All-pneumatic sand blasting machine with multiple sand blasting guns

A sandblasting gun, all-pneumatic technology, applied in the direction of spray guns, abrasive jet machine tools, abrasive feeding devices, etc., can solve the problems of high mechanical cost, inability to effectively improve the work efficiency of operators, and inability to fully utilize the mechanical potential, etc. Improved mechanical potential, stable blasting output, and easy recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the features, technical means and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

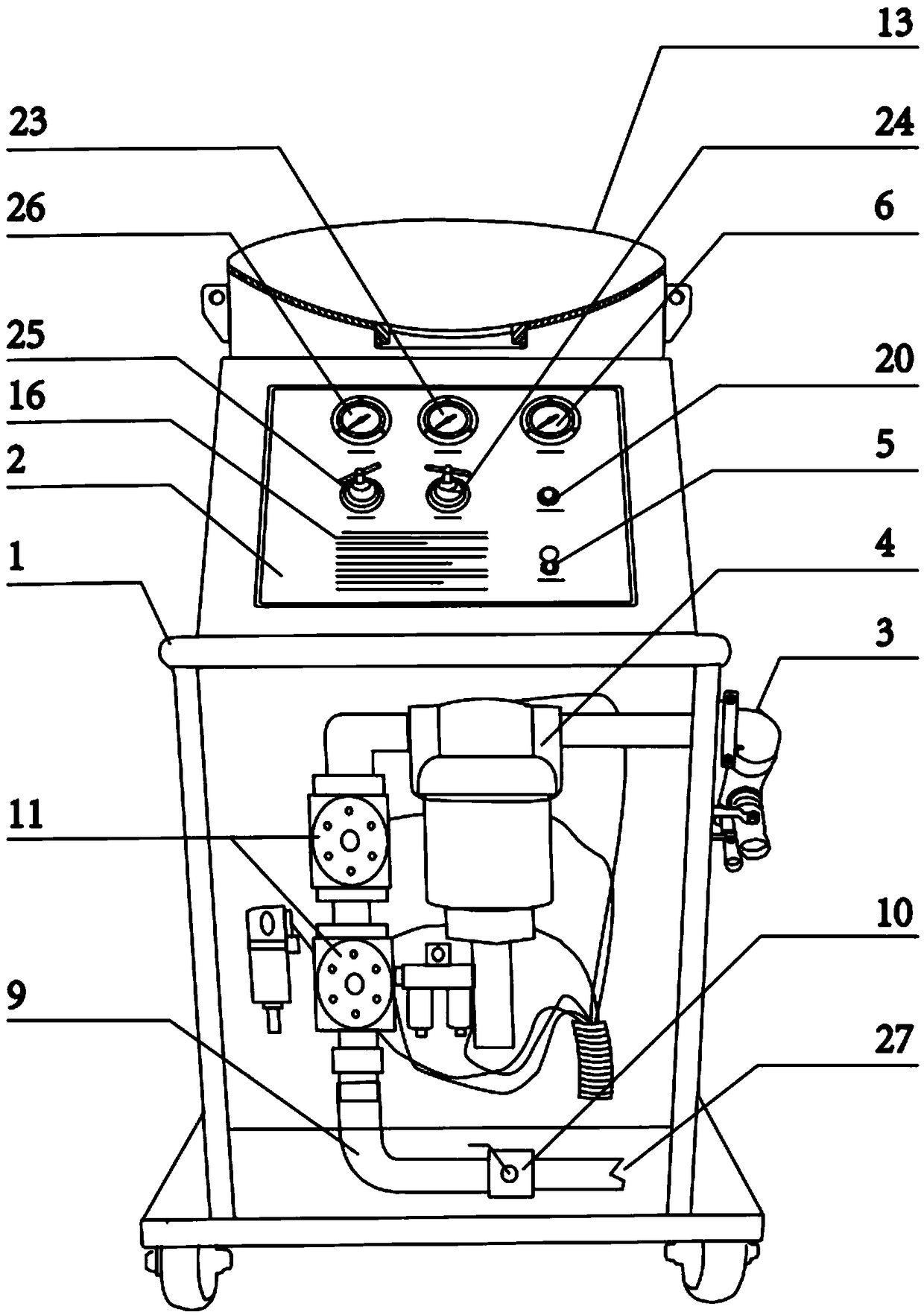

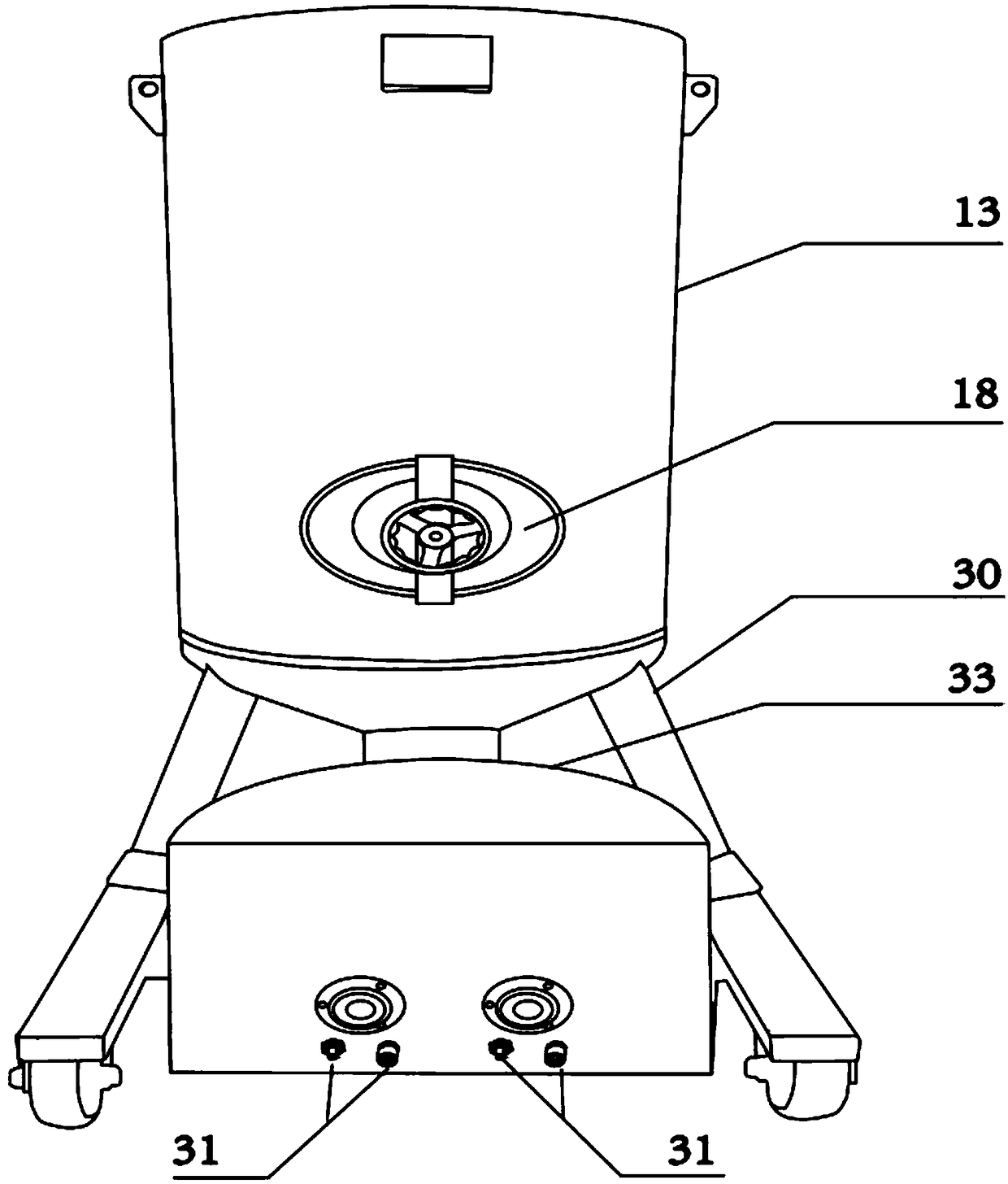

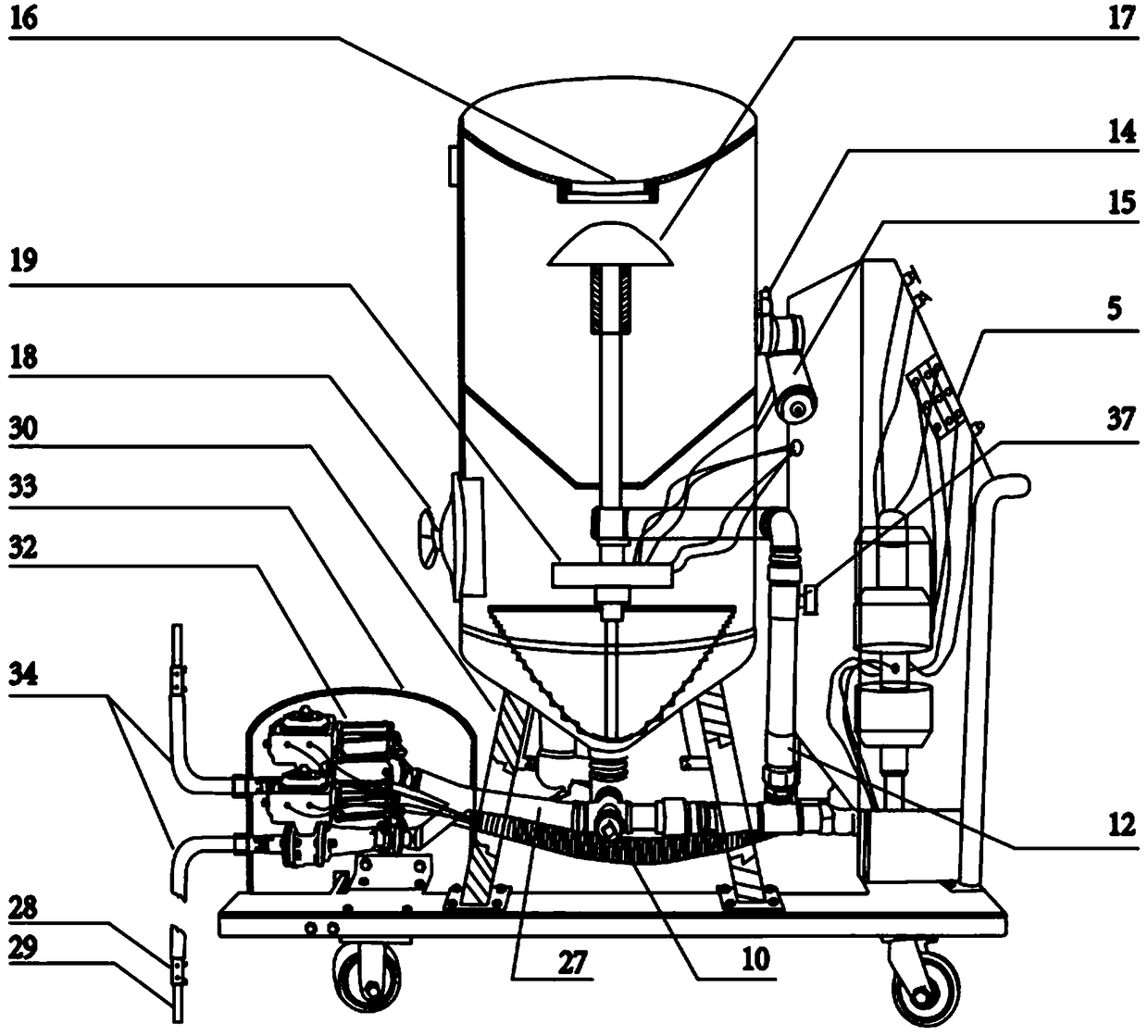

[0024] Please refer to the accompanying drawings, the sandblasting machine of the present invention is a multi-functional full-pneumatic synchronous and asynchronous multi-blasting gun construction, a fully pneumatic sandblasting machine that uses rust-removing sand as the spraying material, the present invention includes a body 1, and the body 1 can be used Mobile, vehicle-mounted, or fixed structural forms, the machine body 1 can be provided with an equipment console 2 for controlling the sandblasting machine, and the equipment console 2 has an instrument for displaying pressure and a valve for controlling the process. There are equipment pressure gauge 6, air control valve 5, injection pressure contro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com