Rollover-prevention tire with spare steel rim

An anti-rollover and steel ring technology, applied in tire parts, transportation and packaging, vehicle parts, etc., to achieve the effect of convenient maintenance and disassembly, protection of safety, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

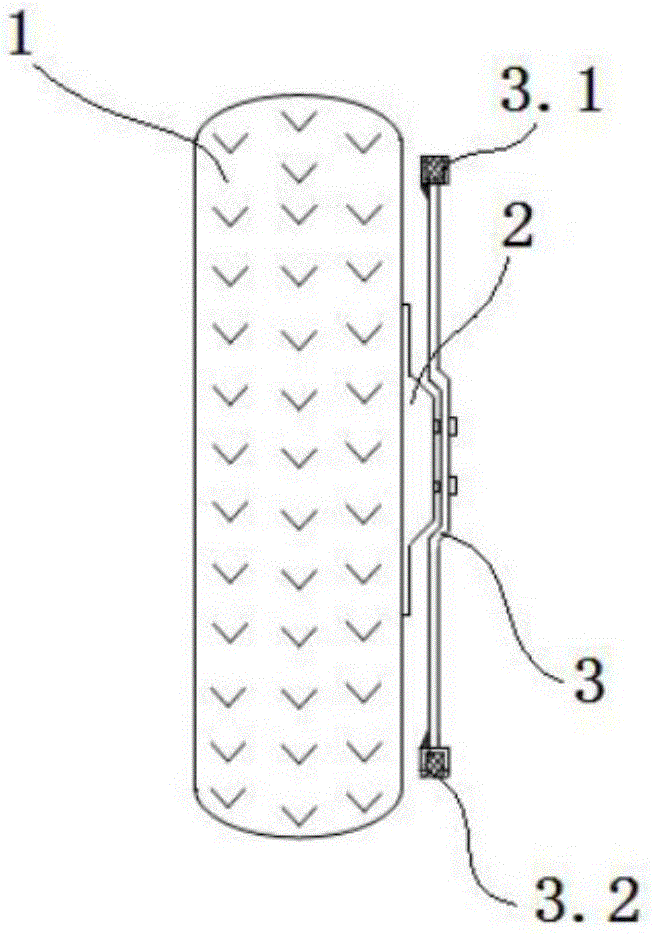

[0020] See figure 1 , an anti-rollover tire with a spare steel ring, comprising a tire 1 and a steel ring 2, the present invention is characterized in that a spare steel ring 3 is installed on the wheel center of the tire.

[0021] The present invention is provided with a groove 3.1 on the edge of the spare steel ring 3, and a rubber strip 3.2 is embedded in the groove 3.1, and screw holes are drilled on the top and the rubber strip 3.2 respectively, and the rubber strip 3.2 is fixed in the concave groove by using screws. Inside the slot 3.1.

[0022] The edge diameter of the spare steel ring 3 of the present invention is 3-5 cm larger than the edge diameter of the steel ring 2. The distance between the ring 3 and the tire is 1.5-2.5 cm.

[0023] The spare steel ring 3 of the present invention refers to putting on the new steel ring that is matched with this type of vehicle on the original steel ring of the ordinary tire used by the vehicle.

[0024] Spare steel ring 3 of t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com