Multi-drive system titanium alloy rail stress detection device

A stress detection, titanium alloy technology, applied in the direction of measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem that the rail stress detection device is difficult to adapt to different environmental requirements, achieve a variety of measurement rail types, and reduce the external environment Dependence, the effect of improving detection efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

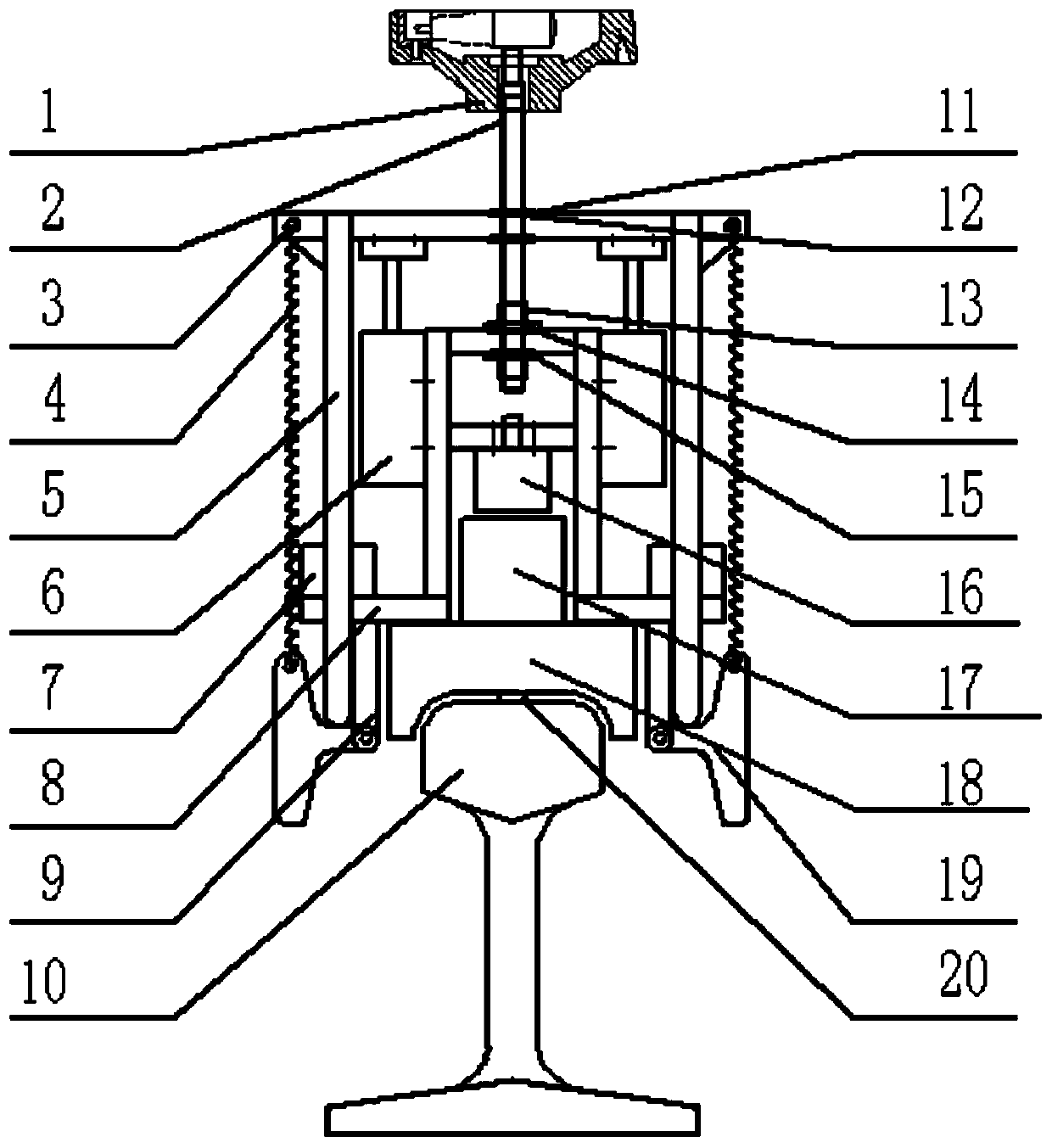

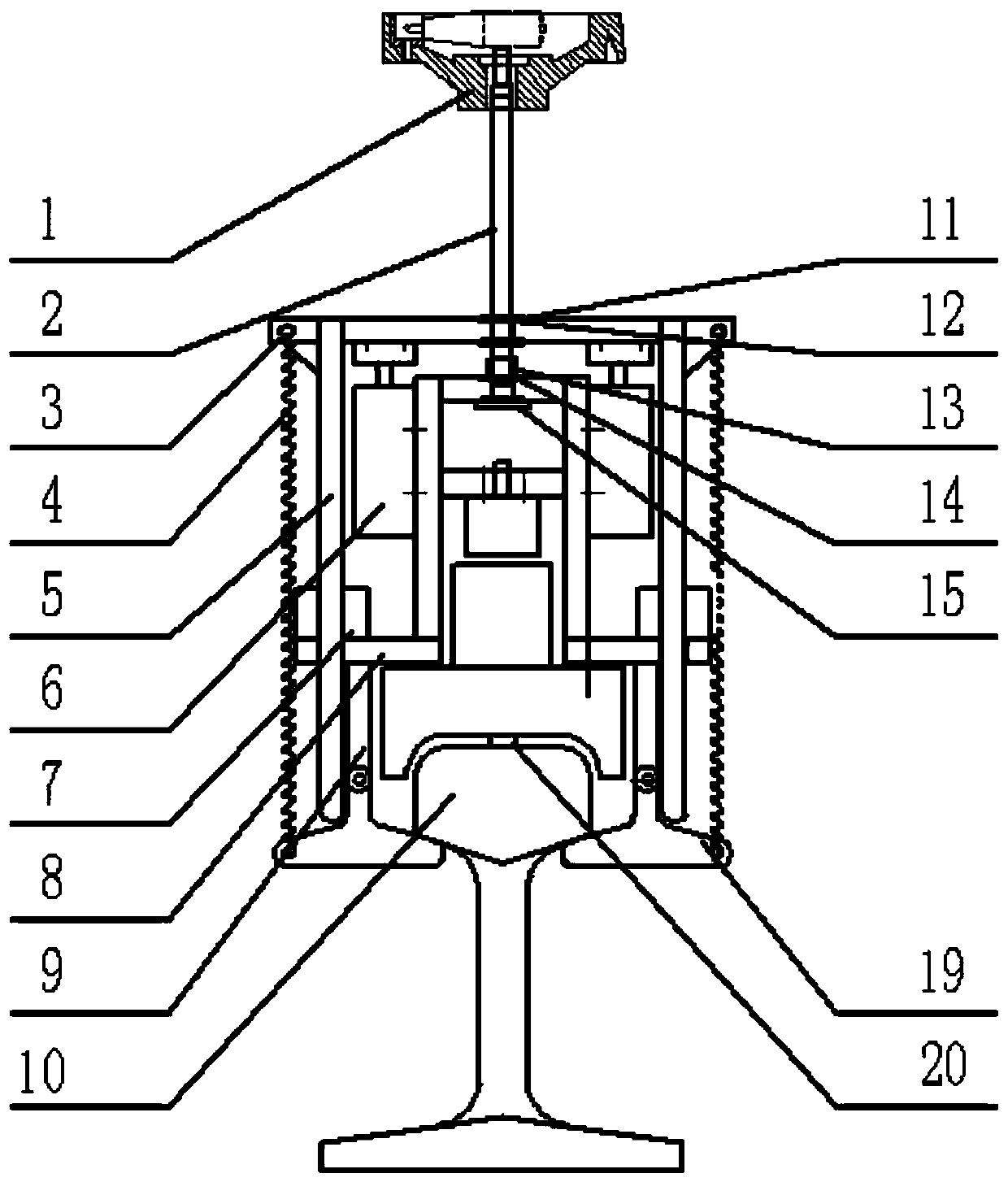

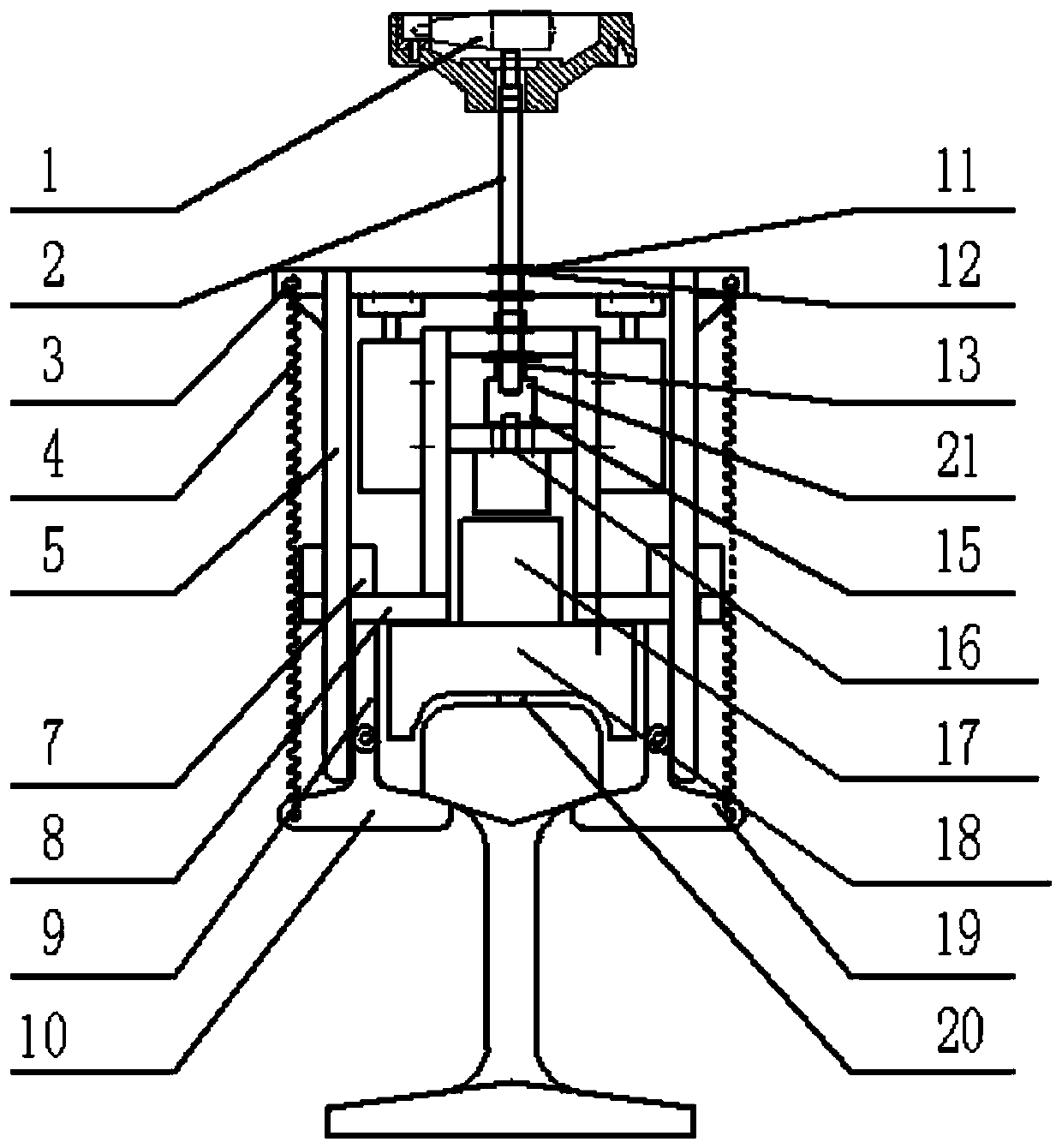

[0017] A multi-drive system titanium alloy track stress detection device of the present invention comprises a foldable handwheel 1, the output end of the foldable handwheel 1 is connected to one end of a lead screw 2, the middle part of the lead screw 2 is provided with a beam 3, and the lead screw 2 Go through the crossbeam 3 and set it perpendicular to the crossbeam 3. At the connection between the lead screw 2 and the crossbeam 3, a limit nut 11 is arranged above the crossbeam 3, and a lead screw nut 12 is arranged below. Both ends of the crossbeam 3 are connected to one end of the spring 4. , the other end of the spring 4 is connected with a claw 19, the cross-section of the claw 19 is a T-shaped structure, the spring 4 is vertically arranged with the crossbeam 3, and the two ends of the crossbeam 3 are fixedly connected with a vertical be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com