Air tightness rotating backblowing device for cloth bag dust remover

A bag filter, reverse blowing technology, applied in chemical instruments and methods, dispersed particle separation, dispersed particle filtration, etc., can solve the problems of high air leakage rate, poor cleaning performance, unbalanced injection pressure, etc., to increase the use of Long life, low maintenance cost, good cleaning effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

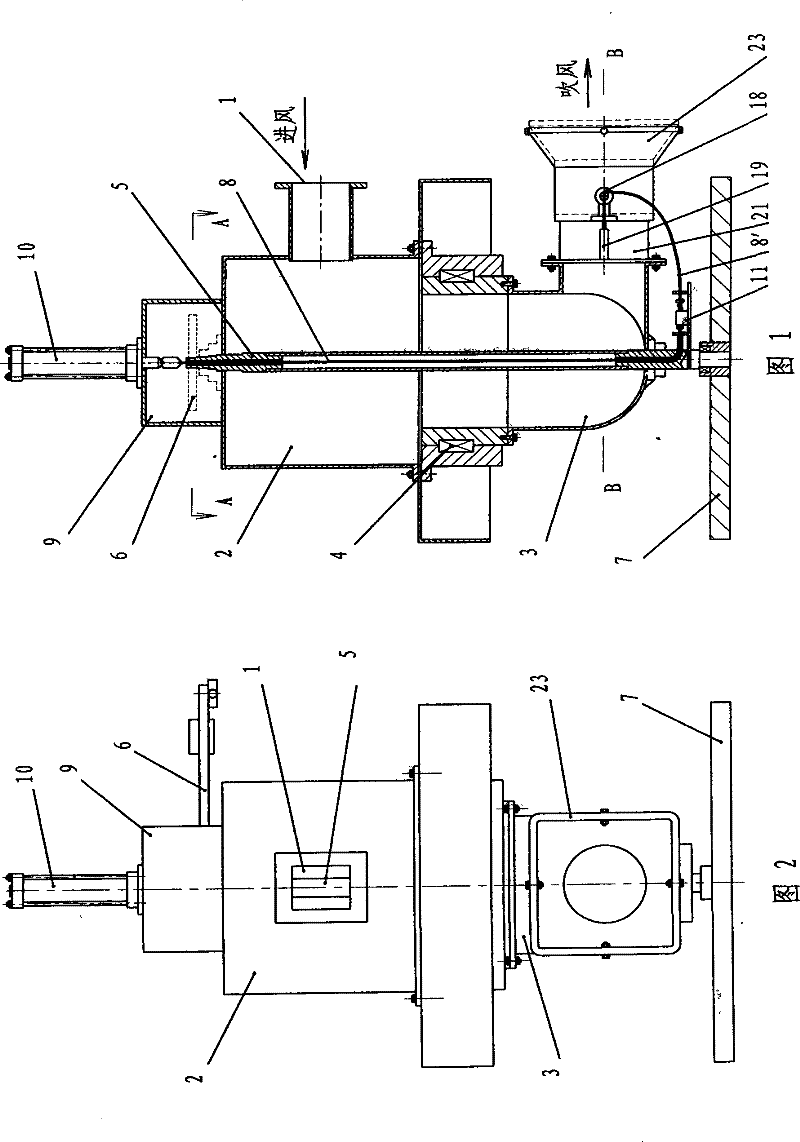

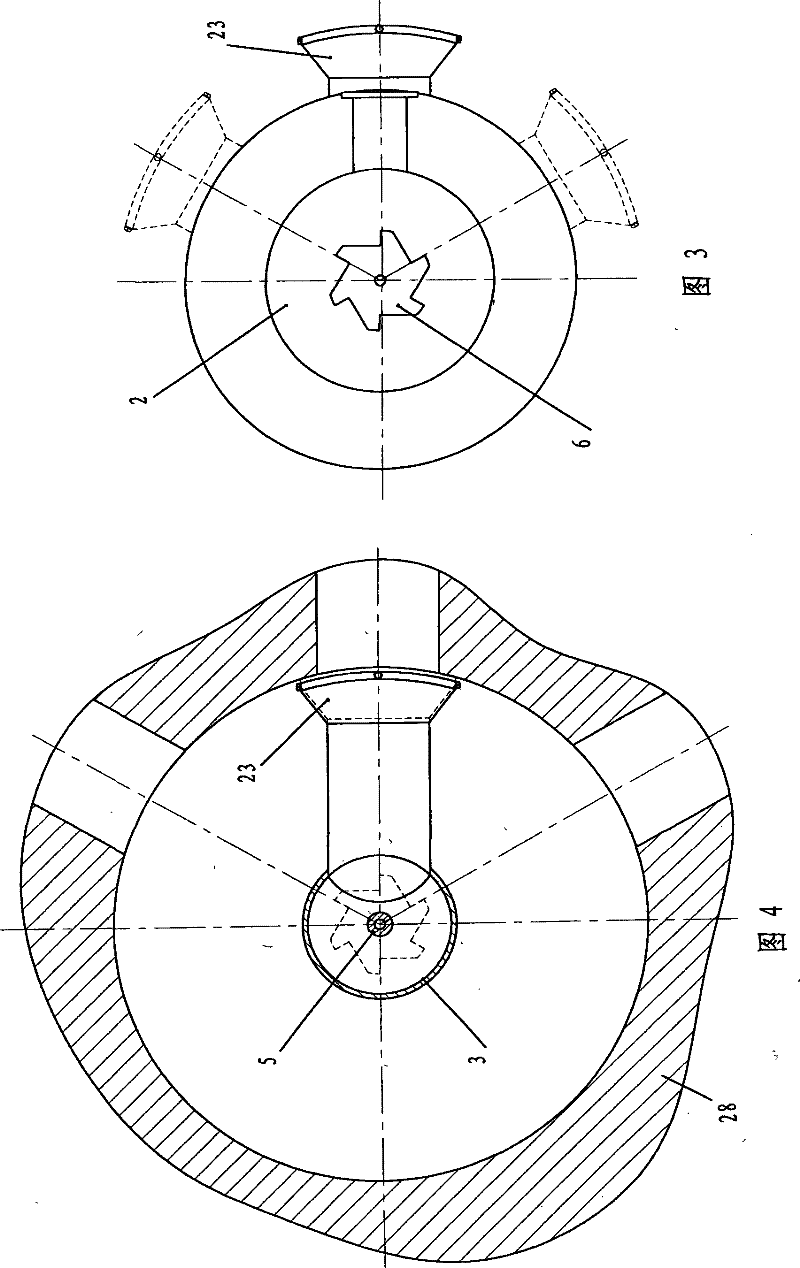

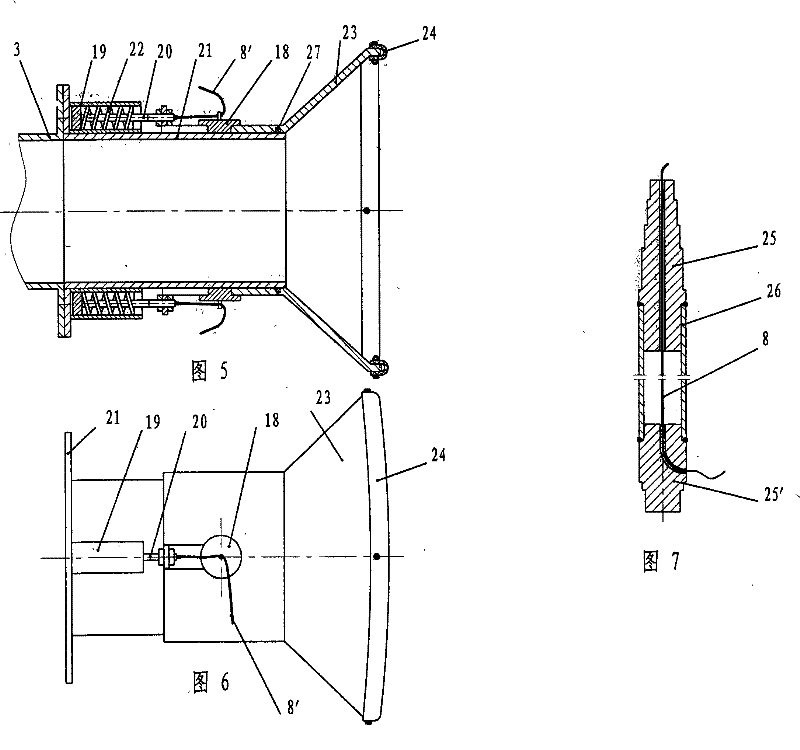

[0021] Depend on Figure 1 ~ Figure 2 It can be seen that the airtight rotary anti-blowing device for the bag filter of the present invention includes the anti-blowing box 2 that is rotatably connected to the upper part of the rotating shaft 5 and the right-angled blowing pipe joint 3 that is fixedly connected to the lower part. The lower end of the rotating shaft 5 protrudes and is fixed on the dust collector. The bracket 7 on the box body 28 is rotatably connected, and the upper part of the blowing pipe joint 3 is fixedly connected with the lower part of the anti-blowing box body 2 through the rotating part 4, wherein the rotating shaft 5 is a hollow structure, and the first drag cable 8 is housed in the rotating shaft 5. The upper end of a drag cable 8 passes through the rotating shaft 5 and is fixedly connected with the piston rod of the cylinder 10 installed on the top of the support frame 9 through the rigging turnbuckle 16', see Figure 8 . The support frame 9 is fixed...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com