Intermittent drive non-abrasion hard sealed butterfly valve

A hard-sealing, non-wearing technology, applied in shaft seals, lift valves, valve details, etc., can solve the problems of complex manufacturing process and assembly process, uneven specific pressure of the sealing surface, reduced valve stem strength, etc., and achieve installation accuracy. Low requirements, various drive modes, and improved sealing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Further describe the present invention below in conjunction with embodiment and accompanying drawing thereof, but it does not limit the protection scope of the claims of the present invention.

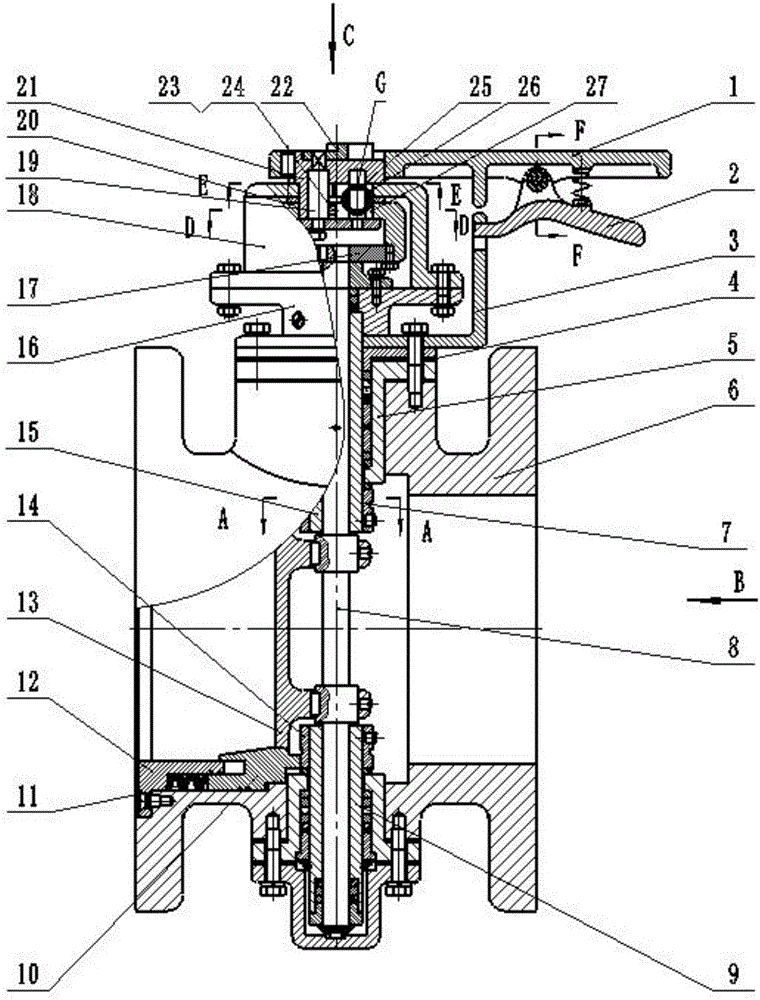

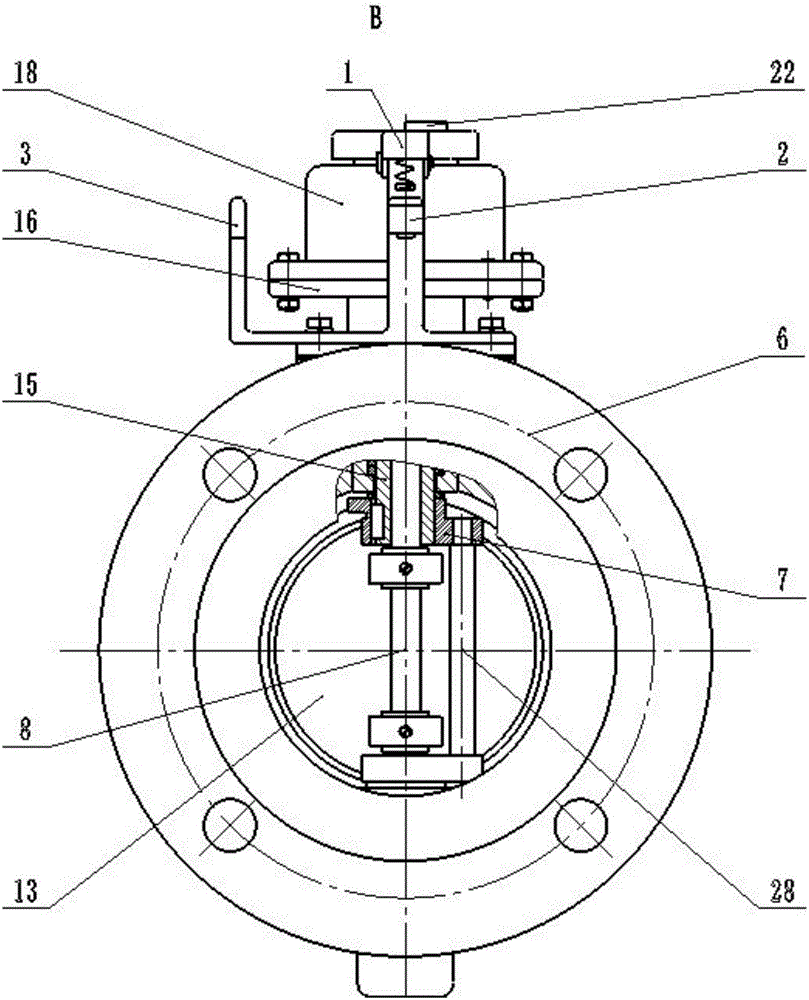

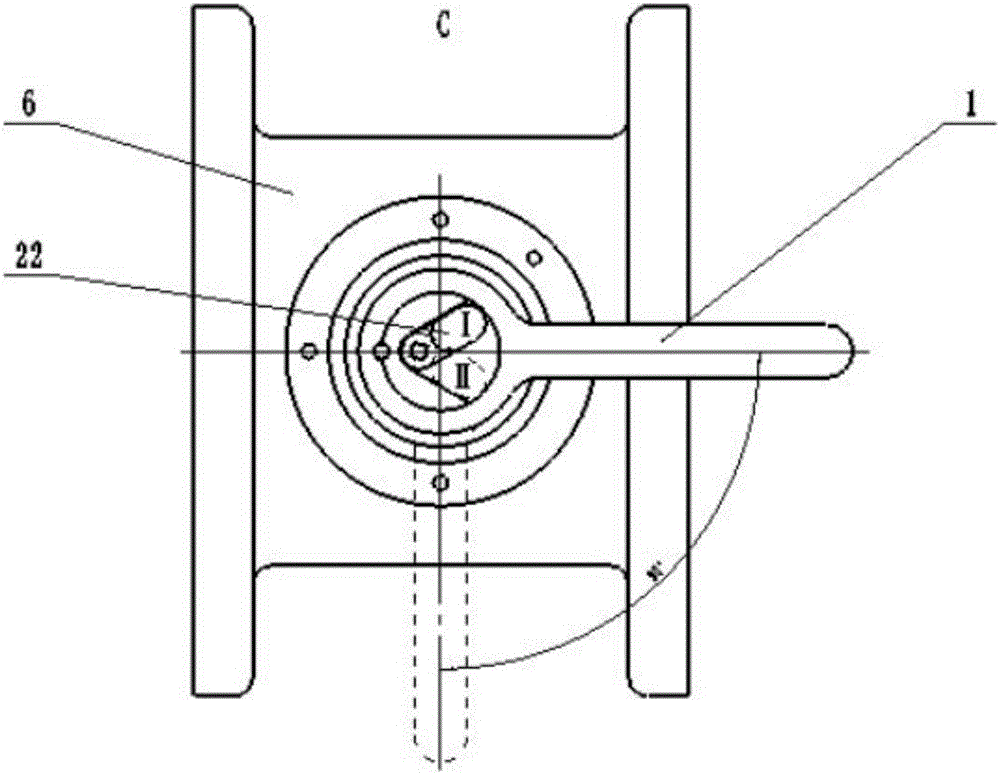

[0026] An intermittently driven wear-free hard-sealed butterfly valve designed by the present invention (hereinafter referred to as butterfly valve, see figure 1 ), the butterfly valve includes a valve body 6, a movable valve seat 10, a valve stem 8, a lower valve stem cover 9, an upper valve stem cover 15, a butterfly plate 13 and an intermittent drive device; The flange of the body 6 axis is used for the connection between the butterfly valve and the pipeline flange, and the upper and lower ends of the valve body 6 are provided with an upper valve stem sleeve hole and a lower valve stem sleeve hole, and the overall valve body 6 is cast process, the design and manufacturing process is simple, the processing is convenient, and the cost is reduced. The actual production is relati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com