Fuel high pressure generator for oil supply system with direct jetting of liquefied petroleum gas/petrol in cylinder

A gasoline direct injection and liquefied petroleum gas technology, which is applied to liquid fuel feeders, charging systems, machines/engines, etc., can solve problems such as poor sealing performance, reduced matching accuracy of plunger couplings, and device failure. , to stabilize the fuel injection pressure and improve the reliability of the system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

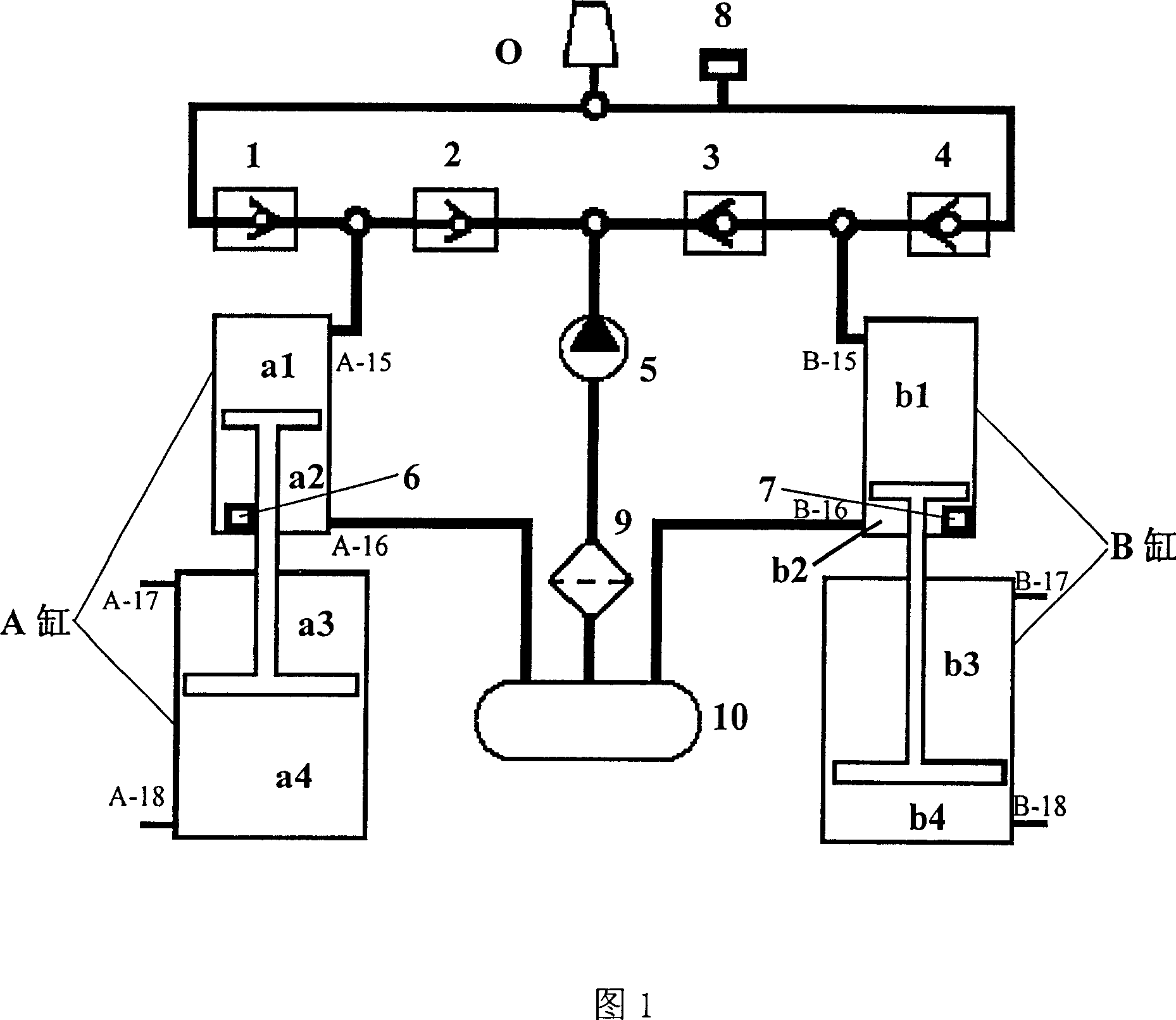

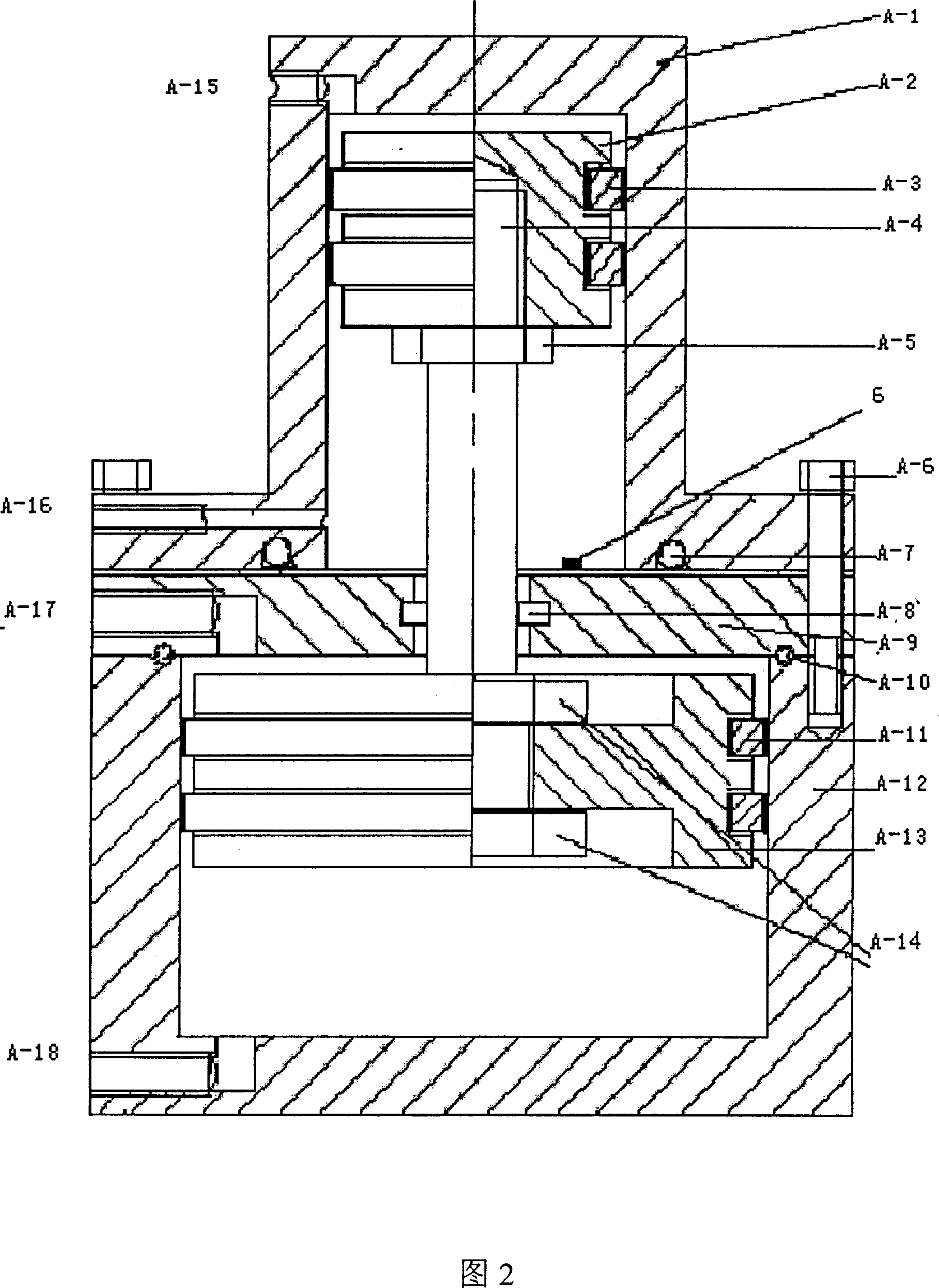

[0013] As shown in Figure 1, the fuel high-pressure generator of LPG (liquefied petroleum gas) / gasoline engine cylinder direct injection oil supply system, fuel filter 9, fuel delivery pump 5, on the fuel delivery pump 5 successively connect with first One-way valve 2, second one-way valve 1, pressure sensor 8, third one-way valve 4, fourth one-way valve 3, the connection point between the first one-way valve 2 and the second one-way valve 1 and the fuel pressure increaser The upper end a1 cavity of the first cylinder A of the pressure device is connected, and the connection point of the third check valve 4 and the fourth check valve 3 is connected with the b1 cavity at the upper end of the second cylinder B of the fuel pressure booster device; in the fuel pressure booster device A fuel compression cylinder position sensor 6 is installed in the a2 cavity of the first cylinder A, and a fuel compression cylinder position sensor 7 is installed in the b2 cavity of the second cylind...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com