Swirl nozzle for treatment after exhaust of engine

A technology of exhaust post-treatment and swirling nozzles, which is applied in the direction of engine components, machines/engines, exhaust devices, etc., can solve the problems of NOx conversion efficiency decline, decline, exhaust pipe clogging and purification efficiency, etc., and achieve atomization quality Good, simplify the system structure and reduce the effect of installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

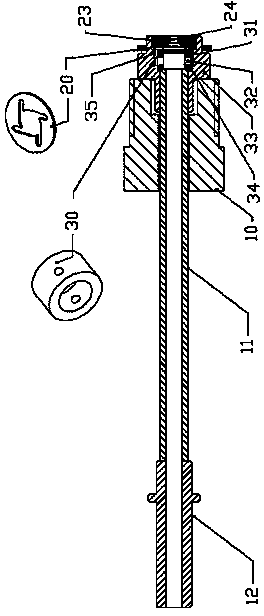

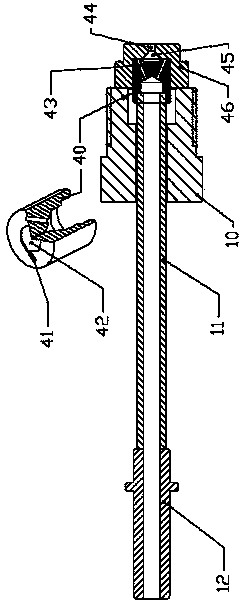

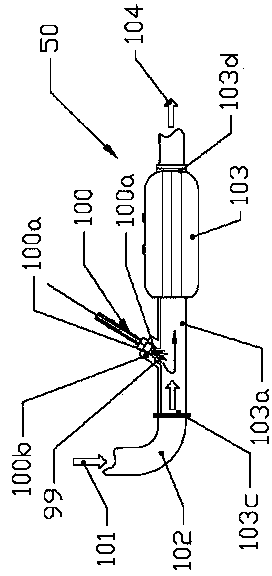

[0032] Such as figure 1Shown is a schematic structural diagram of the first embodiment of the swirl nozzle provided by the present invention, including swirl core 3, orifice plate 8, nozzle body 9, lock nut 10, heat insulating tube 11, quick connector 12 and so on. The swirl core 3 is a square cylinder as a whole, and one end face is provided with a swirl chamber 1 close to a cylindrical cavity and a tangential flow channel 2 tangential to the edge of the swirl chamber 1, while the other end face is provided with a connection center and Peripheral radial runners 15. The orifice plate 8 is a circular plate with a circular spray hole 5 in its center. One end of the heat insulating pipe 11 is inserted into the nozzle body 9 tightly, or is fixed integrally with the nozzle body 9 by means of welding, etc., and the other end is tightly connected with a quick connector 12 (by means of welding or pressing). The quick connector 12 meets the SAEJ2044 standard. The length of heat-insu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com