Plastic film welding device

A welding device and plastic film technology, which is applied in the field of plastic film welding device and ethylene-tetrafluoroethylene copolymer film welding, can solve the problems that ordinary plastic welders cannot be used for direct welding, so as to reduce safety accidents and improve stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

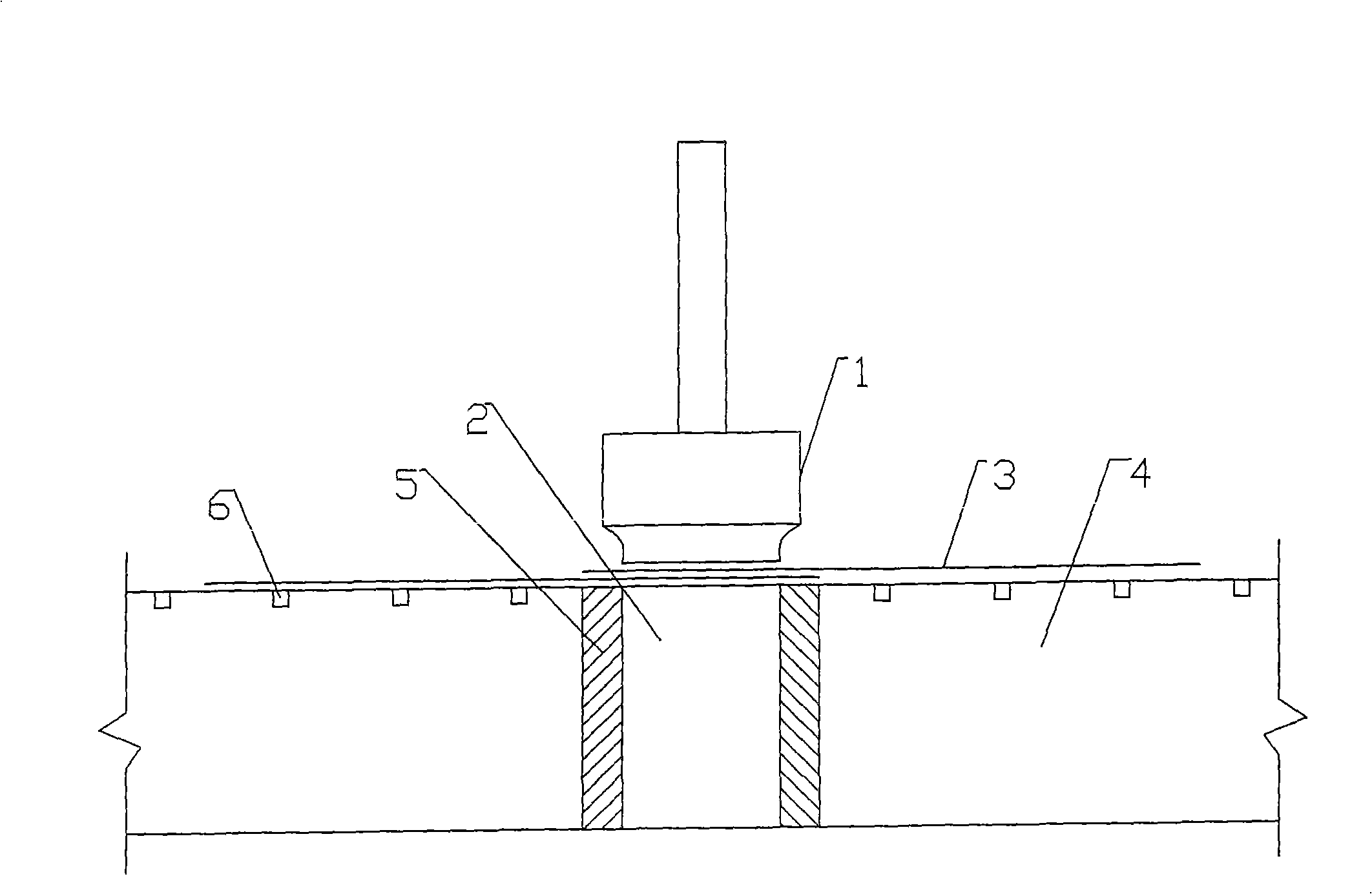

[0021] A plastic film welding device, including a heating plate 1 driven by a driver, a heating electrode 2 matched with the heating plate 1, and two working platforms 4 for placing plastic films 3, the working platforms can be made of high temperature resistant materials, and the heating The electrode 2 is arranged between the two working platforms 4, and the heating plate 1 is arranged above the heating electrode 2 to cooperate with the heating electrode to weld the plastic film. The driver in the present invention is a hydraulic driver, an electric driver, a cylinder driver and the like.

[0022] Working process of the present invention is as follows:

[0023] First, place the plastic film 3 superimposed on the welding edge on the working platform 4, and the superimposed welding layer is located on the heating electrode 2, and then start the driver to drive the heating plate 1 to move to the heating electrode 2, and the heating plate 1 moves to the heating electrode 2 When...

Embodiment 2

[0025] A plastic film welding device, including a heating plate 1 driven by a driver, a heating electrode 2 matched with the heating plate 1, and two working platforms 4 for placing plastic films, and the heating electrode 2 is arranged between the two working platforms 4 , the heating plate 1 is arranged above the heating electrode 2 . The driver in the present invention is a hydraulic driver, an electric driver, a cylinder driver and the like. Moreover, an insulating layer 5 is arranged between the working platform 4 and the heating electrode 2, and the working platform 4, the insulating layer 5 and the heating electrode 2 are fixedly connected as a whole.

Embodiment 3

[0027] A plastic film welding device, comprising a heating plate 1 driven by a driver, a heating electrode 2 cooperating with the heating plate 1, and two working platforms 4 for placing a plastic film 3, the heating electrode 2 is arranged on the two working platforms 4 Between, the heating plate 1 is arranged above the heating electrode 2 . The driver in the present invention is a hydraulic driver, an electric driver, a cylinder driver and the like. Moreover, an insulating layer 5 is arranged between the working platform 4 and the heating electrode 2, and the working platform 4, the insulating layer 5 and the heating electrode 2 are fixedly connected as a whole. The working platform 4 is set as a vacuum adsorption platform, and the working surface of the working platform 4 is provided with adsorption holes 6 for absorbing plastic films.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com