Lithium battery textile coating packaging structure

A textile coating and packaging structure technology, applied to structural parts, secondary batteries, battery pack parts, etc., can solve the problems of adjusting heat dissipation effect, inconvenient maintenance and disassembly, poor heat dissipation effect, etc., to achieve easy maintenance and disassembly, practicality High, good cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

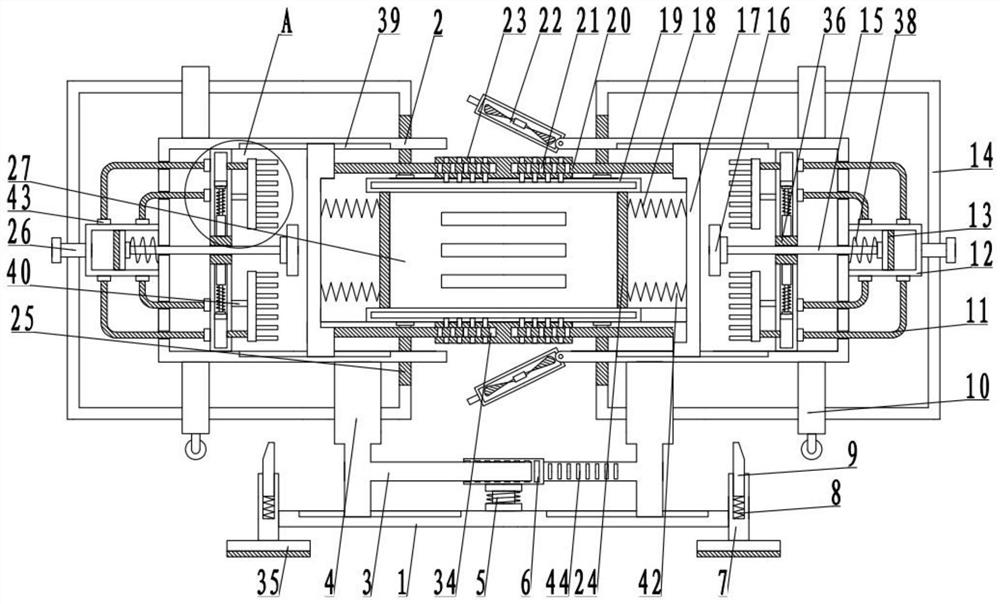

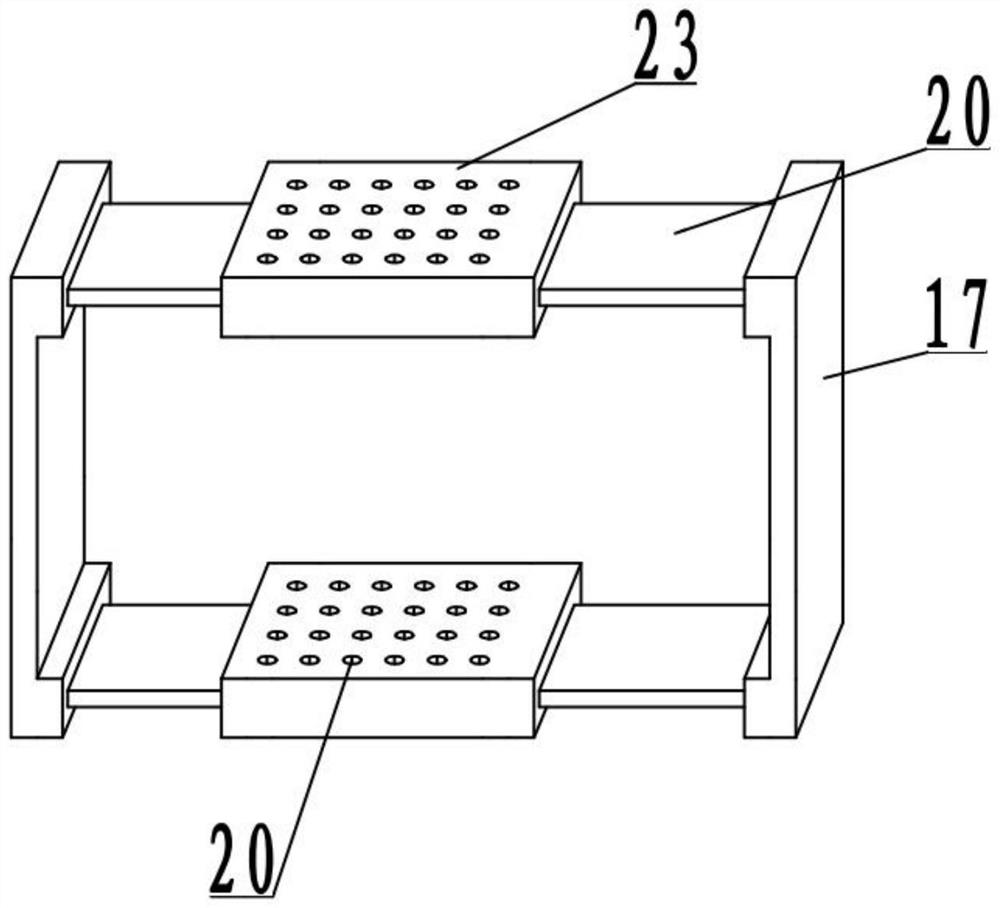

[0022] see Figure 1-4 , a lithium battery 27 textile coating packaging structure, including a bottom plate 1, also includes: the installation frame 2 arranged on both sides above the bottom plate 1, the side of the installation frame 2 is slidingly provided with a coaming plate 17; it is arranged between the coaming plates 17 The packaging mechanism 39 includes a heat conduction shell 19 arranged between the enclosures 17, the interior of the heat conduction shell 19 is a cavity structure, the top of the heat conduction shell 19 is fixedly connected to the limit plate 23, and the two sides of the limit plate 23 are provided with installation grooves 34 , the valve plate 20 is slidably set in the installation groove 34, and the air guide hole 21 is set on the valve plate 20 and the limit plate 23. One side of the valve plate 20 is fixedly connected with the surrounding plate 17, and a clamping The component 42 is used for clamping and fixing the lithium battery 27, and the hea...

Embodiment 2

[0025] see Figure 1-4 , the other content of this embodiment is the same as that of Embodiment 1, except that the clamping assembly 42 includes an elastic member 18 fixedly arranged on one side of the inner wall of the enclosure 17, and one side of the elastic member 18 is fixedly connected to the clamping plate 24 A lithium battery 27 is arranged between the clamping plates 24, and by arranging the elastic member 18 and the clamping plate 24, the clamping and fixing of the lithium batteries 27 of various sizes can be realized, which improves the range of use of the device.

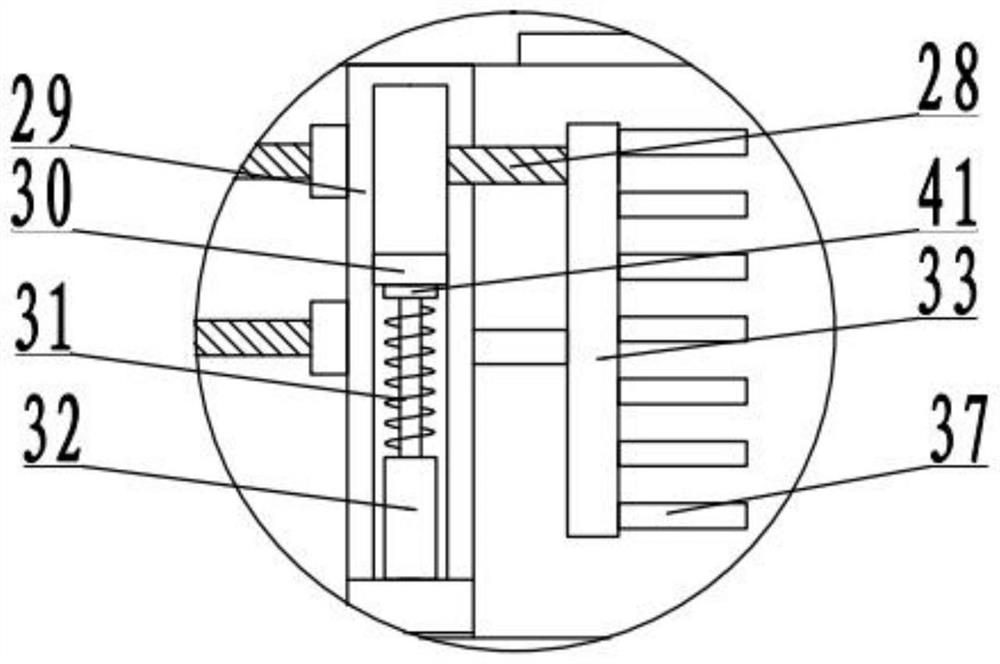

[0026] The piston assembly 41 includes a telescopic cylinder 32 , one side of the telescopic cylinder 32 is fixedly connected to the bottom of the installation cylinder 29 , and the top of the telescopic cylinder 32 is fixedly connected to the piston plate 30 .

[0027] The pressure accumulator assembly 43 includes a pressure accumulator cylinder 12, which is fixedly arranged on the outer wall of the ins...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com