Polyacrylamide reversed-phase microemulsion profile control system

A technology of inverse microemulsion and polyacrylamide, which is applied in the direction of drilling compositions, chemical instruments and methods, and can solve the problems of uncontrollable and poor microsphere expansion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Add 120g of gasoline, 56g of sorbitan monostearate, and 18g of octylphenol polyoxyethylene ether (7) into the reaction kettle, stir to mix evenly, control the temperature in the kettle to 29°C, and the stirring speed to 300rpm. Add 75g of water, 96g of acrylamide, 20g of sodium acrylate, 20g of N-vinylpyrrolidone, 2g of triallylamine, 2g of sodium malonate, 0.5g of disodium edetate, and 2g of isopropanol into the batching kettle , 5g thiourea, 3g sodium thiosulfate, 2.4g azobisisobutylamidine hydrochloride, stir to make it dissolve evenly, adjust the pH value to 8.2 with NaOH aqueous solution; in addition, dissolve 3.5g ammonium persulfate in 10g In deionized water, 1.2g of N-phenylmaleimide was dissolved in 4.8g of gasoline for subsequent use. Introduce the prepared water phase and gasoline solution of N-phenylmaleimide into the reactor, stir to make it fully emulsified, add ammonium persulfate aqueous solution, the temperature of the system rises to 66°C, continue the...

Embodiment 2

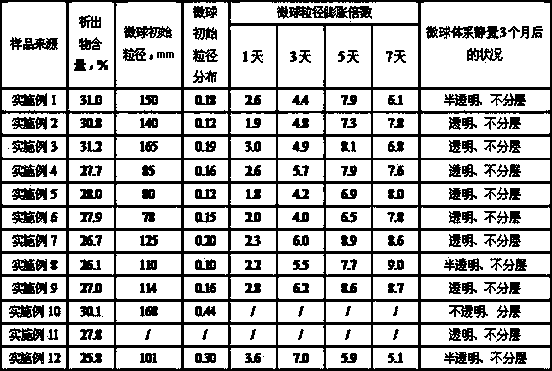

[0036] With [Example 1], just replace 1.2g N-phenylmaleimide with 0.9g N-phenylmaleimide and 0.3g n-butyl methacrylate, adopt [Example 1] Described method or standard test the extractable solids content, microsphere initial particle size and distribution, expansion multiple of the product obtained, and observe its steady state, the results are shown in Table 1.

Embodiment 3

[0038] With [Example 1], just replace N-phenylmaleimide with n-octadecyl acrylate, adopt the method described in [Example 1] or the standard test of the product's extractable solids content, micro The initial particle size and distribution of the ball, the expansion multiple, and observe its steady state, the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com