A rear tug wheel device for a sewing machine

A sewing machine and tugboat technology, which is applied in the direction of sewing machine control devices, sewing machine components, sewing equipment, etc., can solve the problems of cumbersome installation, troublesome debugging synchronization, inconvenient use, etc., and achieve reduced maintenance costs, diverse driving methods, and great practicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The following are specific embodiments of the present invention and in conjunction with the accompanying drawings, the technical solutions of the present invention are further described, but the present invention is not limited to these embodiments.

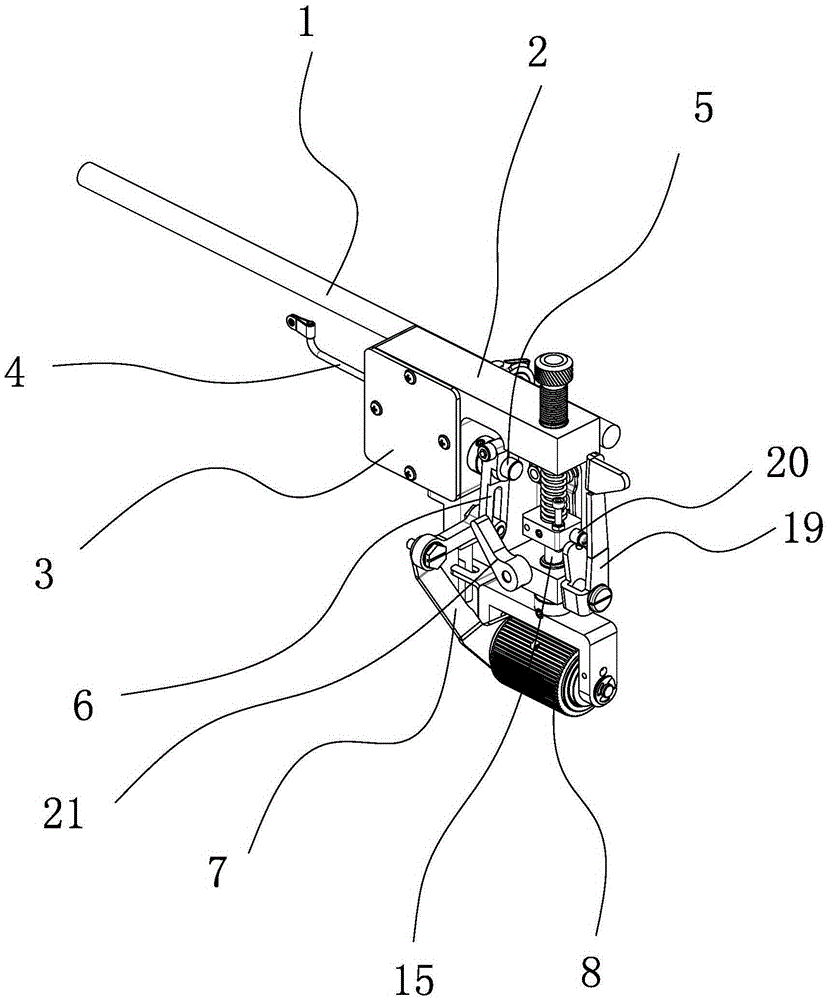

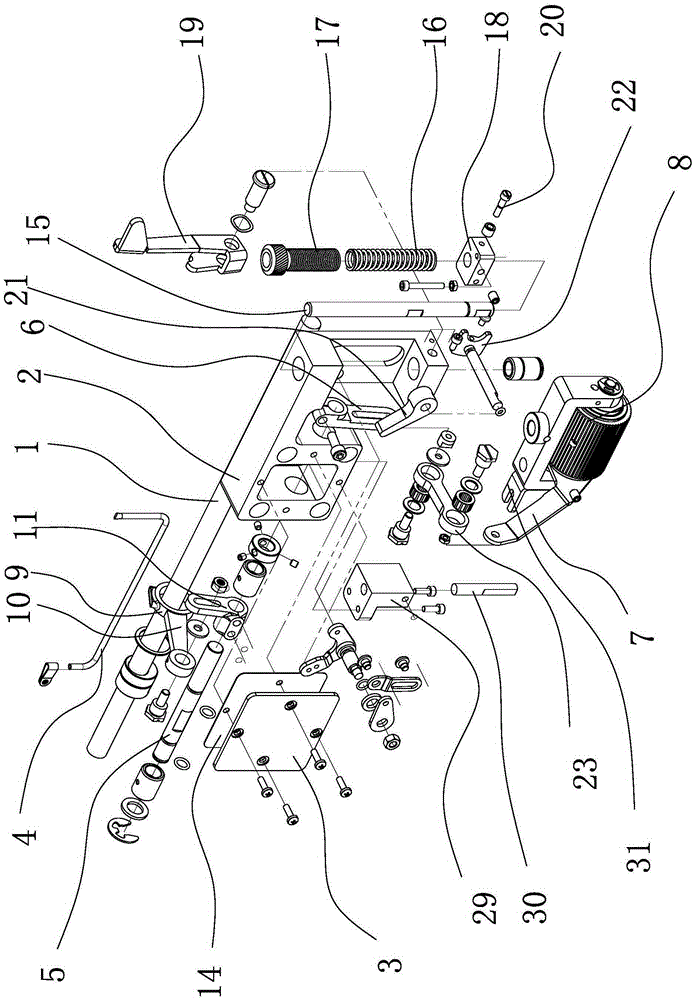

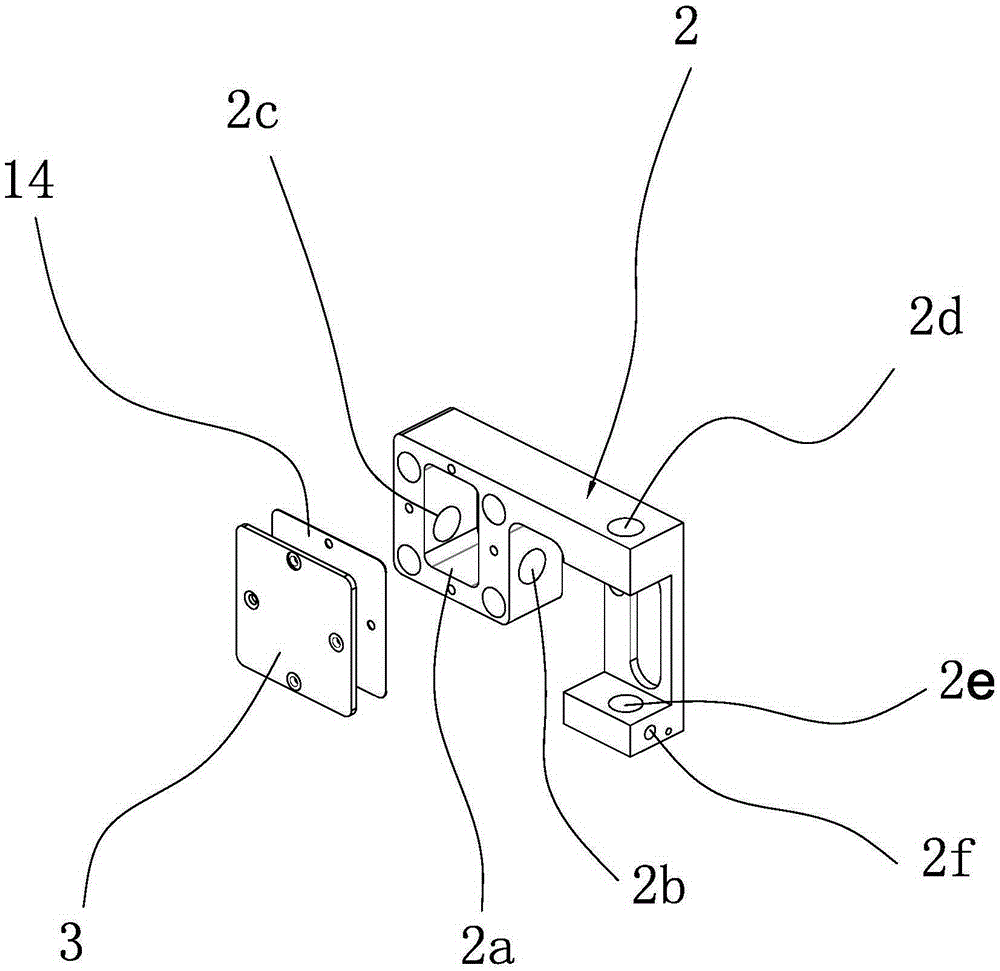

[0026] refer to figure 1 and figure 2 , the present embodiment is a rear tug wheel device of a sewing machine, which has a closed and integrated automatic lubrication structure, and can also realize the linkage between the rear tug wheel and the presser foot. The sewing machine in the present embodiment comprises machine head, main shaft 1, lifting presser foot assembly and rear tugwheel device, and this rear tugboat device comprises rear tugwheel 8, is used for driving the power mechanism of rear tugwheel 8 lifting and is used for driving rear tugwheel 8 along with Linkage mechanism for lifting presser foot assembly. There is a vertical shaft 15 vertically arranged on the rear tug wheel 8 and a rear tug wheel wrench 19...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com