Magnetic-control brake

A magnetic control and brake disc technology, applied in vehicle components, electrical components, electromechanical devices, etc., can solve the problems of large mechanical vibration, large friction lining loss and reduction, and achieve the effect of eliminating vibration and reducing mechanical wear.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

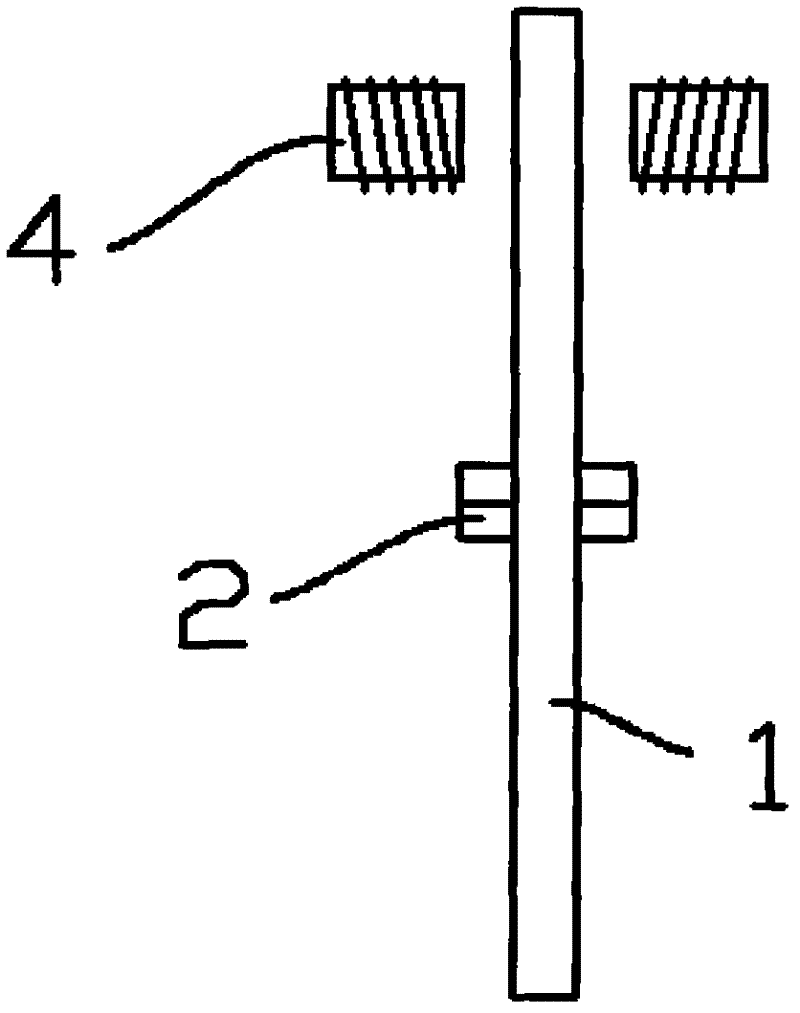

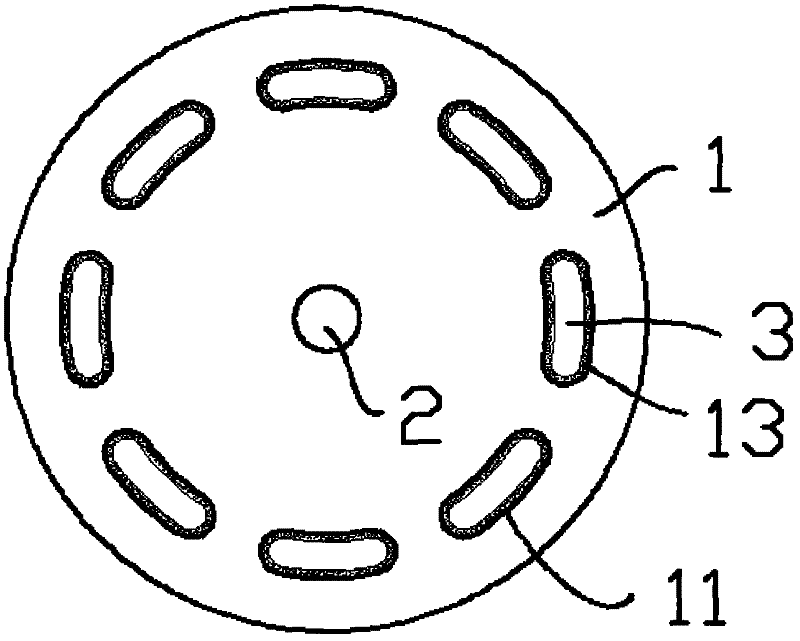

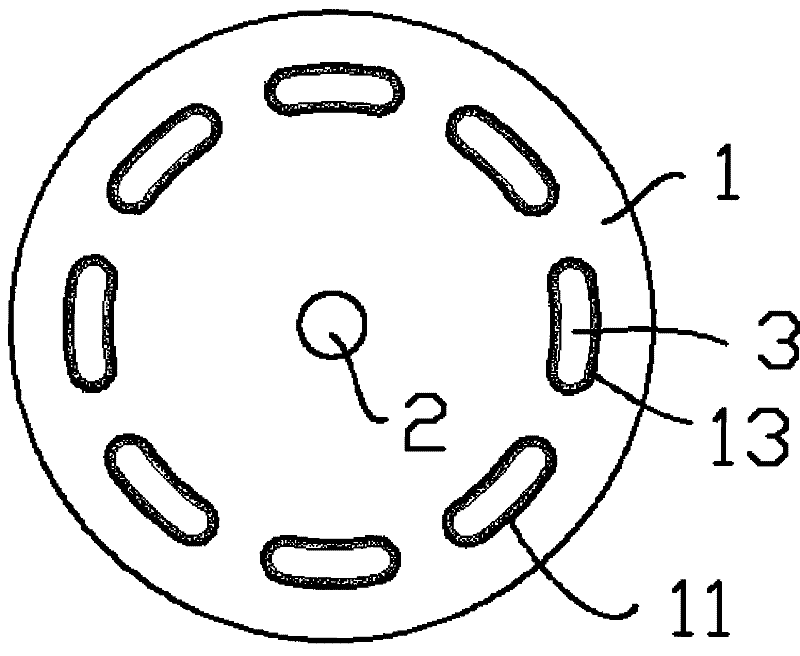

[0014] exist figure 1 , figure 2 In the shown embodiment, the magnetic control brake includes a metal brake disc 1, and the center of the brake disc 1 has a shaft connecting body 2 consolidated with the wheel shaft. 11. Each through hole 11 is provided with a soft magnet 3 adapted to the shape of the through hole. The soft magnet 3 is made of silicon steel. A pair of coils 4 are arranged on both sides of the brake disc 1, and the pair of coils 4 are a pair of Helmholtz coils, which generate a parallel magnetic field orthogonal to the brake disc 1 when energized.

[0015] In the above-mentioned magnetic control brake, the distance between each of the through holes 11 and the outer edge of the brake disc 1 is not less than the height of a disc brake pad, so as to ensure that the disc brake pad can also be installed on the brake disc 1, so that the low-speed wheel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com