Brush-type nozzle capable of automatically adjusting flow of grinding fluid

A technology of automatic adjustment and grinding fluid, applied in the field of grinding processing, can solve the problems of poor washing performance and high cost, and achieve the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

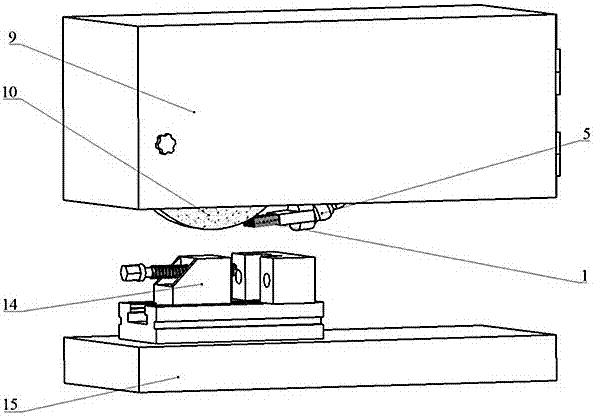

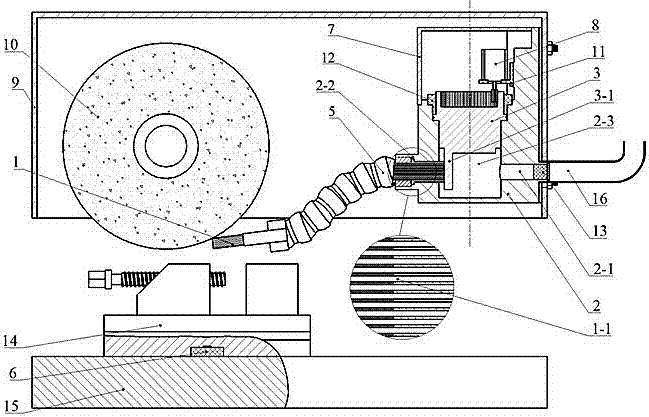

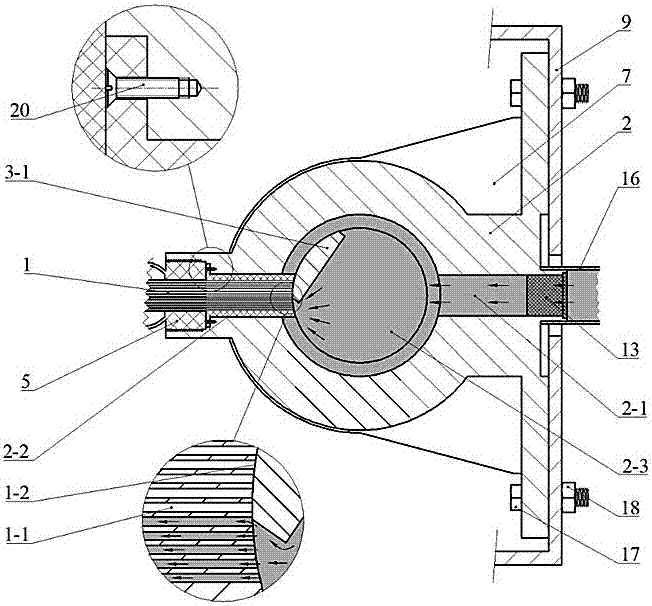

[0034] The technical solution of the present invention will be further described below in conjunction with the accompanying drawings.

[0035] The invention relates to a brush nozzle capable of automatically adjusting the flow rate of grinding fluid, which comprises a brush nozzle and a flow automatic adjustment system. The brush nozzle includes a universal bamboo tube 5 and a hollow fiber bundle 1; Grinding liquid enters the inner cavity 2-3 of the valve body 2 through the liquid inlet 2-1, then passes through the fiber opening 1-2 and the hollow fiber 1-1 in sequence, and finally reaches the grinding center area. In this process, the number of fiber openings 1-2 communicating with the valve inner cavity 2-3 is adjusted by the motor 8 according to the feedback signal of the force sensor 6 through the gear 4 to drive the valve core 3 to rotate, so as to achieve grinding under different grinding conditions. Automatic adjustment of grinding fluid flow. The implementation and f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com