Active cooling engine fuel switching device and switching method

An active cooling and switching device technology, which is applied in the direction of engine components, engine cooling, turbine/propulsion device cooling, etc., can solve the problems of reduced penetration depth, engine flameout, and reduced engine combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

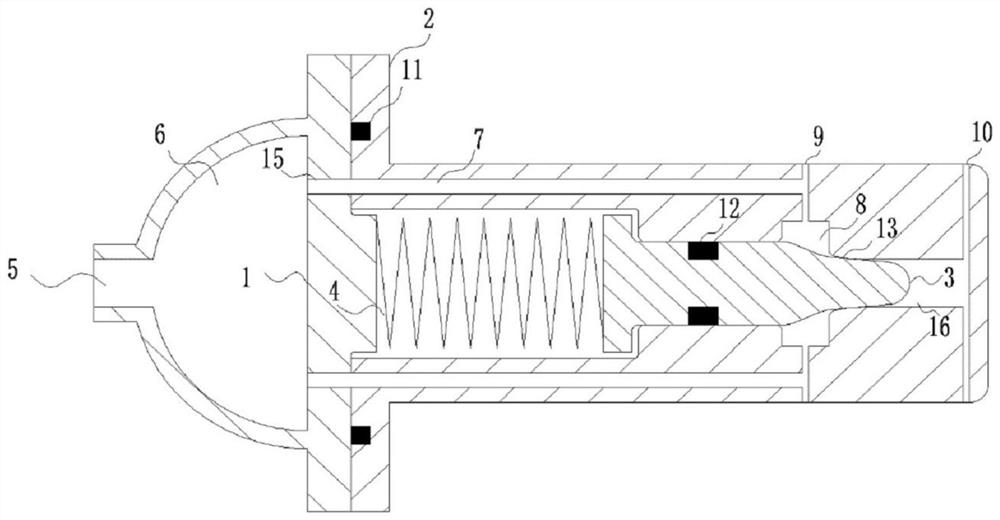

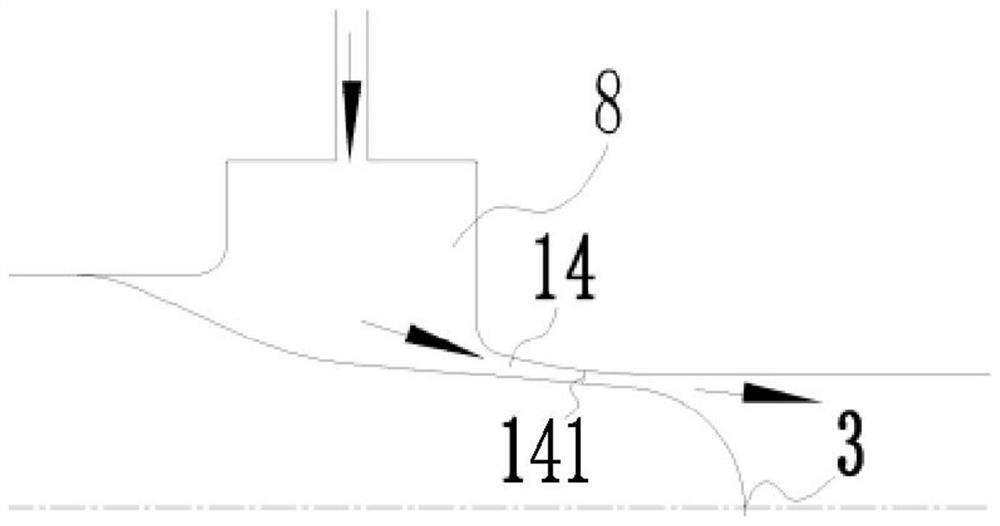

[0040] An active cooling engine fuel switching device, comprising a housing 2 with one end open, and an end flange 1 is installed on the opening side of the housing 2, and the side of the inner cavity of the housing 2 away from the end flange 1 is sequentially provided with Through the confluence chamber 8 and the downstream chamber 16, the needle cone 3 is inserted in the inner cavity of the housing 2, and the head of the needle cone 3 penetrates the confluence chamber 8 and extends to the downstream chamber 16, the confluence chamber 8 and the downstream chamber The junction of the chamber 16 is provided with an inner flow channel wall 13 matching the side wall of the needle cone 3, and a contraction-expansion flow channel 14 is formed between the side wall of the needle cone 3 and the inner flow channel wall 13, and the contraction-expansion flow The section of the channel 14 close to the confluence cavity 8 is a contraction section, and the section close to the downstream c...

Embodiment 2

[0057] This embodiment provides a fuel switching method based on an active cooling engine fuel switching device, including the following steps:

[0058] S1. The fuel flows through the fuel inlet 5, the buffer chamber 6, the inner flow channel 15 of the end flange and the inner flow channel 7 of the housing to the confluence cavity 8 and the upstream injection hole 9;

[0059] S2. According to the different states of the fuel, the fuel switching device performs self-adaptive adjustment;

[0060] S2-1. When the fuel is in liquid state, the resultant force of the fuel pressure in the manifold chamber 8 and the gas pressure in the downstream chamber 16 on the surface of the needle cone 3 is less than the preload force of the elastic element 4, and the needle cone 3 is under the preload force of the elastic element 4. Fit the inner runner wall 13 under tight force, and the fuel is injected from the upstream nozzle hole 9;

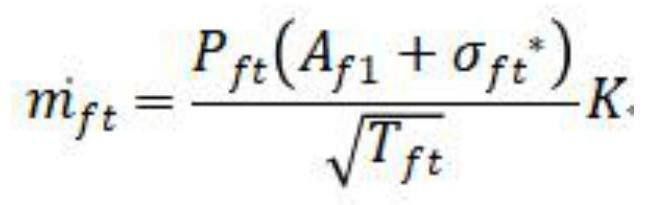

[0061] S2-2. When the fuel is in a supercritical or gaseo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com