Novel sliding sleeve tool for achieving opening without ball throwing pressure control

A new type of pressure control technology, applied in wellbore/well valve devices, wellbore/well components, earthwork drilling and production, etc., can solve the problems of large consumables, long time consumption, difficulty in meeting the requirements of new fracturing processes, etc., and achieve Effect of Stabilizing Injection Pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

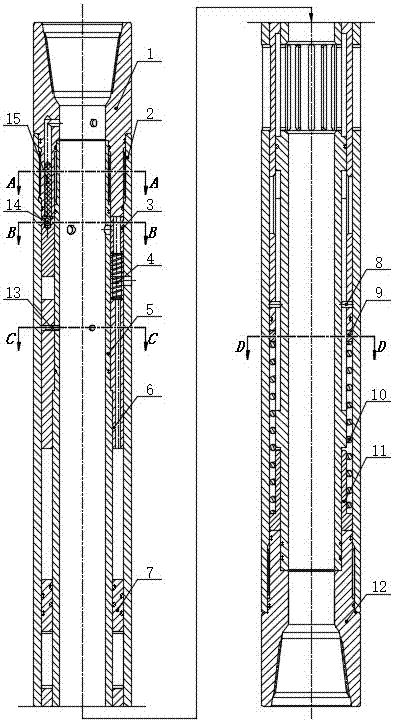

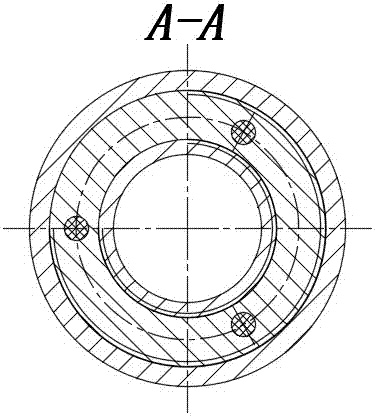

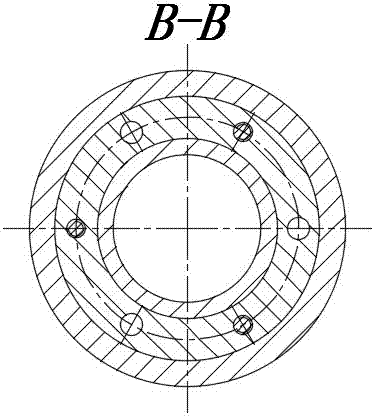

[0019] As shown in the accompanying drawings, the new type of sliding sleeve tool that can be opened without ball pressure control is mainly composed of an upper joint, an outer shell, a starting piston, a starting spring, a central tube, a starting piston joint, a switch piston, a track pin A, and a spring stopper. Ring, positioning spring, spring holder, lower joint, positioning screw, driving piston rod seat, driving piston rod, track pin B, etc., is characterized in that the upper joint 1, the outer shell 2 and the lower joint 12 are connected by threads in turn; There are 3 blind holes spaced 120° apart in the radial direction of the joint 1, and 3 holes spaced 120° apart along the axial direction to communicate with the three blind holes in the radial direction; the drive piston The rod 15 is located in the three axial round holes of the upper joint 1, and its lower end is connected with the driving piston rod seat 14, so that it is fixed with the starting piston 3; the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com