Brake structure for large-sized oil tanker deck trolley

A technology for large oil tankers and decks, applied in the field of ships, can solve the problem of low efficiency and achieve the effect of simple structure and convenient maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

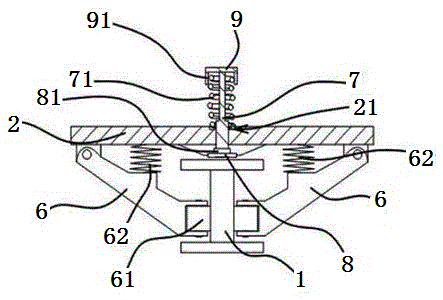

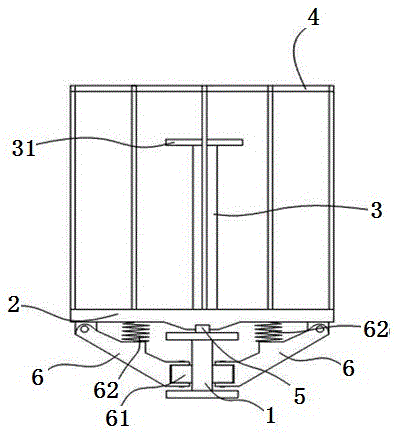

[0020] The brake structure of a deck trolley of a large oil tanker of the present invention comprises a guide rail 1, a conveying platform 2, a positioning groove 21, a fixed rod 3, a disk 31, a railing 4, a roller 5, a clamping arm 6, a roller 2 61, a pressing Spring 62, brake lever 7, return spring 71, brake pad 8, fixed sleeve 81, pedal 9 and positioning ring 91, the deck of the large oil tanker is laid with circular guide rails 1, and the deck trolley is arranged on the guide rail 1 , the deck car includes a delivery platform 2, the delivery platform 2 is arranged on the guide rail 1, the brake structure includes a brake lever 7 and a return spring 71, the delivery platform 2 is provided with a through hole aligned with the upper surface of the guide rail 1, and the section of the brake lever 7 It is square, the cross-sectional area of the lower e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com