Methods for connecting double-surface printed circuit board and welding electronic components by employing ultrasonic waves

A technology of ultrasonic welding and double-sided printing, which is applied in the direction of assembling printed circuits, electrical components, and printed circuits with electrical components, which can solve the problems of high price and many filling metal processes, achieve short welding time, and meet the utilization rate of space design. , the effect of not fragile metal properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

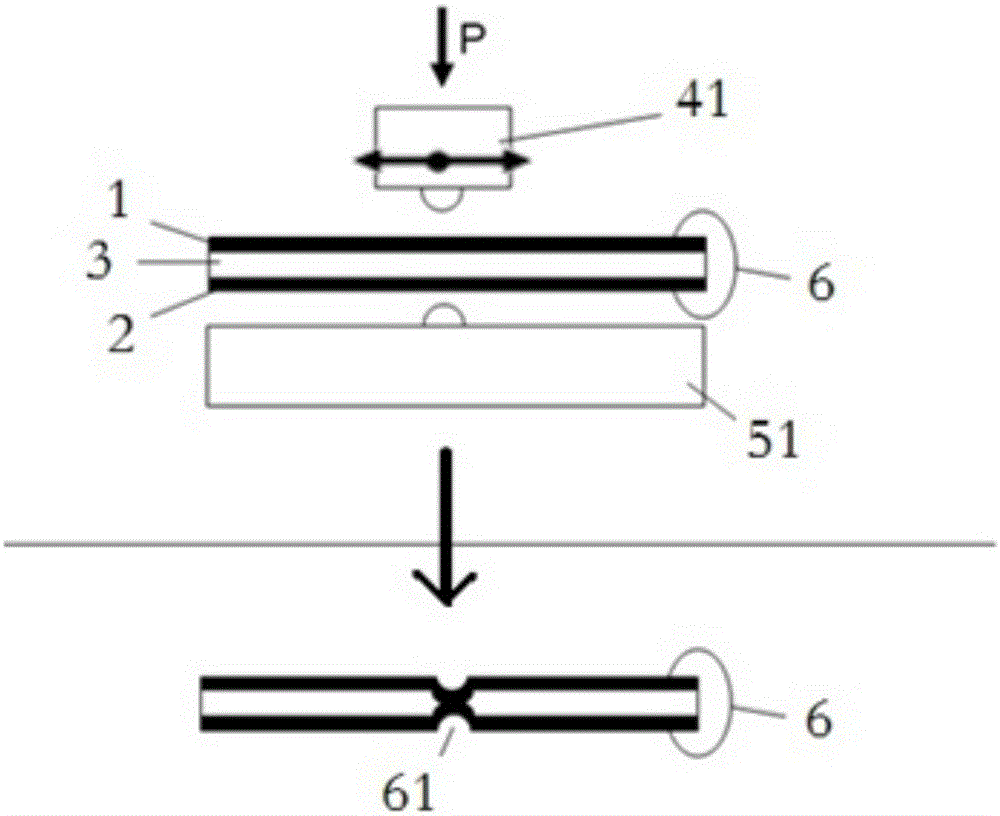

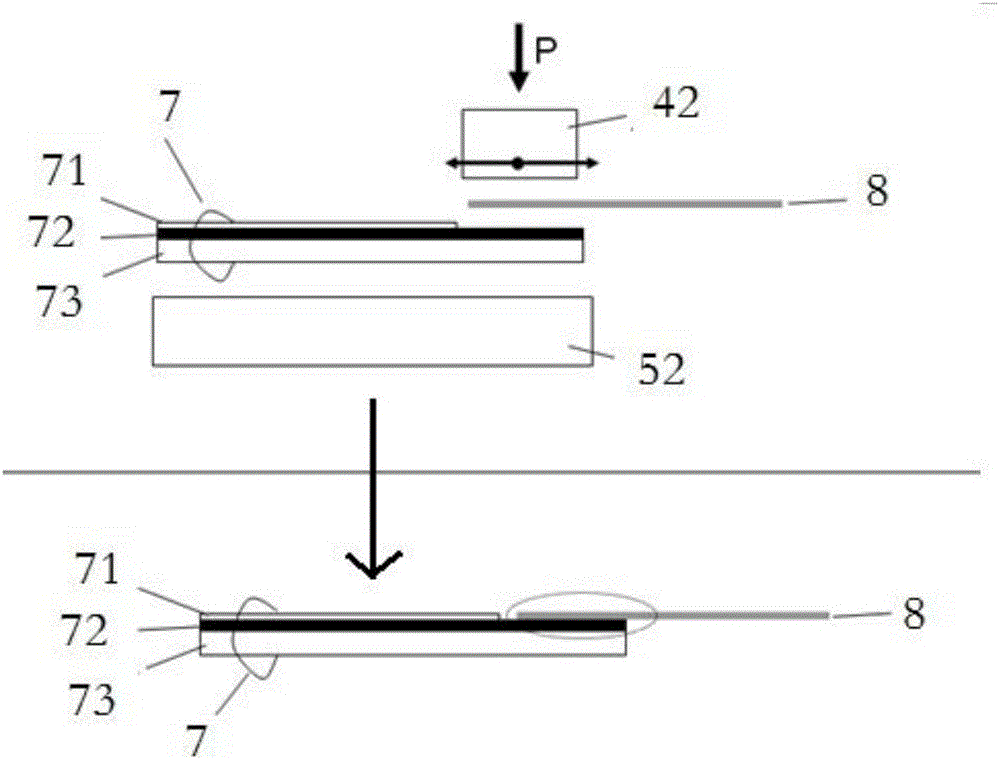

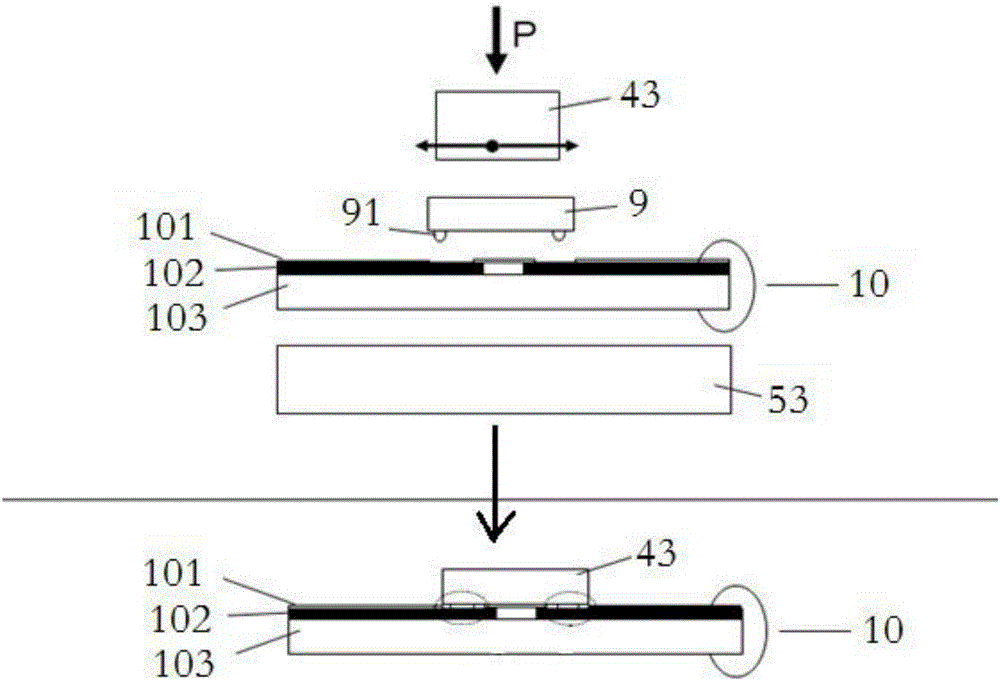

[0027] The present invention will be described in detail below in terms of specific embodiments in conjunction with the accompanying drawings. The following examples will help those skilled in the art to further understand the present invention, but do not limit the present invention in any form. It is to be noted that other embodiments may be utilized or structural and functional modifications may be made to the embodiments set forth herein without departing from the scope and spirit of the invention.

[0028] The object of the present invention is to provide a method for connecting double-sided printed circuit boards and soldering electronic components with ultrasonic waves. These two methods are all based on the same principle: high-frequency vibrations are generated on the contact surface of the workpiece through ultrasonic transmission, and high-frequency vibrations generate high-frequency vibrations. Density energy thus completes the welding between the two workpieces. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com