Gas welding method for ultra-thin stainless steel workpieces

A technology of stainless steel and stainless steel wire, applied in the direction of gas flame welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of power supply, low productivity, and large environmental impact, and achieve simple operation methods, high work efficiency, and low labor intensity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

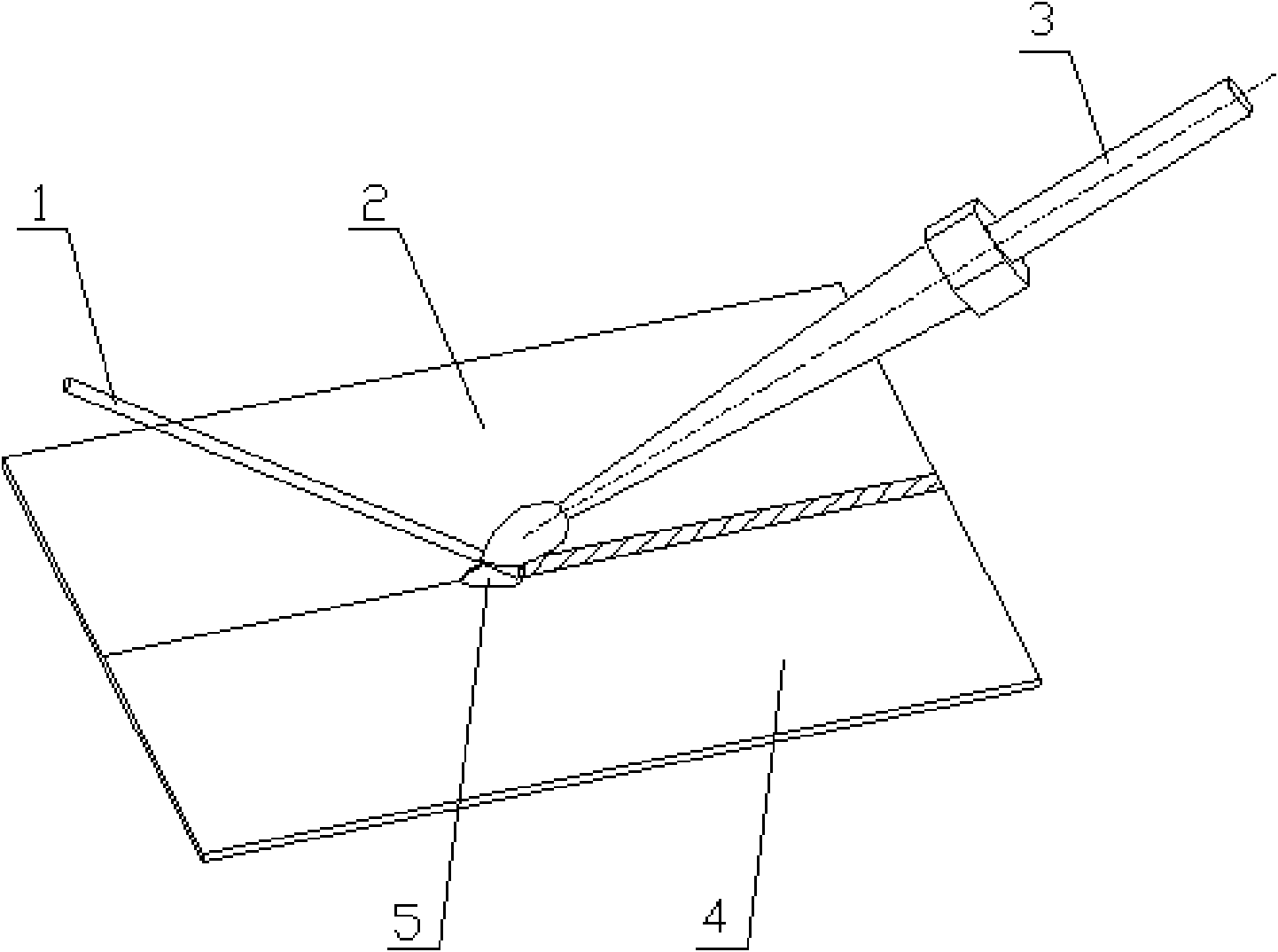

[0025] When the welding material is 1Cr18Ni9Ti, Φ25×1.2 mm acid tank heating tube, first use the usual method to remove the rust, oil stains, paint and other dirt in the welded area, and select the welding wire 1 with the brand name of 0Cr18Ni9Ti and a diameter of 1.5 mm. Apply type "101" solder powder to the wire and weld. Align the two acid tank heating tubes 2 and 4 that need to be welded, and position the two workpieces by spot welding. The distance between points during spot welding is 30 mm. The aperture of the welding tip used by the thick low carbon steel is small, and the present embodiment adopts the No. 4 welding tip of the small size, and welds the heating pipes of the two acid tanks with the heat dissipation method of the loose welding method or the rigid fixing method. When welding, weld in sections from the middle to both ends. There is no heat treatment after welding, and the performance of the weld is good.

Embodiment 2

[0027] The welding material is 1Cr18Ni9Ti, Φ60×0.8 mm engineering safety guardrail. First, use the usual method to remove the rust, oil stains, paint and other dirt in the welded area. "101" solder powder is applied to the wire and to the weld. Align the two acid tank heating tubes that need to be welded, and position the two workpieces by spot welding. The distance between the spots during spot welding is 30mm. The flame adopts a slight carbonization flame. The welding tip used by the carbon steel has a small aperture. In this embodiment, a small No. 4 welding tip is used, and the two acid tank heating pipes are welded by a loose welding heat dissipation method or a rigid fixing method. When welding, weld in sections from the middle to both ends. There is no heat treatment after welding, and the joint performance is good.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com