Mold applied to production process of automotive interior parts

A technology for automobile interior parts and production processes, applied in the field of manufacturing equipment, can solve the problems affecting the production efficiency of automobile interior parts, increase the manufacturing cost of manufacturers, and unqualified workpiece quality, so as to reduce the scrap rate of products, improve the quality, Long service life effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

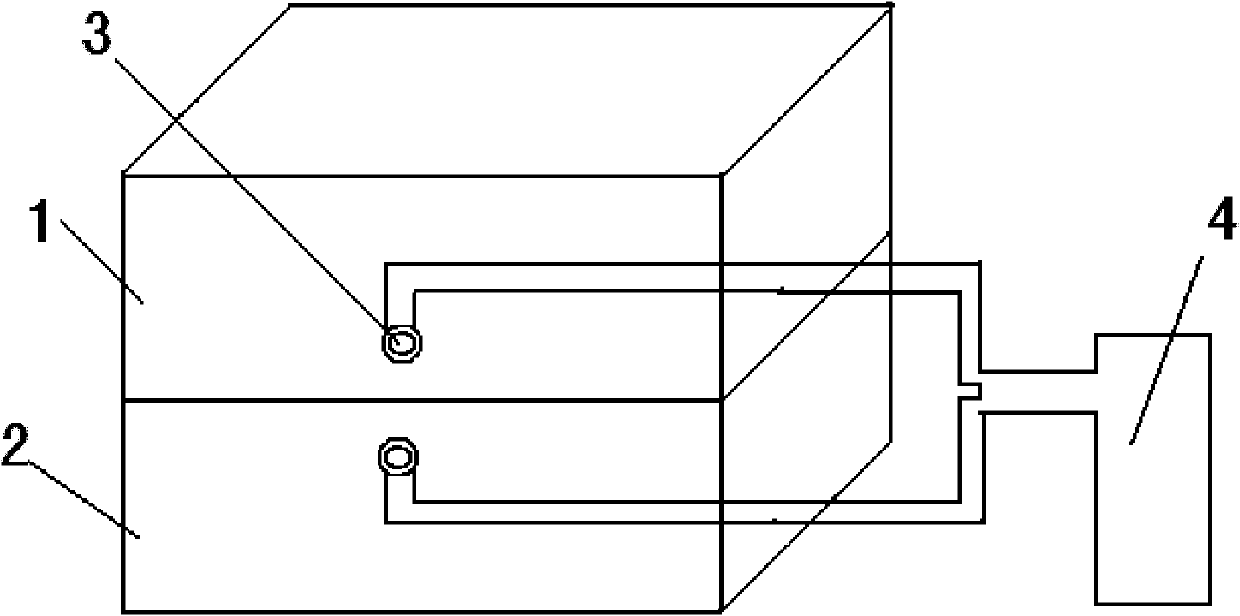

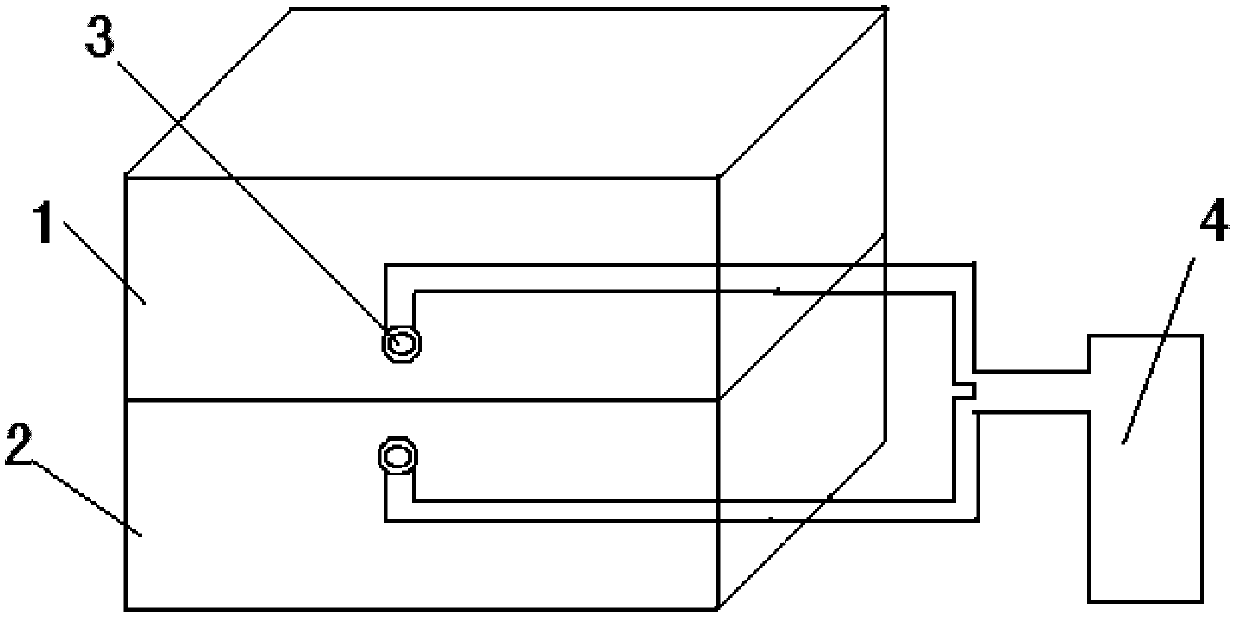

[0018] In the technical field of manufacturing equipment used in the production process of automotive interior parts, especially for the production process of automotive plastic parts, the existing mold design is unreasonable, there is no exhaust groove, and the produced product has air marks. The solution is to add exhaust grooves on the mold to solve the problem of product air marks. According to the process requirements of the mold product, design the track of the exhaust groove, measure the size; use the equipment to mill out the exhaust groove, and finally open the exhaust groove that meets the mold process requirements.

[0019] Such as figure 1 As shown, the technical solution provided by the present invention is to apply to the mold in the production process of automobile interior parts, the mold is provided with an exhaust hole 3, and the exhaust hole 3 is connected to the exhaust pipeline, and the exhaust hole The pressure in the gas line is less than atmospheric pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com