Polymorphic sample injection device

A sampling device, multi-modal technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of sample air leakage, injury, operation error, etc., to reduce the possibility of leakage, simple structure, improve accuracy and repetitive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific embodiments of the present invention will be further described below in conjunction with the drawings:

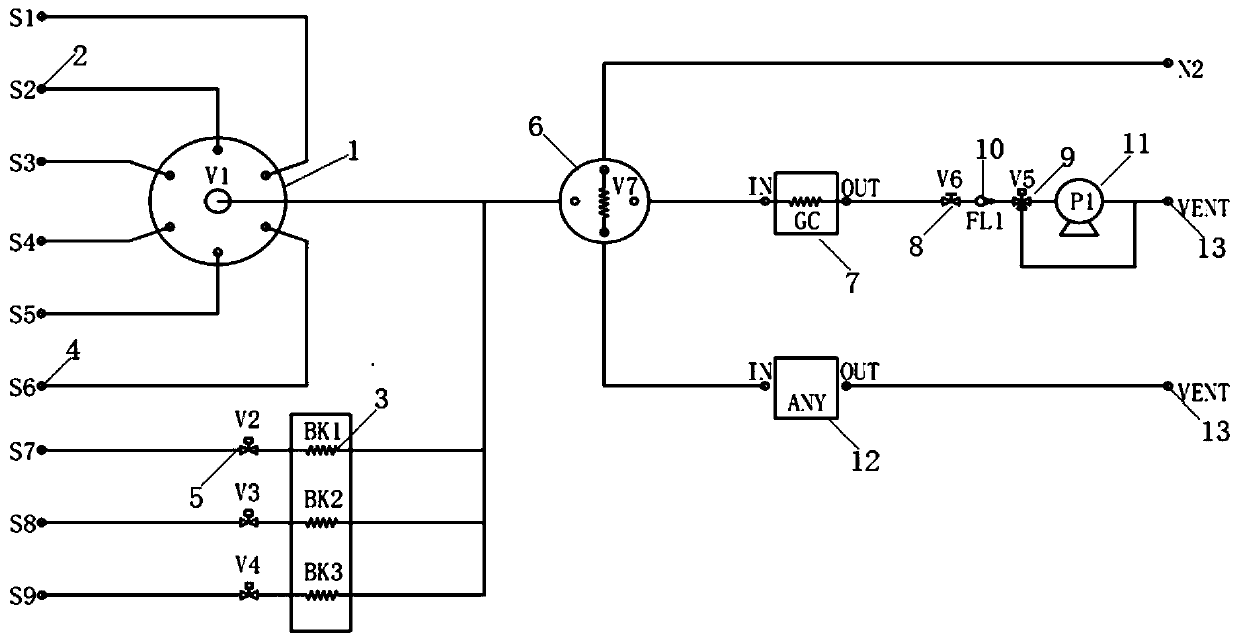

[0031] Such as figure 1 As shown, a multi-modal sample injection device includes a six-way anti-adsorption injection valve 1, three-channel capillary tubes 3, a quantitative switching valve 6, a chromatograph 7, an experimental analyzer 12, and a vacuum diaphragm pump 11. The six ports of the six-way anti-adsorption injection valve 1 are respectively connected to the 6 corresponding air bag sample inlet pagoda connectors 2 through corresponding pipes. In this embodiment, the 6 air bag sample inlet pagoda connectors 2 are respectively For S1-S6, 6 air bag sample inlets, Pagoda connector 2 is used to connect with the sample air bag.

[0032] The three channel capillaries 3 are respectively communicated with three corresponding quick connectors 4 for the sample injection ports of steel cylinders through corresponding pipes, which are S7-S9 in this embodiment.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com