the pneumatic muscle has function innovation and extension and is worthy to be applied.

Owner:CHINA JILIANG UNIV

Shift register unit, driving method, gate driving circuit and display device

ActiveCN106251804AVarious drive methodsIncrease flexibilityStatic indicating devicesDigital storageDriving modeDisplay device

The invention discloses a shift register unit, a driving method, a gate driving circuit and a display device, which belongs to the technical field of display. The shift register unit comprises a clock control module, an output control module and an output module. The shift register unit can output clock signals with different frequencies or different duty ratios to the output control module and the output module through the clock control module. The output module can output driving signals with different frequencies or different duty ratios to pixel units through an output end to adjust the charging time of the shift register unit to each row of pixel units. The driving mode of the gate driving circuit to the display device is enriched. The driving flexibility is improved. The shift register unit, the driving method, the gate driving circuit and the display device are used for displaying images.

Owner:BOE TECH GRP CO LTD +1

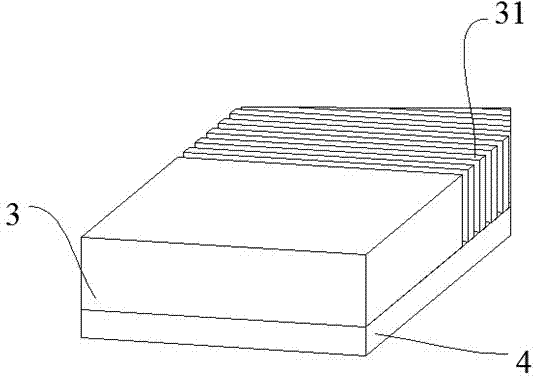

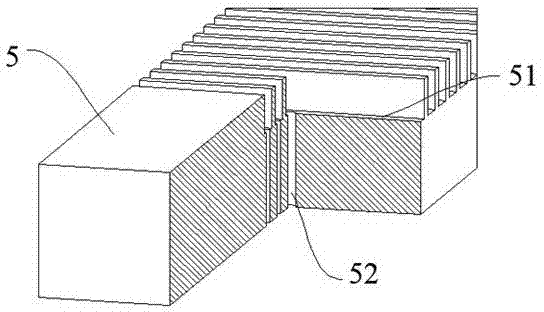

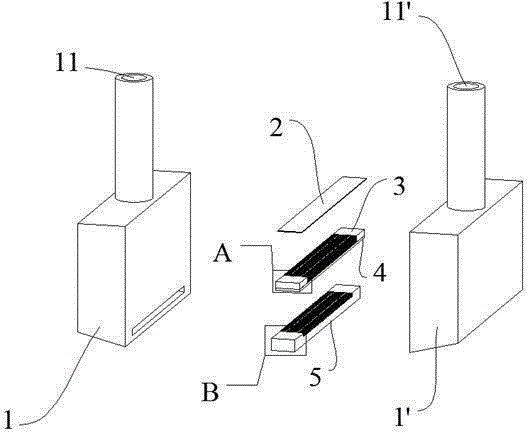

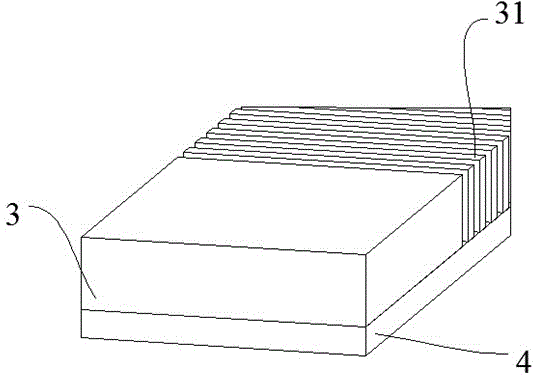

Ink-jet printing head and ink-jet printer

ActiveCN103496257ABraking structure is simpleLarge amount of deformationInking apparatusEngineeringActuator

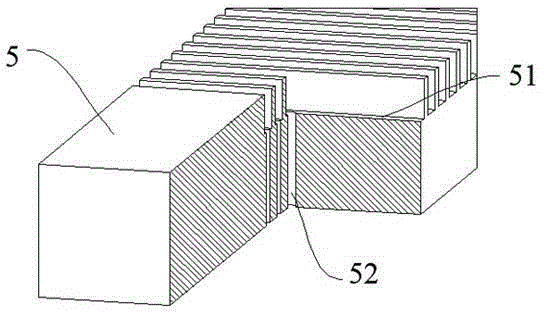

The invention discloses an ink-jet printing head which comprises at least one jetting unit, a cover film, a piezoelectric ceramic actuator, a cover plate, a fluid inflowing pipeline, a fluid outflowing pipeline and a driving circuit device. The cover film, the piezoelectric ceramic actuator and the cover plate are matched with the jetting unit, the piezoelectric ceramic actuator and the cover plate are connected to form a plurality of disconnected and independent piezoelectric ceramic units, the cover plate is connected with the jetting unit, a plurality of fluid grooves are formed in the position, arranged on one side of the jetting unit, of the connecting contact face, the piezoelectric ceramic units correspond to grooves in the fluid grooves in position, the fluid grooves and the cover plate form a fluid channel, each fluid channel is correspondingly provided with at least one nozzle to be communicated with the exterior, and therefore the ink-jet printing head forms the side face or end face jetting. Correspondingly, the invention further discloses an ink-jet printer. According to the ink-jet printing head and the ink-jet printer, on the premise that the deformation amount of the piezoelectric ceramic actuator can be increased, and the effective jetting motion of the large-particle-size ink is achieved, the adjacent nozzles can conduct simultaneous motion, therefore all the nozzles can work at the same time, and the working efficiency is improved.

Owner:广东金刚新材料有限公司 +2

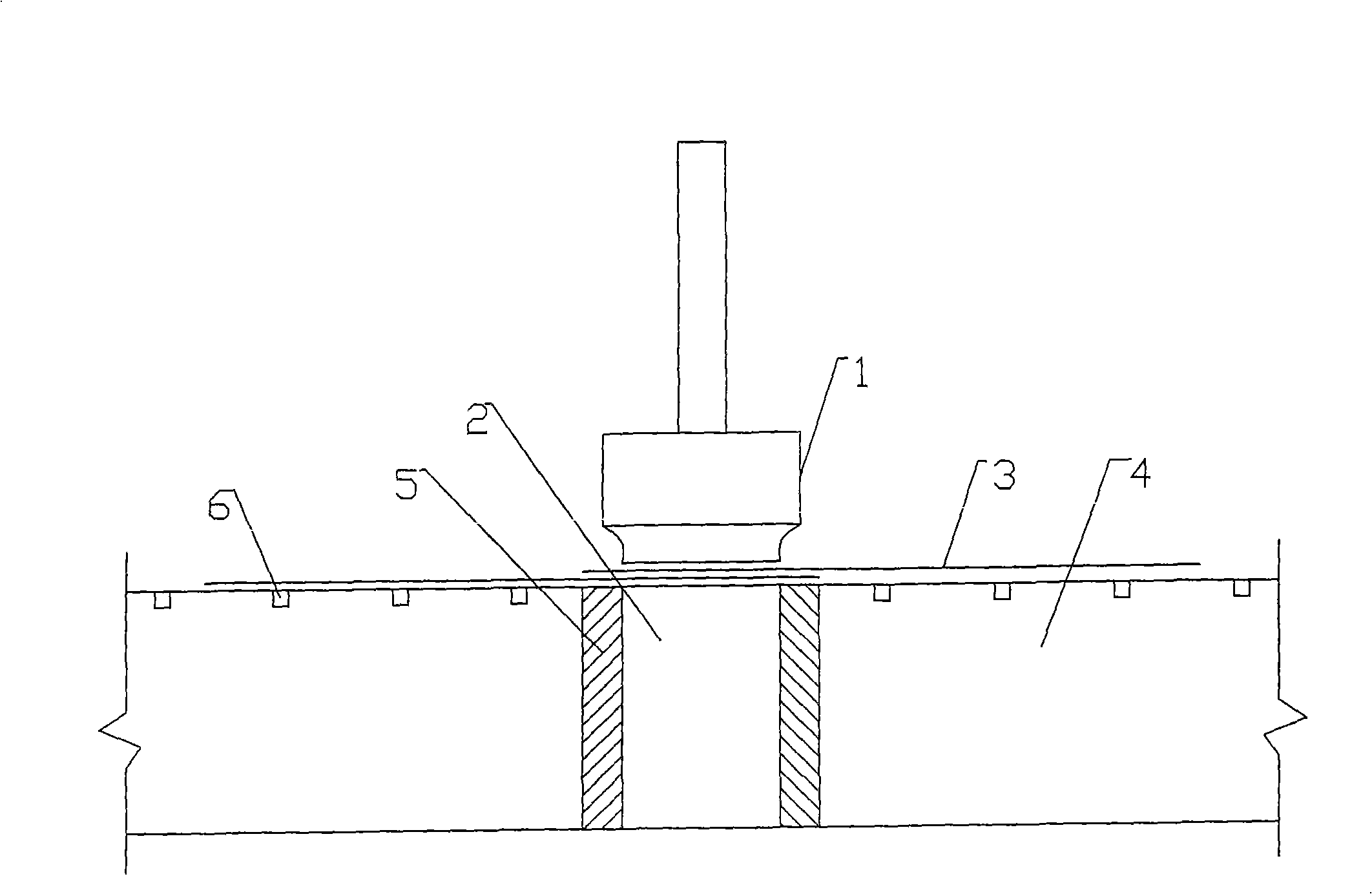

Plastic film welding device

InactiveCN101407111ASuitable for weldingEvenly balanced weldingFlat articlesTetrafluoroethyleneWeld seam

The invention discloses a plastic film welding device. The device comprises a heating plate driven by a driver, a heating electrode matched with the heating plate and two working platforms for loading plastic films, wherein the heating electrode is arranged between two working platforms, the heating plate is arranged above the heating electrode. The device can be used for welding common plastic films and particularly for welding ethylene-tetrafluoroethylene copolymer films, increase the strength of welding seams of the welded ethylene-tetrafluoroethylene copolymer films to bigger than that of the ethylene-tetrafluoroethylene copolymer films and increase the connection firmness and safety.

Owner:四川蒙特工程建设有限公司

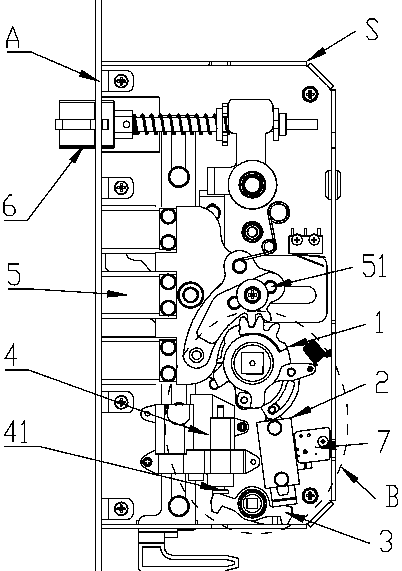

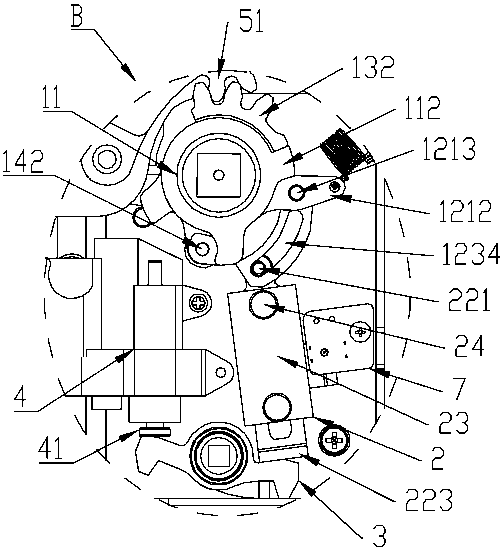

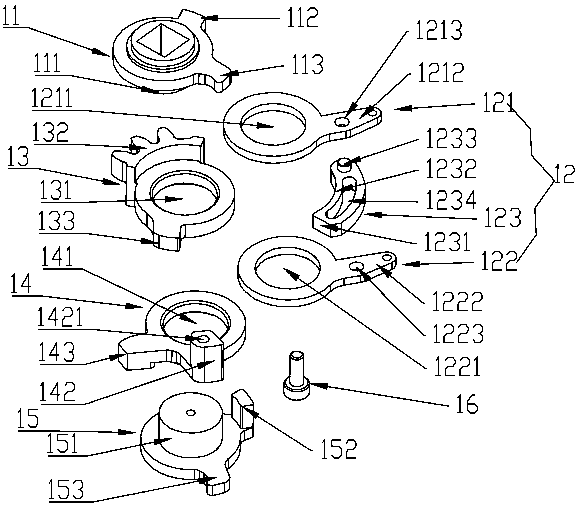

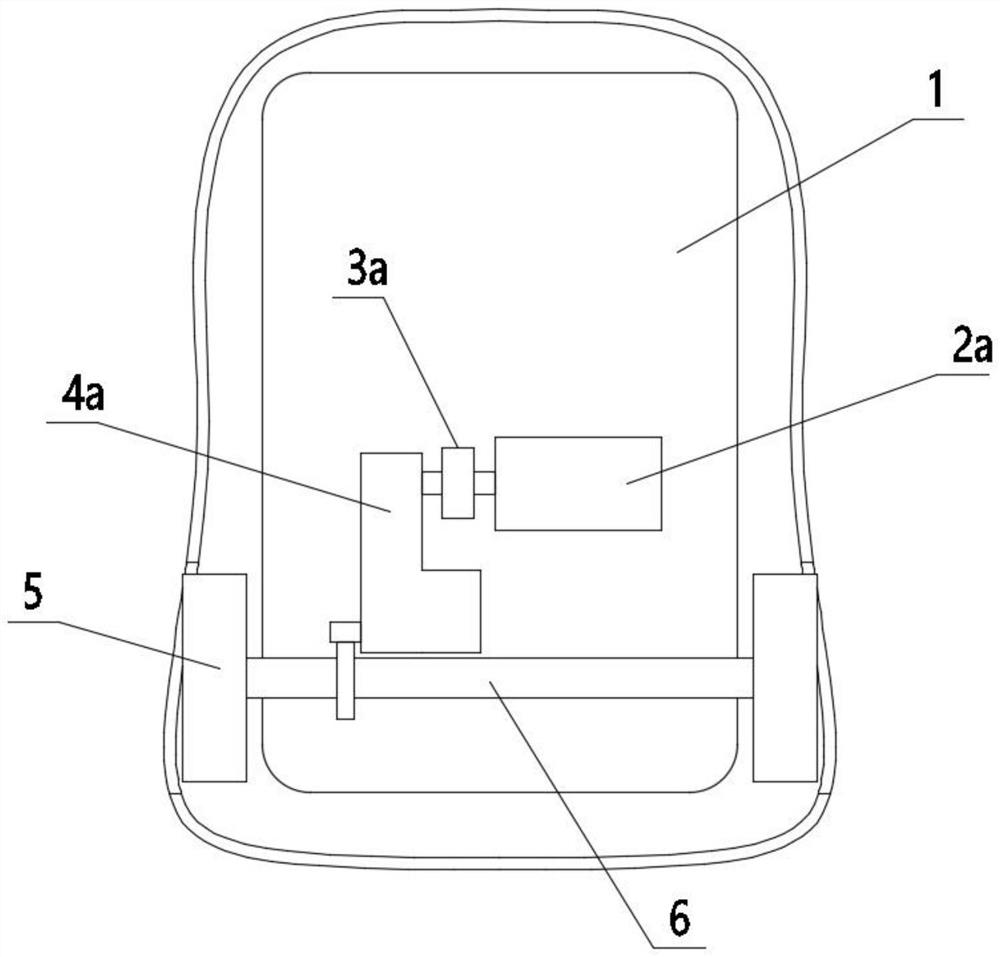

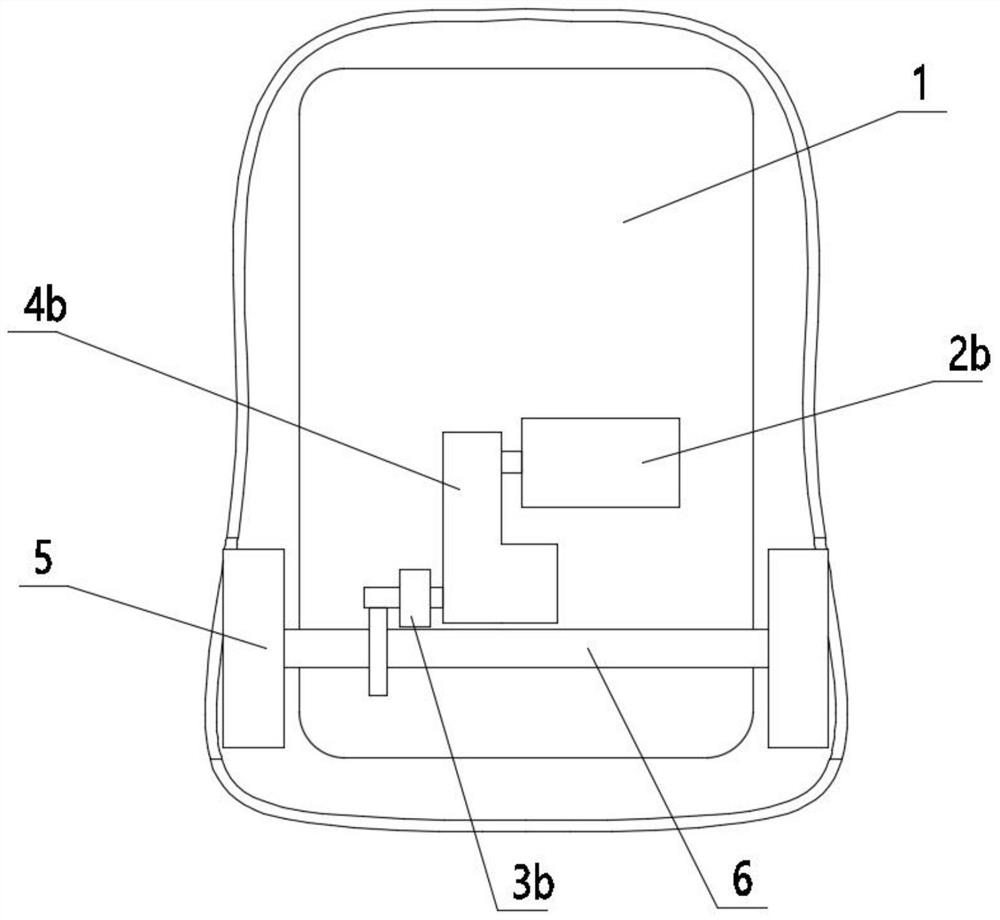

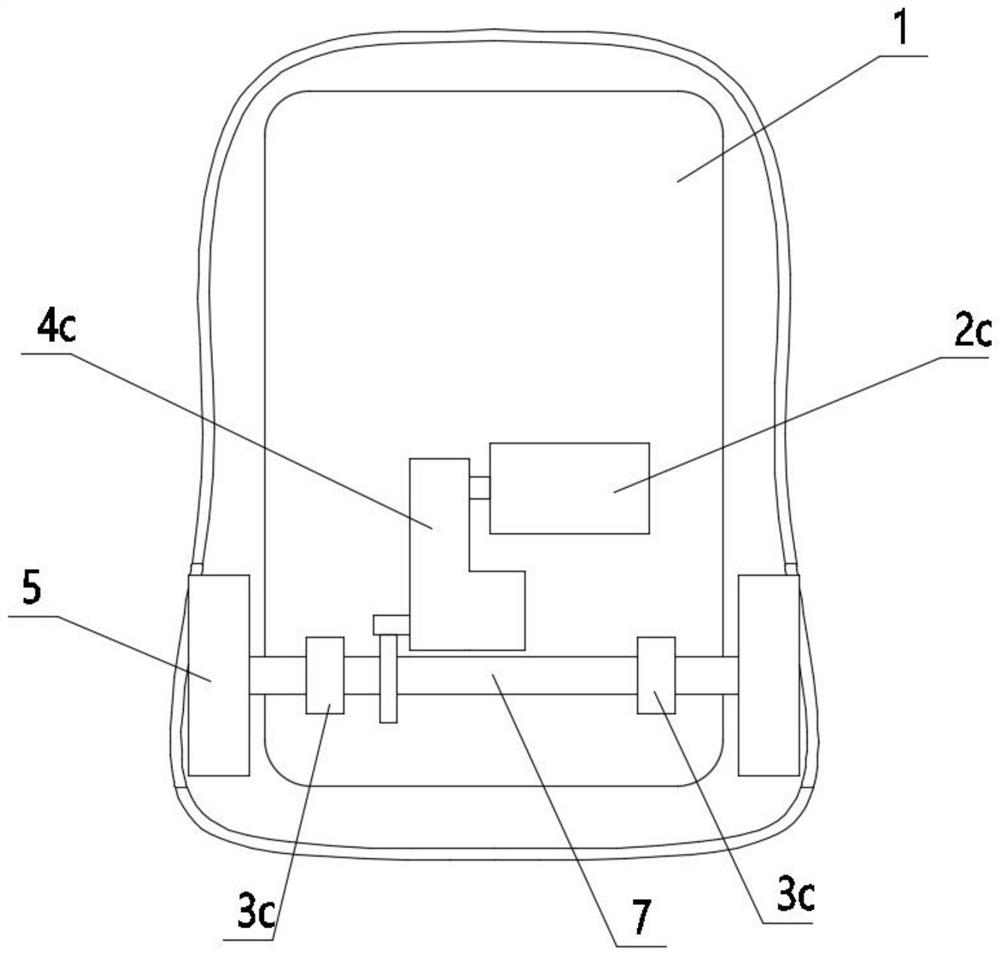

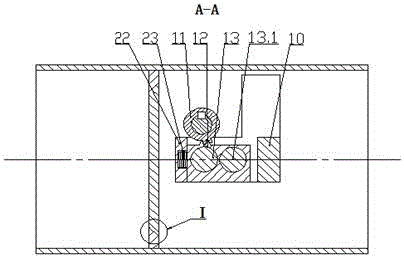

Intelligent lock drive device

The invention discloses an intelligent lock drive device. The intelligent lock drive device comprises a shell of a lock body, a square tongue mechanism, an oblique tongue mechanism and a square bar. Shell sides comprise shell side walls. A drive device comprises an electric drive mechanism and a square bar drive mechanism. The square bar drive mechanism comprises a clutch part. The clutch part comprises a clutch piece. The clutch piece comprises a fixed end and a free end. The electric drive mechanism can drive the fixed end of the clutch piece to rotate around the fixed end as an axis. The intelligent lock drive device is simple in structure, core components can be produced in a modular manner, and therefore assembling is convenient, and the intelligent lock drive device is more suitablefor batch production. The stroke is small during clutch driving, a transmission structure is simple, small and exquisite, less space is occupied, the appearance is small and exquisite and attractive,and the intelligent lock drive device is more popular with users. By means of a sensor, the moving path of the electric drive mechanism is determined, the stability and the accuracy of the whole drivedevice are improved, the failure rate is reduced, repeating motion cannot occur, and the loss for no reason in the motor moving process is avoided.

Owner:INNO ELECTRIC INC

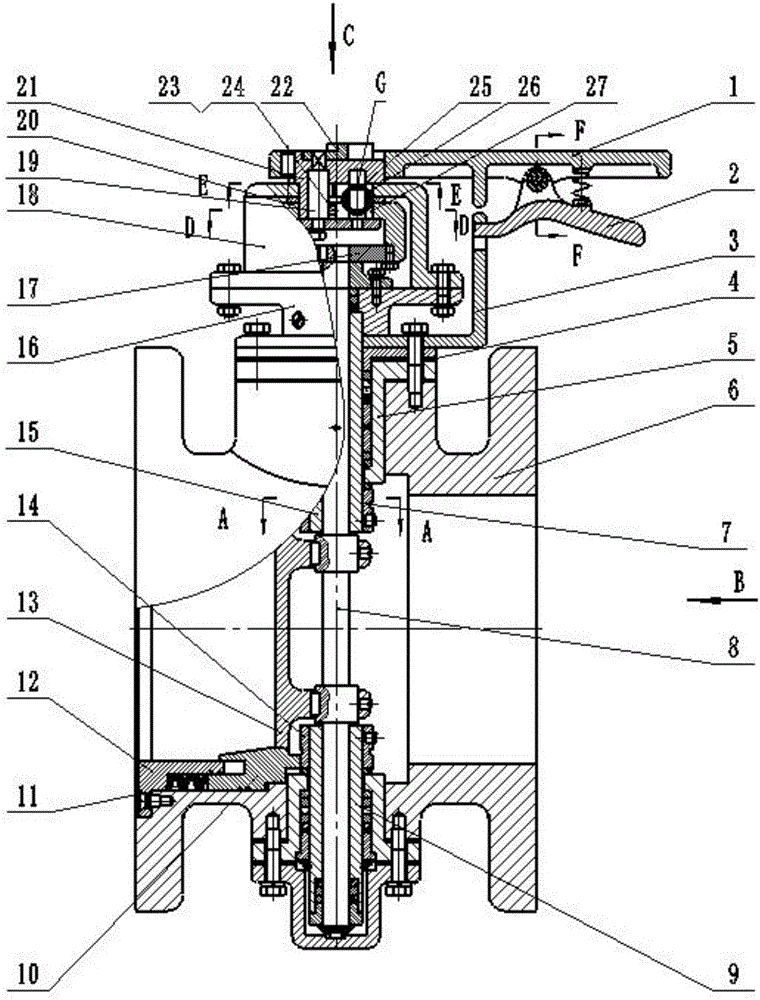

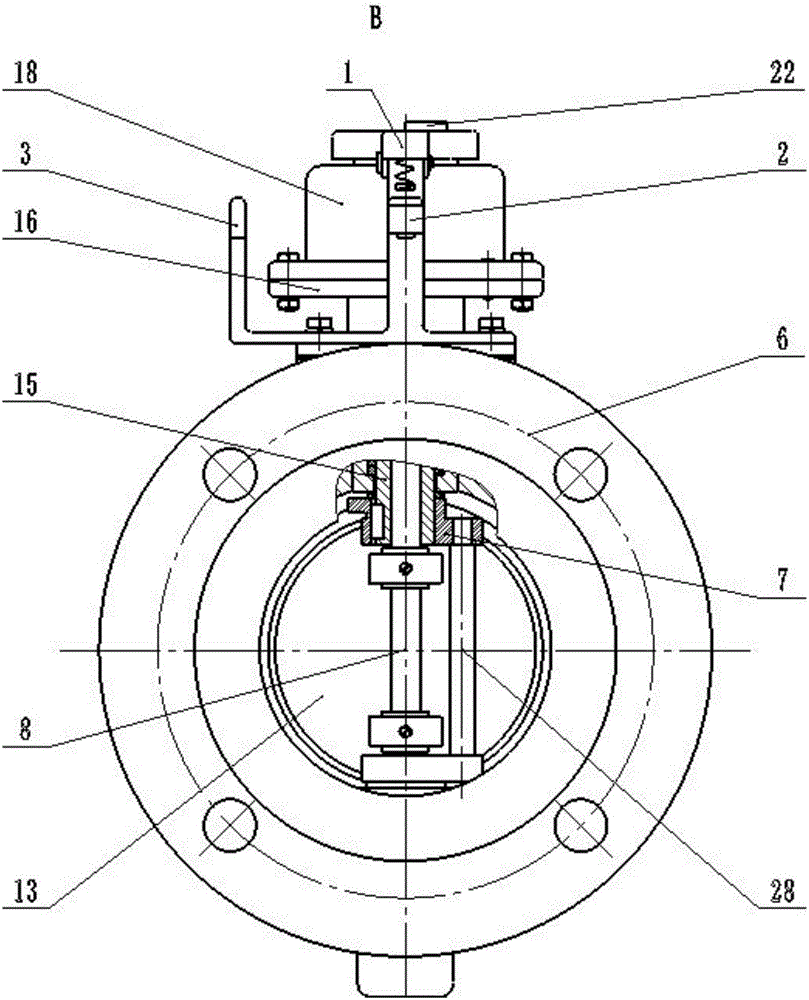

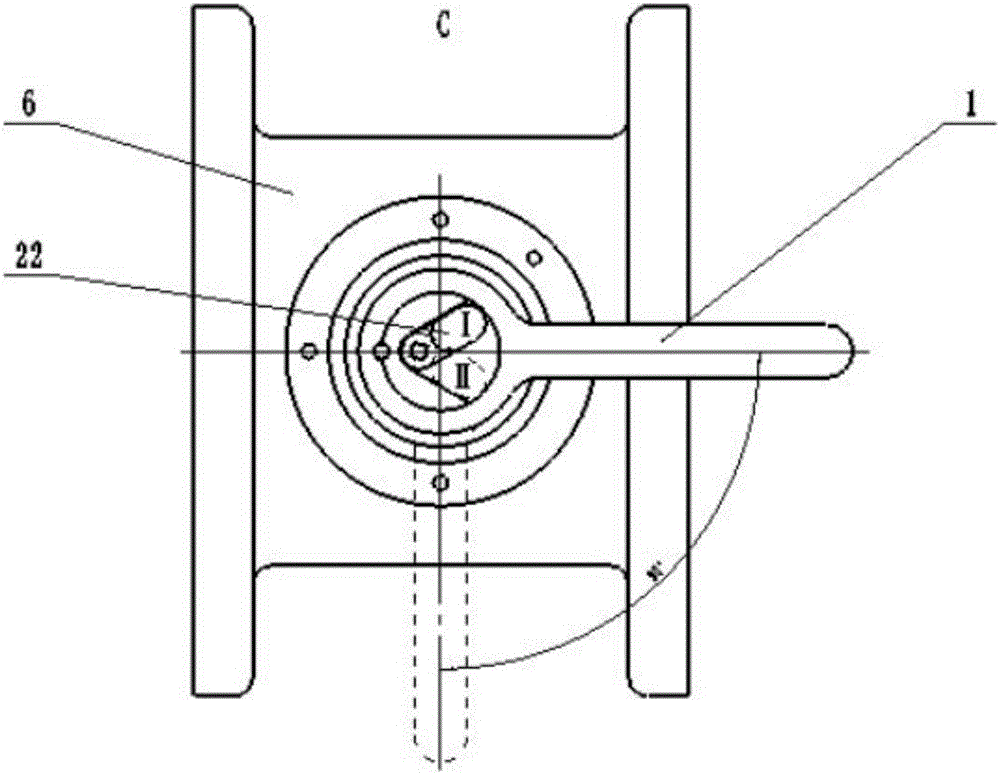

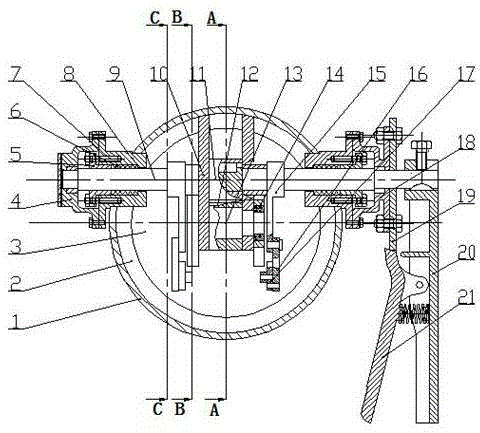

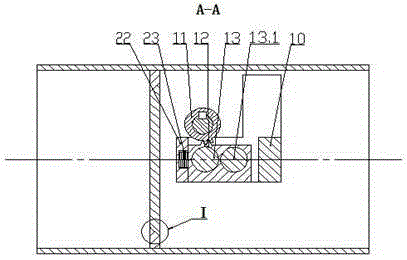

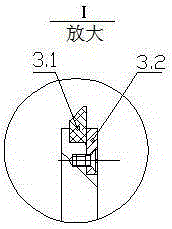

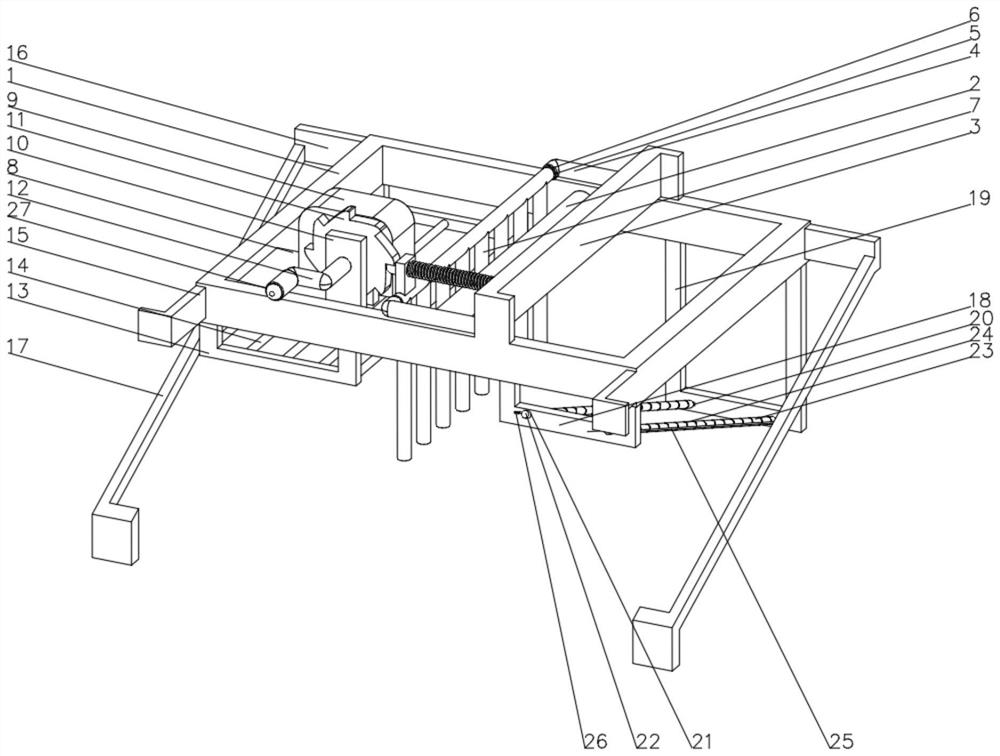

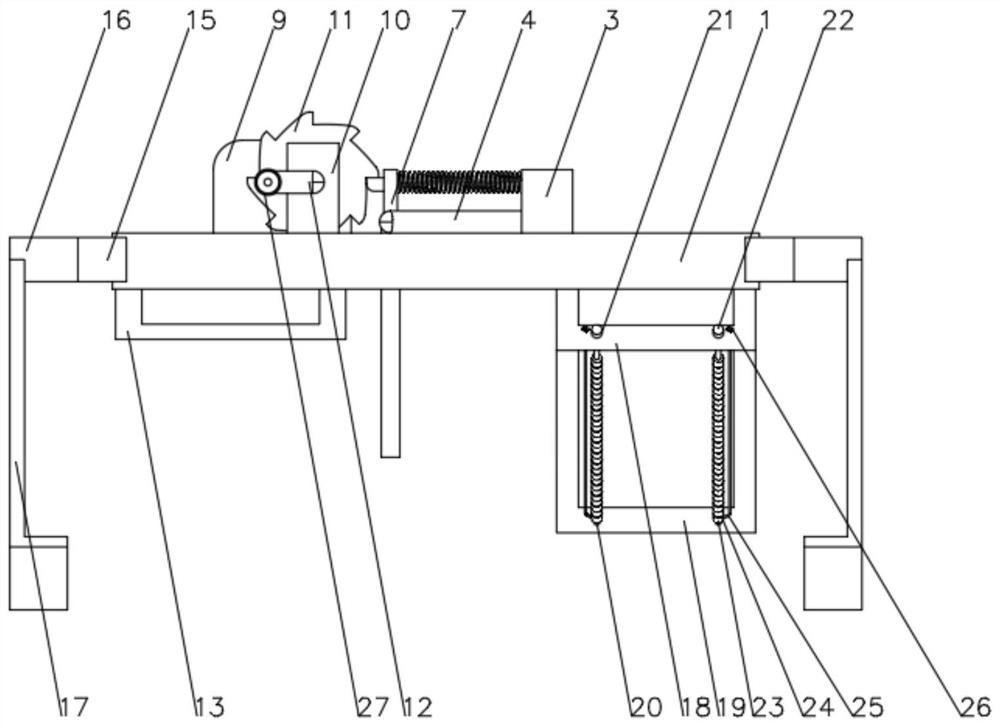

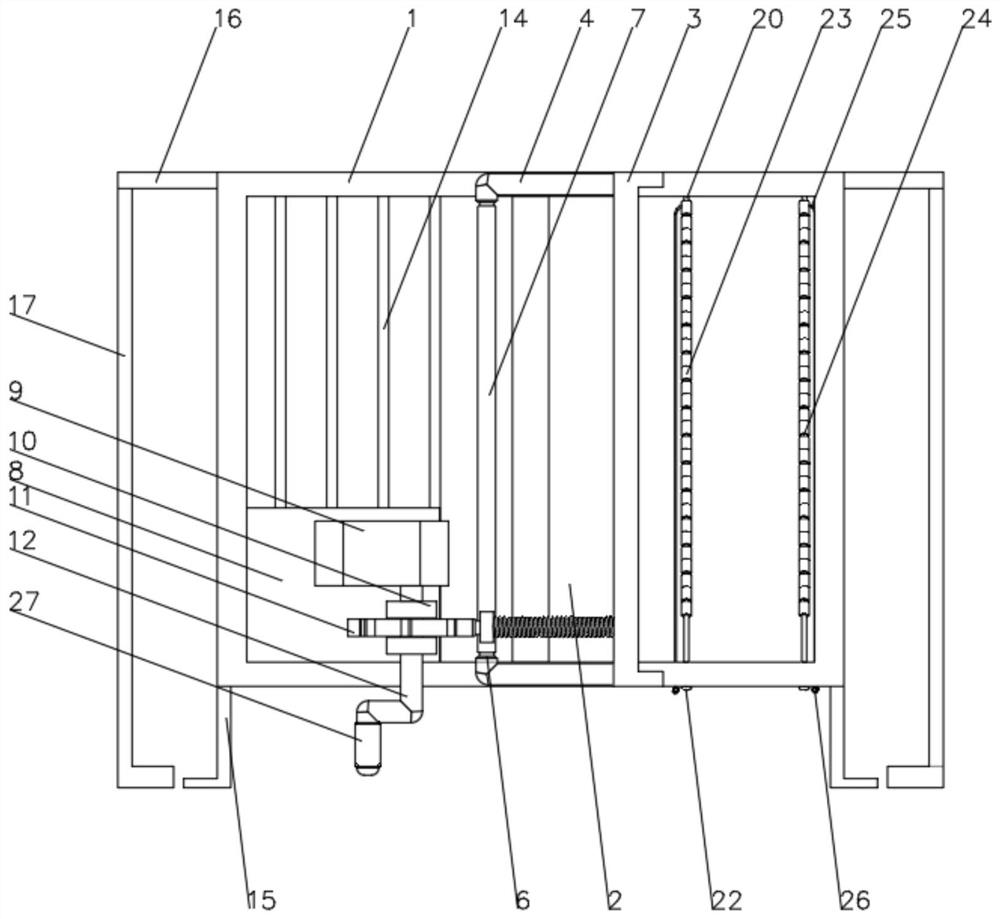

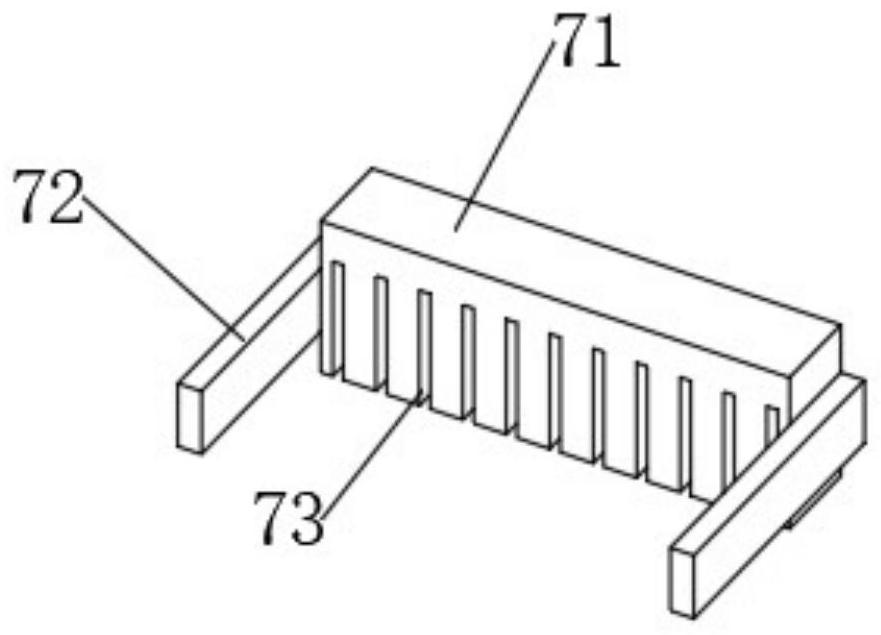

Intermittent drive non-abrasion hard sealed butterfly valve

ActiveCN106678378AVarious drive methodsWide applicabilitySpindle sealingsOperating means/releasing devices for valvesBusbarCam

The invention discloses an intermittent drive non-abrasion hard sealed butterfly valve. The intermittent drive non-abrasion hard sealed butterfly valve is characterized in that the butterfly valve comprises a valve body, a movable valve seat, a valve rod, a lower valve rod sleeve, an upper valve rod sleeve, a butterfly plate and an intermittent driving device; the left side and the right side of the valve body are provided with flanges perpendicular to the axis of the valve body; the flanges are used for connecting the butterfly valve with a pipeline flange; the upper end and the lower end of the valve body are provided with an upper valve rod sleeve hole and a lower valve rod sleeve hole; a cavity of the valve body is a stepped hole; the upper valve rod sleeve and the lower valve rod sleeve penetrate into the valve body through the upper valve rod sleeve hole and the lower valve rod sleeve hole correspondingly; retainer cups are arranged between the upper valve rod sleeve and the valve body as well as between the lower valve rod sleeve and the valve body; the retainer cups are connected with the valve body through bolts, and adjusting gaskets are installed between the retainer cups and the valve body; both the upper end and the lower end of the same busbar of the upper valve rod sleeve are provided with flat key grooves, in addition, an upper cam is fixedly installed at the lower end of the upper valve rod sleeve through a flat key, and the upper end of the upper valve rod sleeve is connected with the intermittent driving device; the upper end of the lower valve rod sleeve is provided with a flat key groove, and a lower cam is fixedly installed at the upper end of the lower valve rod sleeve through a flat key; and a transferring shaft is installed between the upper cam and the lower cam.

Owner:HEBEI UNIV OF TECH

Pneumatic artificial muscles with self-sensing and actuating functions

InactiveCN105856219BImprove shrinkageWide range of stiffness adjustmentProgramme-controlled manipulatorFiberVoltmeter

The invention belongs to the pneumatic artificial technical field and in particular relates to a pneumatic artificial muscle with self-sensing and driving functions. The pneumatic artificial muscle comprises fibers, an elastic hose, a cylindrical sleeve pipe, a fiber collecting hoop, a fiber collecting hole, a piezoelectric body, an electrode, a sensing circuit, a drive circuit, a hoop and an air pipe joint. The pneumatic artificial muscle has the beneficial effects that via the direct piezoelectric effects of the piezoelectric body, the contractility of the fibers can be measured to obtain the external load driving force of the pneumatic muscle; meanwhile, collision of the pneumatic muscle can be self-sensed according to the real-time reading of a voltmeter; via the inverse piezoelectric effects of the piezoelectric body, the amount of contraction of the pneumatic muscle can be increased and the rigidity of the pneumatic muscle can be changed; compared with the same model of pneumatic muscle on the market, the pneumatic muscle provided by the invention can achieve the effects of detecting the external load driving force, self-sensing collision, increasing the amount of contraction of the pneumatic muscle and changing the rigidity of the pneumatic muscle; the properties of the pneumatic muscle are improved and enriched; and the pneumatic muscle has function innovation and extension and is worthy to be applied.

Owner:CHINA JILIANG UNIV

Non-abrasion hard-sealing butterfly valve

The invention relates to a wear-free hard-sealed butterfly valve, which includes a valve body, a valve rod, a butterfly plate and a valve seat, and is characterized in that the valve seat is a movable valve seat that can move axially along the inner wall of the valve body; one side of the valve body There is a side body; a sealing ring is installed between the valve seat, the valve body and the side body; the seal is fastened on the butterfly plate frame; there is a moving fit gap between the inner and outer sides of the valve seat and the valve body and the side body , there is a spring between the outer end surface of the valve seat and the side body, and the inner end surface is connected with the valve stem through a push rod; There is a long keyway in the middle of the valve stem, and there are upper and lower keys respectively fixed on the upper and lower connecting seats, and the upper and lower connecting seats are respectively fastened on the butterfly plate; the push rod It includes upper and lower push rods, one end of which is equipped with a roller, one end of the lower push rod is embedded in the lower curved groove, and can slide, and the other end is hinged with the inner end surface of the movable valve seat; the upper push rod and the lower push rod are installed symmetrically ; There is a single eccentric structure between the disc rotation axis and the sealing plane.

Owner:HEBEI UNIV OF TECH

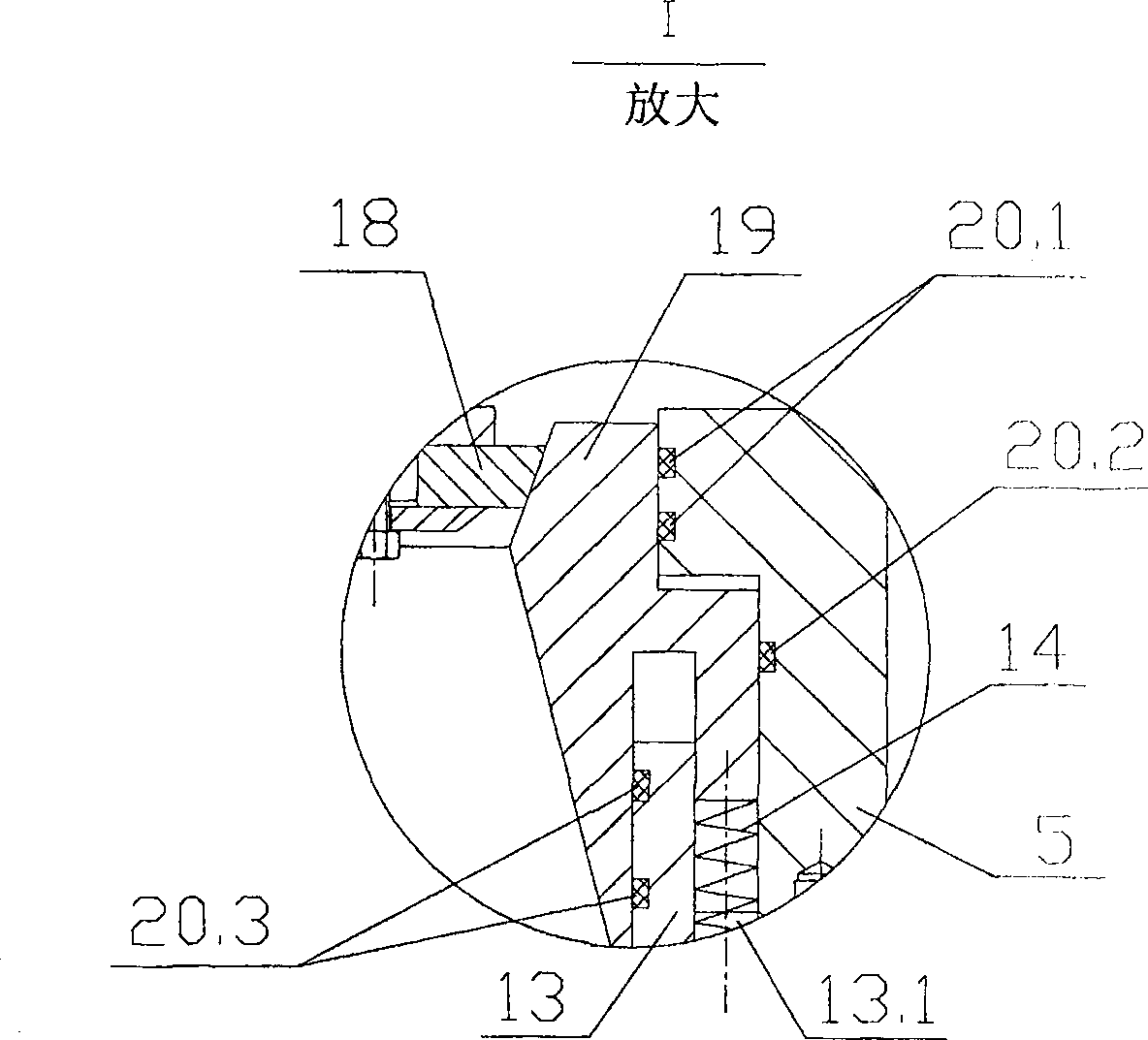

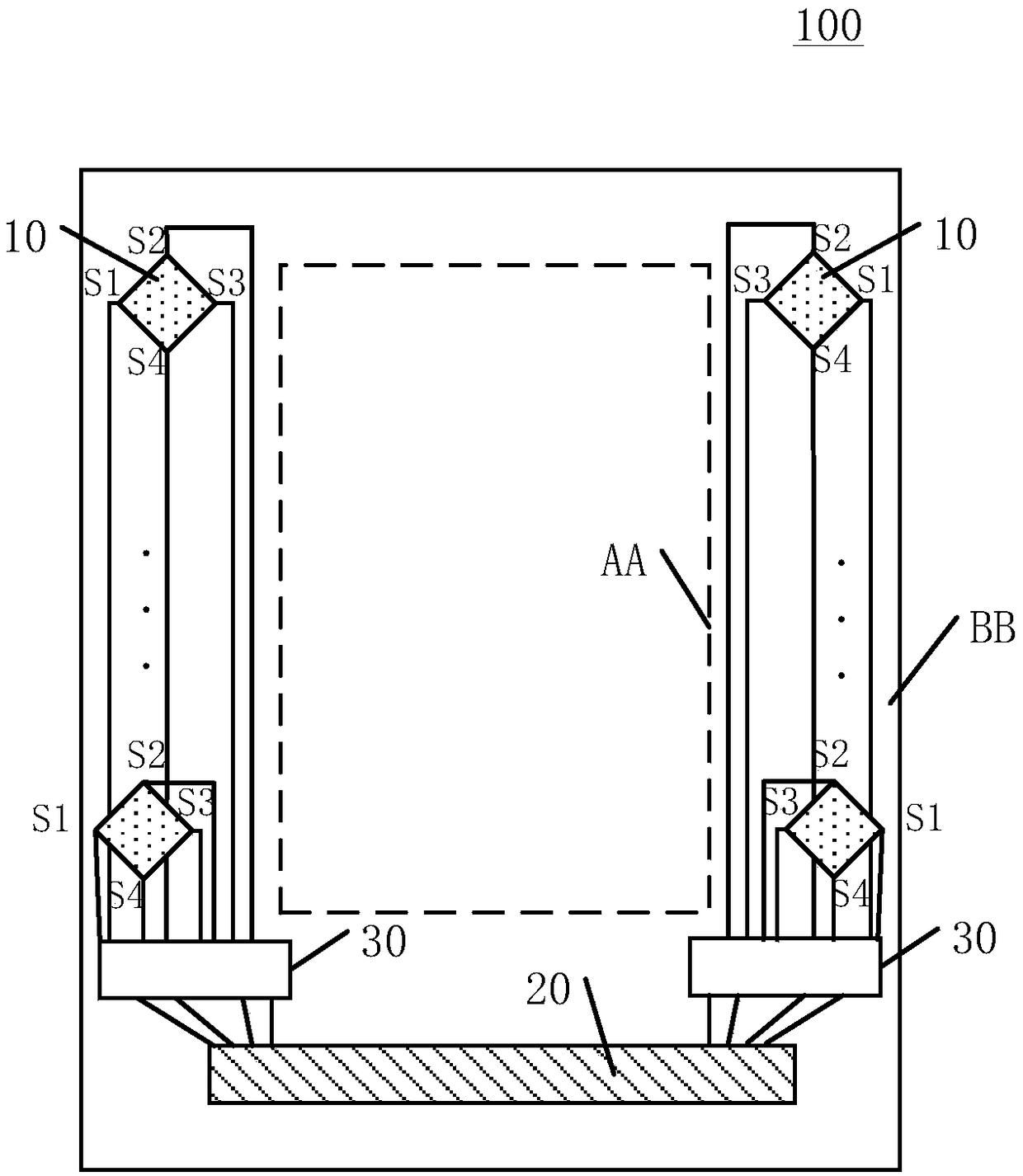

Touch substrate, touch display panel and touch display device

ActiveCN108693993AImprove featuresImprove the attenuation effectInput/output processes for data processingUltrasound attenuationEnd-group

The invention discloses a touch substrate, a touch display panel and a touch display device and belongs to the field of a touch technology. The touch substrate comprises at least one pressure sensor,wherein the pressure sensor includes a first signal end, a third signal end, a second signal end and a fourth signal end; the first signal end and the third signal end are a first end group; the second signal end and the fourth signal end are a second end group; one of the first end group and the second end group receives a bias voltage provided by a signal processing unit, and the other of the first end group and the second end group outputs a detection voltage to the signal processing unit; the bias voltage includes a first voltage signal and a second voltage signal; the touch substrate comprises a signal switching unit; and the signal switching unit is used for enabling the first end group and the second end group to respectively receive the bias voltage at different moments, or the signal switching unit is used for enabling switching of voltage signals of the two signal ends in the end group for receiving the bias voltage. Compared with the prior art, the phenomena of characteristic degradation and performance attenuation of the pressure sensor can be improved, and the quality of the touch substrate is improved.

Owner:XIAMEN TIANMA MICRO ELECTRONICS

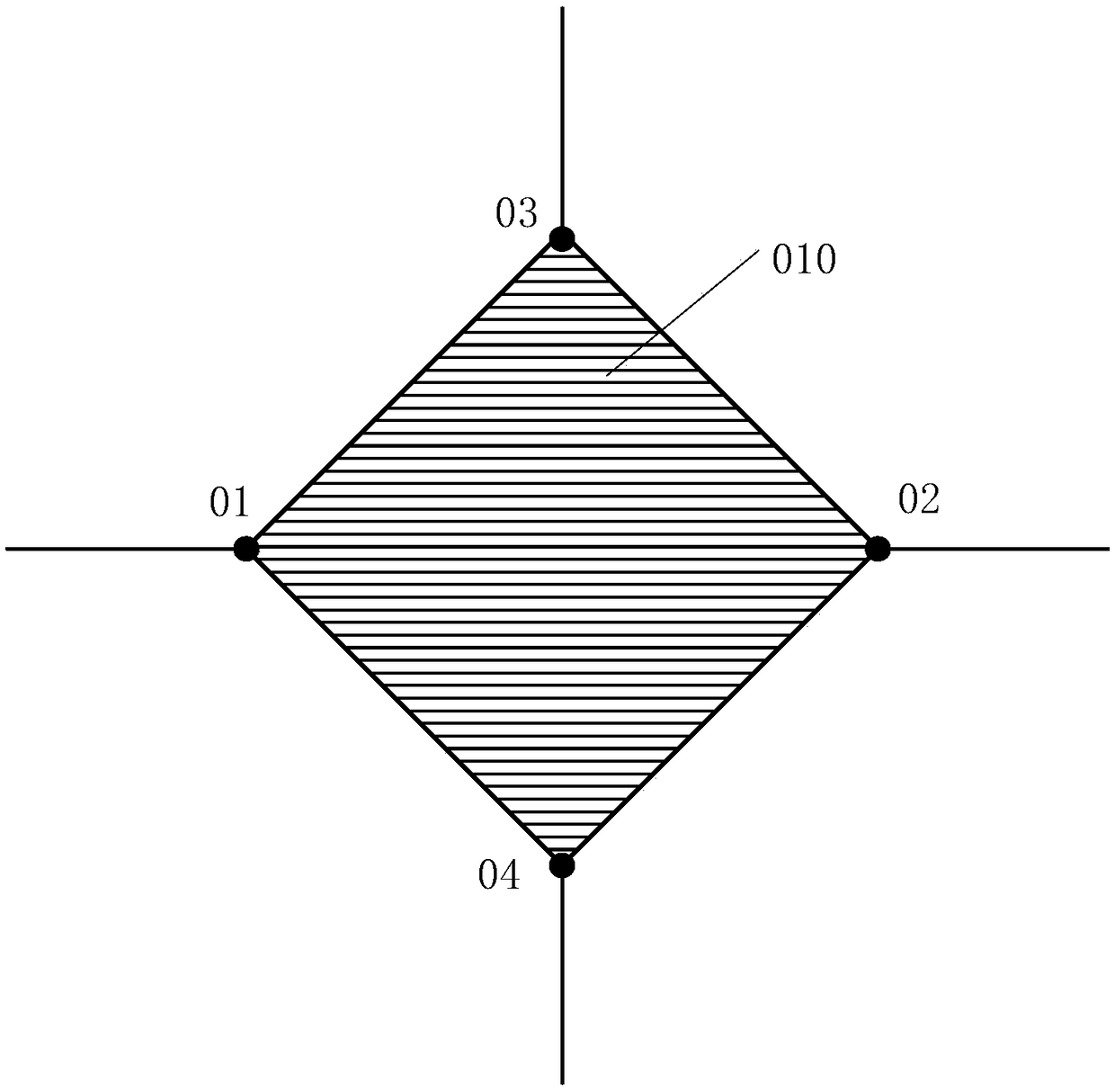

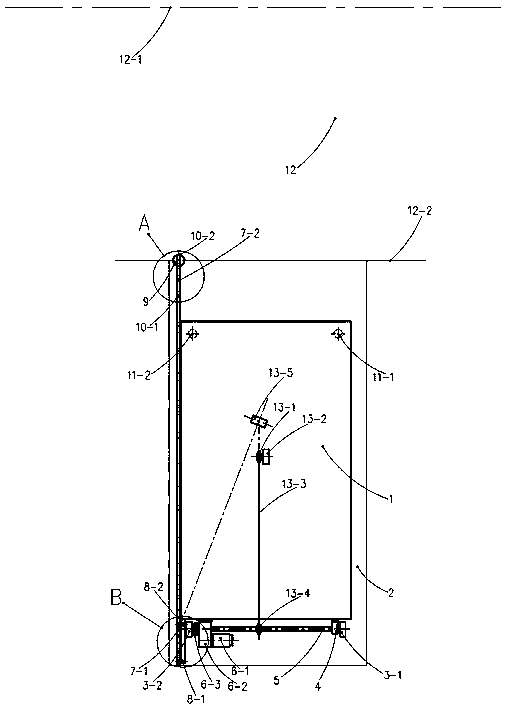

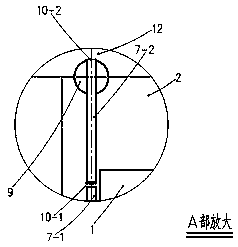

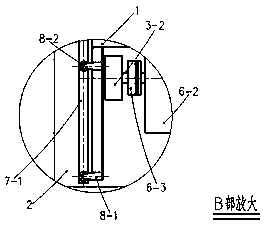

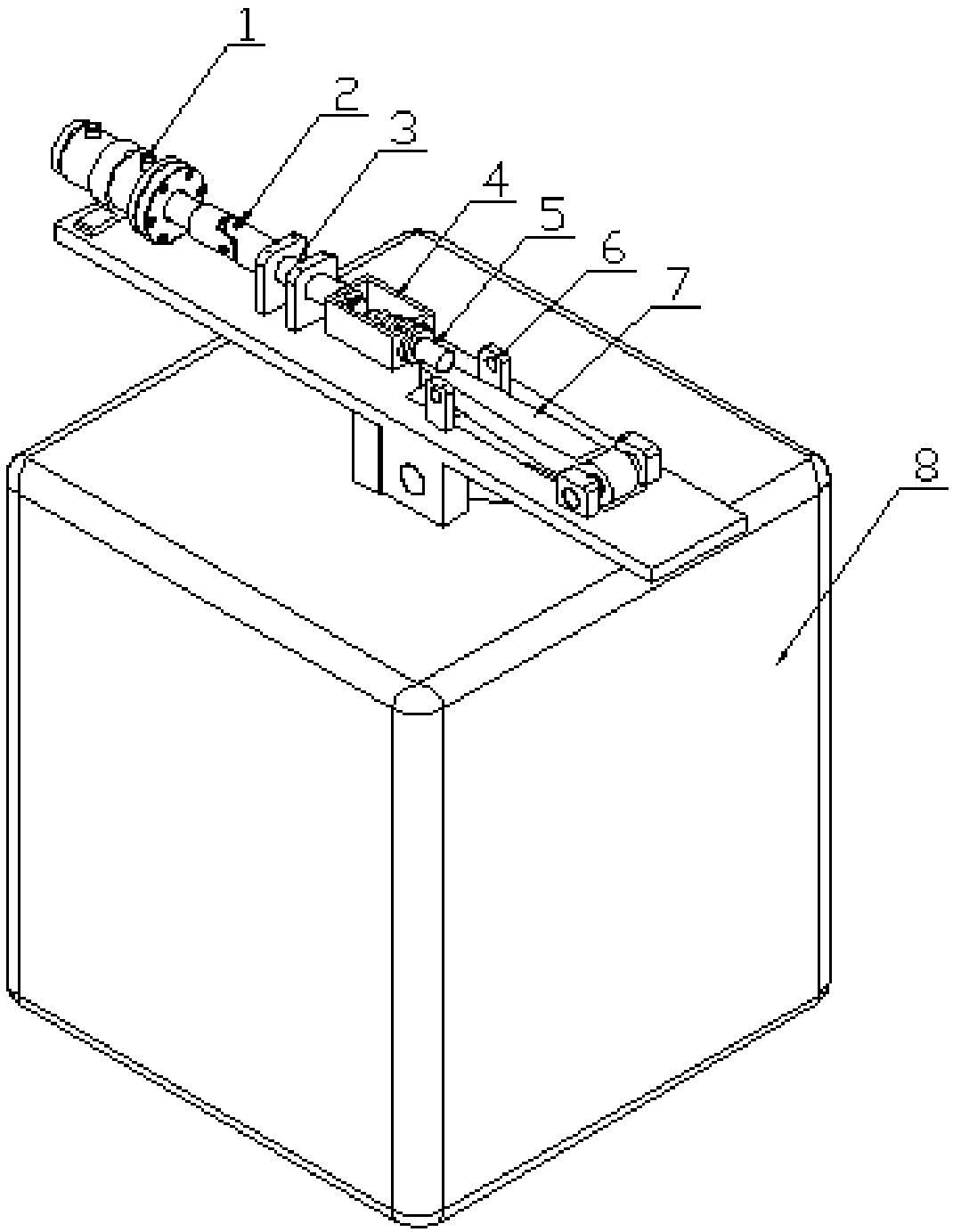

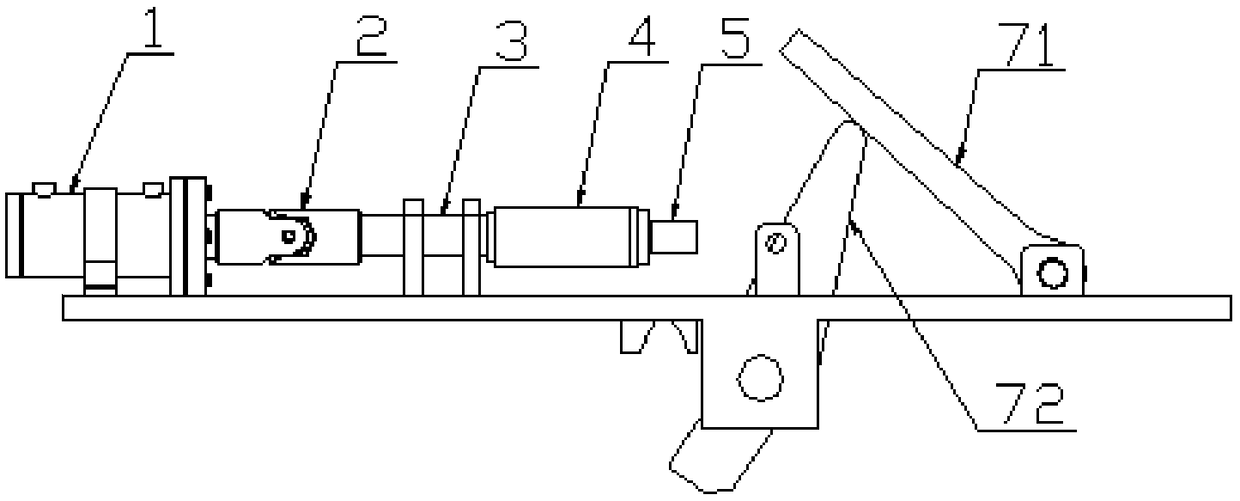

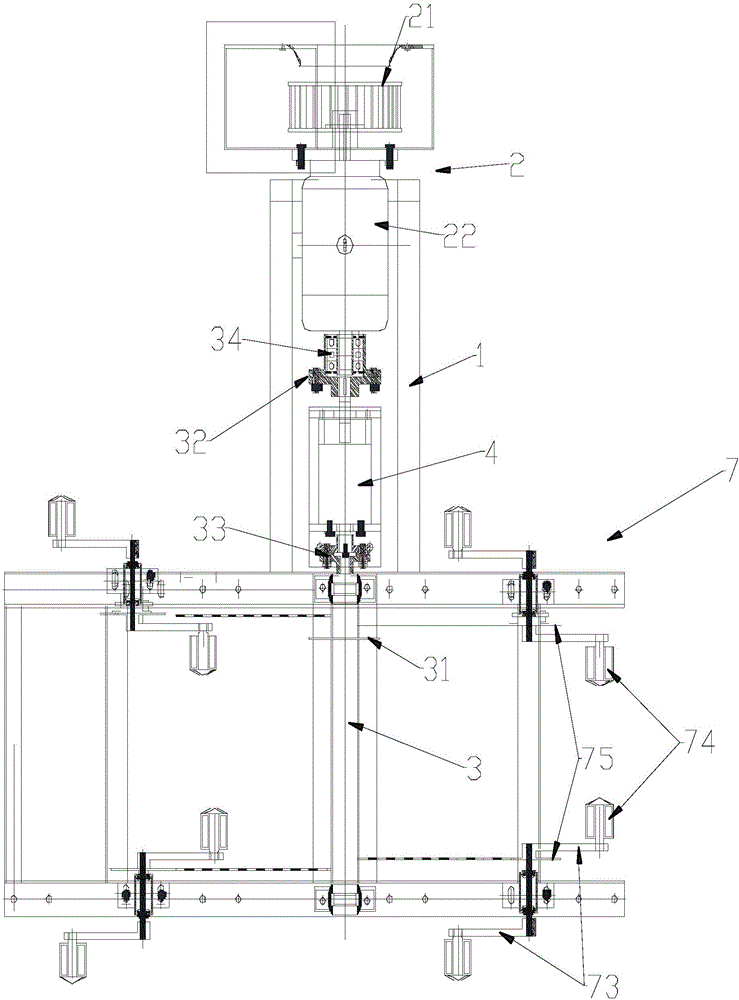

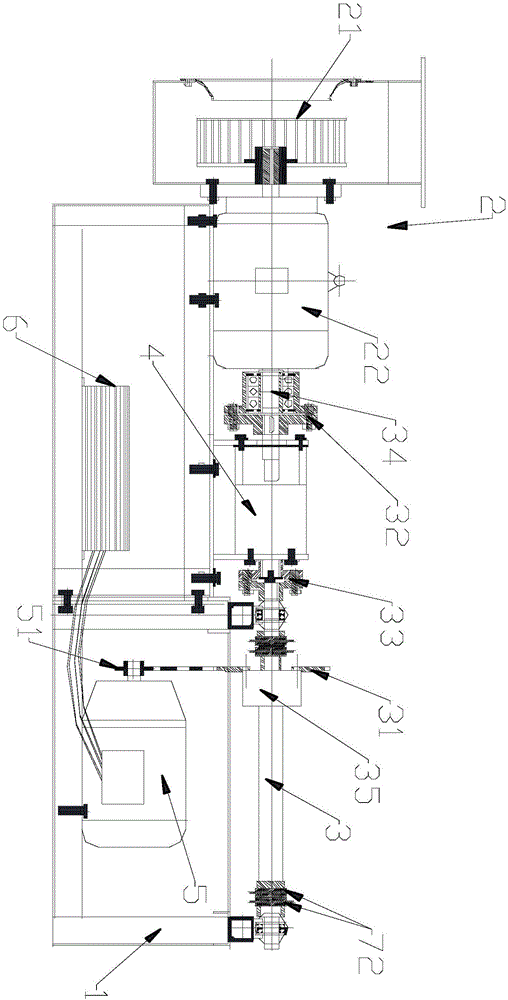

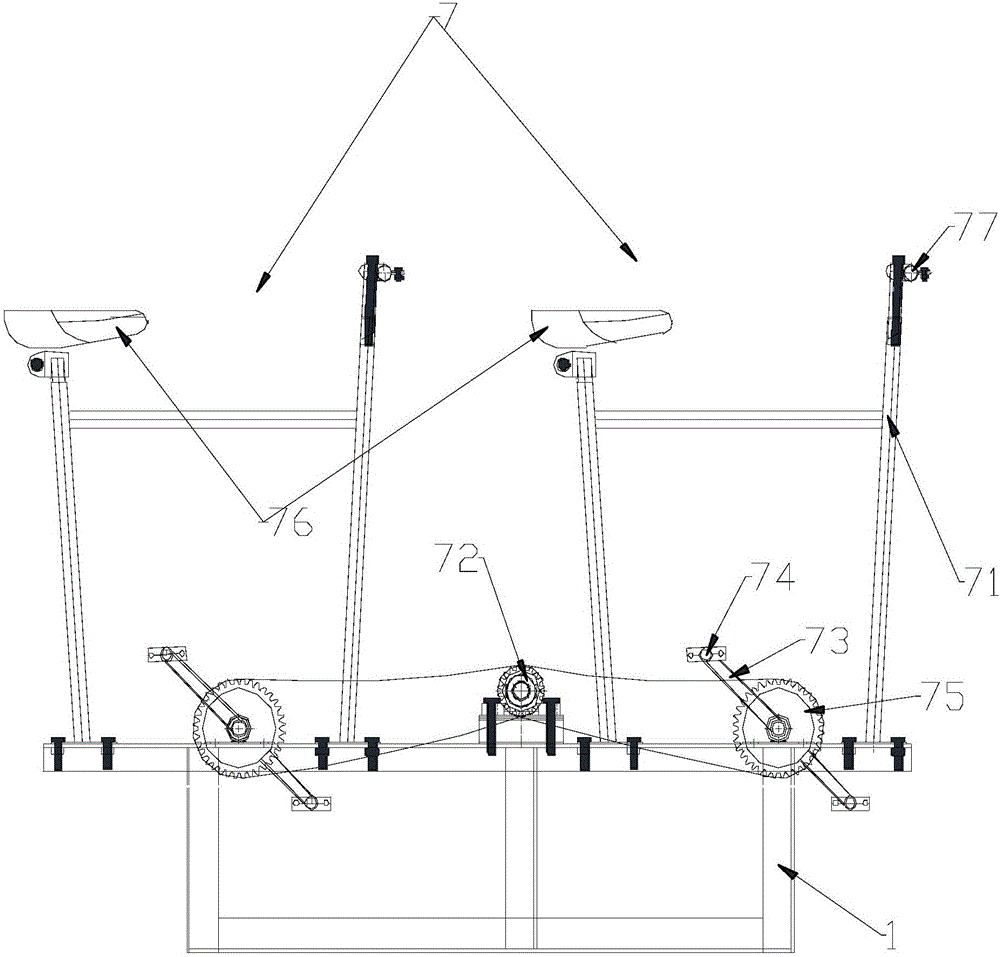

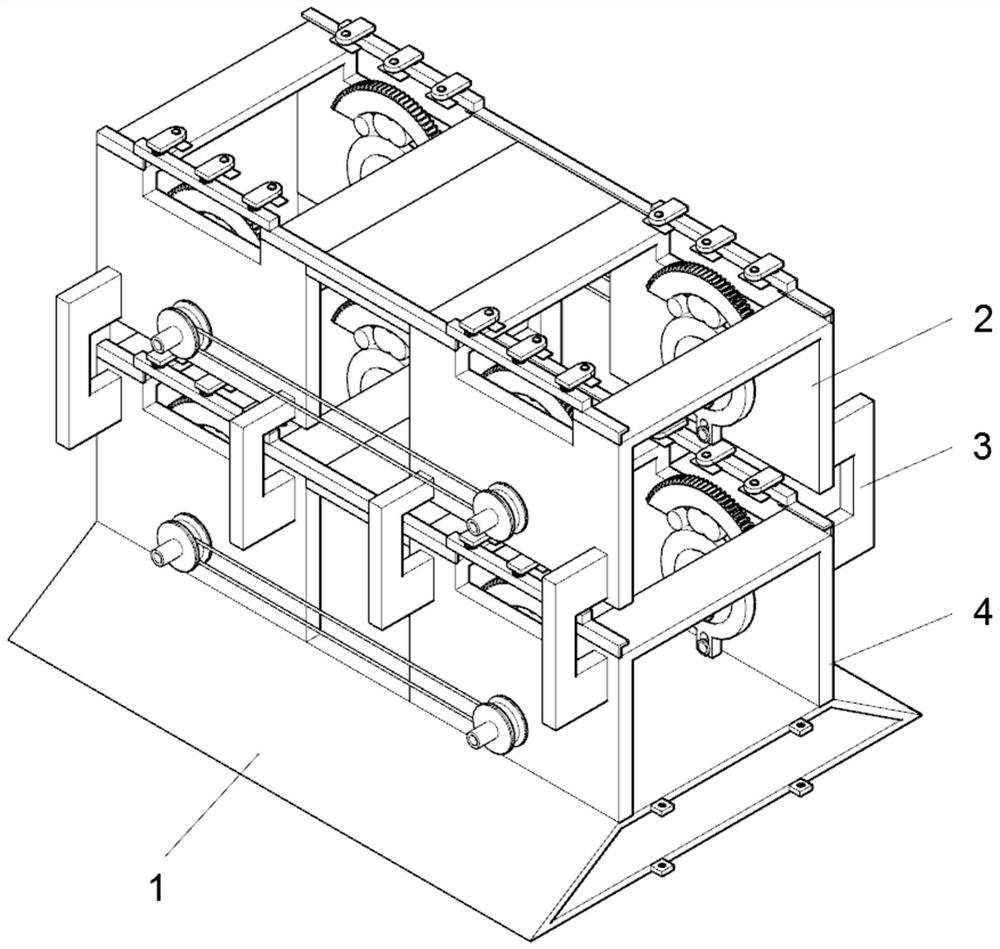

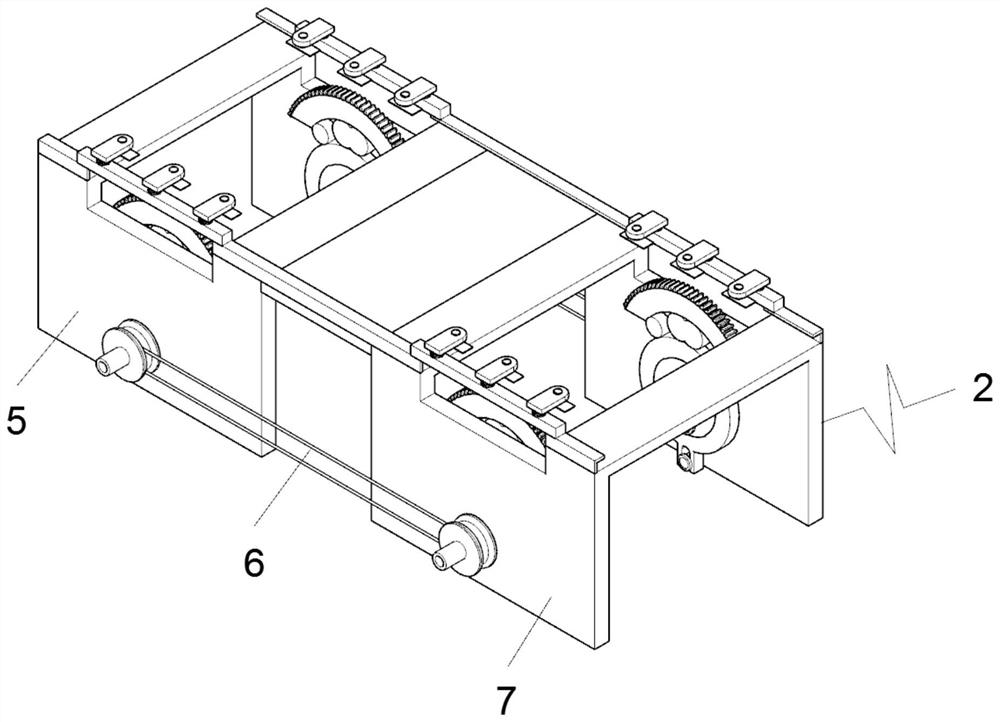

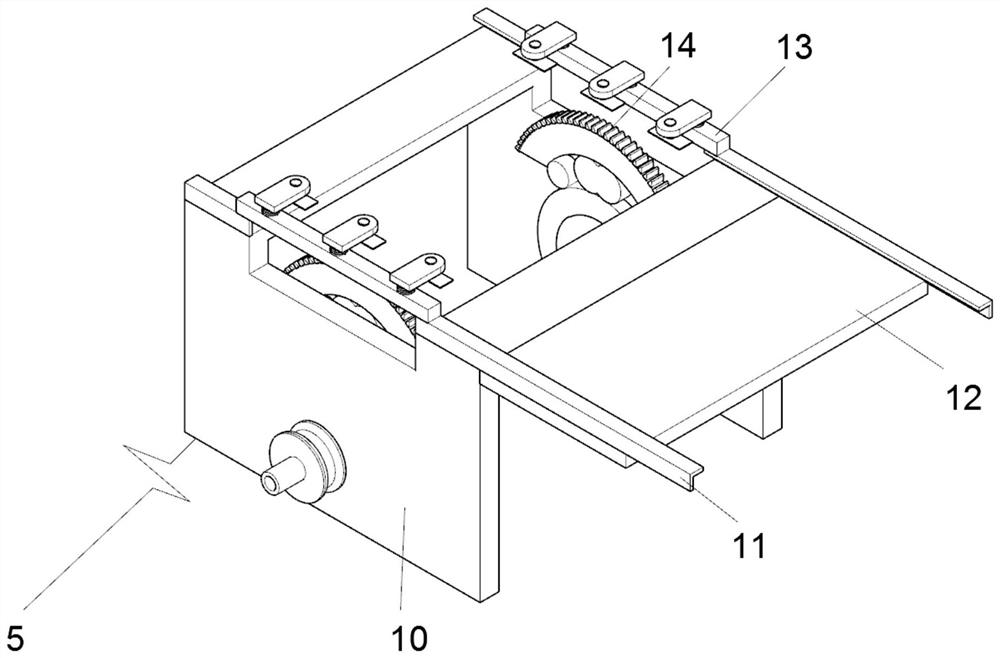

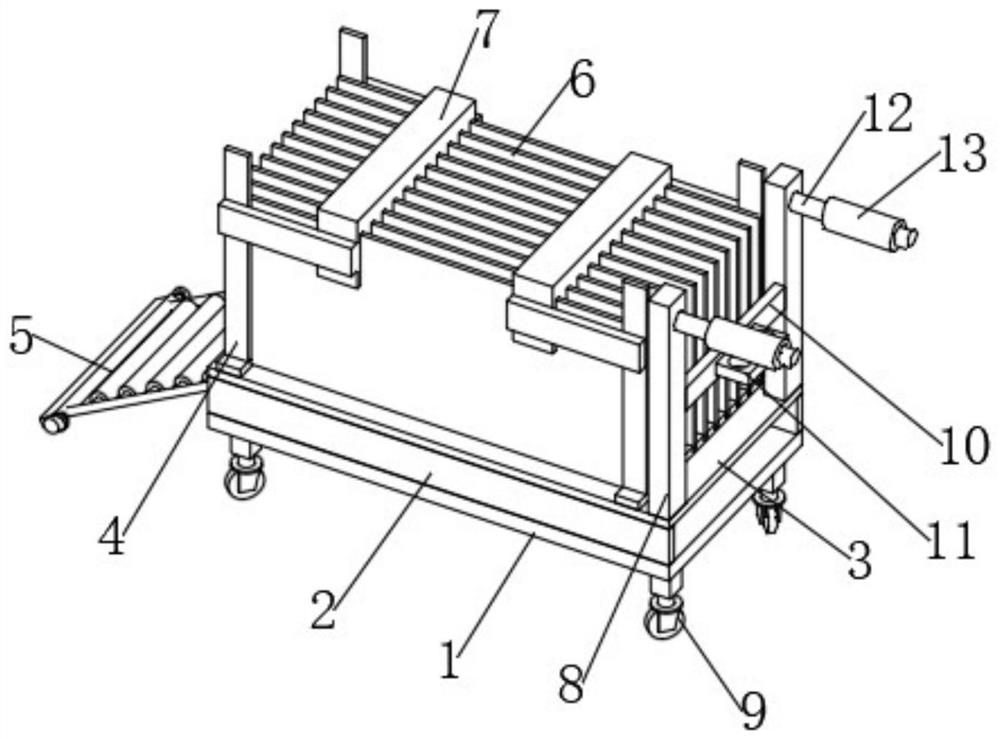

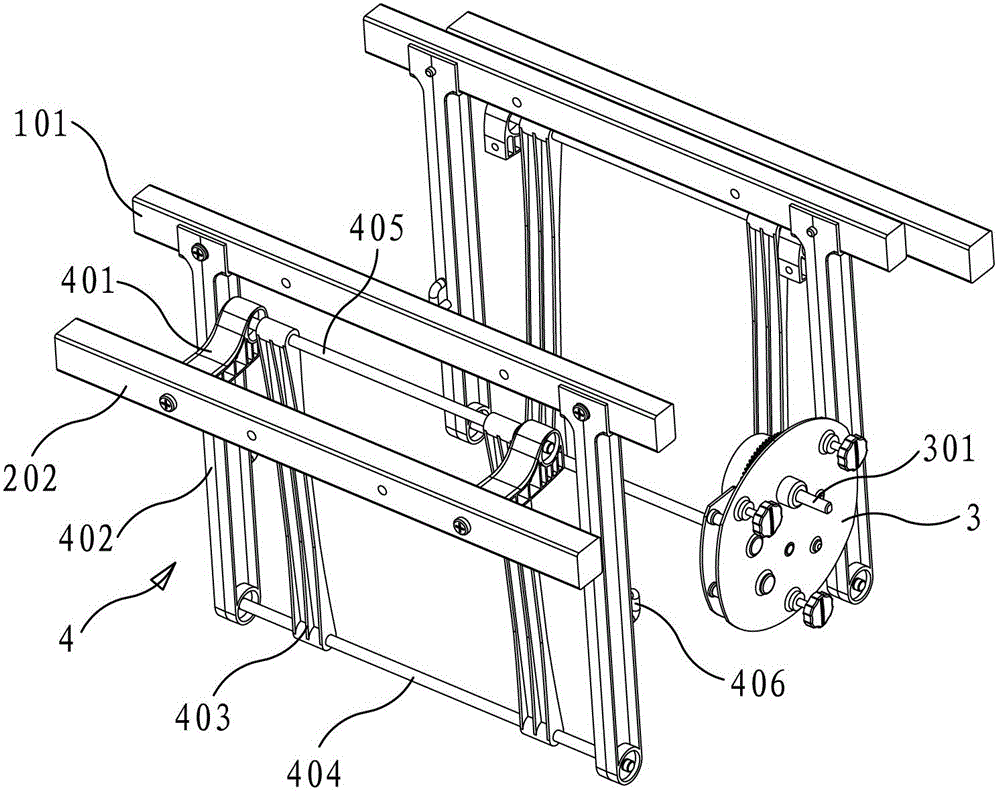

L-shaped displacement mechanism for lower platform plate of parking equipment

InactiveCN110566008AVarious drive methodsLinear displacement is stableParkingsControl systemEngineering

The invention discloses an L-shaped displacement mechanism for a lower platform plate of parking equipment. The L-shaped displacement mechanism comprises the lower platform plate, a long guide rail, arotating and traverse moving guide unit, a position detection unit, a positioning unit, a rear drive system, a front drive system and a control system. The front drive system and the rear drive system are mounted in front and rear of the lower platform plate correspondingly. The long guide rail is located on one side of the lower platform plate in the length direction. The rotating and traverse moving guide unit is positioned at the end, close to a lane, of the long guide rail. According to the L-shaped displacement mechanism, an existing lower platform plate driving mode is improved, and therear driving system is formed; meanwhile, the front driving system capable of being switched between linear displacement auxiliary driving of a chain wheel chain mechanism driving a straight drivingwheel and rotating rolling wheel auxiliary rotating following-up is additionally arranged, the long guide rail is adopted to be matched with a rotating slidable guide rail and a guide wheel to guide,the steering non-obstacle between the linear displacement and the rotating displacement is perfectly achieved, and the linear displacement high-speed and stable lower platform plate forward moving, rotating and transverse moving are realized perfectly, namely the L-shaped displacement of the lower platform plate is achieved.

Owner:佛山市诺行科技有限公司

Device for hanging and discarding heavy object in deep sea

InactiveCN108529416AVarious drive methodsImprove reliabilityLoad-engaging elementsEngineeringDriving mode

The invention discloses a device for hanging and discarding a heavy object in deep sea, and relates to the field of deep sea equipment. The device comprises a hydraulic cylinder, a universal coupling,an intermediate shaft, a connector, an explosive bolt, safety pin holes and a two-level lever labor saving mechanism; the hydraulic cylinder and the intermediate shaft are fixedly connected through the universal coupling; the intermediate shaft and the explosive bolt are fixedly connected through the connector; oil is supplied to the hydraulic cylinder by an outboard hydraulic source; the two-level lever labor saving mechanism comprises a first lever and a second lever; the tail end of the first lever is subjected to the contact constraint of the explosive bolt; the tail end of the second lever is used for fixing a lifting lug of the heavy object; and a safety pin is inserted into each safety pin hole when the device is maintained. The problem that a traditional device for hanging and discarding the heavy object is single in driving mode and is only suitable for discarding a heavy object not heavy in weight in shallow water is solved; the effect that the heavy object is discarded by contraction motion of the hydraulic cylinder and by detonating the explosive bolt, and the device is suitable for a deep sea environment is achieved.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

Zero-friction hard seal butterfly valve

ActiveCN105221767AExtended service lifeAvoid frictionOperating means/releasing devices for valvesLift valveInterference fitEngineering

The invention discloses a zero-friction hard seal butterfly valve. The zero-friction hard seal butterfly valve is characterized in that the butterfly valve comprises a valve opening, a valve body, a valve seat, a disc, a valve shaft, a guide groove, an incomplete gear, a rack, a guide shaft No.1, a guide shaft No.2, a self-lubricating shaft sleeve, a linkage rod, an intermittent mechanism, a driving handle and a seal device, a through hole is formed in the valve body, a valve neck is welded at the part of the through hole, the valve seat is welded on the inner circumferential surface of the valve body, and the outer circumferential surface of the valve seat is a conical surface; the disc is a moving type disc and adopts a ring structure, a hard seal ring is mounted at the outer circle part of the disc, and the movement type refers to a motion structural mode that the disc can first make transverse movement along the axial direction of the valve body and then rotate with the guide shaft No.1 as a center and is opened in a zero friction manner; the disc is connected with the guide shaft No.1; the guide shaft No.1 is mounted in the guide groove and penetrates through the rack, and the guide shaft No.1 is also in interference fit with the rack at the connecting part; and the guide shaft No.2 is also mounted in the guide groove.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

Ventilating equipment for civil air defense engineering

PendingCN106837835AImprove work efficiencyImprove rotation efficiencyFrom muscle energyPump installationsDrive shaftEngineering

The invention relates to ventilating equipment for civil air defense engineering. The equipment comprises a base, a fan, a transmission shaft, a transmission, a direct current motor, a direct current motor controller, a storage battery and at least two pedal driving devices, wherein the transmission shaft is rotatably mounted on the base through a fixed seat; the transmission is fixedly mounted on the base and is located between the transmission shaft and the fan; a power output shaft of the transmission is detachably connected to the rotary shaft of a fan through an alternating overrun clutch; a power input shaft of the transmission is detachably connected to one end of the transmission shaft; a direct current overrun clutch is fixedly mounted on the transmission shaft; the power input shaft of the transmission is detachably connected to one end of the transmission shaft; a direct current overrun clutch is fixedly mounted on the transmission shaft; a first driven chain wheel is mounted on an outer wheel of the direct current overrun clutch; and each of the pedal driving devices comprises a pedal frame, a crankshaft, a bicycle flywheel and a bicycle wheel disc. The ventilating equipment for civil air defense engineering provided by the invention has the advantages of being high in work efficiency and diversified in driving modes: three driving modes: alternating current driving, manpower and direct current auxiliary driving and pure manpower driving.

Owner:北京天立成信机械电子设备有限公司

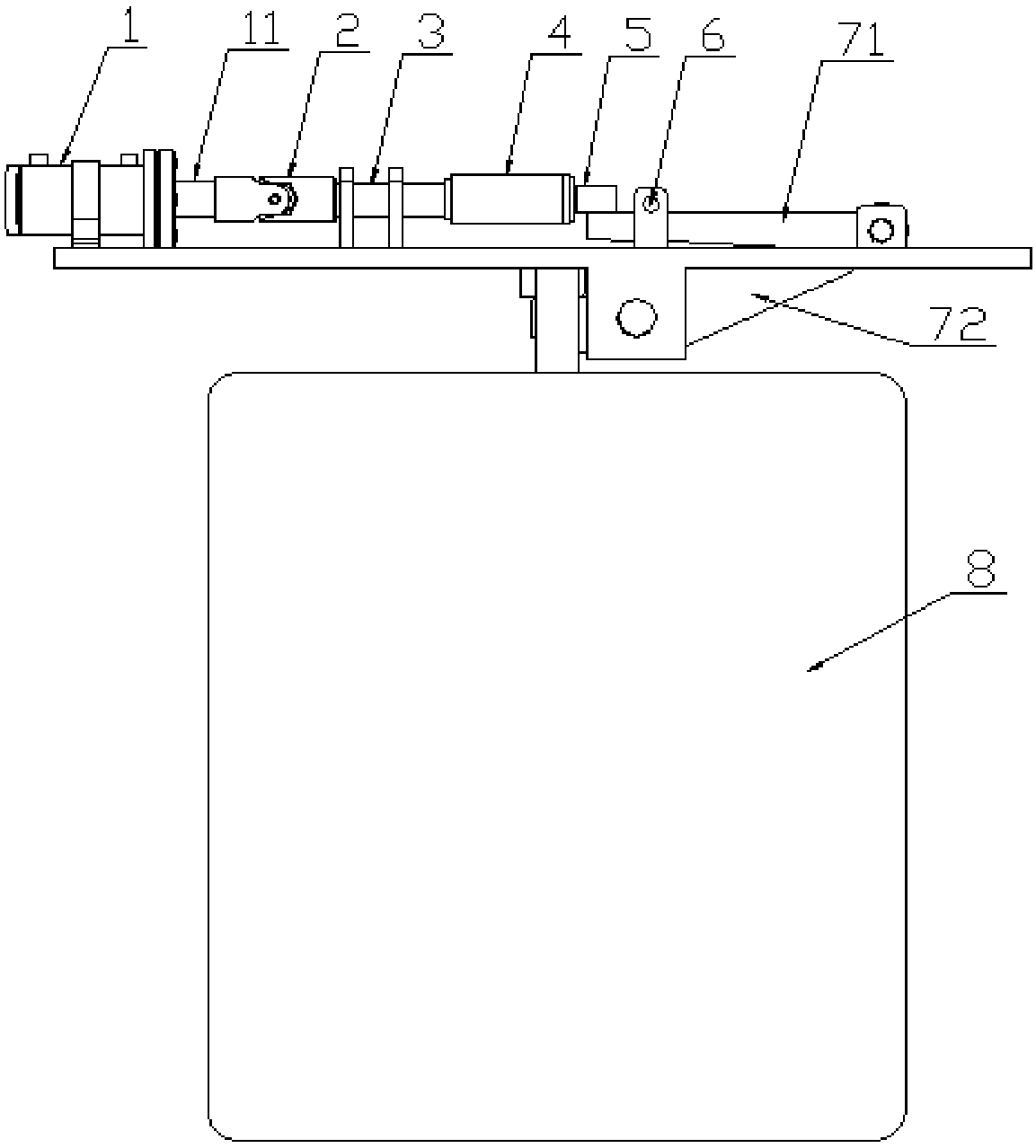

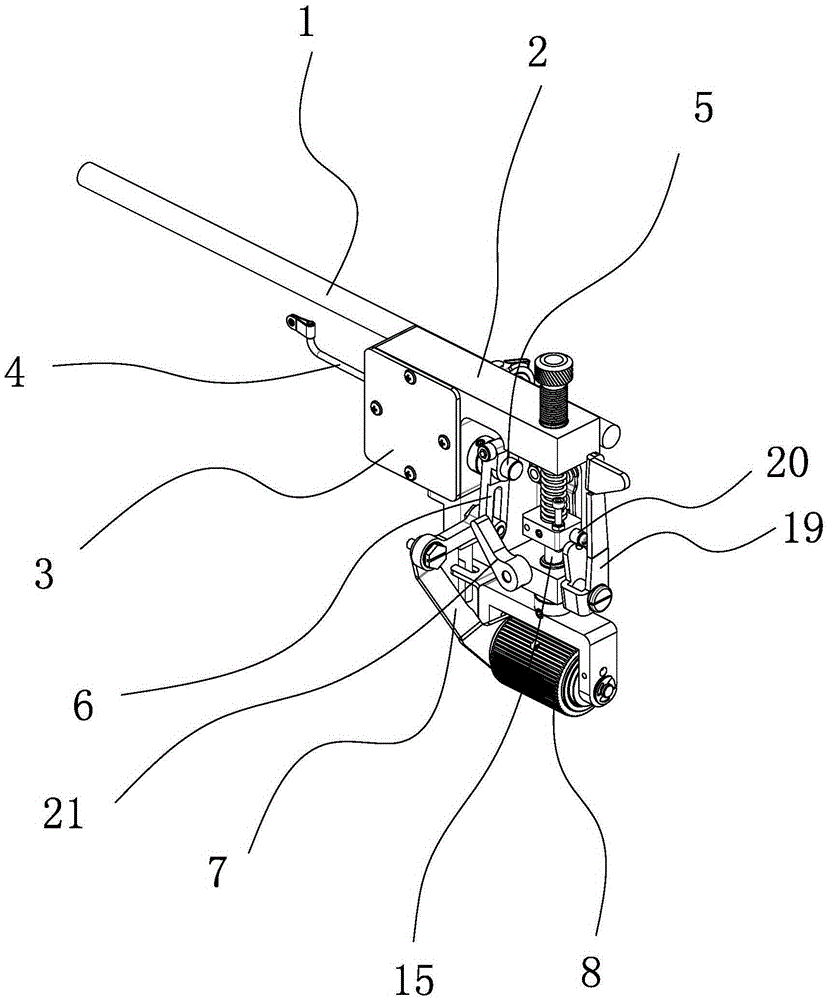

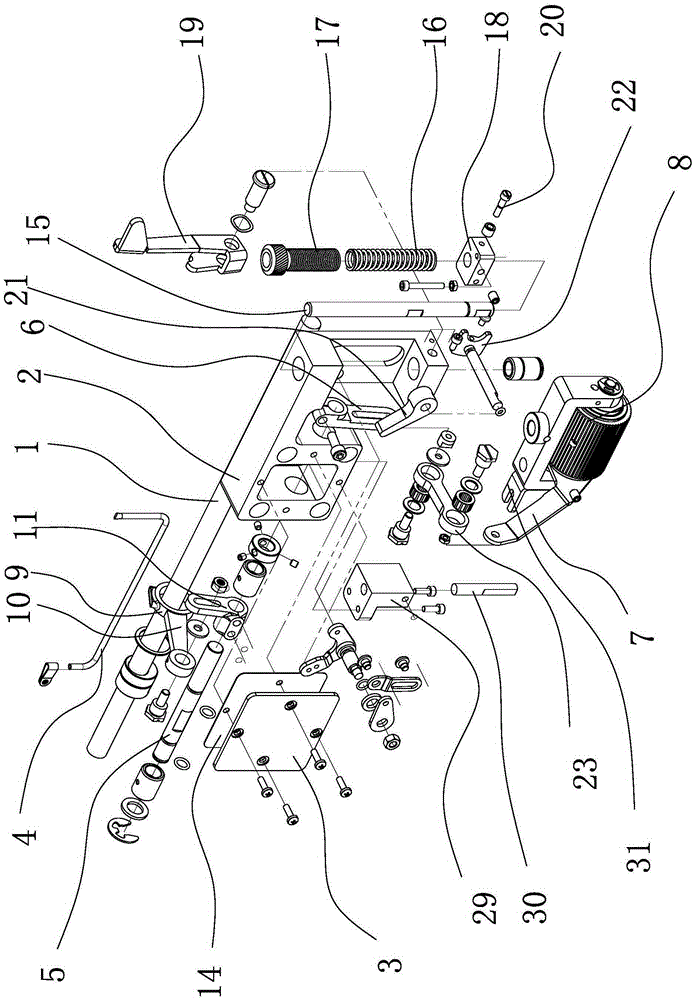

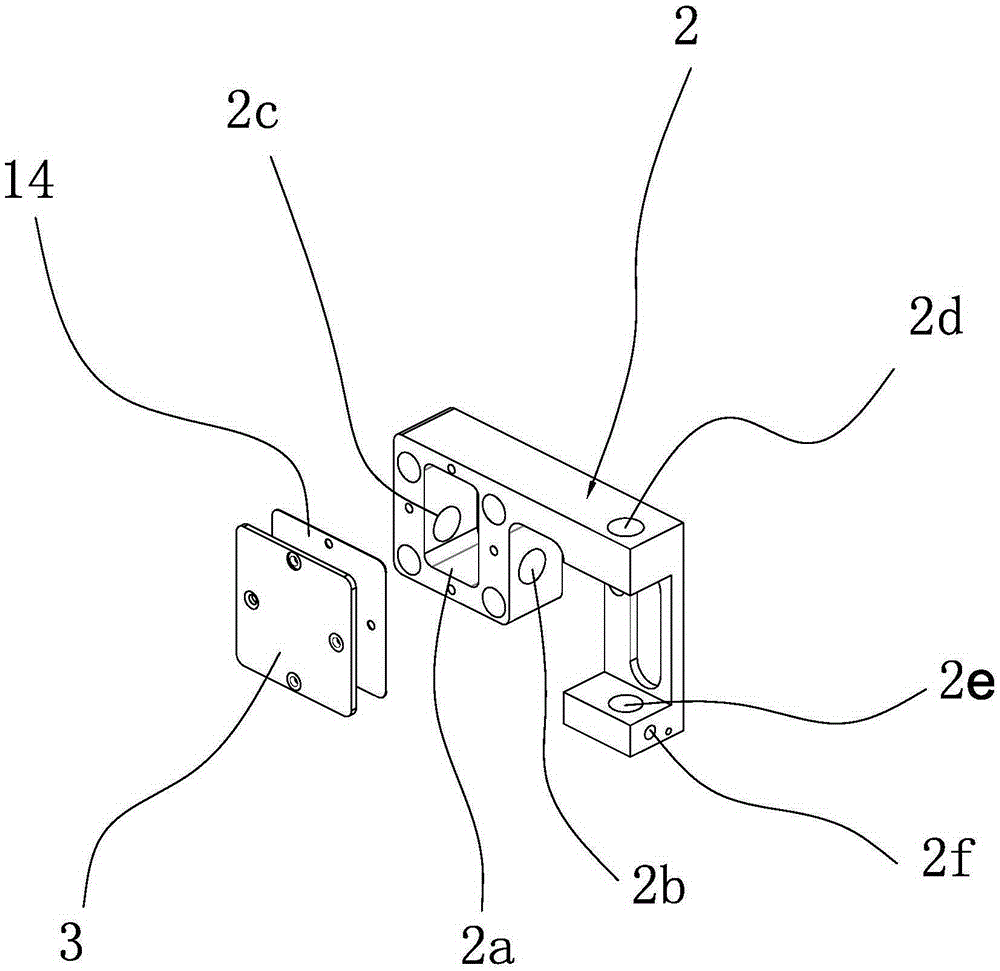

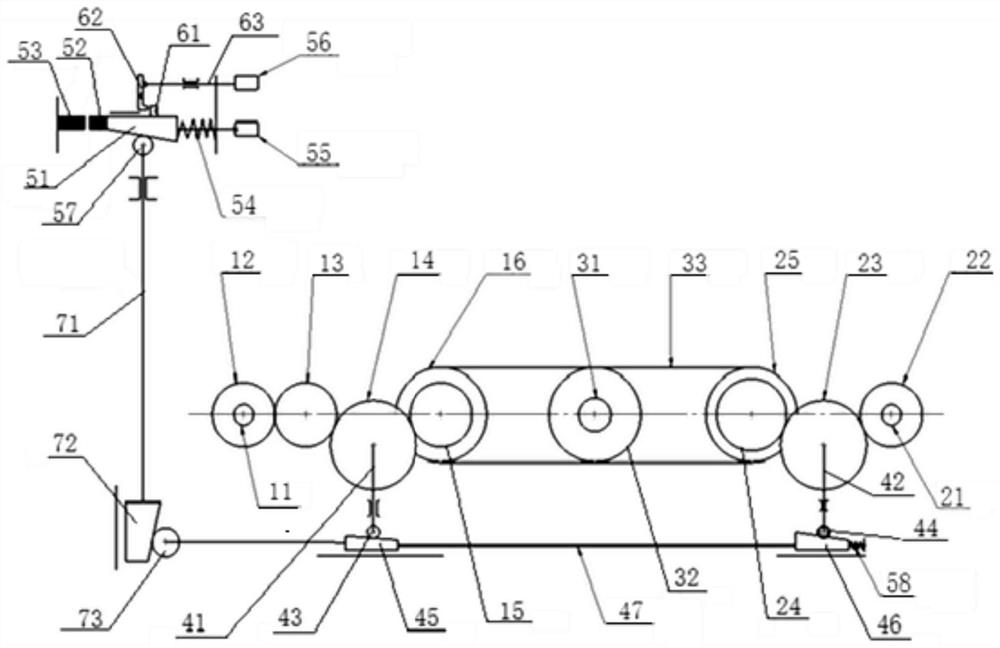

A rear tug wheel device for a sewing machine

InactiveCN103668811BSimple structureBeautiful appearanceSewing-machine control devicesPressersEngineeringDriving mode

The invention provides a rear towing wheel device for a sewing machine, and belongs to the technical field of machinery. The problems of large occupied area, complexity in mounting and debugging synchronization troubles of a conventional rear towing wheel are solved. The rear towing wheel device for the sewing machine comprises a rear towing wheel, a power mechanism for driving the rear towing wheel to ascend and descend and a linkage mechanism for driving the rear towing wheel to ascend and descend along with a presser foot lifting component, wherein a vertically arranged vertical shaft and a rear towing wheel wrench capable of independently driving the rear towing wheel to ascend and descend are arranged on the rear towing wheel; the power mechanism is arranged between a main shaft and the vertical shaft; the linkage mechanism is arranged between the presser foot lifting component and the rear towing wheel, and is connected with a knee-raised pull rod. According to the rear towing wheel device, the rear towing wheel can be independently lifted through the towing wheel wrench, can ascend and descend through the knee-raised pull rod, and can also be operated by the presser foot lifting component to ascend and descend in a linkage way, so that driving modes are diversified, and high practicability is ensured.

Owner:ZHEJIANG SHANGGONG GEM SEWING TECH CO LTD

Automatic walking equipment with adjustable reduction ratio and driving method thereof

PendingCN112145680AImprove driving effectMeet driving needsSpeed controllerControlled membersElectric machineryControl theory

The invention provides automatic walking equipment with an adjustable reduction ratio and a driving method thereof. A clutch and a gear shifting reduction gearbox are arranged between a motor and walking wheels of the automatic walking equipment. According to the automatic walking equipment with the adjustable reduction ratio and the driving method thereof, torque output by the motor can be transmitted through the gear shifting reduction gearbox according to different reduction ratios, so that the automatic walking equipment obtains a better driving effect; and by arranging the clutch, transmission of the torque of the motor can be controlled, and when the automatic walking equipment turns, a larger rotating speed difference is generated between the inner and outer side walking wheels after the equipment is separated from rotation of the motor, so that the automatic walking equipment turns more conveniently.

Owner:NANJING SUMEC INTELLIGENT TECH CO LTD

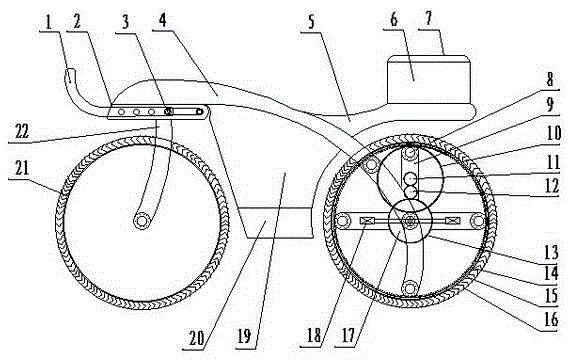

Pedal, electric, solar three-wheel drive bicycle without chain gear transmission

ActiveCN103587637BOvercome wind resistanceComfortable rideWheel based transmissionRider propulsionGear driveMotor drive

The invention provides a chainless gear drive bicycle capable of integrating pedaling drive, electric drive and solar drive. The chainless gear drive bicycle comprises an adjustable handlebar, a handlebar stem, a frame, a front wheel, a rear wheel, a gear drive mechanism, a motor power mechanism and a solar power mechanism. The chainless gear drive bicycle is characterized in that two circles of inner teeth large gears are arranged in an inner ring of a hub of the rear wheel and meshed with a pair of driven large outer gears in the gear drive mechanism for driving, the effect that the ratio of driving force physical torque to ground frictional resistance torque is maximum is achieved, the frame is designed according to human engineering, the handlebar is transversely, vertically, forwards and backwards adjusted, a prostration riding mode and a straight sitting riding mode can be converted, the effects of comfortable riding and the minimum wind resistance are achieved, manpower drive, motor drive and solar drive are scientifically and organically integrated, and the ideal effects of comfort, labor saving, multiple driving modes and the long driving mileage are achieved.

Owner:湖州度信科技有限公司

Inkjet print head and inkjet printer

ActiveCN103496257BBraking structure is simpleLarge amount of deformationInking apparatusComputer printingInk printer

The invention discloses an inkjet printing head, which comprises at least one ejection unit, a cover film matched with the ejection unit, a piezoelectric ceramic actuator and a cover plate, a fluid inflow pipeline, a fluid outflow pipeline and a driving circuit device ; The piezoelectric ceramic brake and the cover plate are connected to form a number of independent piezoelectric ceramic units that are not connected to each other; the cover plate is connected to the injection unit, and the connection contact surface is provided with a number of fluid grooves on one side of the injection unit. The position of the unit corresponds to the position of the groove of the fluid tank; the fluid channel and the cover plate form a fluid channel, and each fluid channel is correspondingly equipped with at least one nozzle leading to the outside, so that the inkjet print head forms side or end surface spraying. Correspondingly, the invention also discloses an inkjet printer. With the present invention, on the premise of increasing the deformation of the piezoelectric ceramic brake and realizing the effective ejection action of the large-diameter ink, adjacent nozzles can operate simultaneously so that all nozzles can work simultaneously, thereby improving work efficiency.

Owner:JIN GANG NEW MATERIALS +2

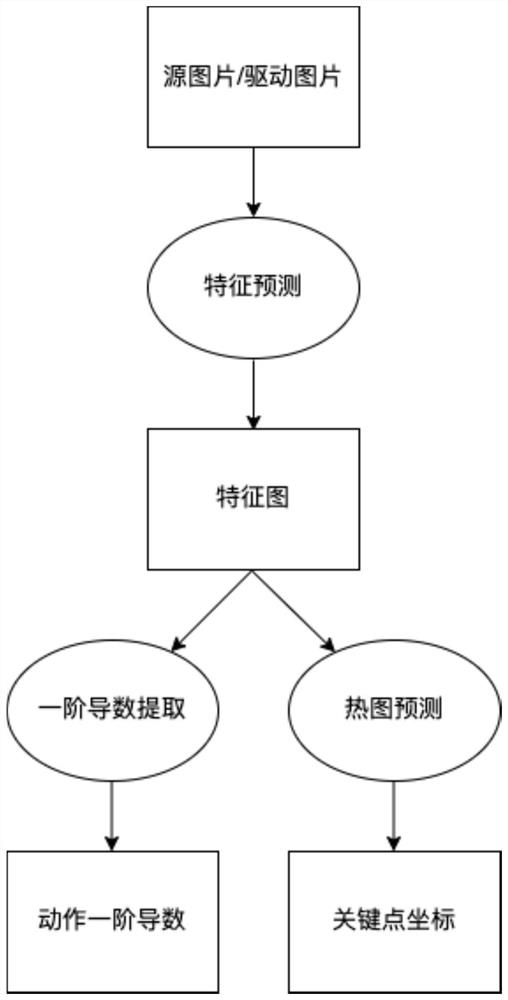

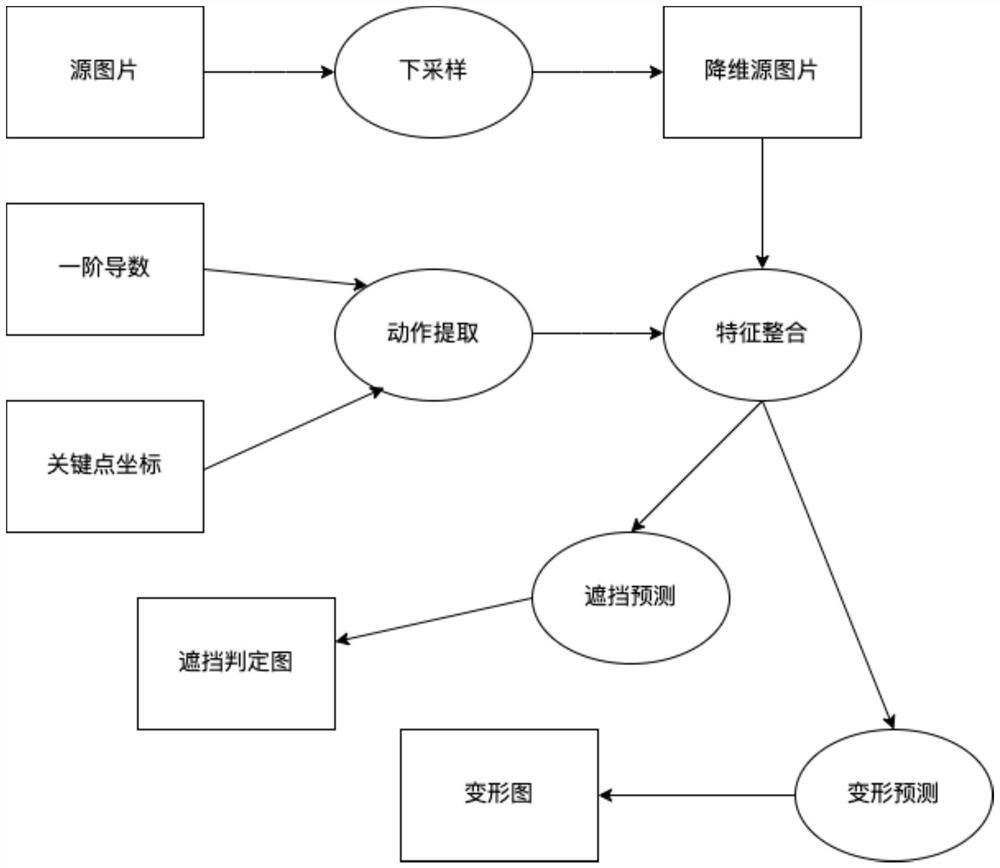

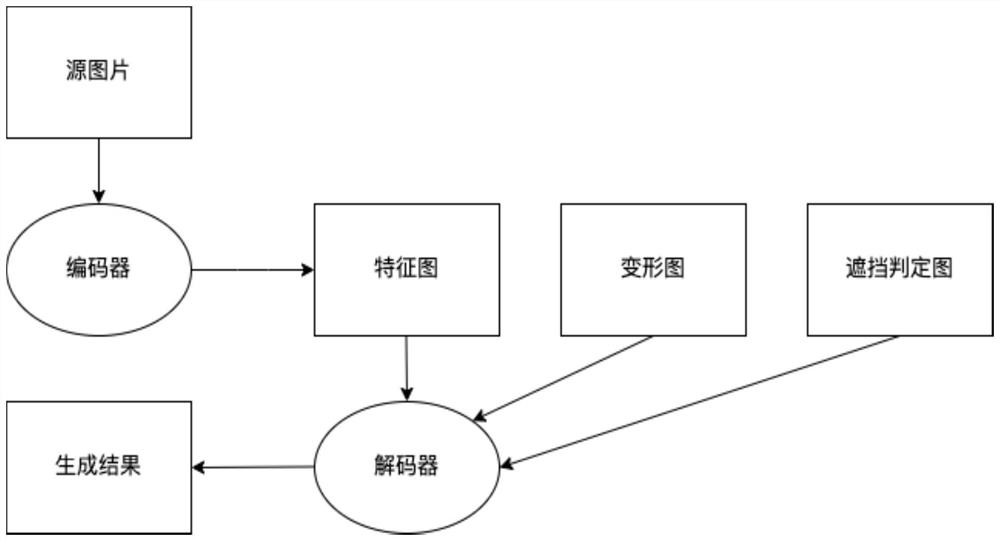

Face image animation method and system based on action and voice features

PendingCN114445529AVarious drive methodsMeet various needsCharacter and pattern recognitionAnimationComputer visionSpeech sound

The invention discloses a face image animation method and system based on action and voice features. The face image animation method comprises an image driving mode and a voice driving mode. Wherein the image driving mode comprises the following steps: inputting a conversation video of a human face and a human face of another person to obtain a dynamic image video of the other person which is originally a static picture; the voice driving mode is as follows: training is carried out for a certain specific person, when the features of another person are used for prediction, one-step conversion is carried out on the features, the features are converted into sound features of the trained person, face feature conversion is carried out on the sound features, and a face image animation is obtained. According to the invention, the target person can be driven in video and audio driving modes, the driving modes are diversified, and various requirements can be met.

Owner:北京中科深智科技有限公司

Multifunctional clothes hanger fixed on balcony and extending outwards

InactiveCN111809366AAvoid knockingSave human effortOther drying apparatusTextiles and paperRatchetElectric machinery

The invention discloses a multifunctional clothes hanger fixed on a balcony and extending outwards, comprising a fixing frame, wherein the center of the inner wall of the fixing frame is fixedly connected with a center airing rod. The part, located on one side of the center airing rod, of the top of the fixing frame is fixedly connected with a top plate. Supporting rods are fixedly connected to the two ends of the side, close to the center airing rod, of the top plate. Rotating grooves are formed in the ends, away from the top plate, of the supporting rods; and a bearing is fixedly connected to the inner walls of the rotating grooves, a beating device is fixedly connected to the inner wall of the bearing, a supporting plate is fixedly connected to one side of the inner wall of the fixing frame, a driving motor and a support are fixedly connected to one end of the top of the supporting plate, and a ratchet wheel is rotatably connected to the inner wall of the support. The multifunctional clothes hanger fixed on the balcony and extending outwards has multiple functions, can prevent people from stretching out of the body to knock a quilt manually, saves manpower, is safe and reliableto use, and is high in drying efficiency.

Owner:苏亮

Door leaf synchronous linkage clutch device and side door

ActiveCN111321971BVarious drive methodsGood choicePower-operated mechanismControl engineeringControl theory

The invention provides a door leaf synchronous linkage clutch device and a side-by-side door, which relate to the technical field of side-by-side doors. The door leaf synchronous linkage clutch device, the left door shaft wheel is coaxially arranged on the left door shaft, the transition wheel is connected to the left door shaft wheel, the right door shaft wheel is coaxially arranged on the right door shaft; the left door shaft is coaxially arranged on the left synchronous wheel There is a left pulley, and the right pulley is coaxially arranged on the right synchronous pulley, and a synchronous belt is connected between the left pulley and the right pulley; The right clutch wheel is set between the synchronous wheels; the clutch mechanism drives the left clutch wheel and the right clutch wheel to be in or not in the press-fit state; in the press-fit state, the transition wheel is connected to the left synchronous wheel through the transmission of the left clutch wheel, and the right door shaft wheel is connected through the right clutch The wheel drive connects the right synchronous wheel. The beneficial effect of the present invention is that by controlling the clutch mechanism by touching the operating mechanism, the synchronous opening and closing of two door leaves can be realized, and the single action of a single door leaf can also be realized.

Owner:QINGDAO CCS ELECTRIC CORP

Shift register unit, driving method, gate driving circuit and display device

ActiveCN106205461BVarious drive methodsAdjust charging timeStatic indicating devicesDigital storageShift registerDisplay device

Owner:BOE TECH GRP CO LTD +1

An intermittently driven non-abrasive hard-sealed butterfly valve

ActiveCN106678378BVarious drive methodsWide applicabilitySpindle sealingsOperating means/releasing devices for valvesBusbarEngineering

The invention discloses an intermittent drive non-abrasion hard sealed butterfly valve. The intermittent drive non-abrasion hard sealed butterfly valve is characterized in that the butterfly valve comprises a valve body, a movable valve seat, a valve rod, a lower valve rod sleeve, an upper valve rod sleeve, a butterfly plate and an intermittent driving device; the left side and the right side of the valve body are provided with flanges perpendicular to the axis of the valve body; the flanges are used for connecting the butterfly valve with a pipeline flange; the upper end and the lower end of the valve body are provided with an upper valve rod sleeve hole and a lower valve rod sleeve hole; a cavity of the valve body is a stepped hole; the upper valve rod sleeve and the lower valve rod sleeve penetrate into the valve body through the upper valve rod sleeve hole and the lower valve rod sleeve hole correspondingly; retainer cups are arranged between the upper valve rod sleeve and the valve body as well as between the lower valve rod sleeve and the valve body; the retainer cups are connected with the valve body through bolts, and adjusting gaskets are installed between the retainer cups and the valve body; both the upper end and the lower end of the same busbar of the upper valve rod sleeve are provided with flat key grooves, in addition, an upper cam is fixedly installed at the lower end of the upper valve rod sleeve through a flat key, and the upper end of the upper valve rod sleeve is connected with the intermittent driving device; the upper end of the lower valve rod sleeve is provided with a flat key groove, and a lower cam is fixedly installed at the upper end of the lower valve rod sleeve through a flat key; and a transferring shaft is installed between the upper cam and the lower cam.

Owner:HEBEI UNIV OF TECH

Shift register unit, driving method, gate driving circuit and display device

ActiveCN106251804BVarious drive methodsAdjust charging timeStatic indicating devicesDigital storageShift registerDisplay device

The invention discloses a shift register unit, a driving method, a grid driving circuit and a display device, belonging to the field of display technology. The shift register unit includes: a clock control module, an output control module and an output module; the shift register unit can output clock signals of different frequencies or different duty ratios to the output control module and the output module respectively through the clock control module , so that the output module can output driving signals of different frequencies or different duty ratios to the pixel units through the output terminal, so as to adjust the charging time of the shift register unit for each row of pixel units, thus enriching the gate driving circuit for display The drive mode of the device improves the flexibility of the drive. The invention is used to display images.

Owner:BOE TECH GRP CO LTD +1

A conveying device for rubber mat production

ActiveCN111674903BVarious drive methodsEasy to useControl devices for conveyorsSupporting framesEngineeringRubber mat

Owner:山东驼风汽车科技股份有限公司

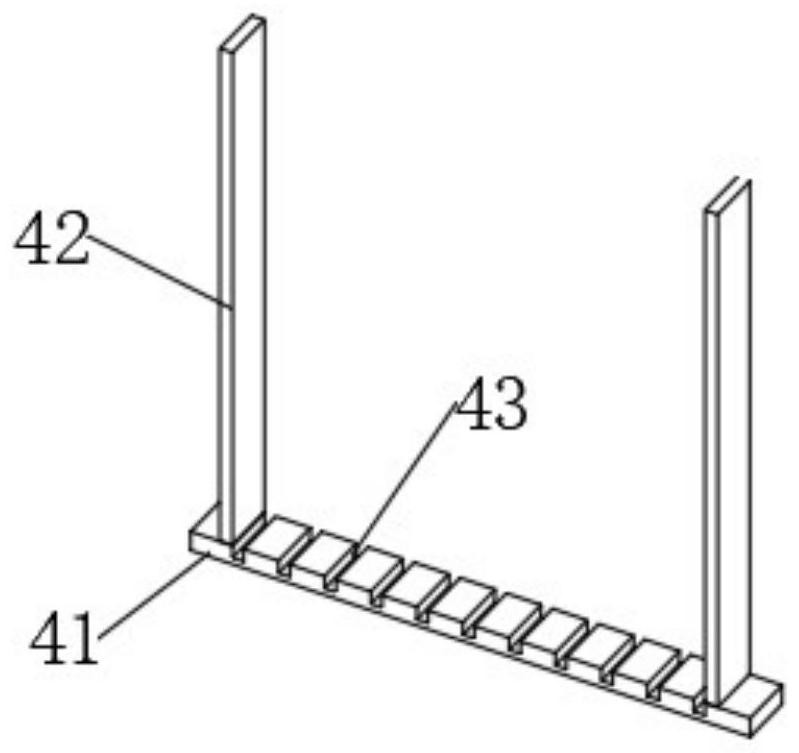

Transportation structure for rock wool board processing

InactiveCN114275024AEasy to pullEasy to pull by handHand carts with multiple axesHand cart accessoriesStructural engineeringMechanical engineering

The transportation structure for rock wool board processing comprises a bottom plate, vertical plates are fixedly installed on the left portion and the right portion of the upper end of the bottom plate, a bearing plate is fixedly installed at the upper ends of the two vertical plates, and fixing bases are fixedly installed on the front portion and the rear portion of the upper end of the bearing plate; a feeding mechanism is arranged between the two vertical plates, a plurality of rock wool board bodies are jointly placed between the two fixing bases, two fixing frames are jointly arranged at the upper ends of the rock wool board bodies, moving mechanisms are fixedly installed at the four corners of the lower end of the bottom plate, and vertical rods are fixedly installed at the left rear corner and the right rear corner of the upper end of the bottom plate. A connecting plate is fixedly connected between the two vertical rods, and handles are fixedly mounted at the upper parts of the rear ends of the two vertical rods. The transportation structure for rock wool board processing is high in working efficiency, convenient to use, capable of achieving a good protection effect on rock wool boards in the transportation process and suitable for popularization.

Owner:江苏罗科雷森建筑材料科技有限公司

A zero friction hard seal butterfly valve

ActiveCN105221767BExtended service lifeAvoid frictionOperating means/releasing devices for valvesLift valveInterference fitGear wheel

The invention discloses a zero-friction hard seal butterfly valve. The zero-friction hard seal butterfly valve is characterized in that the butterfly valve comprises a valve opening, a valve body, a valve seat, a disc, a valve shaft, a guide groove, an incomplete gear, a rack, a guide shaft No.1, a guide shaft No.2, a self-lubricating shaft sleeve, a linkage rod, an intermittent mechanism, a driving handle and a seal device, a through hole is formed in the valve body, a valve neck is welded at the part of the through hole, the valve seat is welded on the inner circumferential surface of the valve body, and the outer circumferential surface of the valve seat is a conical surface; the disc is a moving type disc and adopts a ring structure, a hard seal ring is mounted at the outer circle part of the disc, and the movement type refers to a motion structural mode that the disc can first make transverse movement along the axial direction of the valve body and then rotate with the guide shaft No.1 as a center and is opened in a zero friction manner; the disc is connected with the guide shaft No.1; the guide shaft No.1 is mounted in the guide groove and penetrates through the rack, and the guide shaft No.1 is also in interference fit with the rack at the connecting part; and the guide shaft No.2 is also mounted in the guide groove.

Owner:JIANGSU HUATAI ELECTRIC POWER ELECTRONICS INSTR

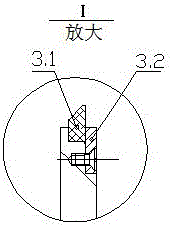

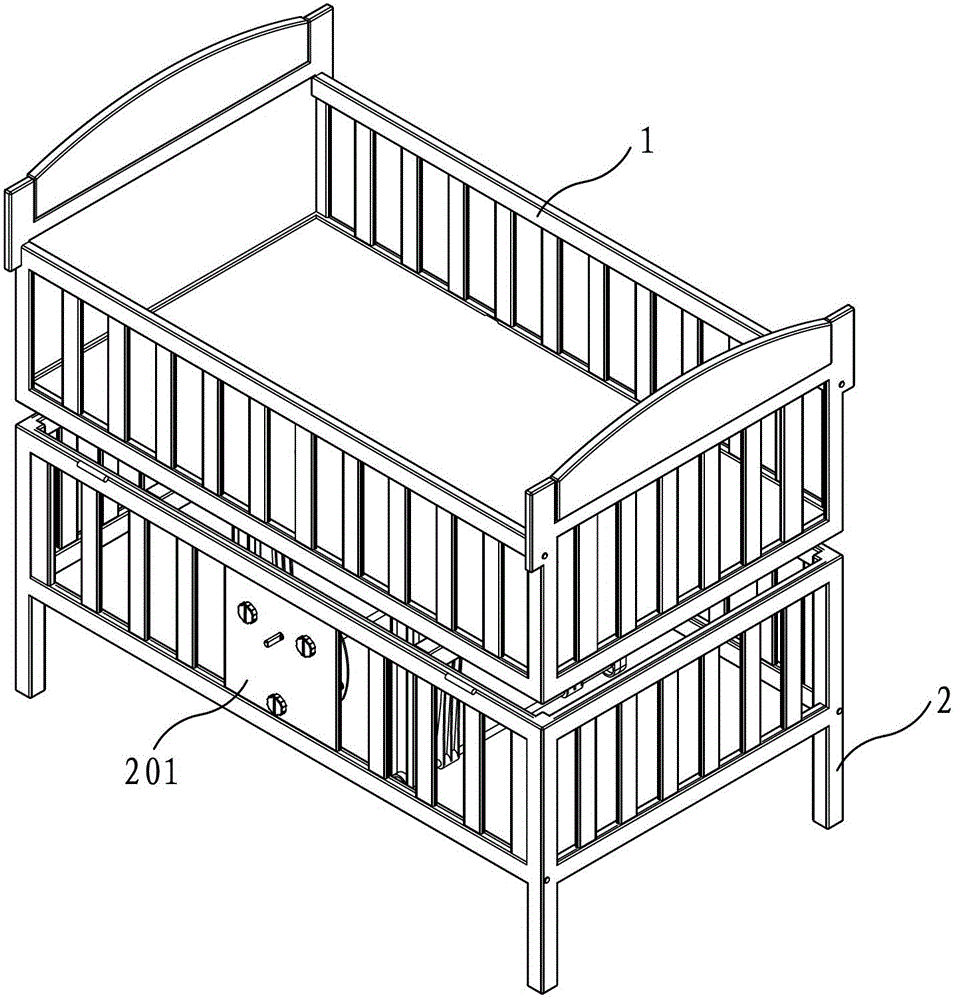

Baby cradle and swaying method thereof

The invention relates to a baby cradle and a swaying method thereof and is designed, aiming at the technical problem that the existing like structure is not good enough in design. The cradle body of the baby cradle comprises a swinging bed and a bed frame; the baby cradle has the following key points: a rocker mechanism is arranged between the swinging bed and the bed frame, a gap for the rocker mechanism to swing left and right is formed, and the rocker mechanism is connected with a swinging component of a driving plate through a hauling rope; and the rocker mechanism consists of two groups of symmetrically-arranged rocker components, and a fixing rod, a swing rod and a driving rod in each group of rocker component are arranged symmetrically to constitute a connecting rod; and the driving plate is arranged on a mounting plate at one side of the bed frame through bolts. The first connecting rod is connected with one ends of the swing rod and the driving rod of each rocker component, and the second connecting rod is connected with the other ends of the fixing rod and the driving rod of each rocker component. According to the baby cradle and the swaying method, the structural design is reasonable, the use, production, assembly and disassembly, and maintenance are convenient, various driving modes can be adopted, the energy consumption and driving force are small, the swaying lasts for long time, and energy conservation and environmental protection are realized; and the baby cradle is suitable for being used as a baby cradle and a structural improvement of like products.

Owner:茅鸿勇

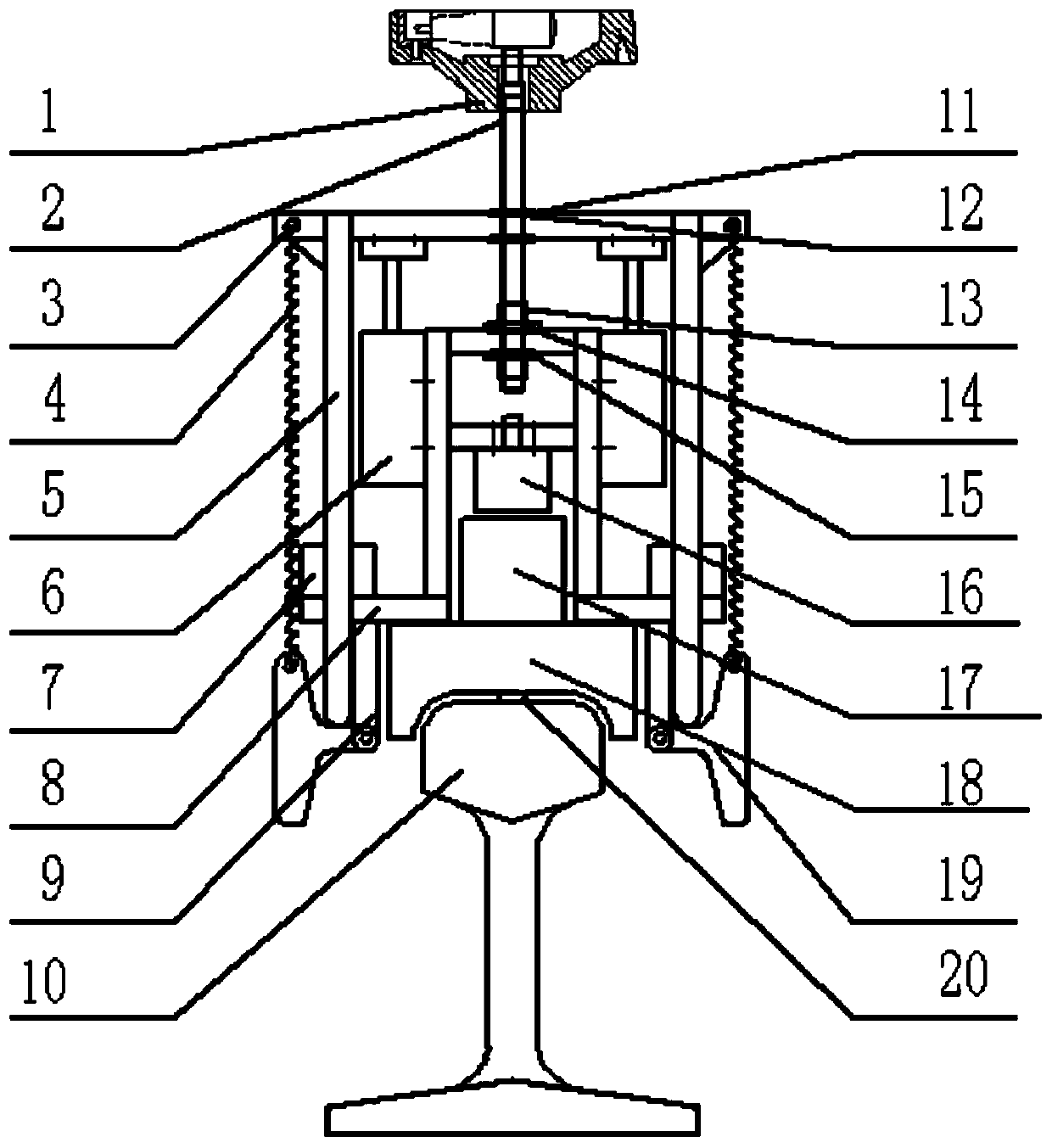

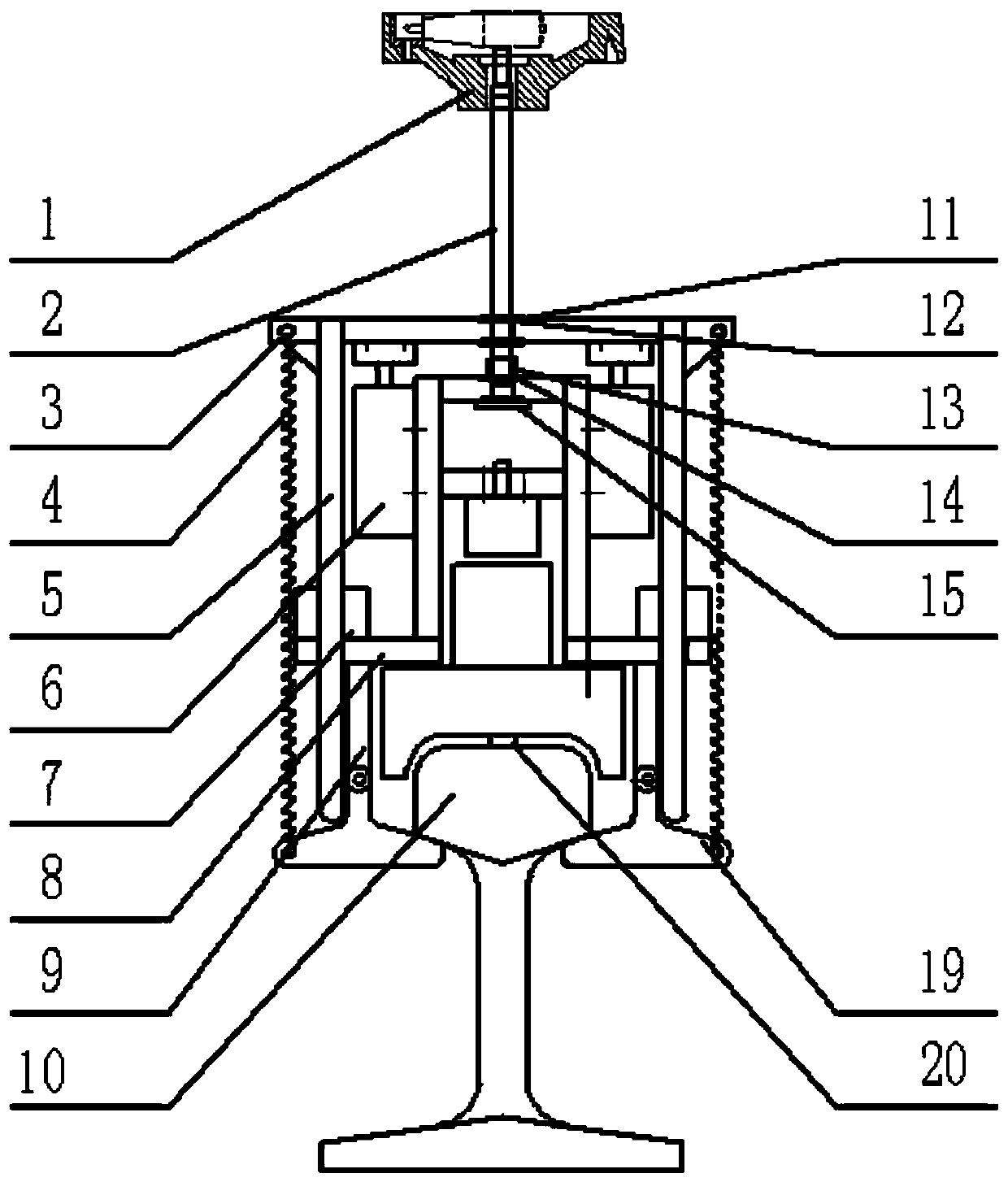

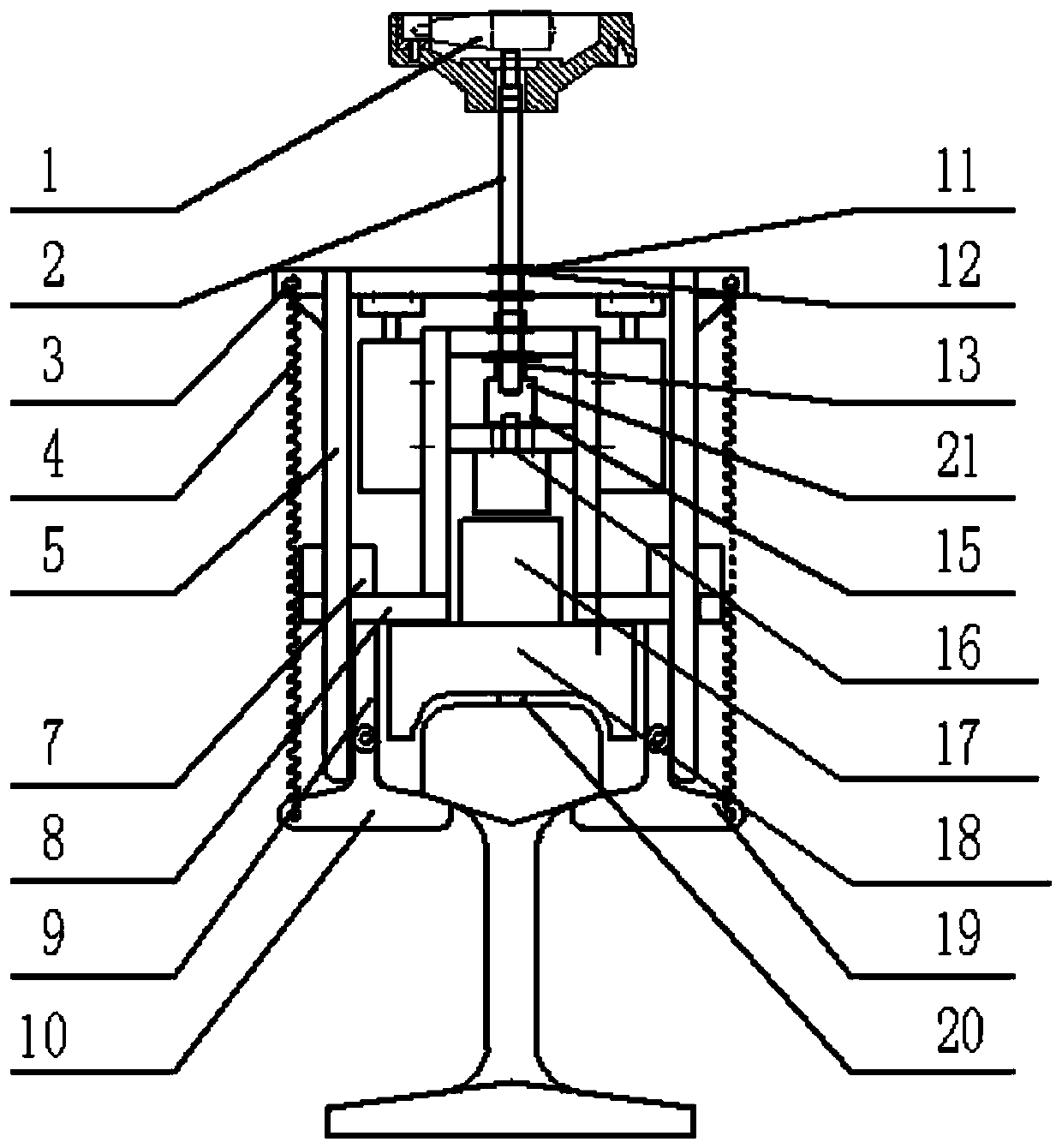

Multi-drive system titanium alloy rail stress detection device

ActiveCN109752129ASimple structureEasy to operateApparatus for force/torque/work measurementMeasurement deviceRail stressing

The invention discloses a multi-drive system titanium alloy rail stress detection device, comprising three working modes of a pneumatic working mode, an electric working mode and a manual working mode. Rail stress detection can be carried out under any severe environment. The device is applicable to stress detection of various rails such as a high-speed rail, a metro and a light rail. In a rail stress detection process, rapid measurement is carried out on stress of the rails such as the high-speed rail, the metro and the light rail through utilization of a simple and feasible measurement device. Drive modes of the measurement device are diversified. Measurement rail types are diversified. The detection device is simple in structure and is easy to operate. After the detection device is employed, dependence of the detection device on an external environment is greatly reduced. Detection efficiency is improved. Detection difficulty is reduced. An operation structure is simple and is easyto operate. After the operation structure is employed, working efficiency can be greatly improved.

Owner:宝鸡欧亚金属科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com