Frame of axial rolling device of ring rolling machine in four pull rod structure

A technology of axial rolling and ring rolling machine, which is applied in the field of large-scale seamless ring hot-rolling forming equipment, can solve the problems of processing, manufacturing and assembling, and the frame is unsuitable due to heavy equipment and large-scale equipment. Easy to process, easy to assemble, and ensure the effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

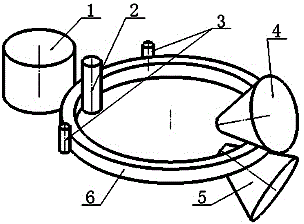

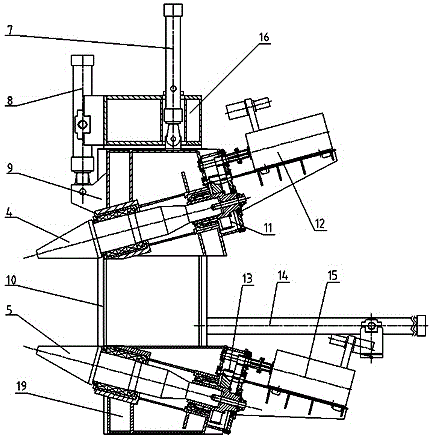

[0019] Such as figure 2 As shown, a ring rolling machine axial rolling device, its main structure consists of a balance oil cylinder 7, a main rolling oil cylinder 8, an upper slider 9, an upper tapered roller 4, a frame 10 (by an upper beam 16, a left column 17 , right side column 21, lower tapered roller seat 19 etc. are formed), following tapered roller 5, upper reduction box 11, motor (12,15), lower reduction box 13, mobile oil cylinder 14 forms.

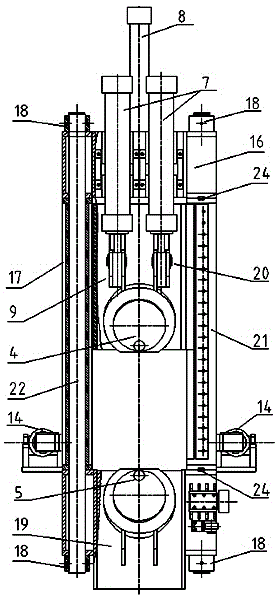

[0020] Such as image 3 and Figure 4 As shown, the first embodiment of the present invention is a frame 10 of an axial rolling device of a ring rolling machine, which includes a left side column 17 and a right side column 21 arranged on the lower tapered roller seat 19. An upper beam 16 connecting the left side column 17 and the right side column 21 is arranged above the side column 17 and the right side column 21 . Both ends of the two front tie rods 22 and the two rear tie rods 23 are provided with threads, the two front ...

Embodiment 2

[0026] Embodiment 2: The similarities between this embodiment and Embodiment 1 will not be repeated, and the difference is that Figure 7 As shown, the left side column 17 and the right side column 21 are all rectangular closed box structures, near the front and rear pull rods, vertical ribs 33) that penetrate up and down are provided, and the upper and lower ends of the left side column 17 and the right side column 21 are made of steel plates For plugging, the end is processed into a plane (referred to as a steel plate plugging plane), and an oblong keyway 32 is processed in the middle of the steel plate plugging plane for installing the flat key 24. Process the circular holes that allow the front tie rods 22 and the rear tie rods 23 to pass through on the plate block plane, and are provided with corresponding through holes that allow the front tie rods 22 and the rear tie rods 23 to pass through on the upper beam 16 and the lower tapered roller seat.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com