Ammonia injection system and control method thereof

An injection system and ammonia gas technology, applied in exhaust gas treatment, exhaust equipment, mechanical equipment, etc., can solve problems such as urea nozzle, exhaust pipe post-processor blockage, high cost of pressure stabilizing valve, high pollution, etc., to achieve Significant cost and reliability advantages, stable ammonia injection pressure, and accurate ammonia metering

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

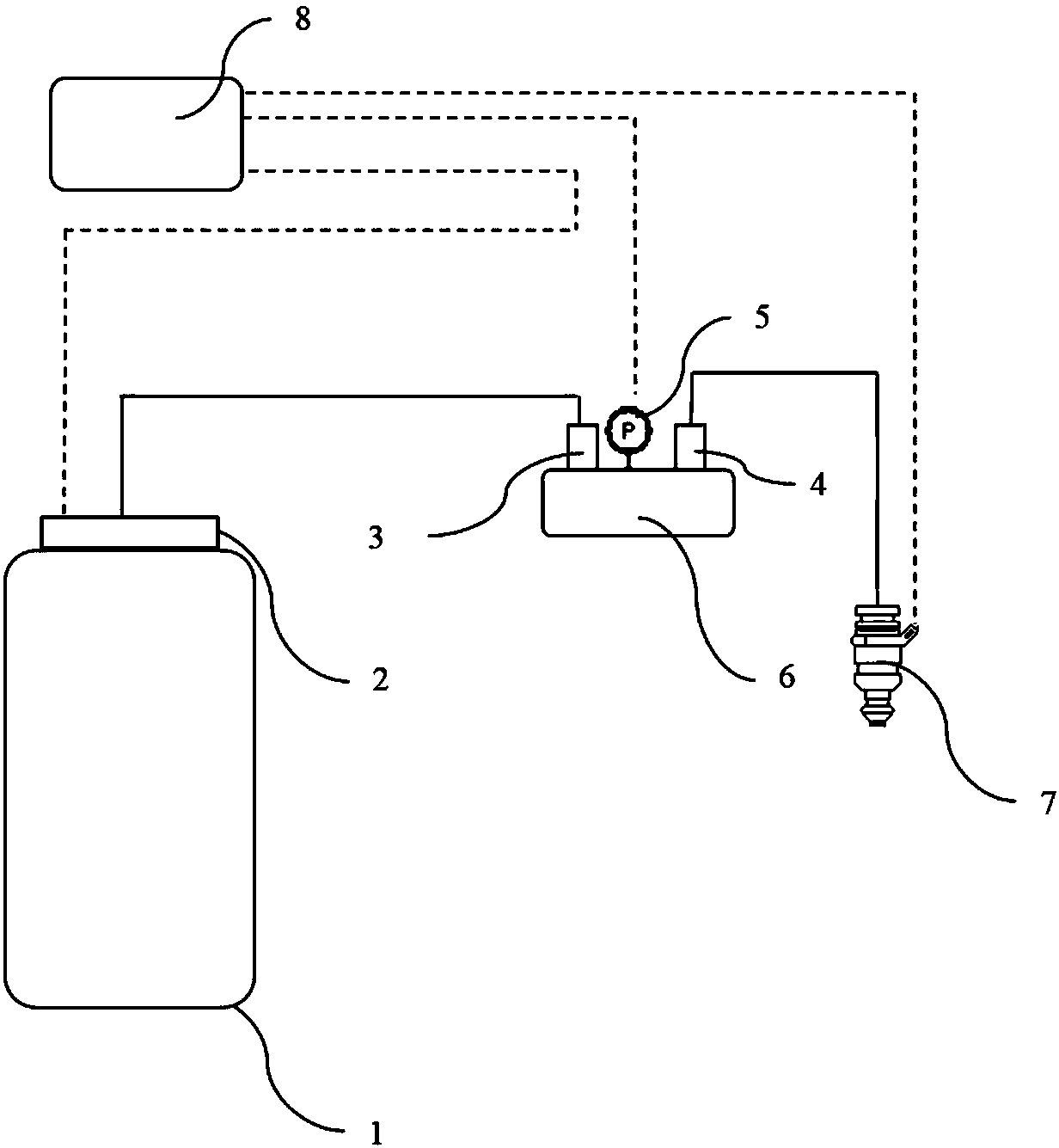

[0039] The present embodiment provides an ammonia gas injection system, which includes an ammonia storage tank 1, an ammonia gas supply module 2, an ammonia gas regulating valve 3, an ammonia gas metering valve 4, a pressure sensor 5, a valve seat 6, an ammonia gas nozzle 7 and Controller (ECU)8.

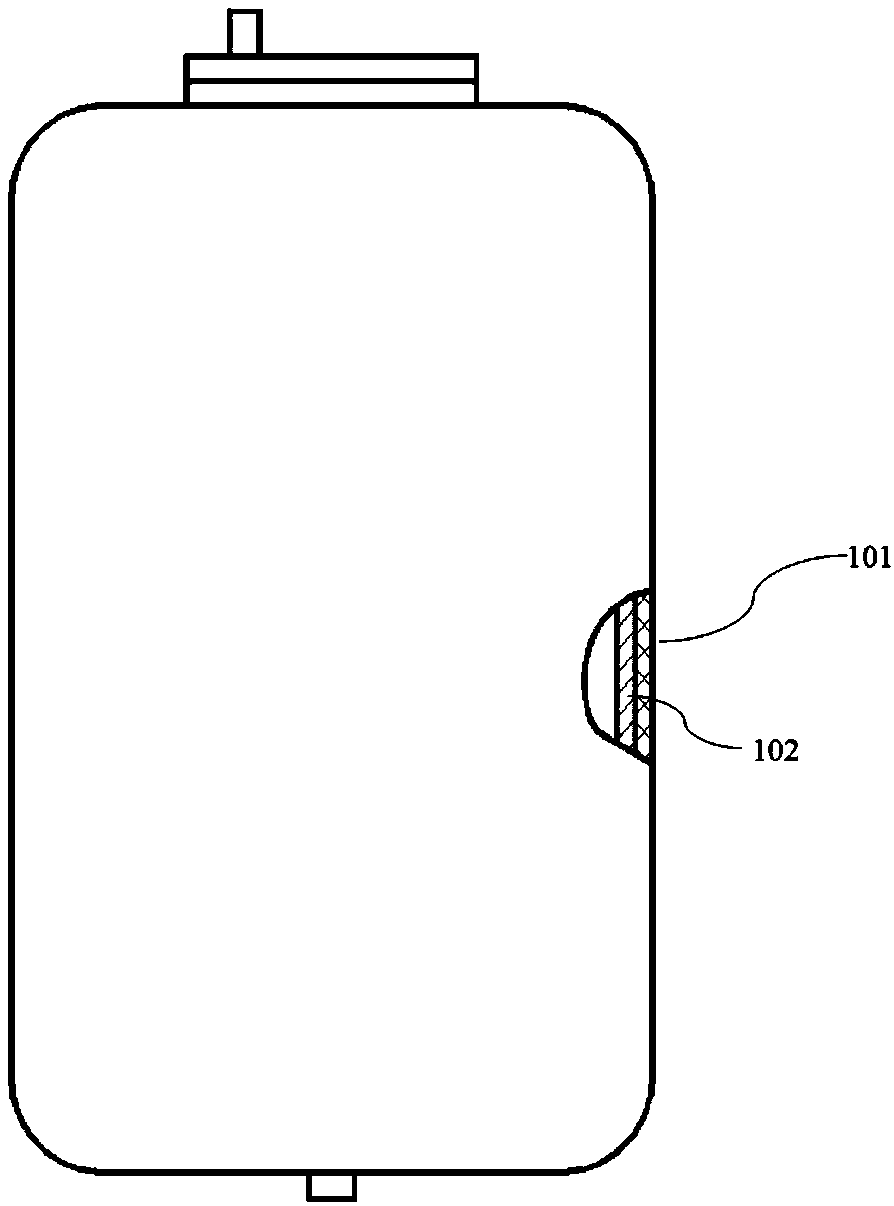

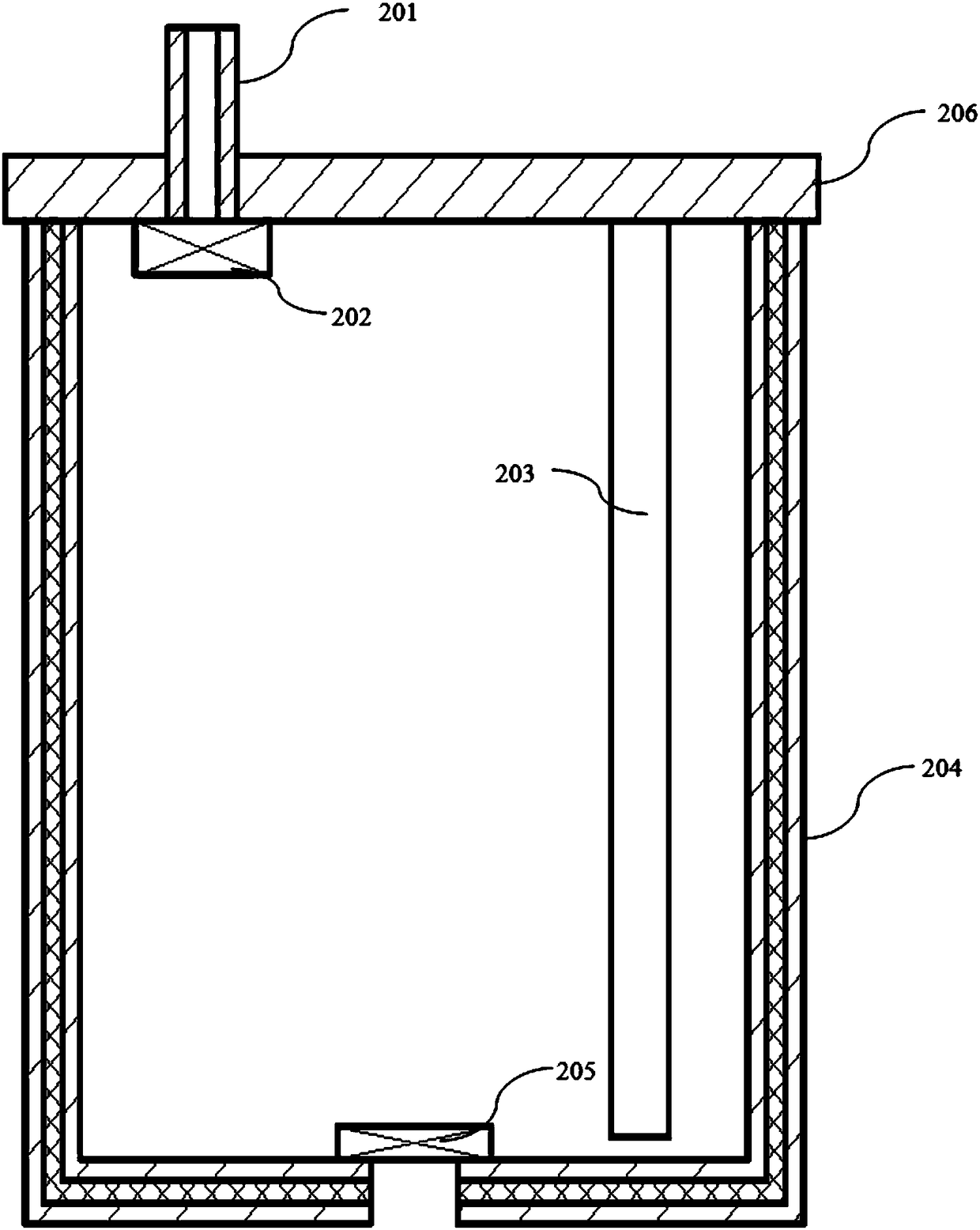

[0040] The tank body 102 of the ammonia storage tank 1 is a stainless steel structure, and the heat insulation layer 101 is coated on the outside of the tank body. When the sunlight is directly exposed, the temperature in the ammonia storage tank will not be too high, and the liquid ammonia temperature will not be too high. Problems of high and excessive pressure. The bottom of the ammonia storage tank is provided with a liquid filling port, and the upper part of the ammonia storage tank is provided with an opening. The ammonia gas supply module is inserted into the opening of the ammonia storage tank, and makes the ammonia storage tank and the ammonia gas Supply module 2 communica...

Embodiment 2

[0056] This embodiment provides a control method for an ammonia gas injection system, which includes:

[0057] The liquid ammonia temperature Tn is set to be kept within a certain range Ta~Tb. After the vehicle starts, the ECU8 judges the liquid ammonia temperature according to the signal of the liquid level and temperature sensor 202. If Tn≥Tb, the heating chamber of the ammonia gas supply module 2 is not controlled. 204 works; if Tn is less than Ta, then control the heating chamber 201 to open, heat the liquid ammonia until Tn=Tb, then stop heating, and then the ECU controls the heating chamber 201 to keep the temperature of the liquid ammonia within the range of Ta to Tb;

[0058] The time required for heating under different ambient temperatures is set by calibration. If the set temperature cannot be reached within the set time, the heating part of the heating chamber will be reported to be faulty, and the system will stop working.

[0059] When Tn≥Ta, it is judged that th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com