Train using electromagnetic brake method

An electromagnetic brake, train technology, applied in the direction of brakes, railway car body parts, railway braking systems, etc. where the braking element interacts with the track, can solve the problems of brake device and wheel wear, brake failure, accidents, etc., to achieve High reliability, simple braking structure, stable braking effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

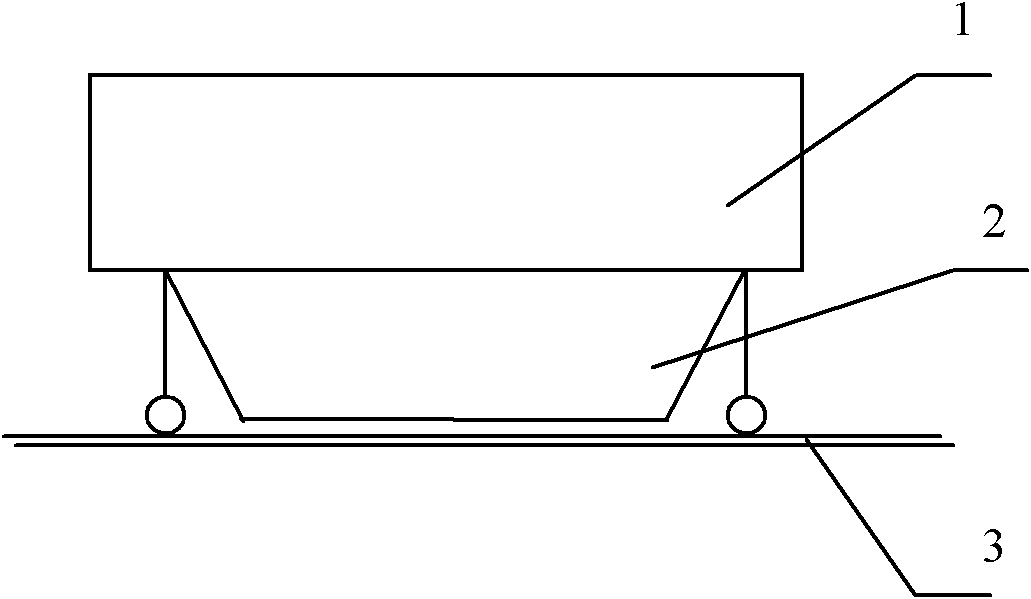

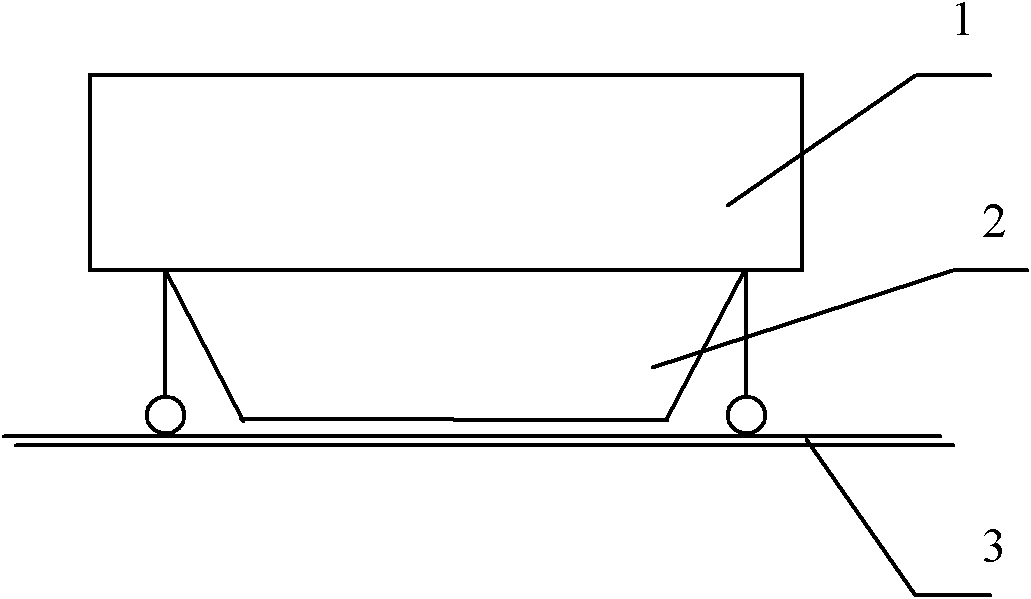

[0010] figure 1 Adopt the schematic diagram of the train of electromagnetic brake mode for the present invention, comprise multiple train carriages, every joint train carriage 1 bottom is equipped with electromagnetic sucker 2, after the electromagnetic sucker at the bottom of every train carriage parallel connects with the train power supply through cable and energized brake switch connection, the energized brake switch is installed in the train cab.

[0011] During the running of the train, the electromagnetic chuck is not energized, and no force is generated between the electromagnetic chuck and the rail 3 . When deceleration or braking is required, the train driver will press the power-on brake switch, so that the train power supply supplies power to the electromagnetic chuck at the bottom of each car, so that the electromagnetic chuck g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com