Injection system used for purifying smoke discharge soot particles and control method

A technology of injection system and carbon particles, which is applied in the direction of electric control of exhaust treatment device, exhaust device, exhaust treatment, etc., can solve the problems of undescribed atomization effect, high processing cost, complex structure, etc., and achieve high injection Accuracy and stability, low manufacturing cost, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

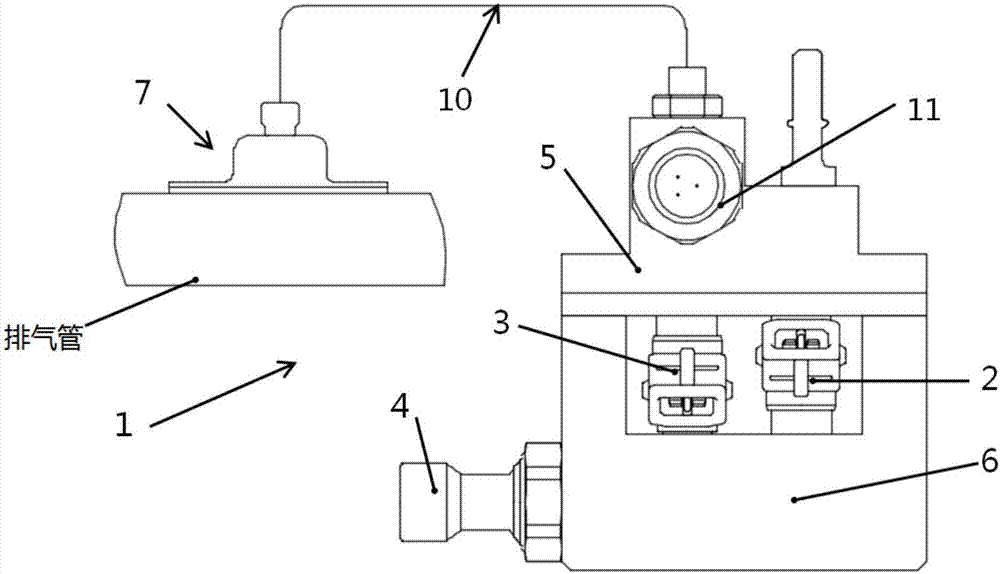

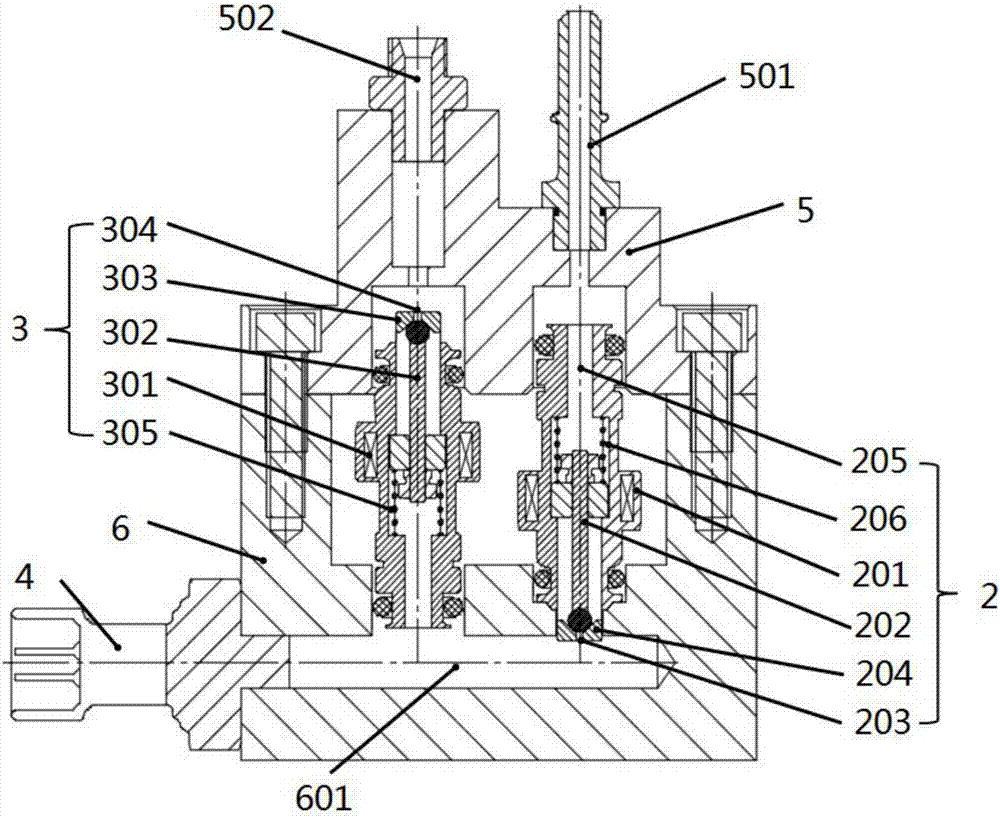

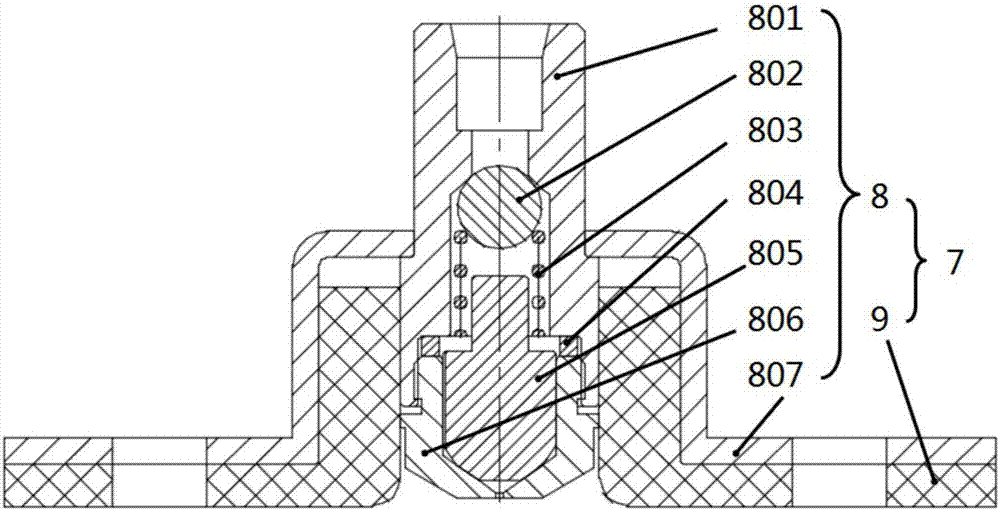

[0024] refer to figure 1 — Figure 4 , an injection system for purifying exhaust carbon particles, the injection system includes a controller 1 and an injector 7; the controller 1 is connected to the ECU 14; the injector 7 is connected to the exhaust pipe 17; wherein The controller 1 includes a switch solenoid valve 2, a metering valve 3, a first pressure sensor 4, a second pressure sensor 11, a controller upper housing 5 and a controller housing 6; the switch solenoid valve 2, metering The valve 3 and the first pressure sensor 4 are installed on the controller housing 6; the controller upper housing 5 is fastened on the controller housing 6 by screws and connected with the switching solenoid valve 2 and the metering valve 3; The second pressure sensor 11 described above is mounted on the controller upper casing 5; the injector 7 includes a nozzle 8 and a high-temperature insulation pad 9; the nozzle 8 is fixed on the exhaust pipe 17; the high-temperature insulation pad The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com