Lithium disilicate glass ceramic, preparation method thereof and application in dental material

A technology of glass-ceramic and lithium disilicate, applied in dentistry, dental preparations, dental prostheses, etc., can solve problems such as unsatisfactory mechanical properties and changes in performance of lithium disilicate glass-ceramics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

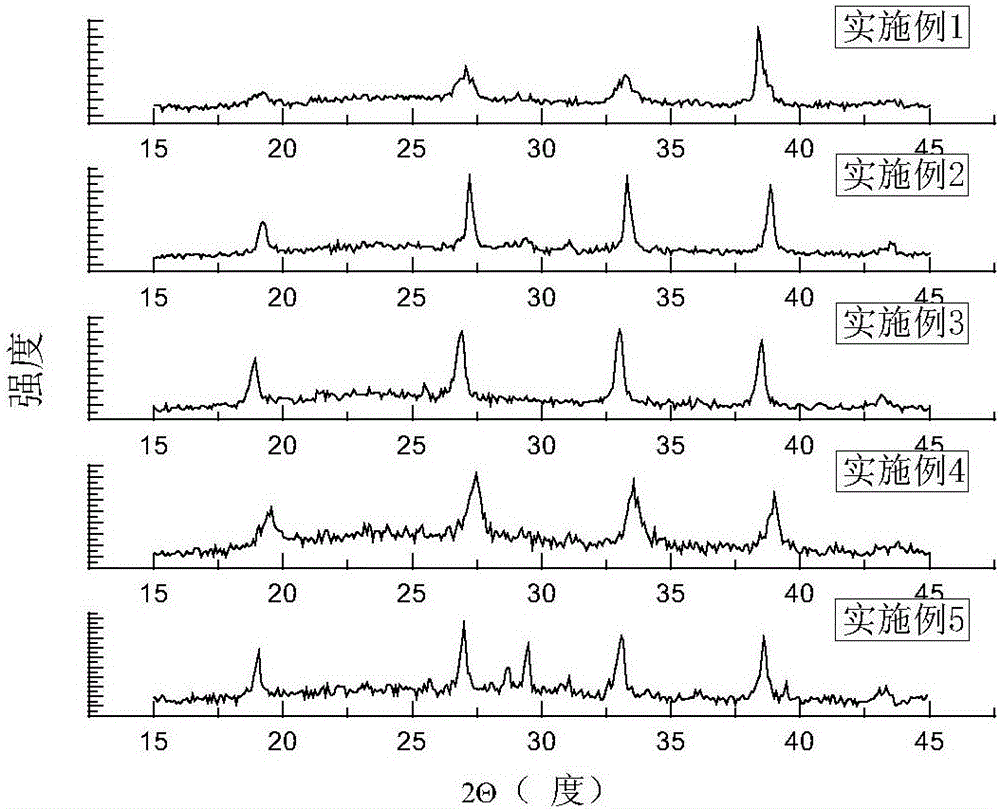

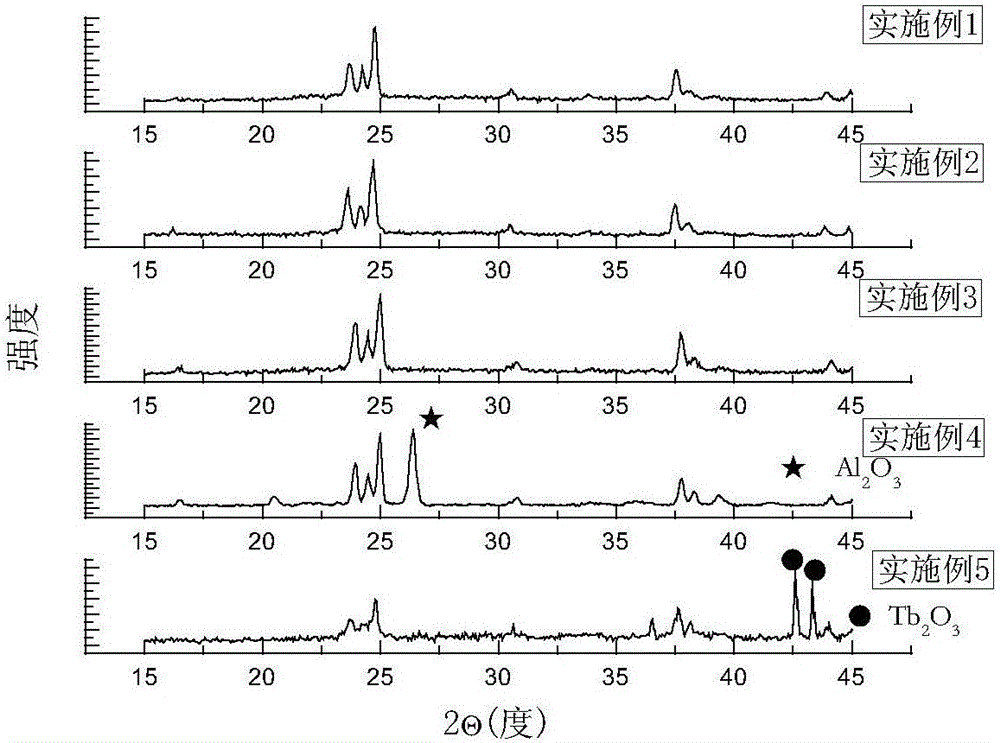

Embodiment 1

[0081] This embodiment provides a lithium disilicate glass-ceramic, and the components included in the lithium disilicate glass-ceramic are shown in Table 1 in terms of mass percentage.

[0082] The preparation method of above-mentioned lithium disilicate glass-ceramics is as follows:

[0083] (1) According to the content of each component in the lithium disilicate of table 1, calculate and take the raw material of corresponding amount, described Li 2 O and K 2 O respectively with raw material Li 2 CO 3 and K 2 CO 3 Introduced in the form of P 2 o 5 Raw material NH 4 h 2 PO 5 Introduced in the form of SiO 2 、Al 2 o 3 and TbO 2 form introduced.

[0084] (2) Mix the raw materials, ball mill for 4 hours, and the dried product is calcined, shaped and annealed: put it into a 50ml corundum crucible, heat it up to 590°C in a silicon-molybdenum resistance furnace at 4°C / min for 2h, and then heat it at 4°C / min Raise the temperature to 1300°C, keep it warm for 1 hour, pou...

Embodiment 2

[0092] This embodiment provides a lithium disilicate glass-ceramic, and the components included in the lithium disilicate glass-ceramic are shown in Table 1 in terms of mass percentage.

[0093] The preparation method of above-mentioned lithium disilicate glass-ceramics is as follows:

[0094] (1) According to the content of each component in the lithium disilicate of table 1, calculate and take the raw material of corresponding amount, described Li 2 O and K 2 O respectively with raw material Li 2 CO 3 and K 2 CO 3 Introduced in the form of P 2 o 5 Raw material NH 4 h 2 PO 5 Introduced in the form of SiO 2 、Al 2 o 3 and TbO 2 form introduced.

[0095] (2) Mix the raw materials, ball mill for 4 hours, and the dried product is calcined, formed and annealed: put in a 50ml corundum crucible, heat up to 590°C in a silicon-molybdenum resistance furnace for 2 hours, and then heat up at 4°C / min To 1400°C, heat preservation for 1 hour, after pouring into a pre-heated gr...

Embodiment 3

[0103] This embodiment provides a lithium disilicate glass-ceramic, and the components included in the lithium disilicate glass-ceramic are shown in Table 1 in terms of mass percentage.

[0104] The preparation method of above-mentioned lithium disilicate glass-ceramics is as follows:

[0105] (1) According to the content of each component in the lithium disilicate of table 1, calculate and take the raw material of corresponding amount, described Li 2 O and K 2 O respectively with raw material Li 2 CO 3 and K 2 CO 3 Introduced in the form of P 2 o 5 Raw material NH 4 h 2 PO 5 Introduced in the form of SiO 2 、Al 2 o 3 and TbO 2 form introduced.

[0106] (2) Mix the raw materials in step (1), ball mill for 4 hours, and the dried product is calcined, shaped and annealed: put in a 50ml corundum crucible, heat up to 590℃ in a silicon-molybdenum resistance furnace at 4℃ / min for 2 hours, and then Raise the temperature to 1450°C at 4°C / min, keep it warm for 0.8 hours, p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| microhardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com