Full-automatic integrated guniting vehicle and using method thereof

A shotcrete truck, integrated technology, applied in earth-moving drilling, wellbore lining, tunnel lining and other directions, can solve the problems of complicated ventilation pipelines and equipment damage frequency, and achieve easy maintenance and disassembly, reduce connection and disassembly, improve The effect of work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

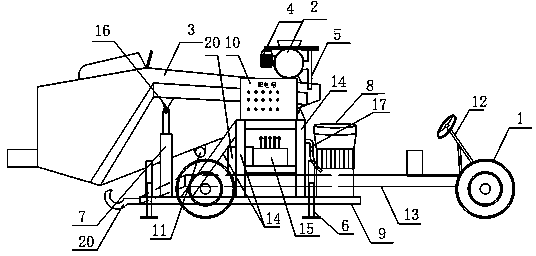

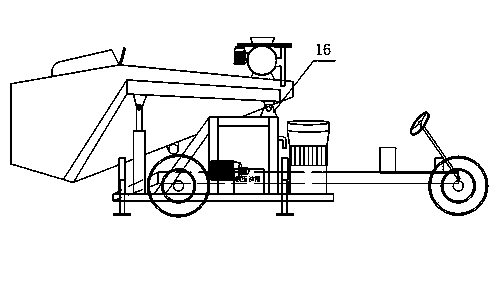

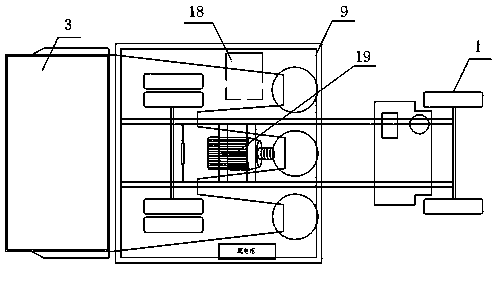

[0028] Embodiment 1, a kind of fully automatic integrated spraying machine, see Figure 1 to Figure 3 , the details are as follows:

[0029] Design a kind of full-automatic all-in-one spraying machine, comprise frame, feeding device, spraying machine and the hook 20 that is used to dock trailer, described feeding device, spraying machine are installed on the frame successively; Said machine The frame includes a chassis, a body frame guard beam set on the chassis, and a cab.

[0030] The feeding device includes a feed bin 3 and a hydraulic cylinder. The feed bin 3 is connected to the frame through a hinged connection. The rear end is hinged with the hydraulic cylinder 7 on the chassis 9 by means of a hinge connection 16, the hydraulic cylinder 7 is fixed on the chassis 9, a vibrator 11 is installed at the bottom of the silo 3, and an accelerator adding mechanism is arranged above the silo 3. Described quick-setting agent adding mechanism comprises quick-setting agent feeding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com