Separate layer gas injection tube pile

A technique of pipe string and gas injection, which is applied in the direction of production fluid, wellbore/well components, earthwork drilling and production, etc., which can solve problems such as inability to layer injection, multiple processes, reduced strength and service life, etc., so as to avoid or Effects of alleviating corrosion, improving gas injection efficiency, and reducing operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

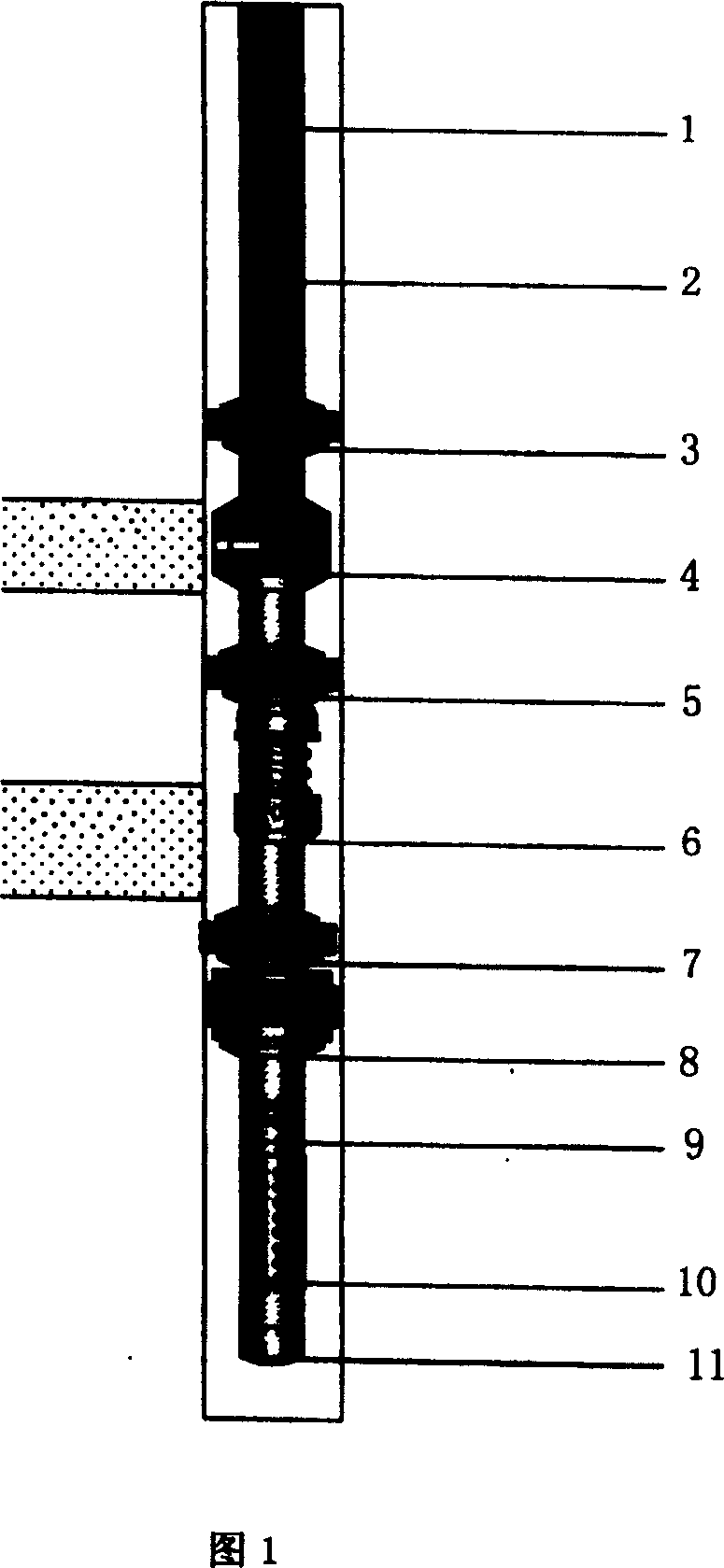

[0014] Referring to the accompanying drawings, a string for layered gas injection process includes outer pipe 1, inner pipe 2, packer with channel 3, balance packer 5, safety injection valve 6, well flushing packer 7, support card tile 8, circulation valve 9, screen pipe 10 and plug 11, and also includes a diversion check valve 4 connected between the channel packer 3 and the balance packer 5, and the outer pipe 1 is connected to the On the spacer 3, the inner pipe 2 passes through the channeled packer 3, and is installed in the diversion check valve 4. The balance packer 5 is connected with the safety injection valve 6, the well flushing packer 7, and the support in sequence. Slips 8, circulation valve 9, screen pipe 10 and plug 11.

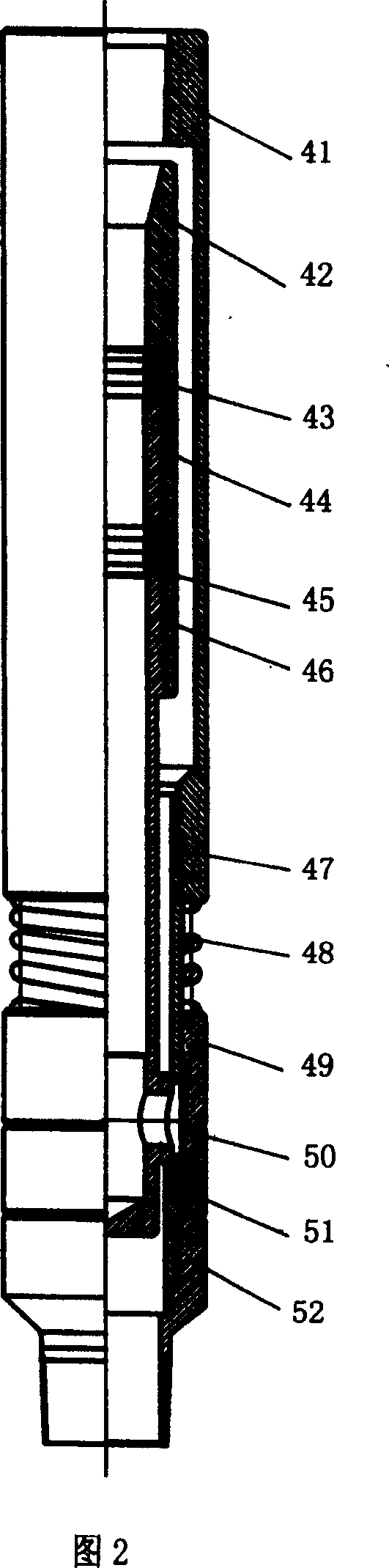

[0015] The diversion check valve 4 comprises an upper joint 41 and a diverter seat 47 connected and installed on it, a lower joint 52, a seal 51, a piston 49, a piston seat 50 and a spring 48, and the diverter seat 47 is arranged in sequence. F...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com