Device and method for multi-directional ultrasonic droplet jetting light-curing additive manufacturing

A micro-droplet injection and additive manufacturing technology, applied in the field of additive manufacturing, can solve the problems of slow forming speed, high failure rate, uncontrollable mechanical properties of formed samples, etc., achieve fast spraying speed, high spraying precision, avoid The effect of the treatment process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

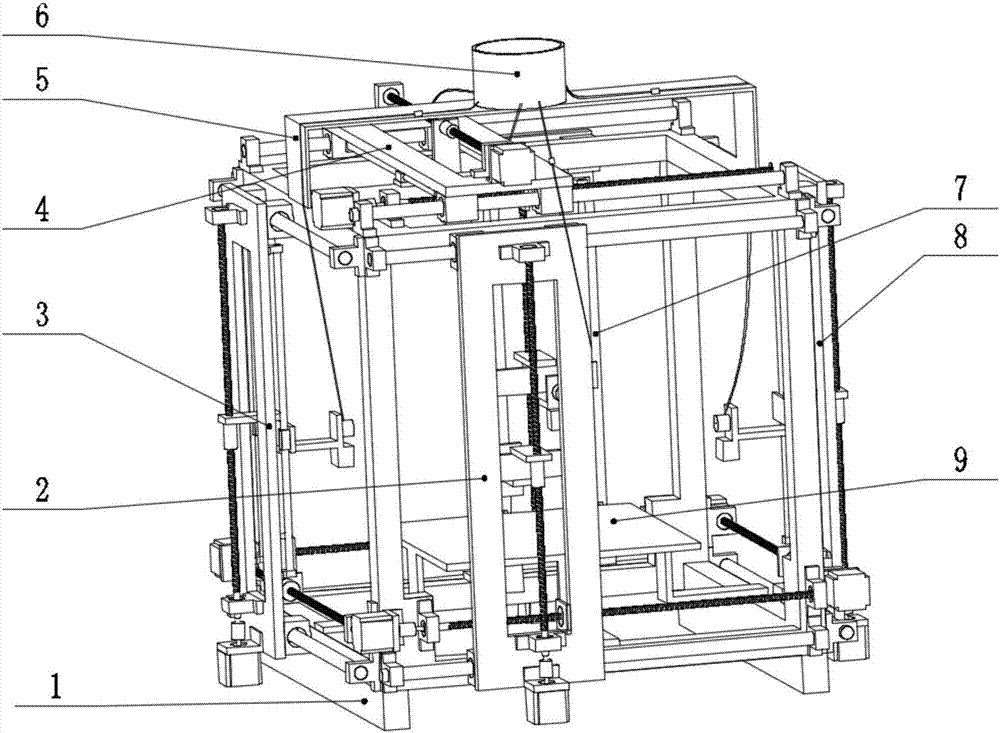

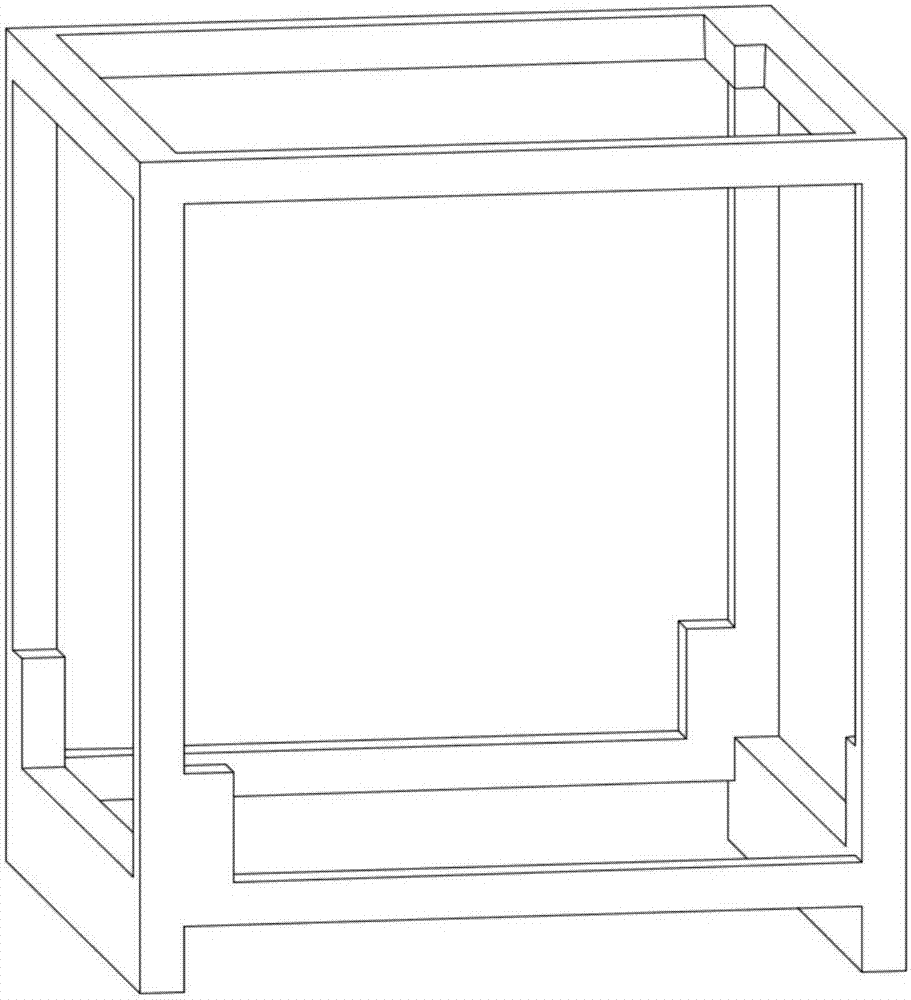

[0029] Including: Rack 1, Two-axis motion component 1, 2, Two-axis motion component 2, 3, Two-axis motion component 3, 4, Feeding system bracket 5, Feeding system 6, Two-axis motion component 4, 7, Two-axis motion component 5 8. Substrate 9, two-axis motion assembly one 2, two-axis motion assembly two 3, two-axis motion assembly four 7, two-axis motion assembly five 8 and two-axis motion assembly three 4 are respectively fixed on the four sides of the frame 1 and On one top surface, the feeding system bracket 5 is fixed on the top of the frame 1, and the erected height is higher than the highest position of the two-axis motion assembly 34, the feeding system 6 is fixed on the feeding system bracket 5, and the base plate 9 is fixed on the rack.

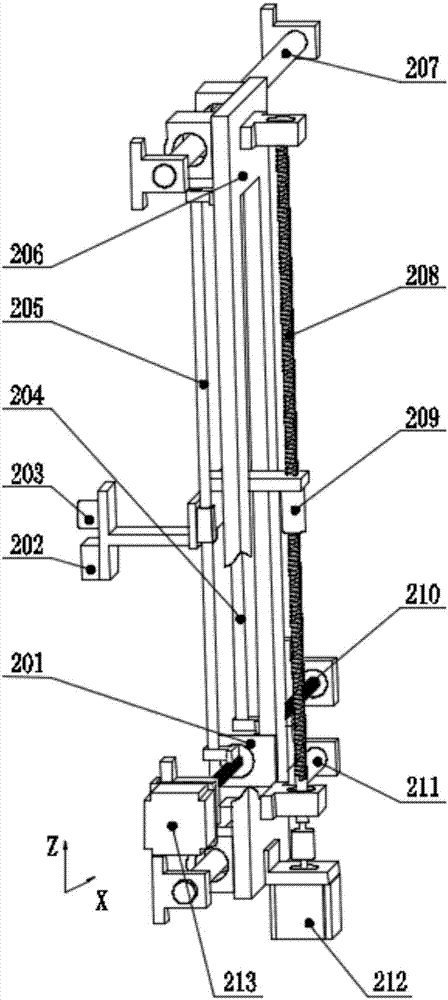

[0030] The structure of the two-axis motion assembly one 2, two-axis motion assembly two 3, two-axis motion assembly three 4, two-axis motion assembly four 7 and two-axis motion assembly five 8 is the same, wherein the structure of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com