Injection molding machine for unsaturated polyester bulk molding compound

A technology of bulk molding compound and injection molding machine, applied in the direction of coating, etc., can solve the problems of difficult-to-form surface quality requirements, difficult to form injection pressure, lack of product compactness, etc., to achieve high injection repeatability, small plastic backflow, and low weight stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

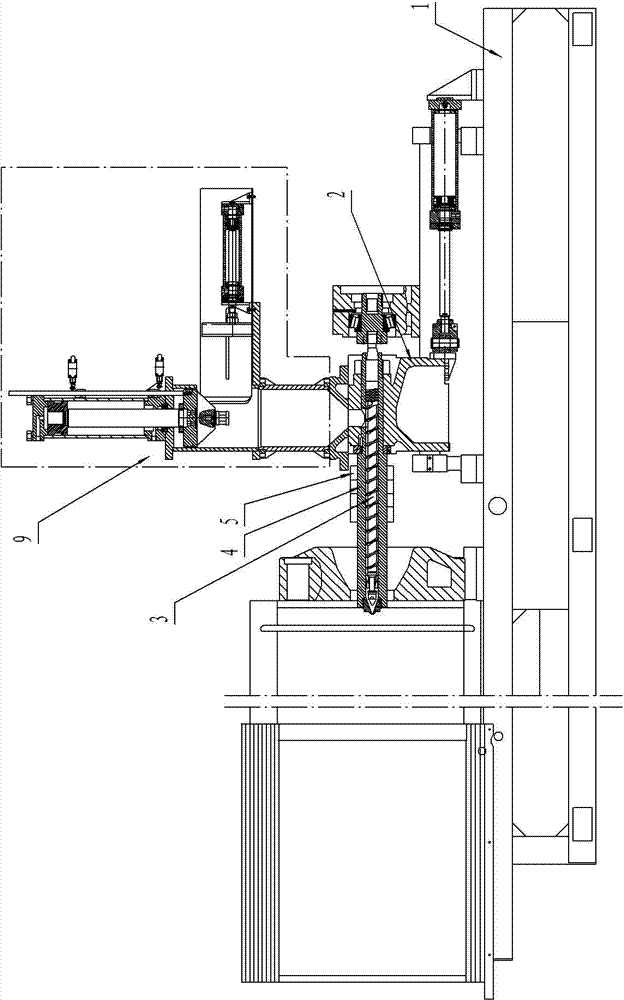

[0022] Below in conjunction with accompanying drawing and embodiment the present invention is further described:

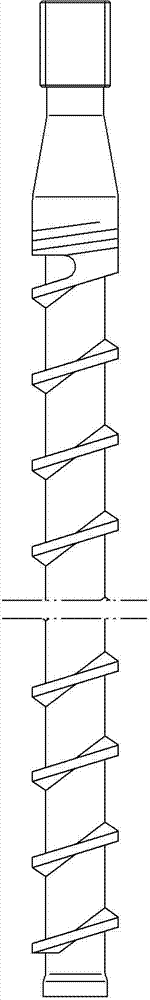

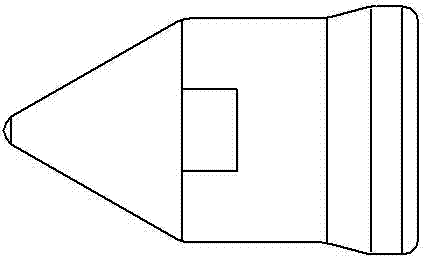

[0023] figure 1 The shown unsaturated polyester mass molding compound injection molding machine includes a frame 1, an injection seat 2 installed on the frame 1, and a cylinder 4 with a screw 3 inside the injection seat 2 installed on the frame 1, installed on the The feeding device 9 above the machine barrel 4 and the heater 5 sleeved outside the machine barrel 4 . Such as figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 , Figure 12 , Figure 13 with Figure 14 As shown, the front end of the screw rod 3 is connected with the screw head 8 through the thrust rod 7, and the front end of the thrust rod 7 is connected with the screw head 8. There is a non-return ring 6 in the set, and the non-return ring 6 is provided with an axial play of 2 to 15 mm between the ring part of the thrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com